Method for preparing SiGe thermoelectric material

A technology of thermoelectric materials and raw materials, applied in the direction of thermoelectric device lead-out wire materials, thermoelectric device manufacturing/processing, etc., can solve the problems of poor mechanical properties, low production efficiency and high production cost of single crystal SiGe, and achieve excellent thermoelectric performance , short holding time and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

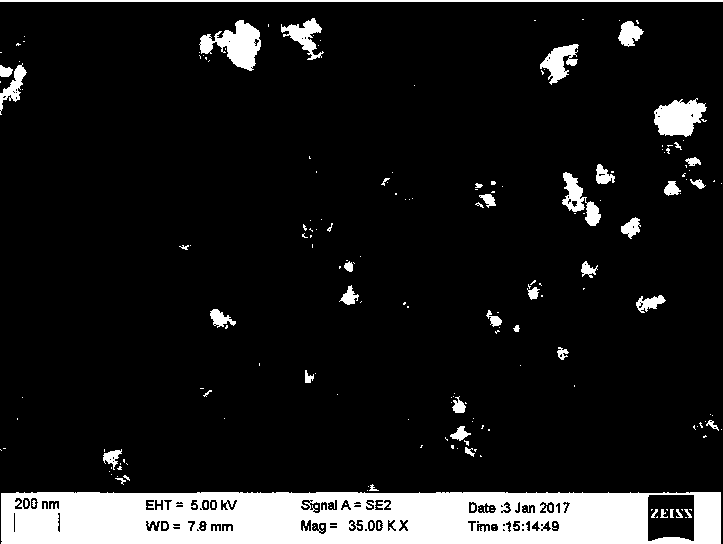

Image

Examples

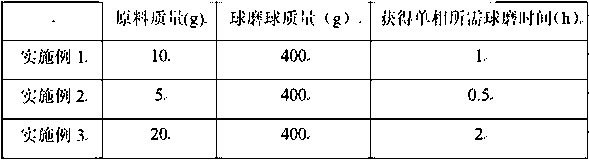

Embodiment 1

[0020] 1. Ingredients, P-type Si 0.795 Ge 0.2 B 0.005 Material ingredients: Weigh 6.049g of Si powder, 3.936g of Ge powder, and 0.0146g of B powder, put them into a mortar and grind and mix them to obtain raw material I; N-type Si 0.7925 Ge 0.2 P 0.0075 Material ingredients: Weigh 6.0127g of Si powder, 3.9245g of Ge powder, and 0.06275g of P block, and put them into a mortar for grinding and mixing to obtain raw material II.

[0021] 2. Filling into cans, transfer raw material I and raw material II to two hard steel ball milling tanks respectively, and add 400g of hard steel ball milling balls to each tank. The ball mill jar was sealed in an Ar gas atmosphere protection glove box and then taken out.

[0022] 3. Ball milling, put the ball milling tank in the planetary ball mill, the speed is 400rpm, first rotate the ball mill forward for 10 minutes, then stop for 10 minutes, and finally reverse the ball milling process for 10 minutes, and obtain single-phase P-type SiGe th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com