Short-flow preparation method for high-performance Mg-Zn-Zr alloy

A high-performance, short-flow technology, applied in metal processing equipment and other directions, can solve the problems of small workpiece size, low feasibility of industrialized mass production, and long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For the Mg-2Zn-0.45Zr alloy selected in this embodiment, the length, width, and height of the sample before hot working are 70 mm, 70 mm, and 80 mm, respectively.

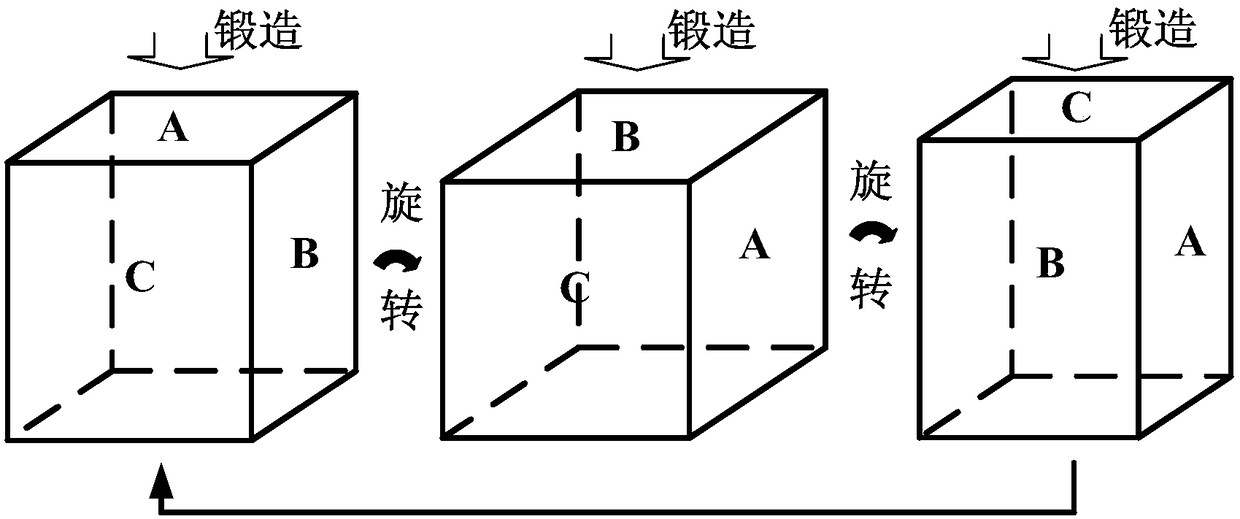

[0027] A high-performance Mg-Zn-Zr alloy short-process preparation method includes the following steps:

[0028] 1) Casting process: Prepare Mg-2Zn-0.45Zr alloy melt according to the magnesium alloy smelting method, and pour the melt into a square water-cooled copper mold. The molding size of the copper mold is 150mm*150mm*150mm, and the mold cooling water capacity is 300ml. The water flow rate is 3 liters / min, the pouring process is sprinkled with sulfur powder to prevent burning, and the ingot is taken out after cooling;

[0029] 2) Thermal processing heating process: Before forming, place the sample in a heating furnace for heating and heat preservation. The heating temperature is set to 300℃, and the holding time is 10 minutes, so that the sample is heated evenly and without grain growth. Ensure that the core ...

Embodiment 2

[0033] The difference between Example 2 and Example 1 is that the processing object is different, and the alloy composition of the processing object is Mg-6Zn-0.45Zr.

[0034] The sample material has a good surface after thermal processing, no obvious cracks, and no obvious macroscopic loss.

[0035] In the following, the microstructure and mechanical properties obtained in Example 1-2 are analyzed in combination with experimental data.

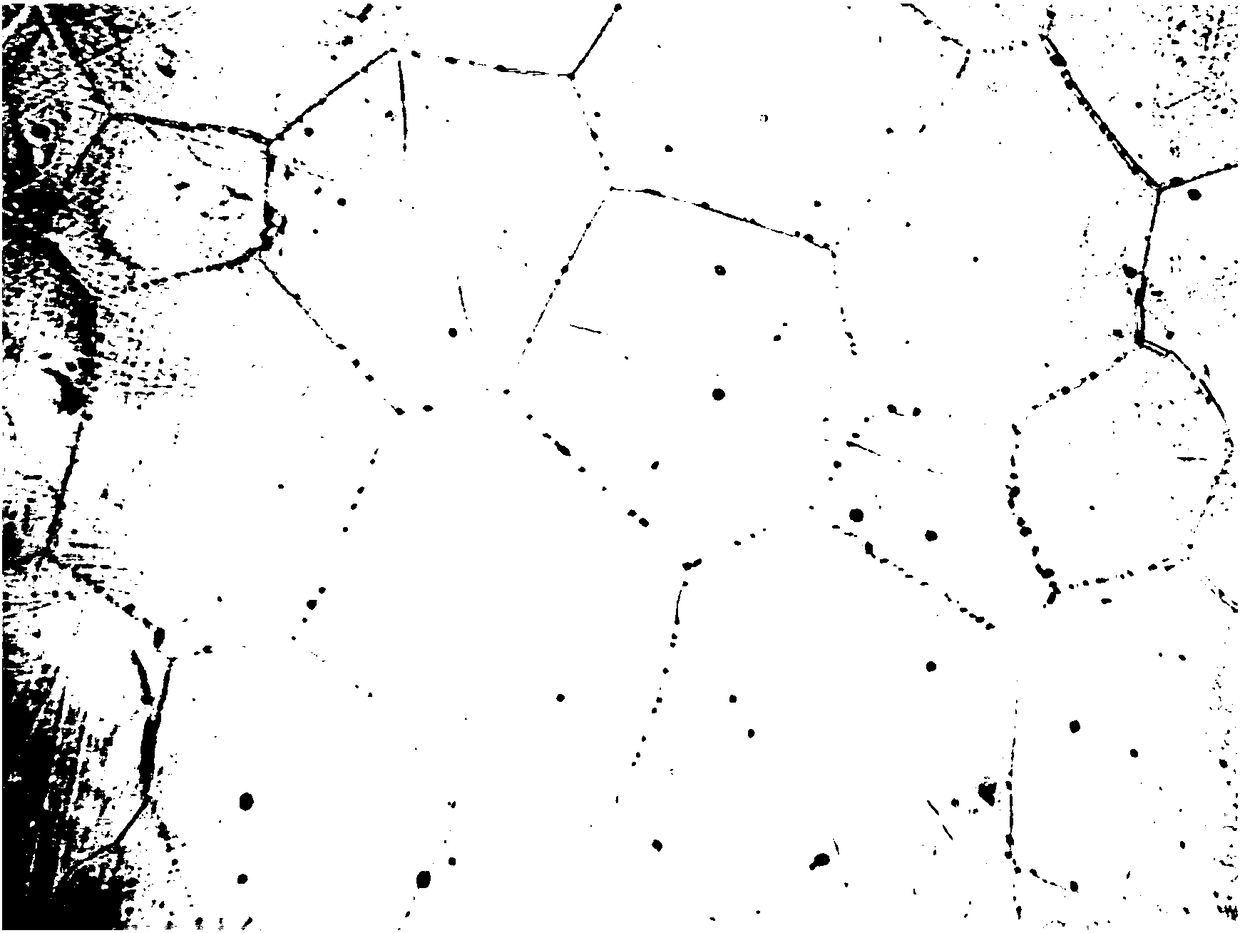

[0036] 1. Microstructure characterization: Select the cast alloy and wrought alloy cores in Example 1-2 to prepare microstructure observation samples. After mounting, pre-grinding, polishing, and corrosion, the MM6 horizontal metallurgical microscope is used to observe the corroded samples. Casting organization such as figure 1 with figure 2 As shown, the deformed tissue is Figure 4-Figure 7 Shown.

[0037] From figure 1 with figure 2 It can be seen that in Example 1 and Example 2, under the action of the water-cooled copper mold, the alloy solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com