Full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material and preparation method thereof

A thermoelectric material and high-performance technology, which can be used in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as poor mechanical properties, and achieve practical application value improvement, power factor improvement, and hardness improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: The general chemical formula of the n-type Mg-Sb-based thermoelectric material with high performance in the full temperature range described in this embodiment is B x Mg 3.2-x Sb 1.99-y Bi y Te 0.01 , x=0.01~0.05, y=0.49~1.49.

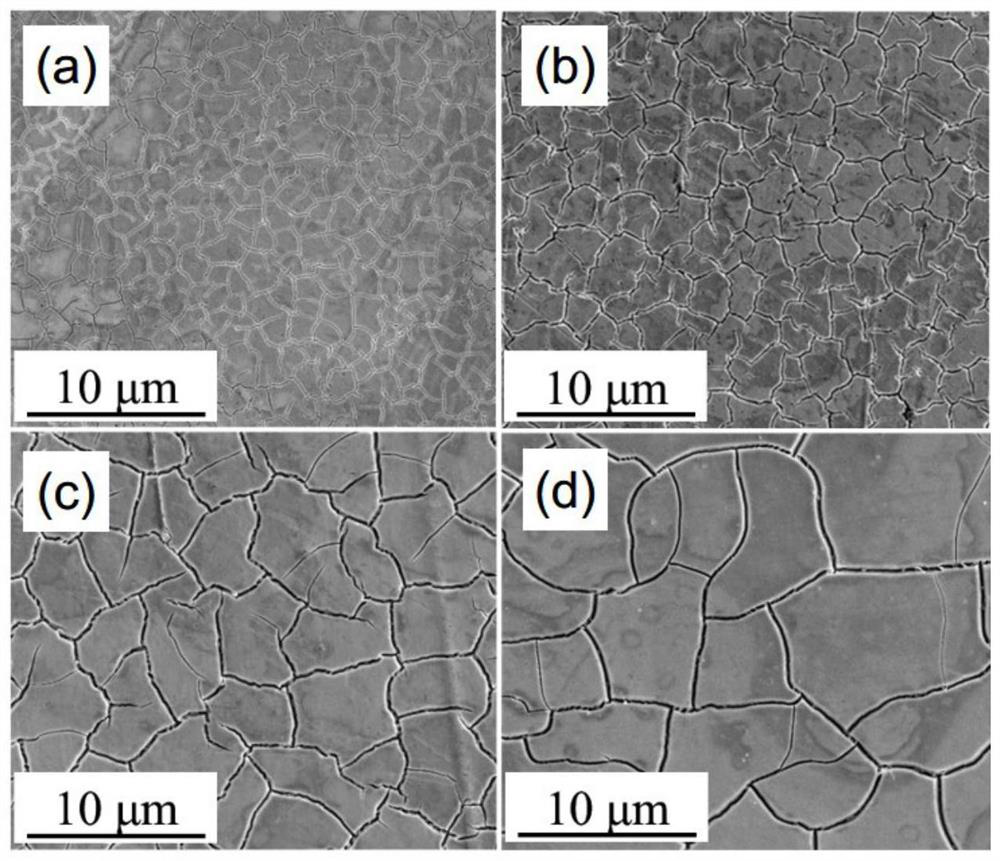

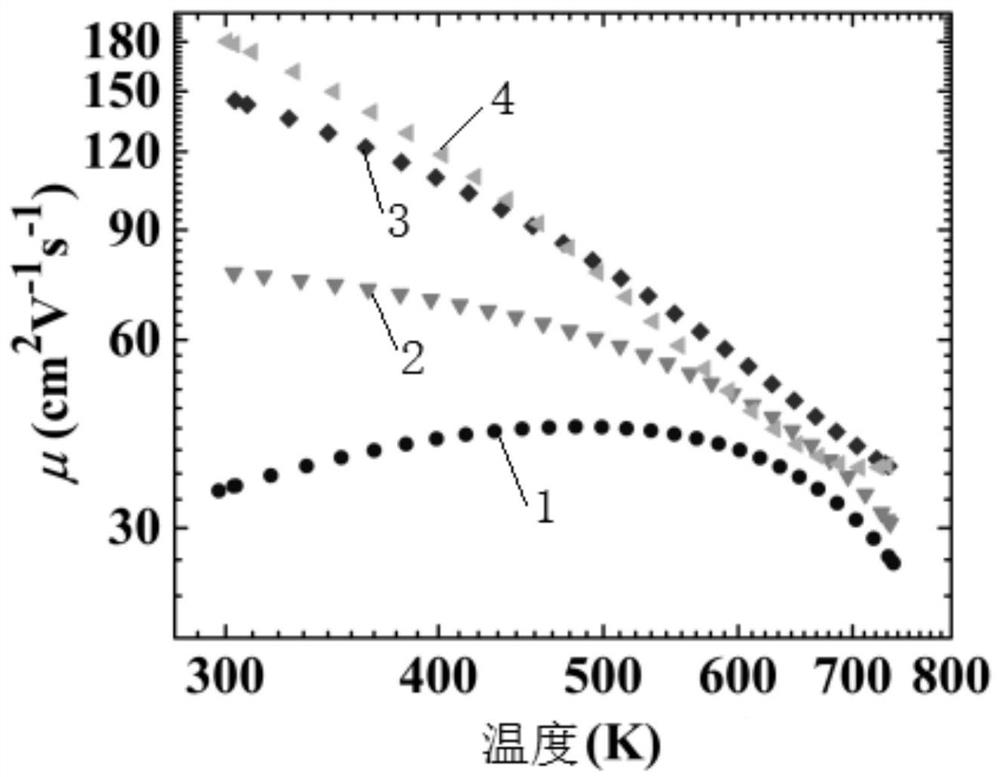

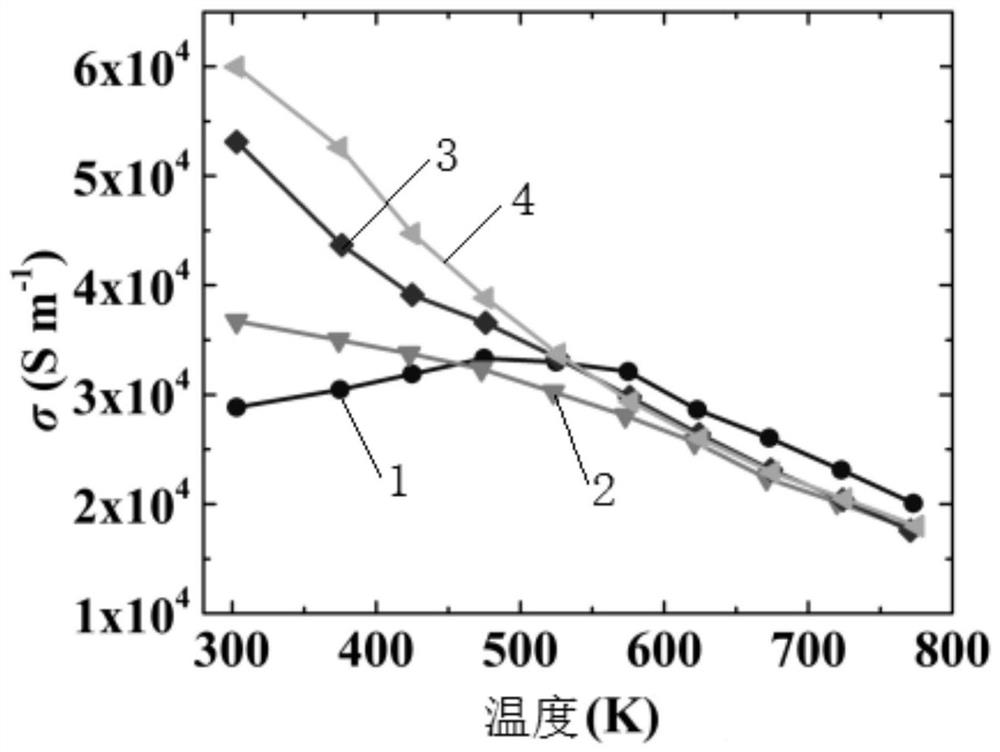

[0027] The beneficial effects of this embodiment are: this embodiment discloses a high-performance n-type Mg-Sb-based thermoelectric material in the full temperature range and its preparation method, which solves the problem of the current n-type Mg 3 Sb 2 Based thermoelectric materials cannot take into account the problem of achieving high performance at room temperature and high temperature at the same time, while improving their mechanical properties. By increasing the sintering temperature as much as possible, on the one hand, the crystal grains can be significantly grown, and the grain boundary density can be reduced to weaken the scattering of carriers by the grain boundaries, so that the carrier mobility of the material...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: x=0.03-0.05, y=0.49-0.99. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the general chemical formula of the n-type Mg-Sb-based thermoelectric material with high performance in the full temperature range is B 0.03 Mg 3.17 Sb 1.5 Bi 0.49 Te 0.01 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com