Patents

Literature

70results about How to "Will not form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

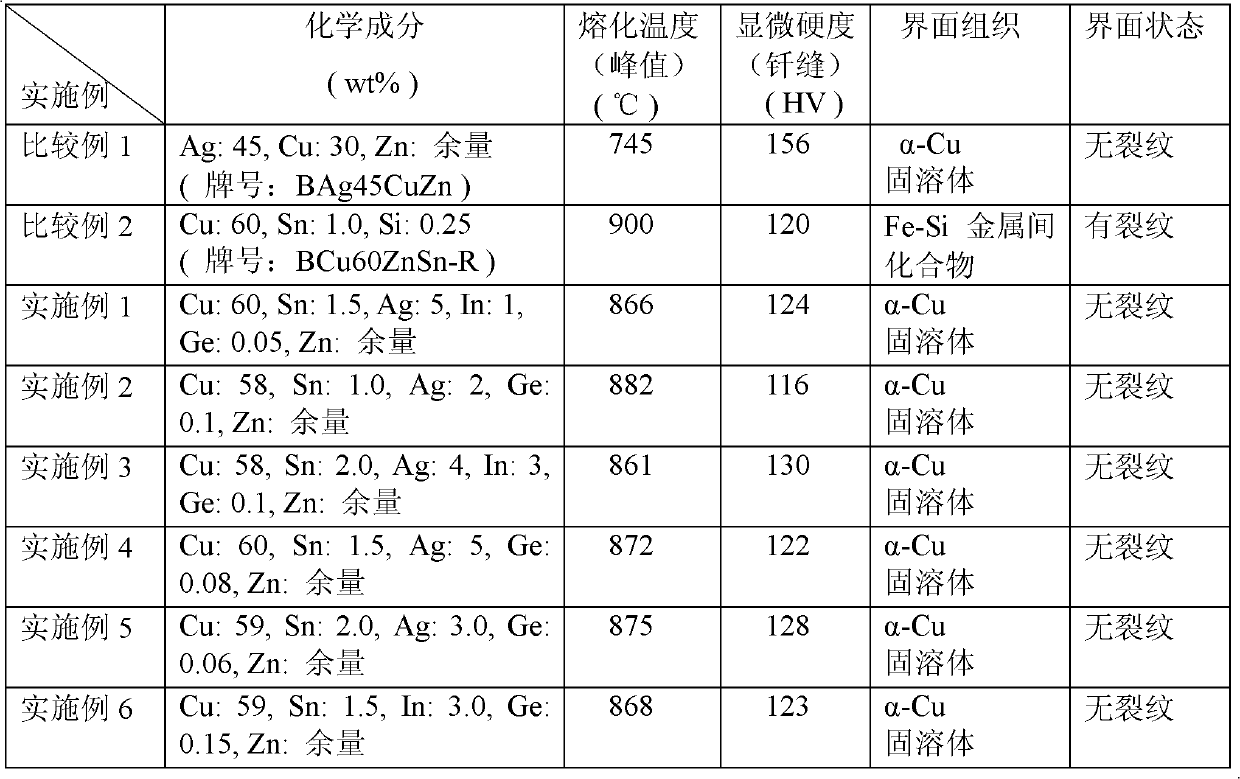

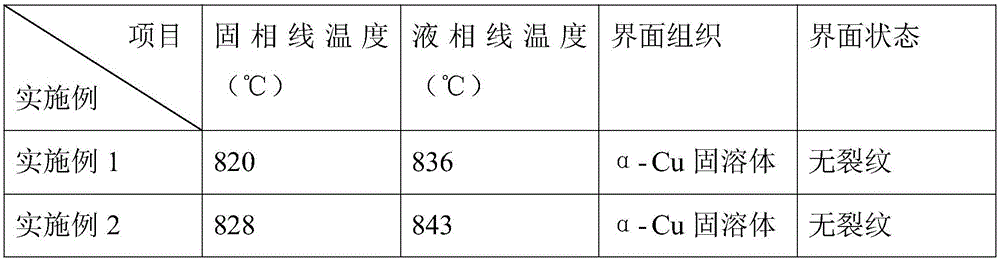

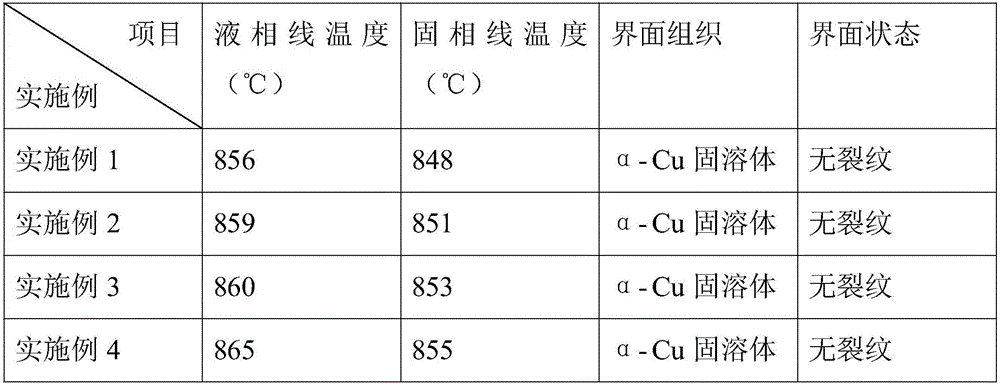

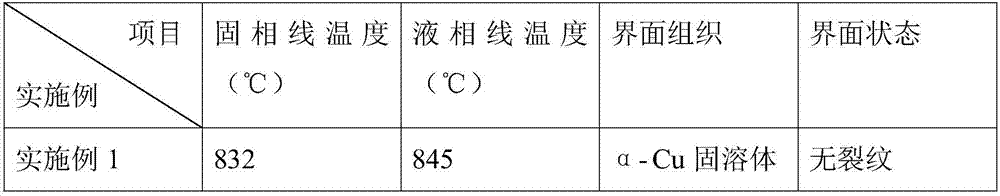

Brass brazing alloy

InactiveCN102601542AImprove reliabilityLow Ag contentWelding/cutting media/materialsSoldering mediaBraze alloyMelt temperature

The invention discloses brass brazing alloy, which comprises Cu, Zn, Sn, Ge, Ag and / or In. The brass brazing alloy consists of components including, by mass percentage, from 58 to 60% of Cu, from 0.5 to 3.0% of Sn, from 1.0 to 6.0% of Ag and / or from 1.0 to 5.0% of In, from 0.05 to 0.3% of Ge and the balance Zn. Compared with an existing brass brazing material, the brass brazing alloy has the advantages that melting temperature is low, the brass brazing alloy can replace a silver brazing material to be used for brazing steel / copper joints, and cost is low due to the fact that Ag content of the brass brazing alloy is low.

Owner:SOUTH CHINA UNIV OF TECH

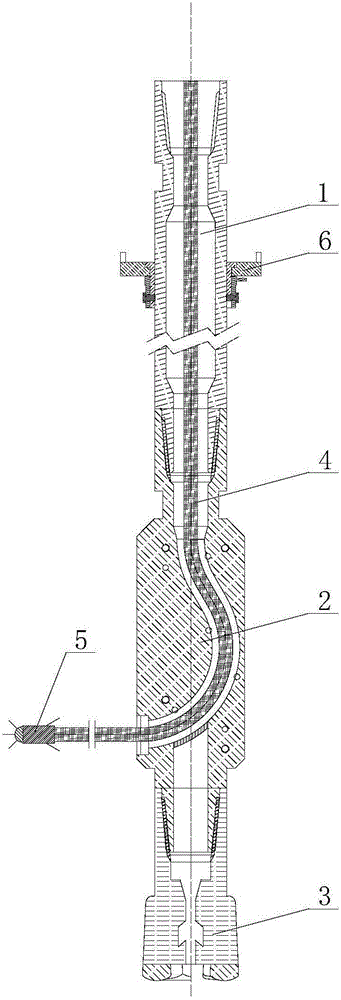

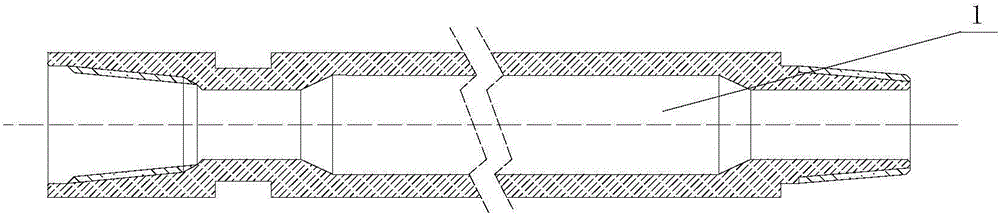

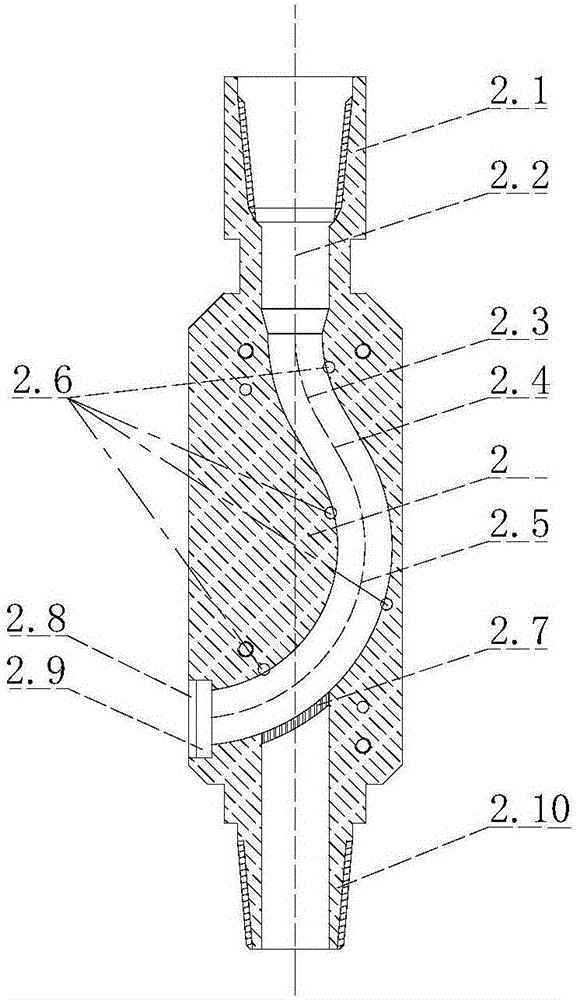

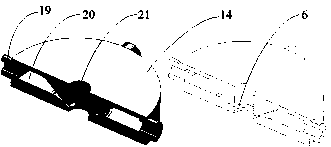

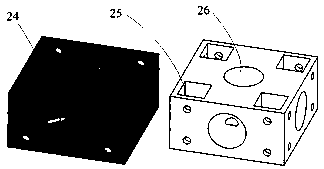

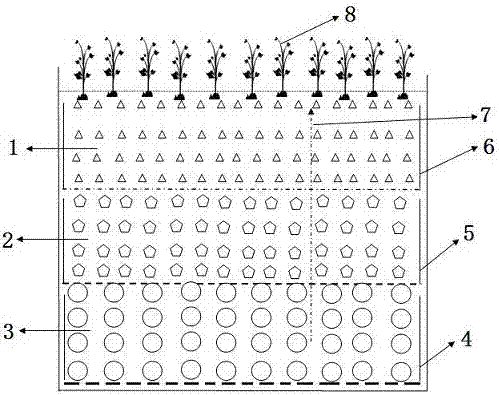

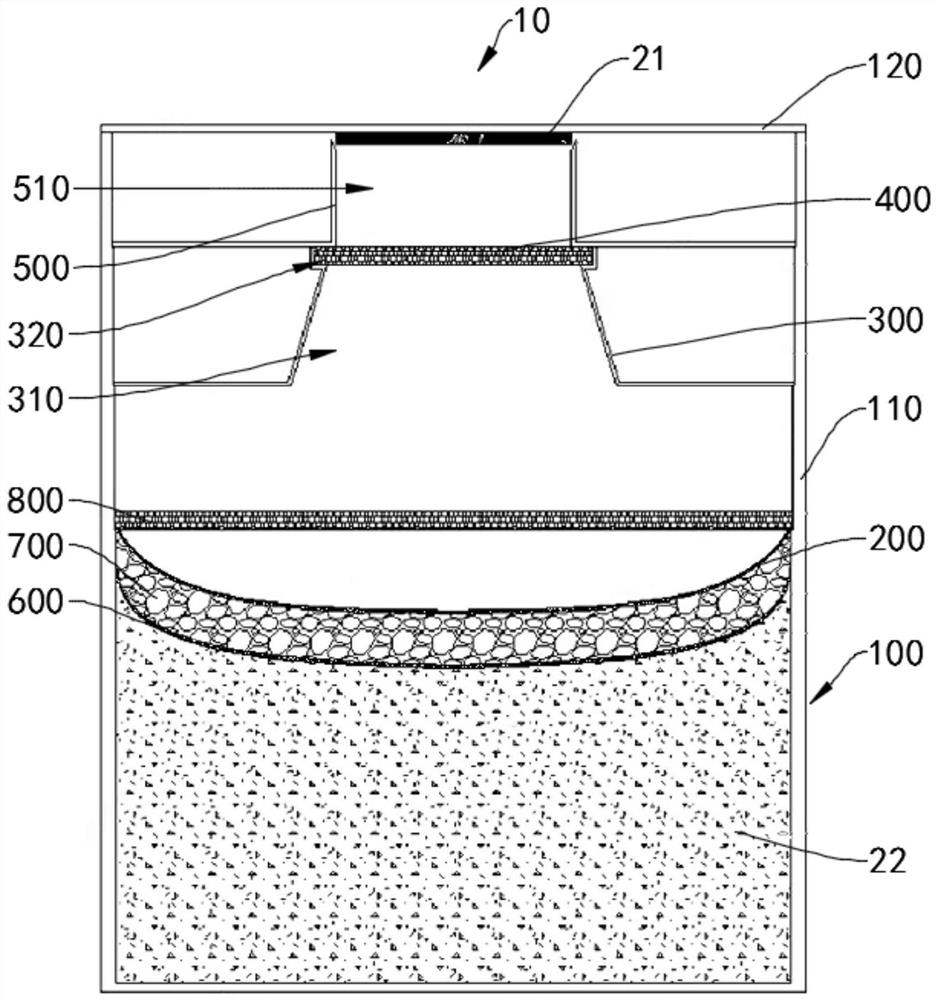

Coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit

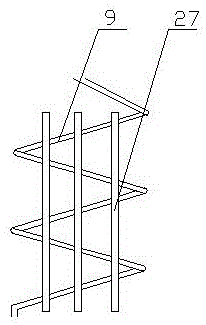

ActiveCN105089500AEasy to useEasy to processLiquid/gas jet drillingDirectional drillingDrill lineTree shaped

The invention relates to a coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit. The drilling unit comprises drill rod, a guider, a drill bit, a high-pressure hose, a self-propelled drill bit and a dial. The drill rod is in threaded connection with the front end of the guider. The drill bit is in threaded connection with the tail end of the guider. The drill rod, the guider and the drill bit are used in cooperation, and the two steps of broaching and guider feeding-in can be finished at the same time. After broaching is finished, the high-pressure hose and the self-propelled drill bit are used for drilling tree-shaped drill holes in a coal seam. The distribution uniformity of the tree-shaped drill holes is controlled by the dial. The main effect of the drilling unit is to drill main holes of the tree-shaped drill holes of the coal seam and the tree-shaped drill holes, and uniform permeability increase of the coal seam is achieved. The drilling unit is simple in structure, convenient to operate and suitable for drilling the tree-shaped drill holes in the gas extraction process of the low-air-permeability coal seam.

Owner:CHONGQING UNIV +1

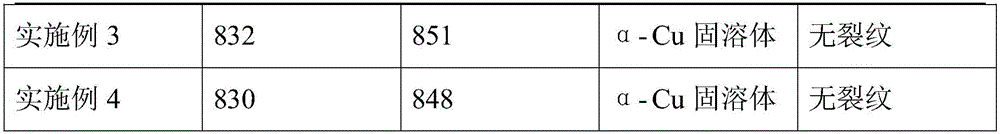

Poly(butylene succinate) and preparation method thereof

The invention discloses a poly(butylene succinate) which is prepared by copolymerizing succinic acid, butylene glycol and cyclic dibasic alcohol. The poly(butylene succinate) comprises succinic acid residue, butylene glycol residue and cyclic diol residue, wherein the butylene glycol residue accounts for 90-98% of the total dibasic alcohol, and the cyclic diol residue accounts for 2-10% of the total dibasic alcohol. The preparation method comprises the following steps: reacting succinic acid, butylene glycol and cyclic dibasic alcohol at 200-230 DEG C under the action of a catalyst to perform direct esterification, thereby obtaining an esterified substance; adding a stabilizer, and carrying out pre-polycondensation reaction at 220-250 DEG C to obtain a prepolymer; carrying out polycondensation reaction on the prepolymer at 235-250 DEG C while gradually reducing the vacuum degree of the reaction system to less than 150Pa; and after the polycondensation finishes, adding carbodiimide compounds into the reaction product, and mixing for 2-15 minutes, thereby obtaining the poly(butylene succinate). The polyester synthesized by the method disclosed by the invention has the advantages of high heat resistance, high melting point, controllable degradation rate, excellent mechanical properties and excellent processability.

Owner:KINGFA SCI & TECH CO LTD +2

Method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces

InactiveCN102344232ANo need to diluteReduce lossesBio-organic fraction processingClimate change adaptationBiotechnologyFeces

The invention discloses a method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces. The method comprises the following steps of feeding directly solid livestock and poultry feces of which dry matter concentration is above 15% into a biogas fermentation device, or mixing the solid livestock and poultry feces and livestock and poultry feces fermentation residues and then feeding the mixture into the biogas fermentation device to carry out biogas production, wherein the fermentation residues obtained by the previous step can be utilized as organic fertilizer or the fermentation residues are subjected to composting and then are utilized for organic fertilizer production. Through the method provided by the invention, livestock and poultry feces is subjected directly to dry fermentation without dilution and desanding pretreatment; scum is not formed in the biogas fermentation device; temperature rise and heat preservation are easy; nutrient loss is less; and produced organic fertilizer has high fertilizer efficiency.

Owner:BIOGAS SCI RES INST MIN OF AGRI

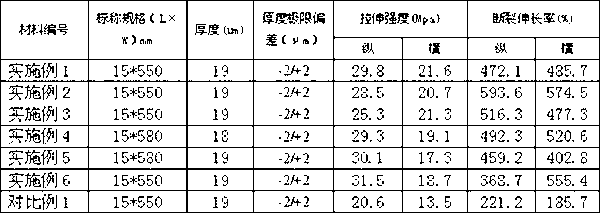

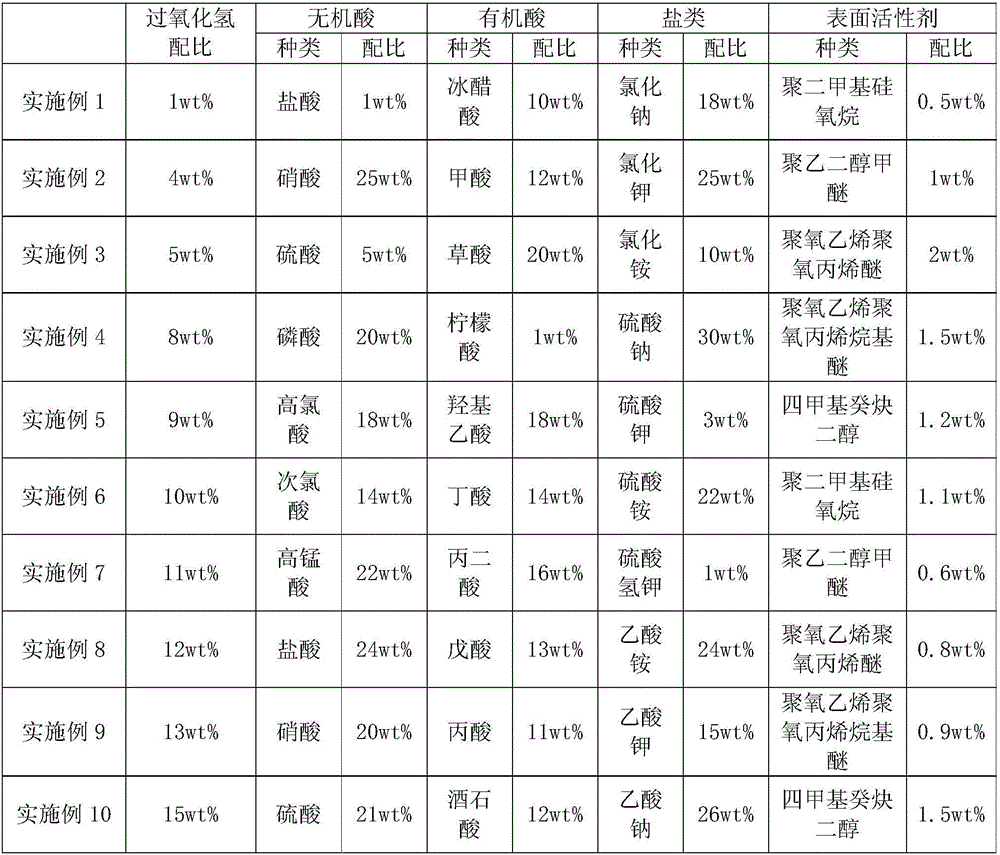

Copper etching liquid with little lateral etching

The invention belongs to the technical field of semiconductor machining and relates to copper etching liquid with little lateral etching. According to a formula, the copper etching liquid comprises 1-15 wt% of hydrogen peroxide, 1-25 wt% of inorganic acid, 1-20 wt% of organic acid, 1-30 wt% of salts, 0.5-2 wt% of a surface active agent and the balance deionized water. The surface active agent is one of polydimethylsiloxane, methoxypolyethylene glycol, polyoxyethylene polyoxypropylene, polyoxyethylene poly(propylene oxide alkyl ether) and tetramethyl decynediol. The copper etching liquid is even in etching, the lateral etching phenomenon is reduced, foam is avoided, and the stability is good.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Preparation method of modified polyethylene diaphragm for lithium ion battery

ActiveCN102993452AImprove thermal deformation resistanceGood adhesivenessPolyurea/polyurethane coatingsCell component detailsParticulatesPolyurethane adhesive

The invention discloses a preparation method of a modified polyethylene diaphragm for a lithium ion battery. The preparation method of the modified polyethylene diaphragm is characterized in that a high-temperature resistance coating is uniformly coated on the two surfaces of the polyethylene diaphragm, and the modified polyethylene diaphragm is formed after drying; and the high-temperature resistance coating comprises inorganic particulate matters, a polyurethane adhesive, a dispersing agent and an ethanol solution. The high-temperature resistance coating adopted in the invention has low surface tension and is more environment-friendly by taking an ethanol solution as a solvent; dispersed phases in the high-temperature resistance coating are coated on the two surfaces of the polyethylene diaphragm to form a high-temperature resistance Al2O3 coating which can stop a positive electrode and a negative electrode from directly contacting when a base material melts, slows down the release of heat energy and improves the safety performance of the battery; and the polyurethane adhesive synthesized in the invention increases an interface bonding force between Al2O3 particles and the base material of the polyethylene diaphragm, enhances the adhesion between the Al2O3 particles and the base material, and simultaneously increases the imbibition capacity and heat resistance performance of the modified polyethylene diaphragm.

Owner:CHINA HAISUM ENG

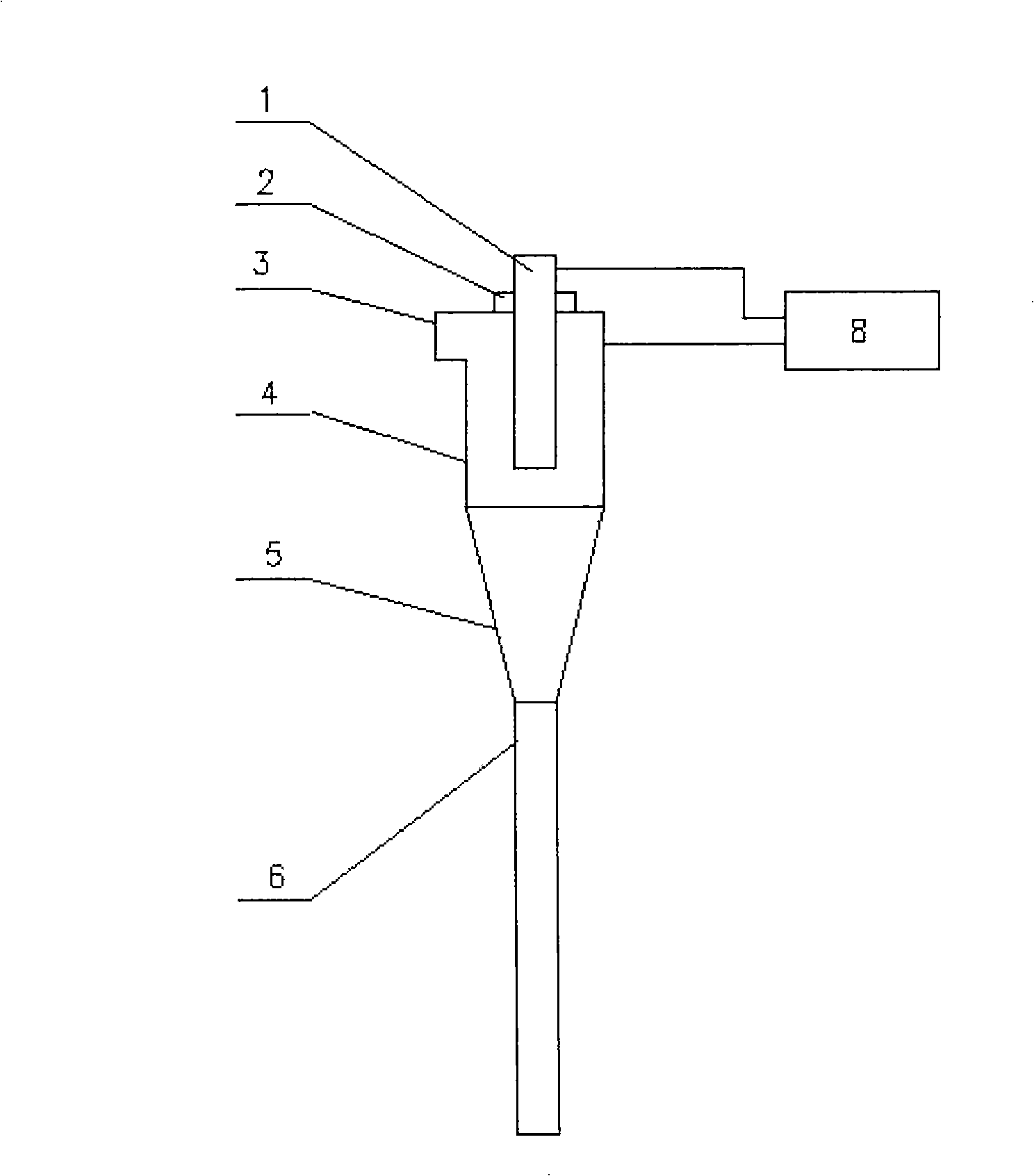

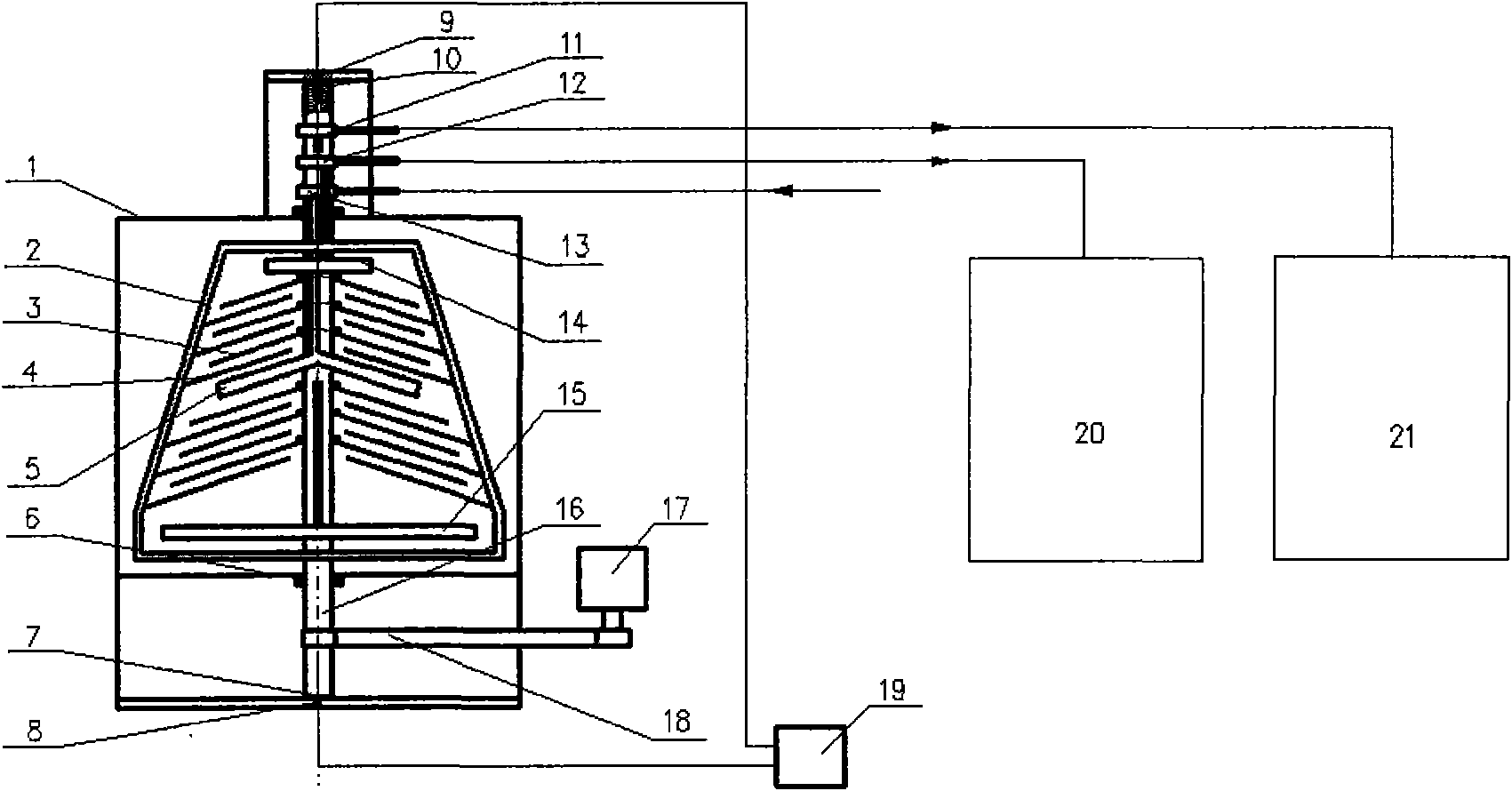

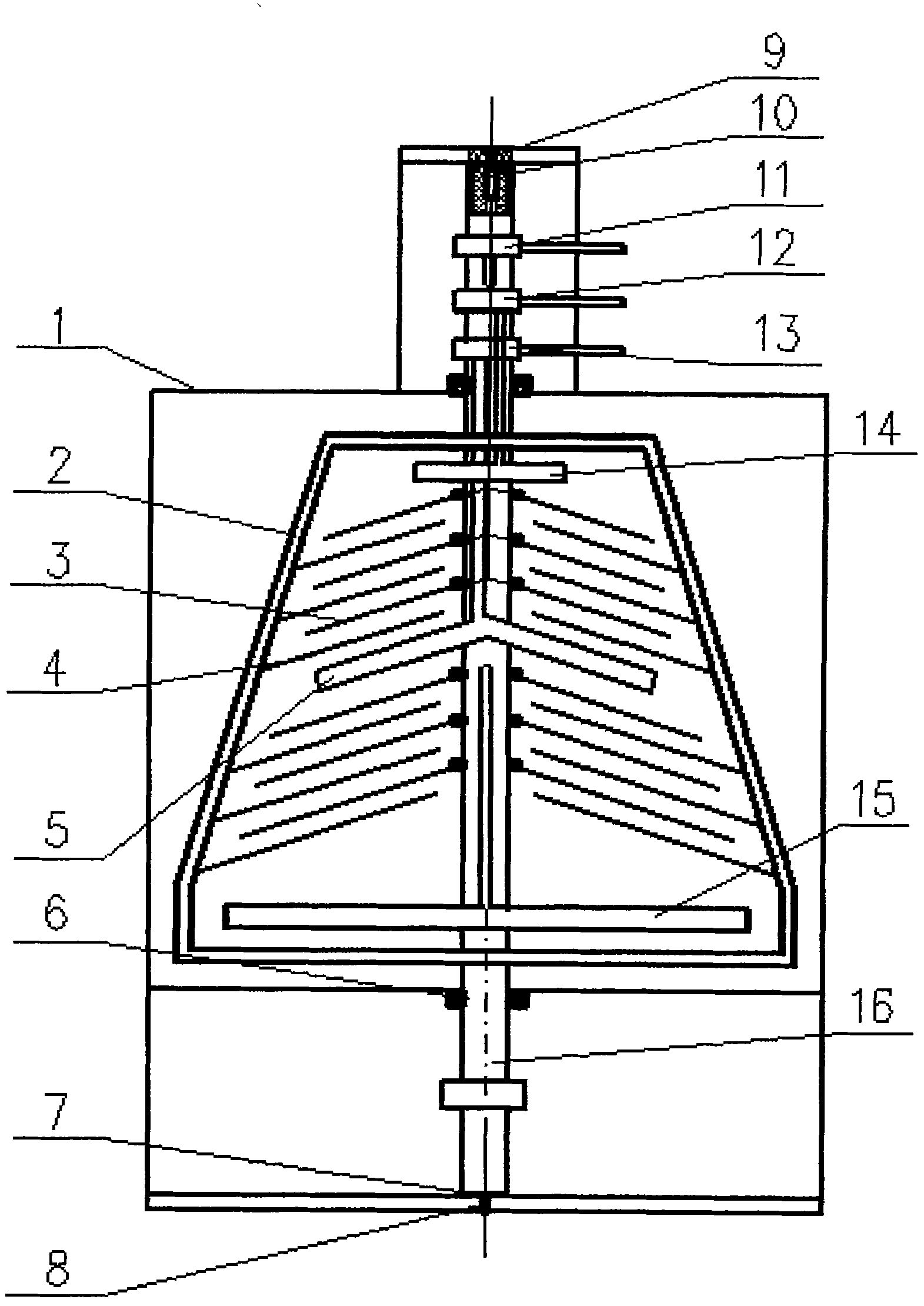

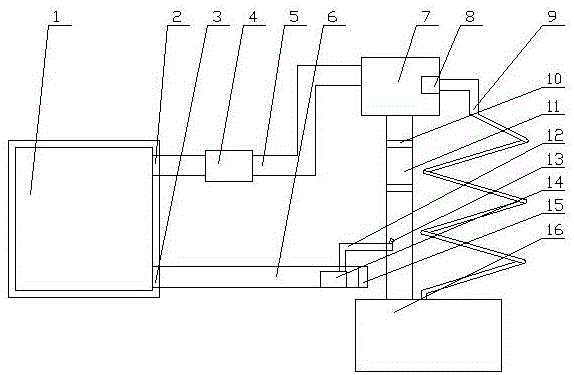

Crude oil dehydration method organically combining electric field and swirling flow field

ActiveCN101638587BSimple structureSimplify the dehydration processDewatering/demulsification with electric/magnetic meansSewagePulse electric field

The invention relates to a crude oil dehydration method organically combining an electric field and a swirling flow field, which is achieved by a crude oil dehydration process consisting of a swirler,a high-frequency pulse dehydration power supply device or other power supply devices, a dehydration electrode and a sewage settling tank, and is characterized by comprising the following steps: enlarging a vortex section, a concentric drawing-down section and a parallel end section of a swirling flow pipe in the same proportion, and setting the swirler consisting of a plurality of swirling flow pipes as a swirler with a single swirling flow pipe; extending an oil outlet pipe of the single swirling flow pipe, vertically inserting the oil outlet pipe into the vortex section as a high-frequencypulse dehydration electrode, or inserting the dehydration electrode into the middle-lower part of the vortex section along the center of the oil output pipe, wherein the output end of the high-frequency pulse dehydration power supply device is connected with the oil outlet pipe or the dehydration electrode through a conducting wire, a crude oil feed pipeline is connected with the inlet of the swirler, and the oil outlet pipe is connected with an oil conveying pipe or a good oil tank; and connecting the parallel end section with the sewage settling tank to form the crude oil dehydration processorganically combining a high-frequency pulse electric field and the swirling flow field.

Owner:SINOPEC PETROLEUM ENG DESIGN

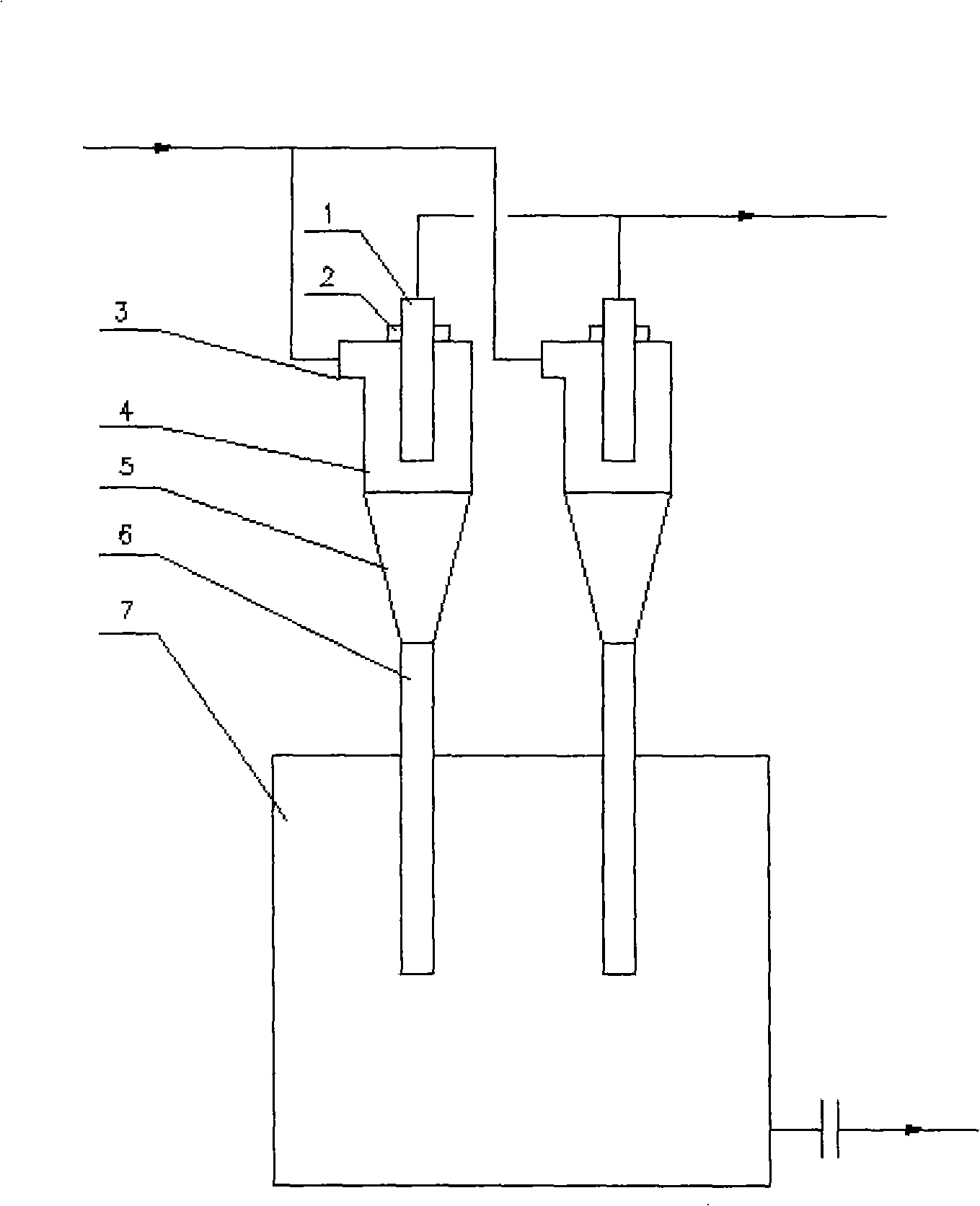

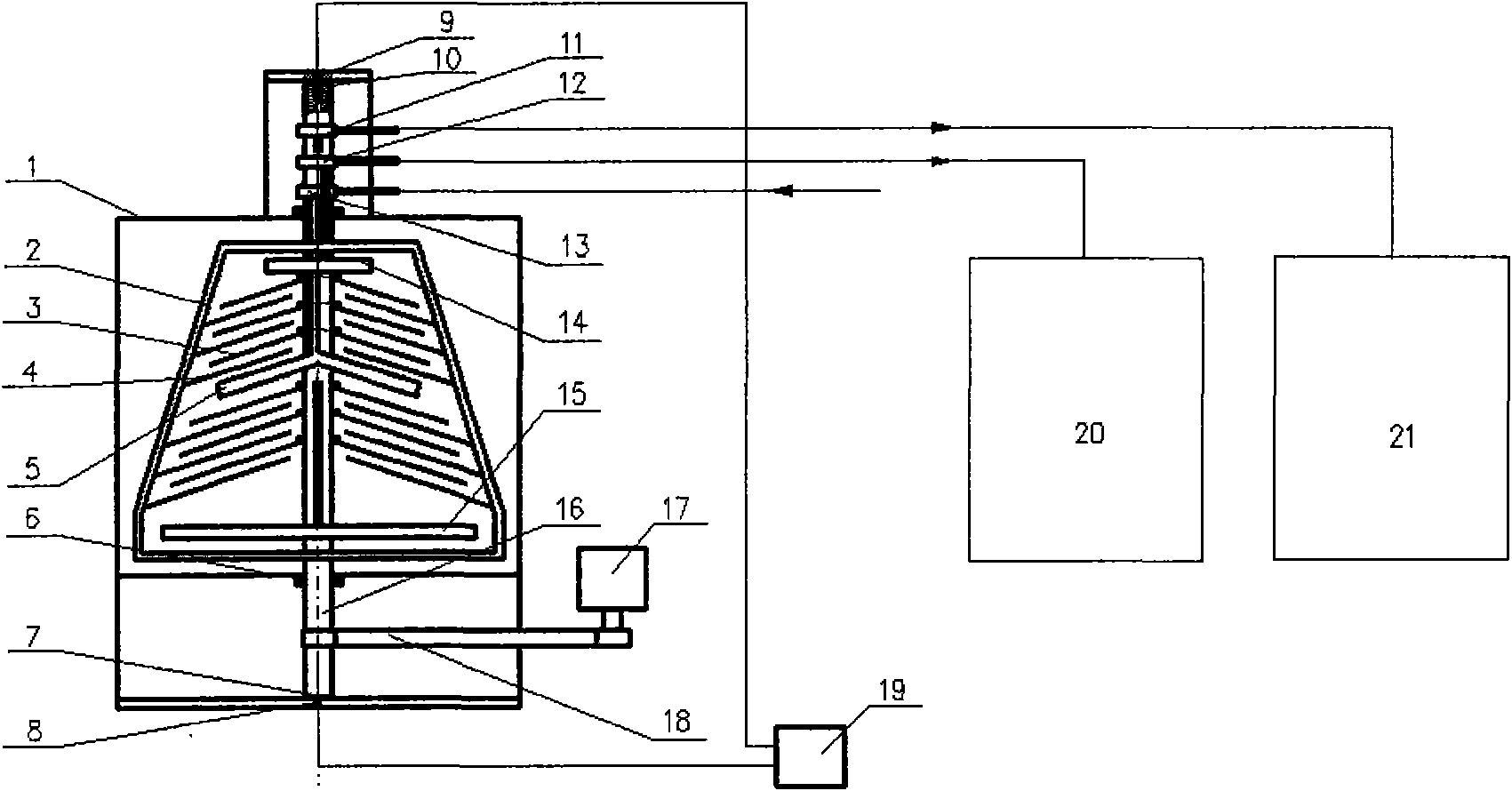

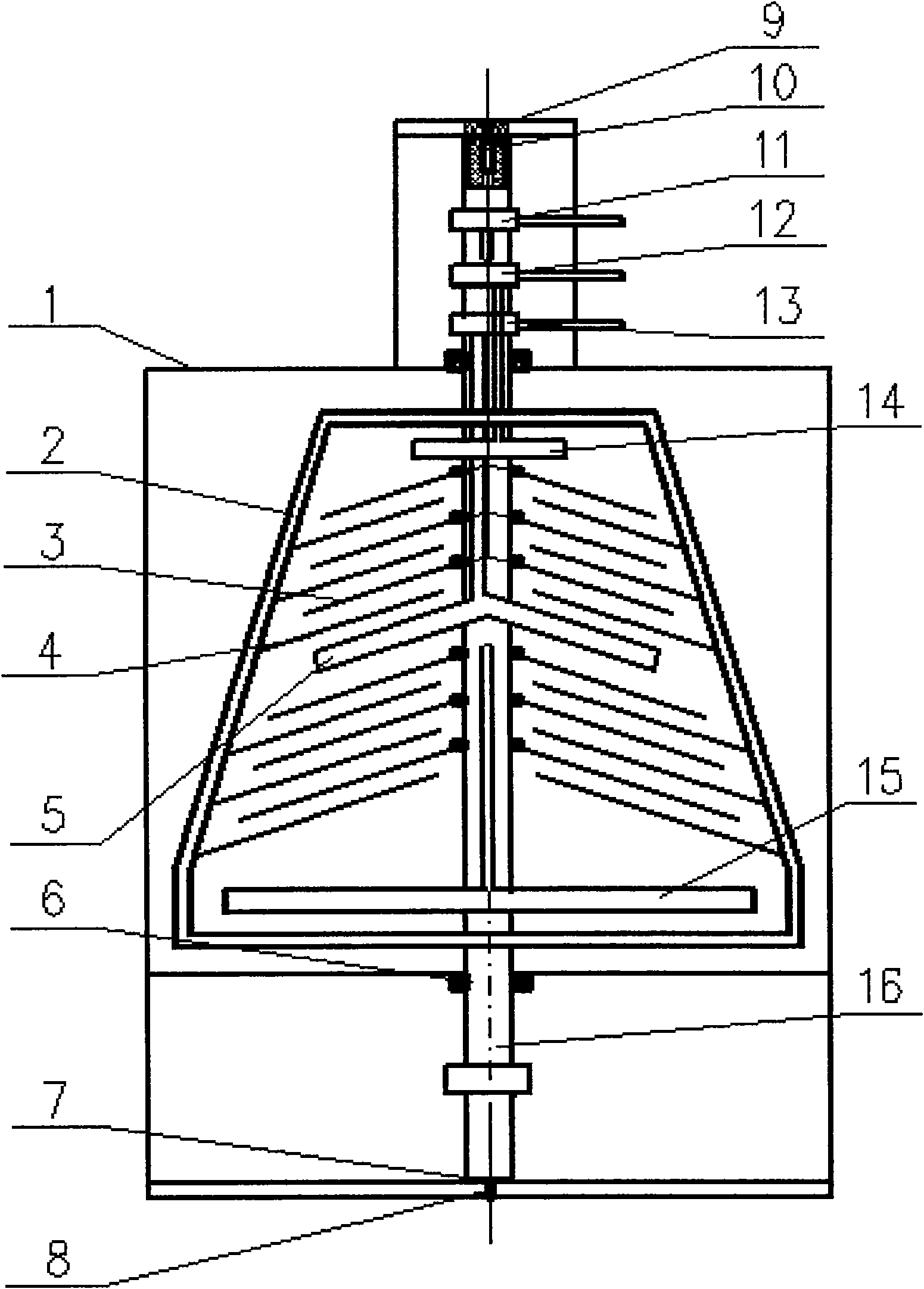

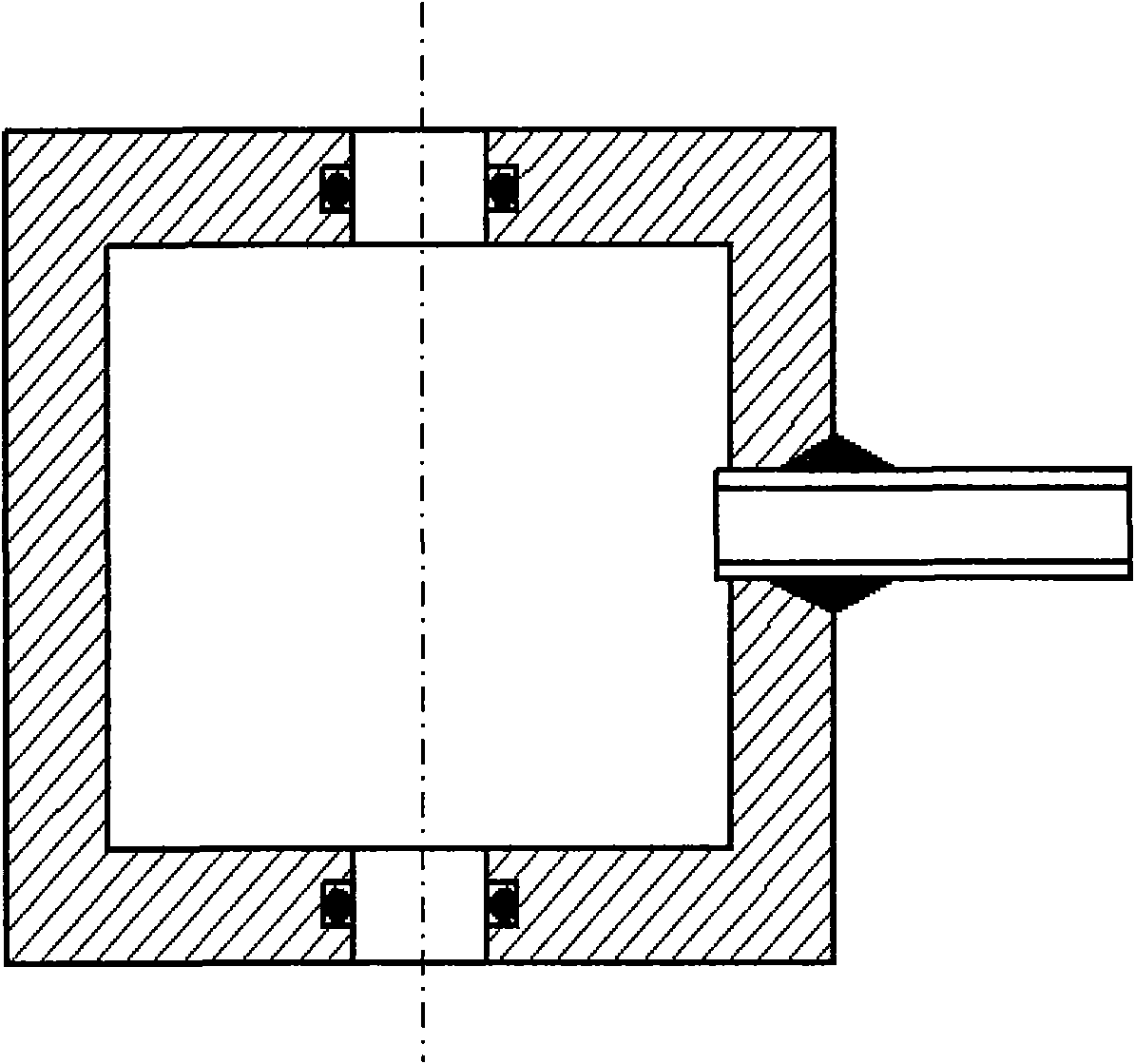

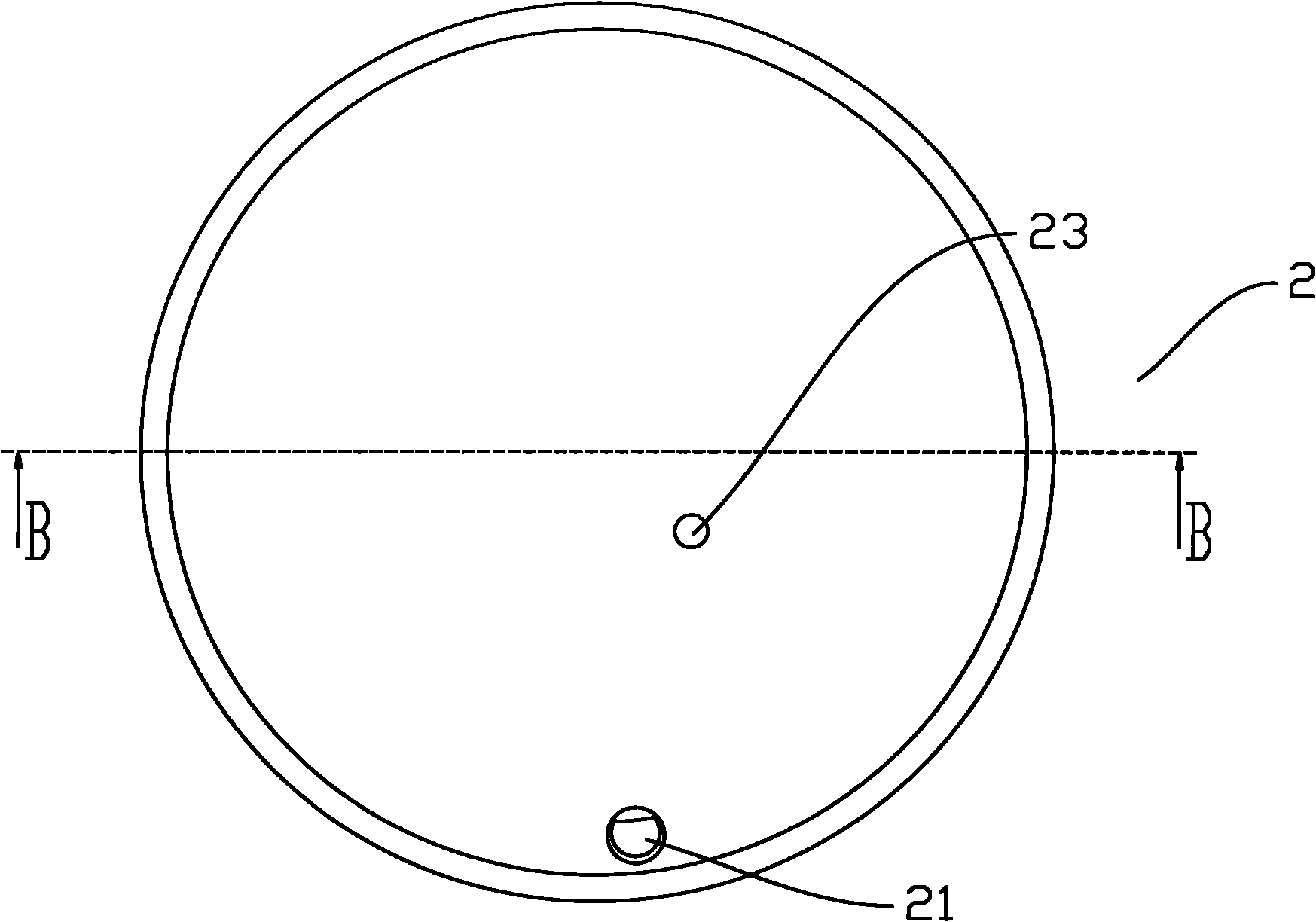

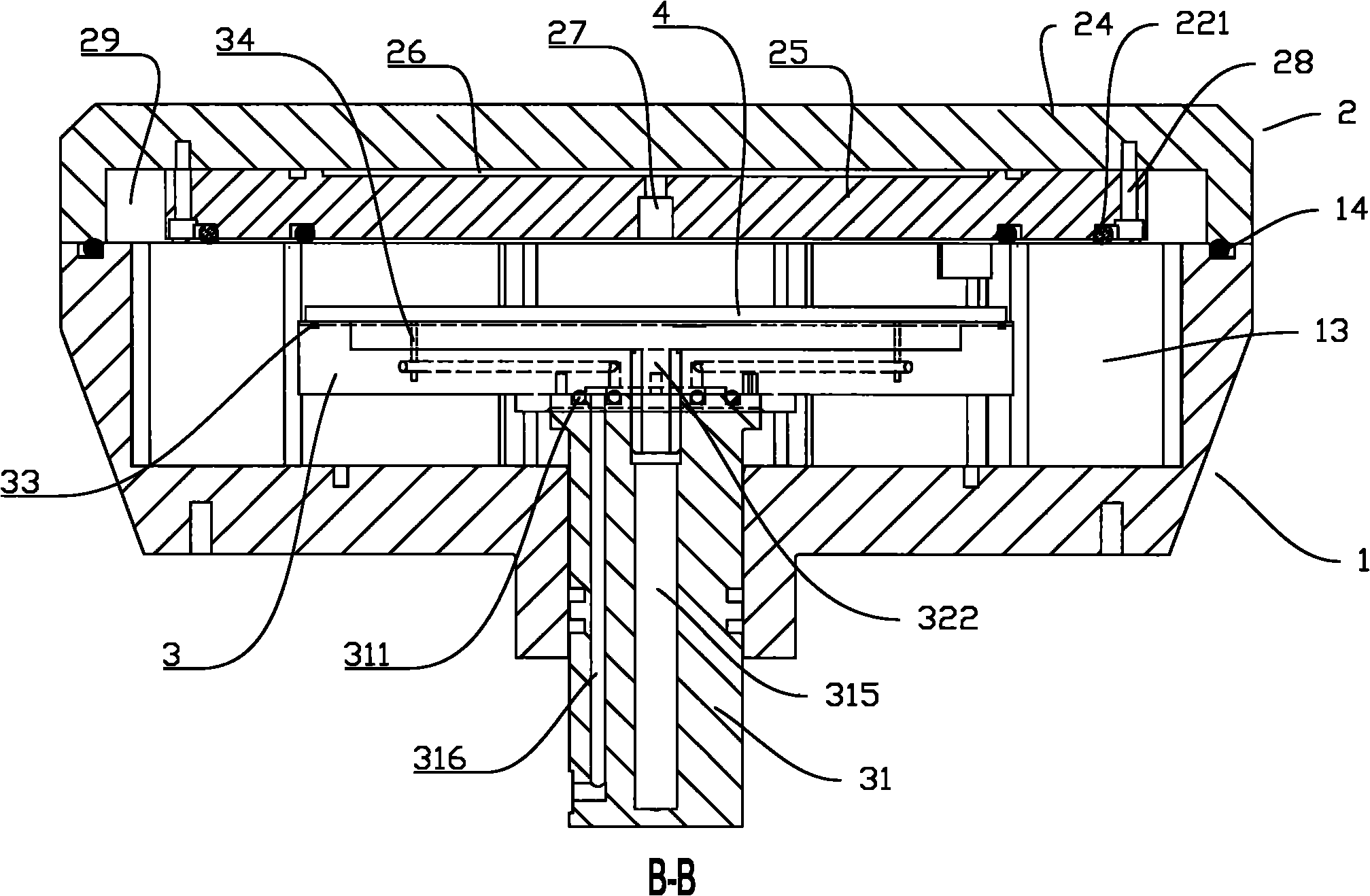

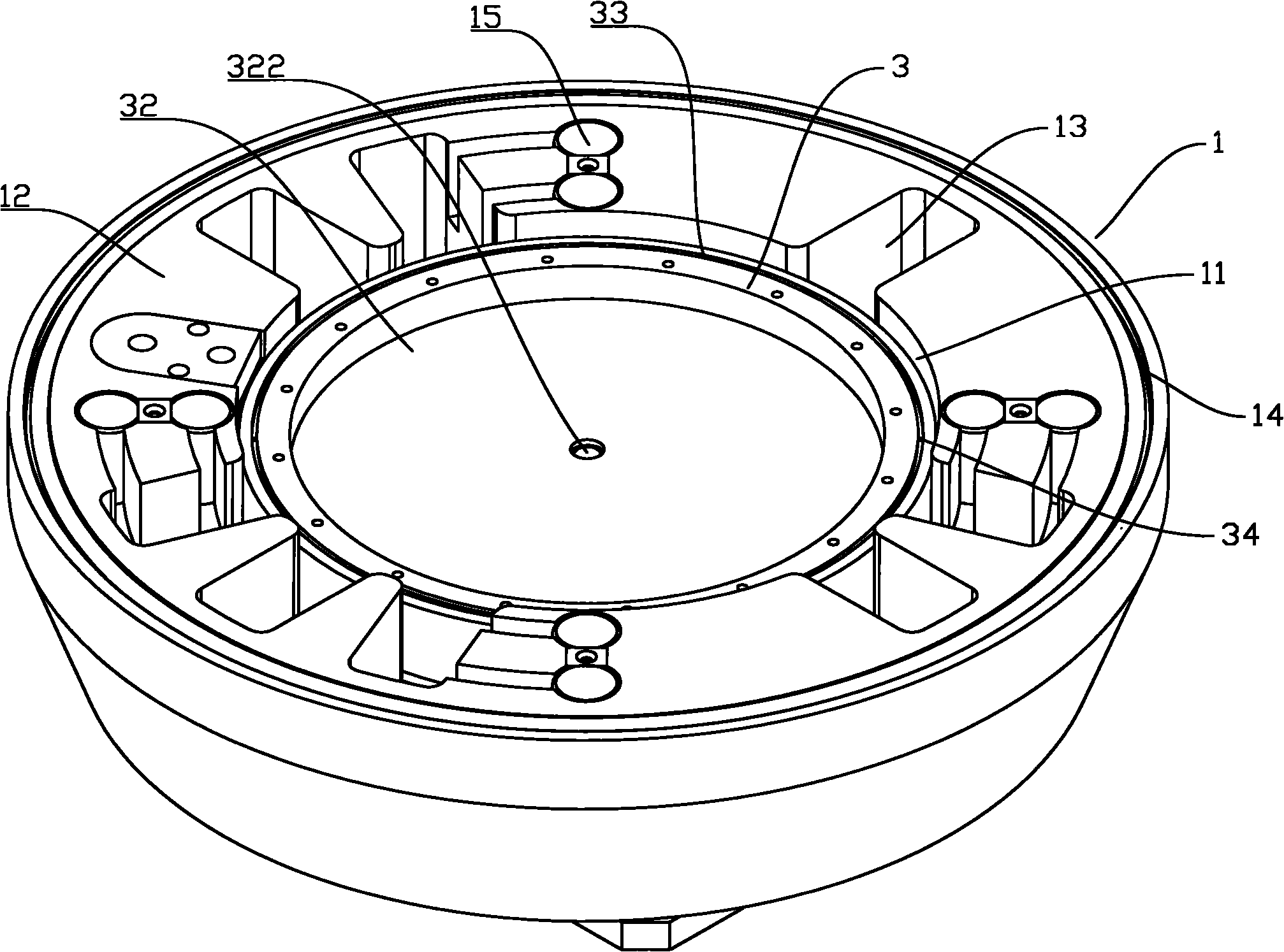

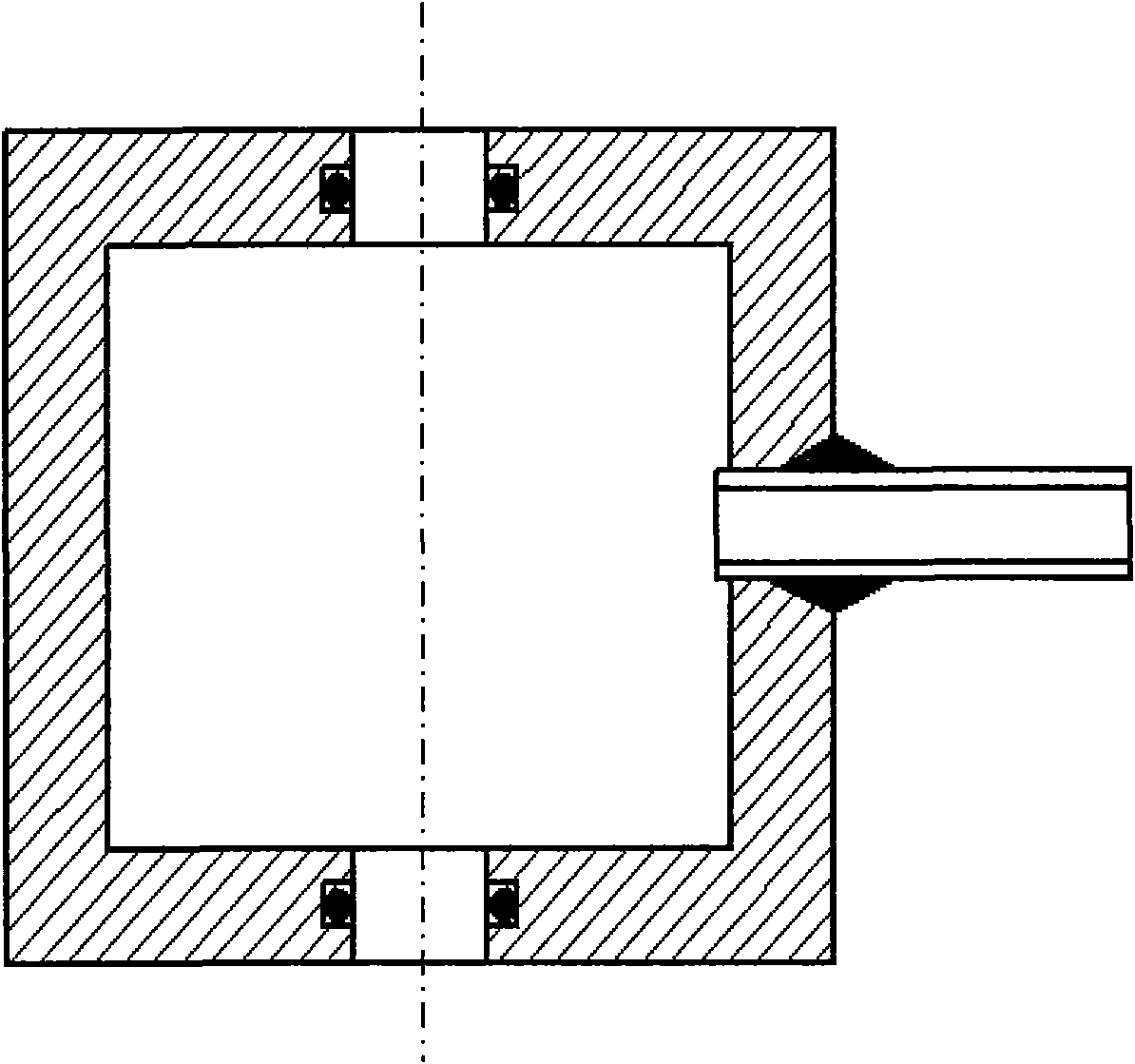

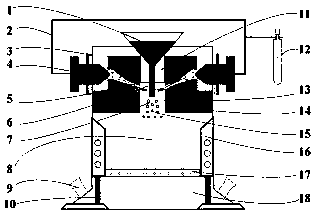

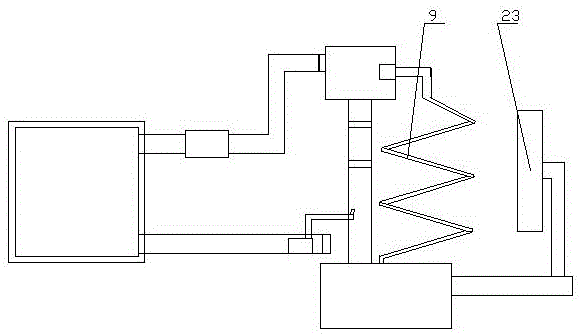

Crude oil dehydrating device combing electric field and centrifugal field

ActiveCN101564605ASimple structureSimplify the dehydration processLiquid separation by electricityElectric fieldEngineering

The invention relates to a crude oil dehydrating device combing an electric field and a centrifugal field, which consists of a shell, an electric field and centrifugal field integral structure, a motor, a pulley, a triangle leather belt, a dehydrating power supply device, an oil tank and a sewage tank. A centrifugal field structure consists of a hollow shaft, a liquid inlet pipe, a water outlet pipe, an oil outlet pipe, a sealed taper centrifugal cavity, an oil collector, a liquid distributor, a water collector, and sealing joints of the water outlet pipe, the oil outlet pipe and the liquid inlet pipe, wherein the hollow shaft is arranged in the vertical center of the shell; the liquid inlet pipe, the water outlet pipe and the oil outlet pipe are arranged in the hollow shaft; the sealed taper centrifugal cavity is arranged in the middle of the hollow shaft; the oil collector is arranged on the upper part in the hollow shaft; the liquid distributor is arranged in the middle of the hollow shaft; the water collector is arranged on the lower part of the hollow shaft; and the sealing joints are arranged on the upper part of the hollow shaft and do not rotate. An electric field structure consists of a disk-shaped electrode plate, the other disk-shaped electrode plate, moving electrodes and fixed electrodes, wherein the disk-shaped electrode plate is arranged between the oil collector and the liquid distributor; the other disk-shaped electrode plate is arranged on the centrifugal cavity and staggered with the electrode plate of the hollow shaft; the moving electrodes are arranged at both ends of the hollow shaft; and the fixed electrodes are arranged at the upper end and the lower end of the shell and correspondingly and movably contact the moving electrodes. The upper fixed electrode and the lower fixed electrode are connected with the dehydrating power supply device; and a motor pulley is connected with the pulley on the lower part of the hollow shaft through the.

Owner:SINOPEC SSC +1

Method and device suitable for laminating film for ultrathin wafer

ActiveCN102082078AReduce minimum thicknessImprove abilitiesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

The invention discloses a method suitable for laminating a film for an ultrathin wafer, which is characterized in that when film lamination is carried out, a certain pressure is supplied to push a wafer to a thin film so as to adhere the thin film and the wafer together. In the method and the device suitable for laminating the film for the ultrathin wafer, provided by the invention, pressure is applied to the wafer so as to enable the wafer to be adhered to the thin film. The wafer and the thin film can be firmly adhered together through the pressure applied to the wafer. When film lamination is carried out, the thin film can supply supporting force to the wafer so as to prevent the wafer from cracking due to excessive deformation. Therefore, by using the method and the device provided by the invention for laminating the film, the problem that the ultrathin wafer cracks can be effectively avoided.

Owner:上海技美科技股份有限公司

Porous adsorbent with surface expressed by polycarboxylic acid, preparation method of porous adsorbent and application of porous adsorbent

ActiveCN108031452AImprove adsorption capacityWill not formOther chemical processesWater contaminantsCross-linkAlcohol

The invention relates to a porous adsorbent with a surface expressed by polycarboxylic acid, a preparation method of the porous adsorbent and an application of the porous adsorbent. 3.5-6.0mL of wateris dropped into 1mL of cross-linked polymerized oil phase with a linear amphiphilic polymer, dropping and stirring are simultaneously performed, water-in-oil type concentrated emulsion is formed andheated and hatched into an elastic porous material in a standing manner, the porous material is washed by ethyl alcohol and dried to obtain the porous material with the hole surface expressed by a hydrophilic section of the linear amphiphilic polymer, and the hydrophilic section is treated and expressed by carboxylic acid to obtain the porous adsorbent with the surface expressed by the polycarboxylic acid. Compared with the prior art, the porous adsorbent is provided with a macroscopic material, the porous adsorbent is directly added into water and can adsorb and remove pollutants such as cationic dyes, cationic surface active agents, arene and metals in water under the condition of pH (potential of hydrogen)=4-9, and the adsorbed pollutants can be released in an acid environment and can be reused after being cleaned with water.

Owner:TONGJI UNIV

Crude oil dehydrating device combining electric field and centrifugal field

ActiveCN101564605BSimple structureSimplify the dehydration processLiquid separation by electricityEngineeringSewage

The invention relates to a crude oil dehydrating device combing an electric field and a centrifugal field, which consists of a shell, an electric field and centrifugal field integral structure, a motor, a pulley, a triangle leather belt, a dehydrating power supply device, an oil tank and a sewage tank. A centrifugal field structure consists of a hollow shaft, a liquid inlet pipe, a water outlet pipe, an oil outlet pipe, a sealed taper centrifugal cavity, an oil collector, a liquid distributor, a water collector, and sealing joints of the water outlet pipe, the oil outlet pipe and the liquid inlet pipe, wherein the hollow shaft is arranged in the vertical center of the shell; the liquid inlet pipe, the water outlet pipe and the oil outlet pipe are arranged in the hollow shaft; the sealed taper centrifugal cavity is arranged in the middle of the hollow shaft; the oil collector is arranged on the upper part in the hollow shaft; the liquid distributor is arranged in the middle of the hollow shaft; the water collector is arranged on the lower part of the hollow shaft; and the sealing joints are arranged on the upper part of the hollow shaft and do not rotate. An electric field structureconsists of a disk-shaped electrode plate, the other disk-shaped electrode plate, moving electrodes and fixed electrodes, wherein the disk-shaped electrode plate is arranged between the oil collectorand the liquid distributor; the other disk-shaped electrode plate is arranged on the centrifugal cavity and staggered with the electrode plate of the hollow shaft; the moving electrodes are arrangedat both ends of the hollow shaft; and the fixed electrodes are arranged at the upper end and the lower end of the shell and correspondingly and movably contact the moving electrodes. The upper fixed electrode and the lower fixed electrode are connected with the dehydrating power supply device; and a motor pulley is connected with the pulley on the lower part of the hollow shaft through the.

Owner:中石化石油工程技术服务有限公司 +1

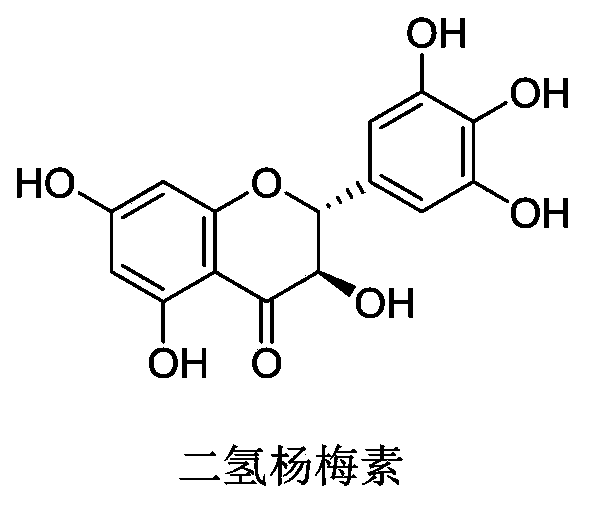

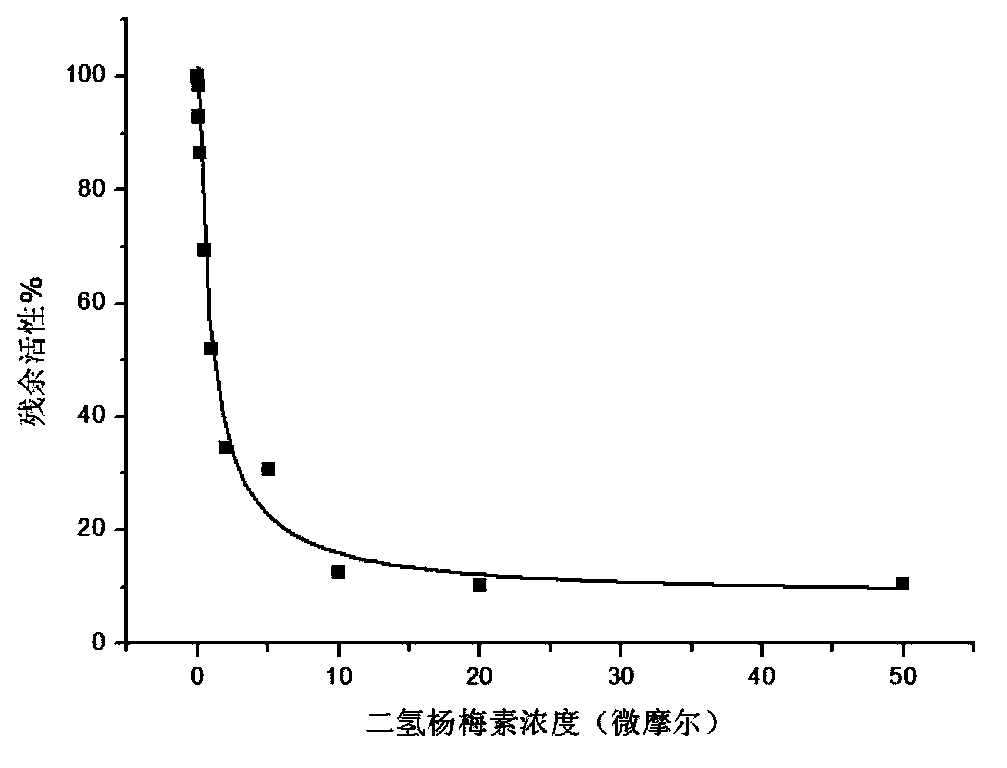

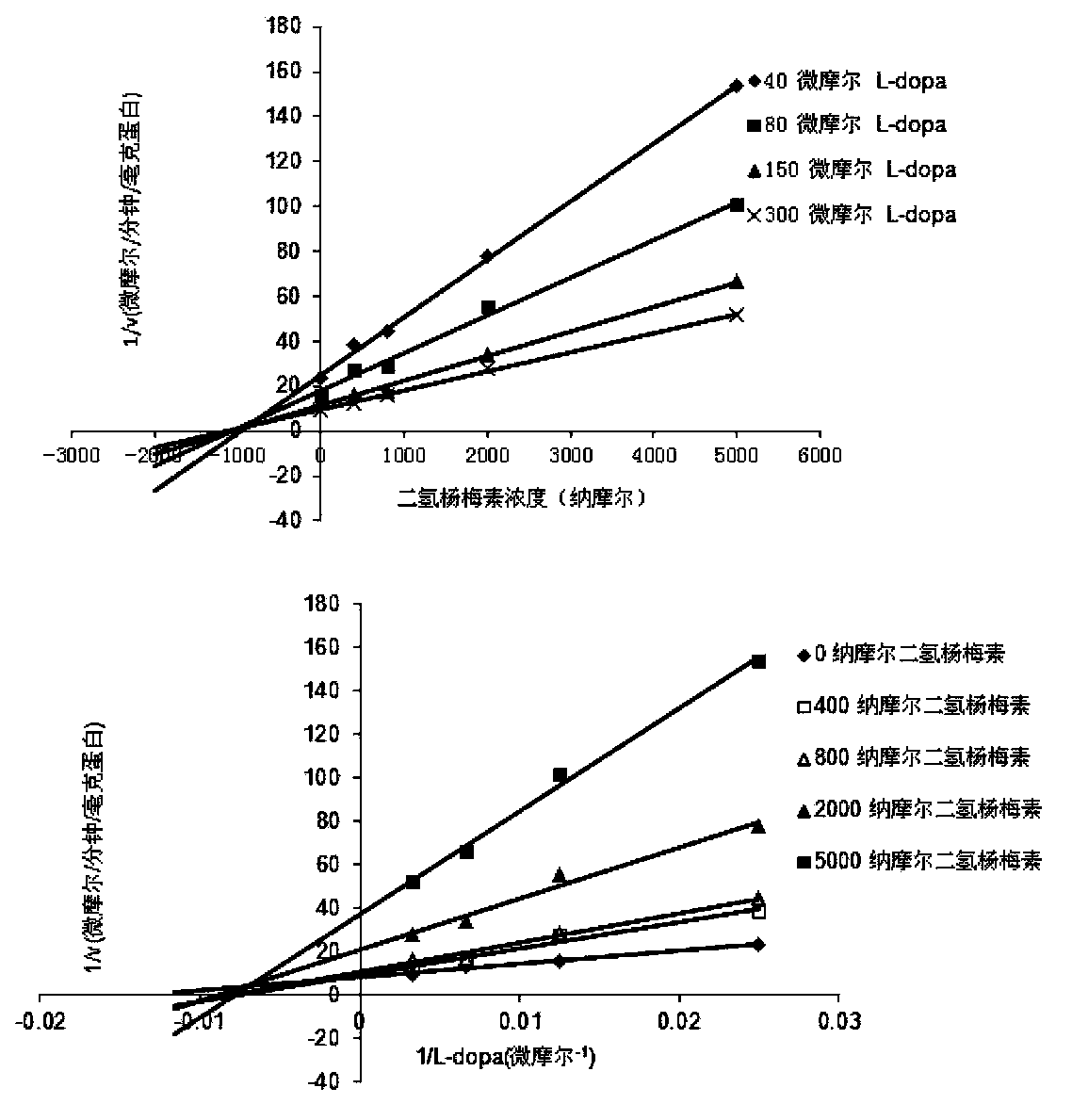

Application of dihydromyricetin to prepare medicines treating Parkinson's syndrome as active composition

InactiveCN104116730ALow toxicityNo toxicityOrganic active ingredientsNervous disorderBlood drug concentrationEstrogens catechol

The invention provides a dihydromyricetin-containing plant extract and application thereof as a superactive catechol methylation transferase inhibitor. The dihydromyricetin-containing plant extract is applicable as a synergist of a medicine levodopa treating Parkinson's syndrome. In-vitro activity determination shows that IC50 of the plant extract inhibiting catechol methylation transferase can reach the micro-mole to nano-mole grade. Rat integral pharmacokinetic research shows that combined usage of dihydromyricetin and levodopa containing the dihydromyricetin-containing plant extract can substantially improve the plasma concentration of levodopa. Additionally, dihydromyricetin and the dihydromyricetin-containing plant extract are high in safety, do not generate active intermediates through metabolism activation, do not combine with a biomacromolecule to form a toxic adduct, and therefore dihydromyricetin and the dihydromyricetin-containing plant extract do not cause liver and kidney toxicity, and are expected to have good application prospect in auxiliary treatment of Parkinson's syndrome.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spelter solder

InactiveCN106695164ALow melting pointTroubleshoot microcracksWelding/cutting media/materialsSoldering mediaSpelterManganese

The invention provides spelter solder. The spelter solder comprises, by weight percent, the flowing raw materials: 52%-58% of copper, 0.5%-1.1% of tin, 0.3%-1.2% of bismuth, 0.05%-0.15% of silicon, 0.03%-0.09% of manganese, 0.02%-0.06% of germanium and the balance zinc. The spelter solder can reduce the melting point of traditional spelter solder and solves the problem of microcracks caused by addition of Si.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Flame-retardant aliphatic-aromatic copolyester and preparation method thereof

The invention discloses flame-retardant aliphatic-aromatic copolyester, which is prepared with aromatic dibasic acid, aliphatic dibasic acid, aliphatic dihydric alcohol and phosphorus-based flame retardant. The amount of the phosphorus-based flame retardant is 0.05-1.00 percent of the flame-retardant aliphatic-aromatic copolyester by weight. A preparation method comprises the steps of: a) preparing butanediol solution of phosphate; b) performing esterification to obtain a corresponding esterified compound; c) performing prepolymerization to obtain a corresponding prepolymer; and d) performing polycondensation reaction. The flame-retardant aliphatic-aromatic copolyester has the beneficial effects that a titanium chelate compound with hydrolysis resistance is adopted as a catalyst, the amount of the added catalyst is reduced, the titanium dioxide precipitate cannot be produced during production, and the maintenance / replacement cycle of production equipment can be extended; and the material has degrading properties and flame retardant properties, the scope of application of the biodegradable material can be broadened further, the effect of stabilizing the color of the copolyester can be achieved while the flame retardant properties of the material is realized, the structure of the copolyester can be controlled easily, no gel can be produced easily during reaction, and the produced membrane is free from crystallization points formed by gel.

Owner:KINGFA SCI & TECH CO LTD +2

Method for preparing high-purity aluminum nitride spherical powder through plasma reaction atomization

PendingCN111470481ASmall particle size distributionFull impact crushingNitrogen compoundsNitrogen plasmaAtomizer nozzle

The invention relates to a method for preparing high-purity aluminum nitride spherical powder through plasma reaction atomization. The method comprises a step of generating nitrogen plasma, namely a step of generating the nitrogen plasma by a plasma torch and jetting the plasma into a reaction atomization device; a step of reaction atomization, namely a step of performing reaction atomization on molten aluminum liquid by the nitrogen plasma in the reaction atomization device and simultaneously reacting the molten aluminum liquid with nitrogen to generate aluminum nitride, with the reaction atomization device comprising a heat source, a reaction atomization nozzle and a reaction atomization chamber, the heat source being used for obtaining the molten aluminum liquid, and the reaction atomization nozzle being used for spraying 360-degree annular plasma beams; a step of powder collection, namely a step of gradually solidifying the aluminum nitride into spherical powder from leaving the reaction atomizing chamber, and finally collecting the spherical powder by a powder collection device. The method is characterized in that the nitrogen plasma is used for carrying out 360-degree surrounding uniform impact on the molten aluminum through the reaction atomizing nozzle, so that the generation and atomization of the aluminum nitride are synchronously carried out, and the high-purity aluminum nitride spherical powder is obtained while the production efficiency is improved.

Owner:SICHUAN UNIV

High-performance water-cooling heat dissipation platform for mainframe

InactiveCN107526417AAvoid pollutionGuaranteed safe operationDigital processing power distributionEnergy efficient computingEnergy consumptionComputer engineering

The invention discloses a high-performance water-cooling heat dissipation platform for a mainframe. The platform includes a sealed mainframe box, the top of the mainframe box is provided with an air inlet hole, the bottom of the mainframe box is provided with a venting hole, the air inlet hole is communicated with an air inlet pipeline, the venting hole is communicated with a venting pipeline, the air inlet pipeline is communicated with the upper end of a water cooling mechanism, the venting pipeline is communicated with the lower portion of the water cooling mechanism, and the air inlet pipeline is internally provided with a drying mechanism. According to the high-performance water-cooling heat dissipation platform, air inside the mainframe box is fully in contact with water to conduct heat transfer, and therefore heat in the mainframe box is exhausted, a heat dissipation effect is well achieved, and meanwhile, the defects of loud noise and big energy consumption in a traditional heat dissipation mode can be overcome; the platform is simple in overall structure, low in manufacturing cost and easy to popularize.

Owner:翟一策

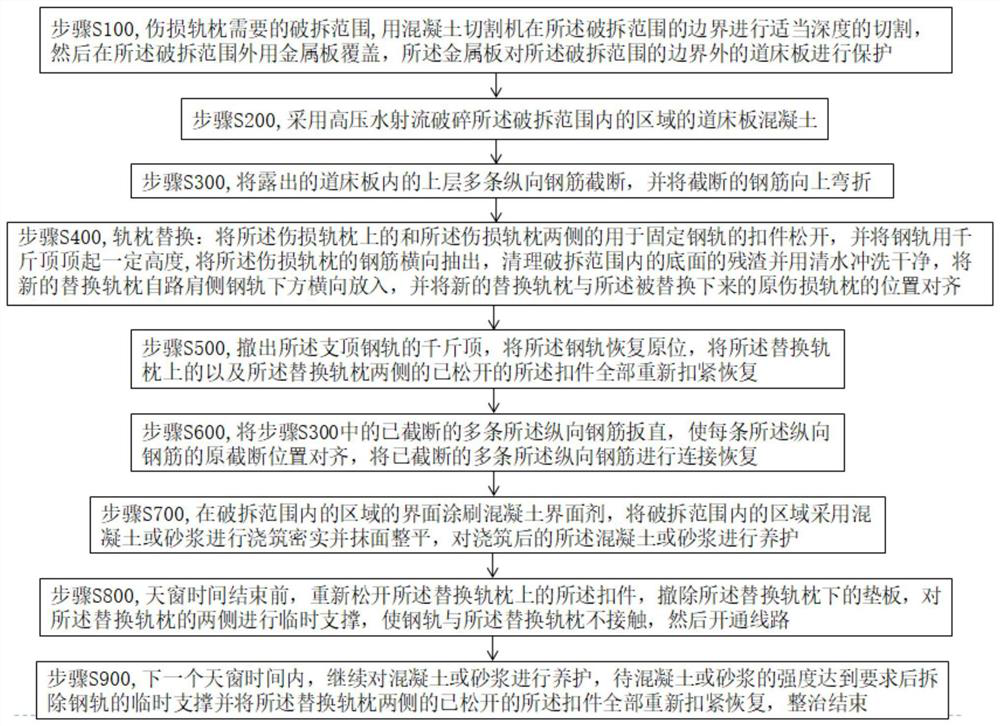

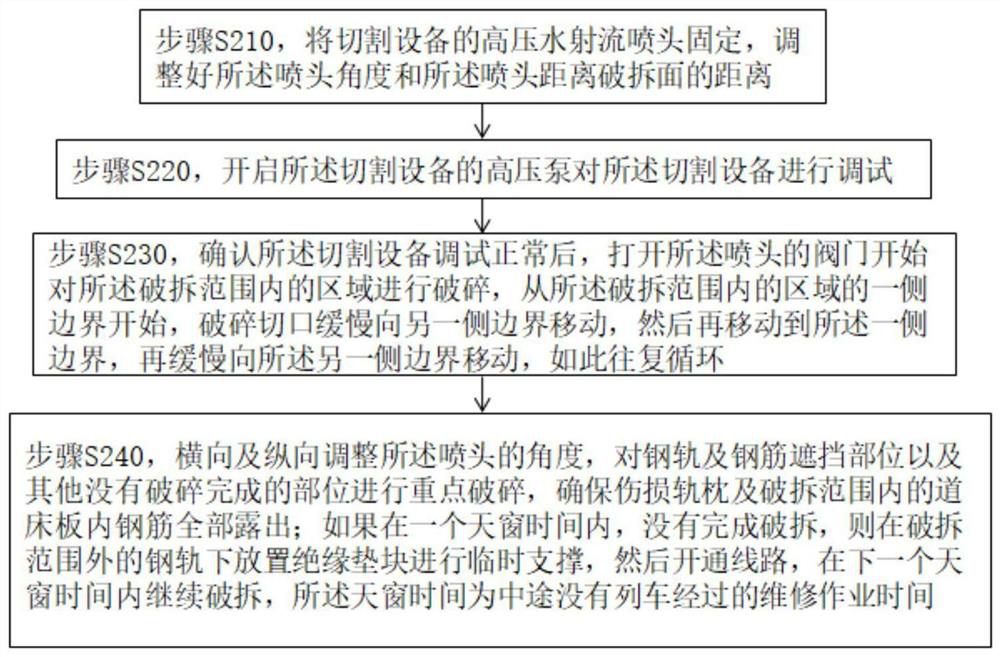

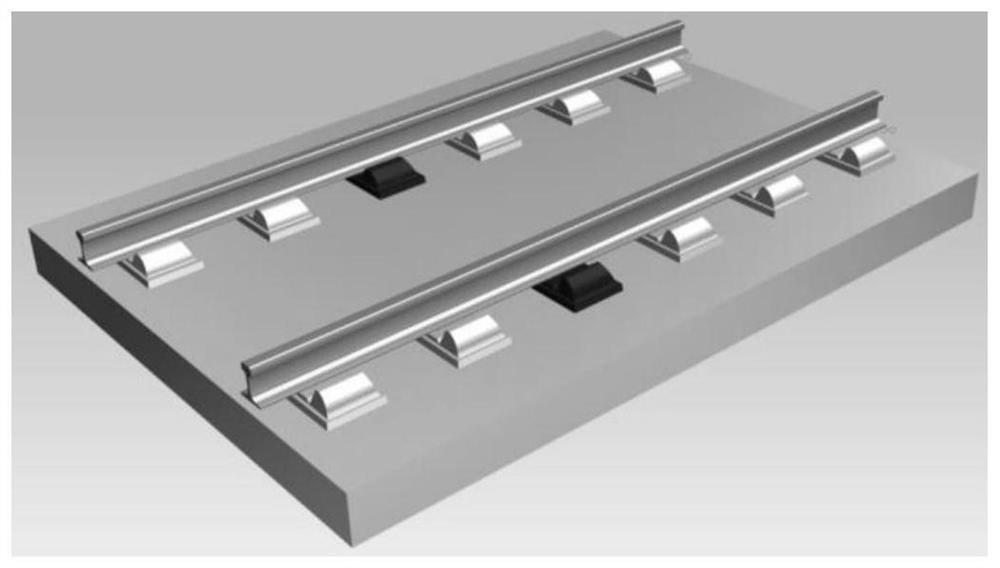

Ballastless track damaged sleeper replacement method

InactiveCN111733639AWill not formWon't hurtRailway track constructionTrackwayArchitectural engineering

The invention discloses a high speed railway ballastless track damaged sleeper replacement method which comprises the following steps: firstly, removing the damaged sleeper, then mounting and fixing anew sleeper, and pouring the new sleeper and a track plate into a whole again; cutting at a proper depth at the boundary of a forcible entry range; adopting high-pressure water jet to cut the area within the forcible entry range; cutting off a plurality of longitudinal reinforcing steel bars in the track plate; carrying out sleeper replacement and fixation, connecting the plurality of cut off longitudinal steel bars; pouring concrete or mortar at the forcible entry part to pour the new sleeper and the track plate into a whole, carrying out leveling maintenance, and temporary supporting on thetwo sides of the replaced sleeper, before skylight time is over, loosening fastener bolts on the sleeper again, removing a base plate below the sleeper, and recovering fasteners after the strength ofthe poured concrete or mortar reaches the designed strength. By means of the method, new cracks cannot be formed in existing concrete, original structural steel bars cannot be damaged, the construction range is accurate, the interface of the dismantled concrete is rough, the binding power is high, binding of new concrete and old concrete is facilitated, and the integrity is better.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

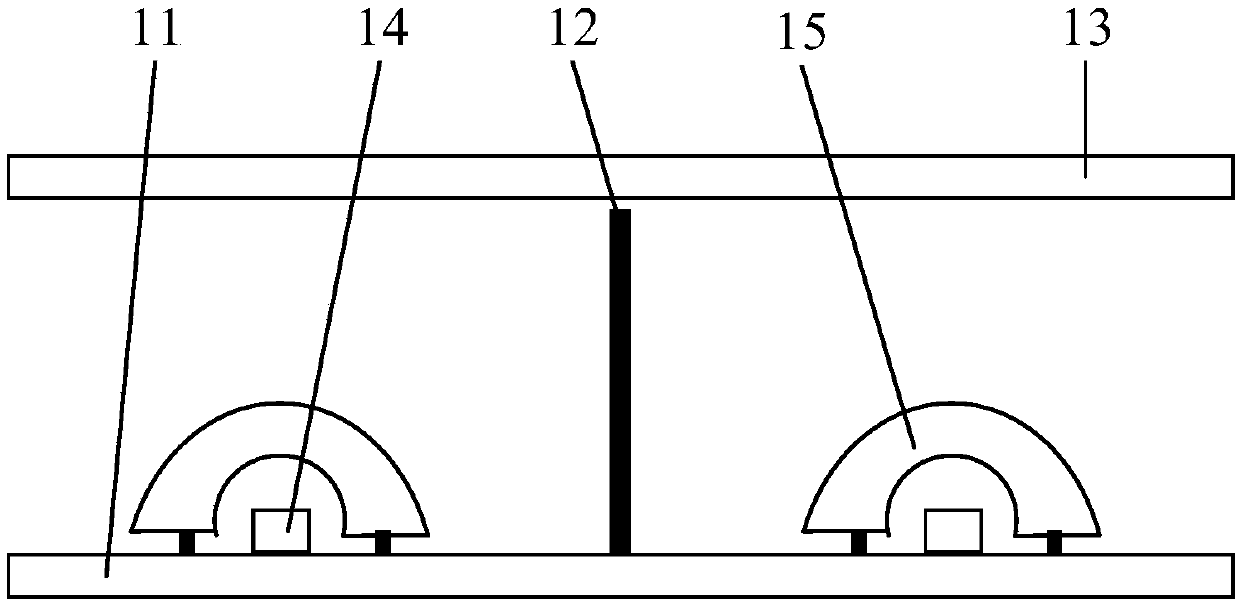

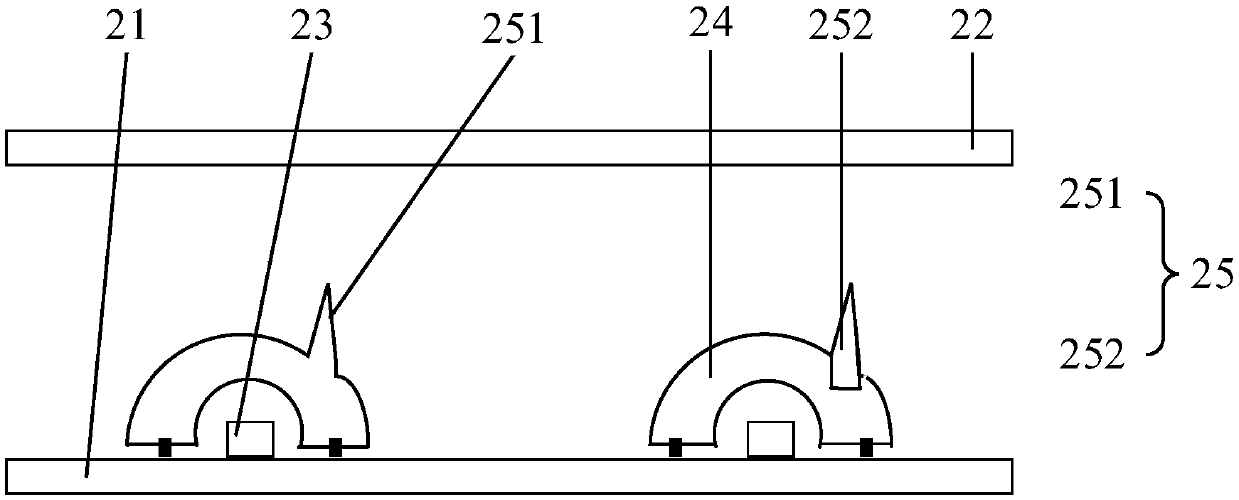

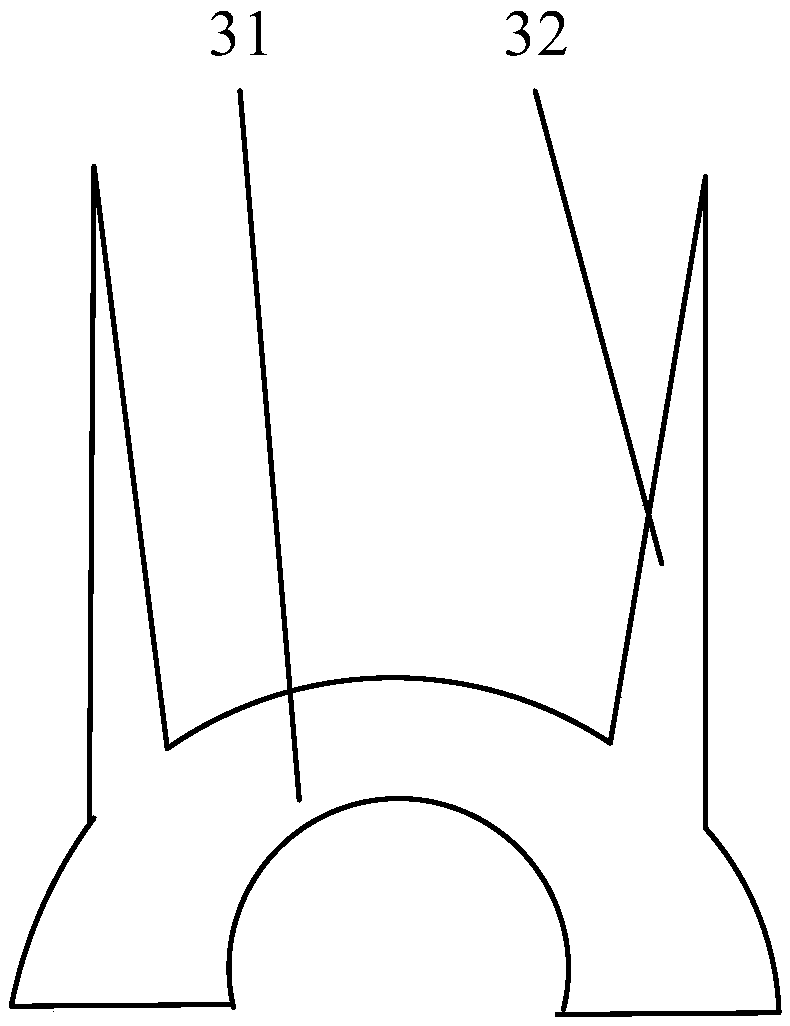

Backlight module

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Fully-washable textile sewing machine oil

ActiveCN103789066AImprove qualityImprove oxidation stabilityLubricant compositionPolyesterAntioxidant

The invention discloses fully-washable textile sewing machine oil which is prepared from the following raw materials in parts by weight: 50 to 60 parts of number 26 white oil, 10 to 20 parts of naphtha, 10 to 20 parts of polyaleneglycol, 1 to 4 parts of antioxidant, 3 to 8 parts of aliphatic ester, 1 to 3 parts of polyester and 8 to 12 parts of non-ionic surfactant. The fully-washed textile sewing machine oil has the characteristics of high quality, good lubrication effects, long life cycle and the like, and can be fully washed after a fabric or leather is stained with the machine oil, and the straining of any other oil stains is avoided; in addition, the accumulation of static electricity can also be prevented, the fully-washable textile sewing machine oil can be cleaned directly by clear water without conventional spray gun water (dichloromethane) and oil stains, and has the characteristics of biodegradability, no damage to the sealing performance of a rubber part and the like, and the requirements of environmental protection are met.

Owner:格林润滑科技(惠州)有限公司

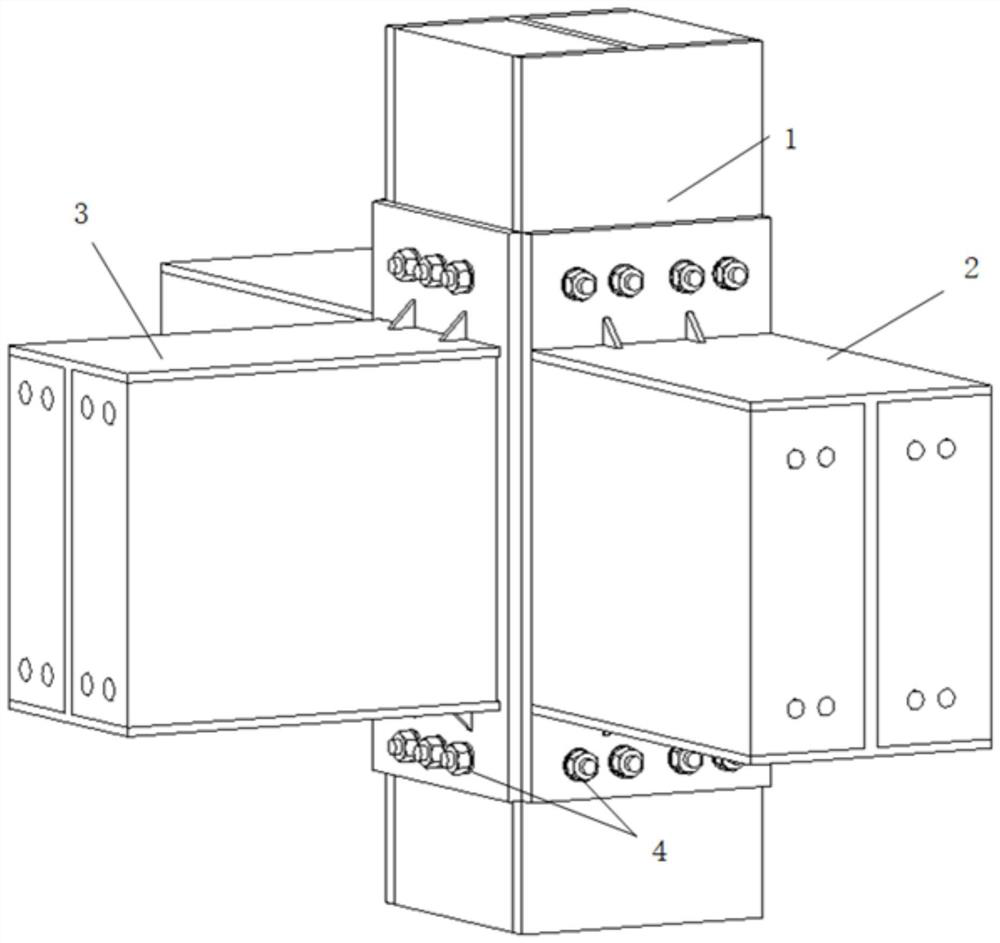

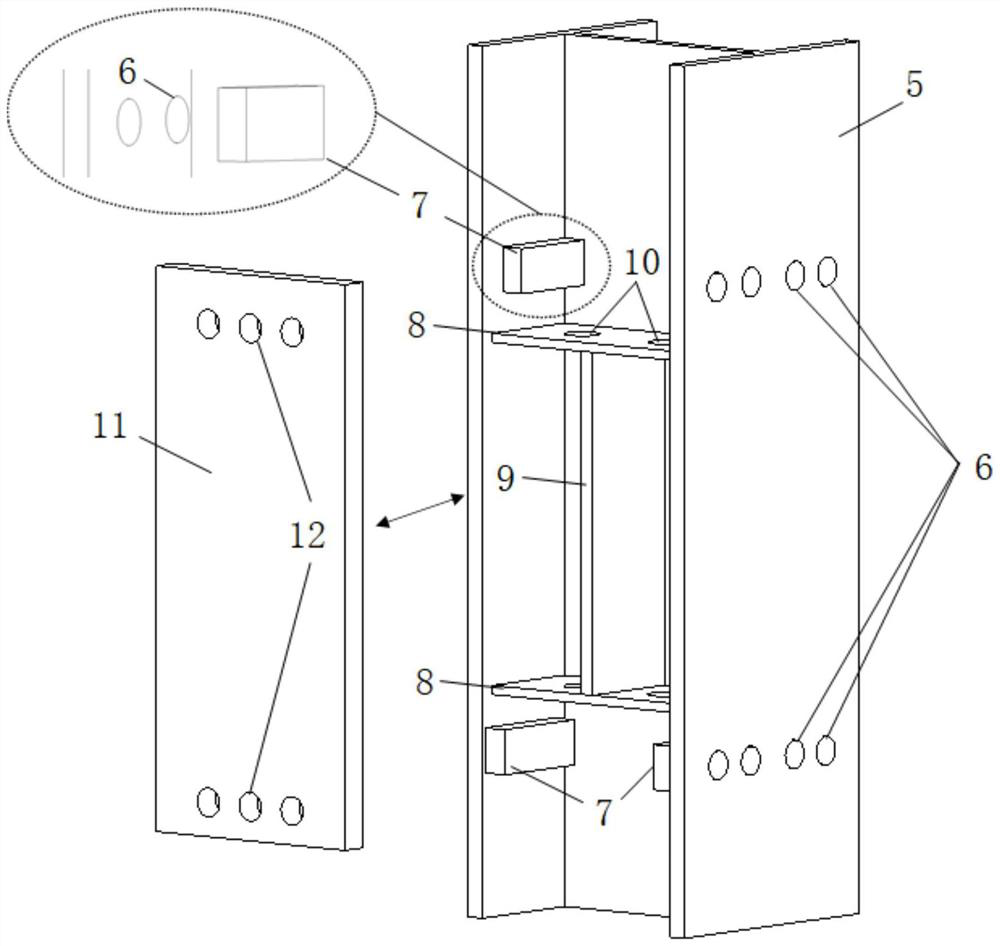

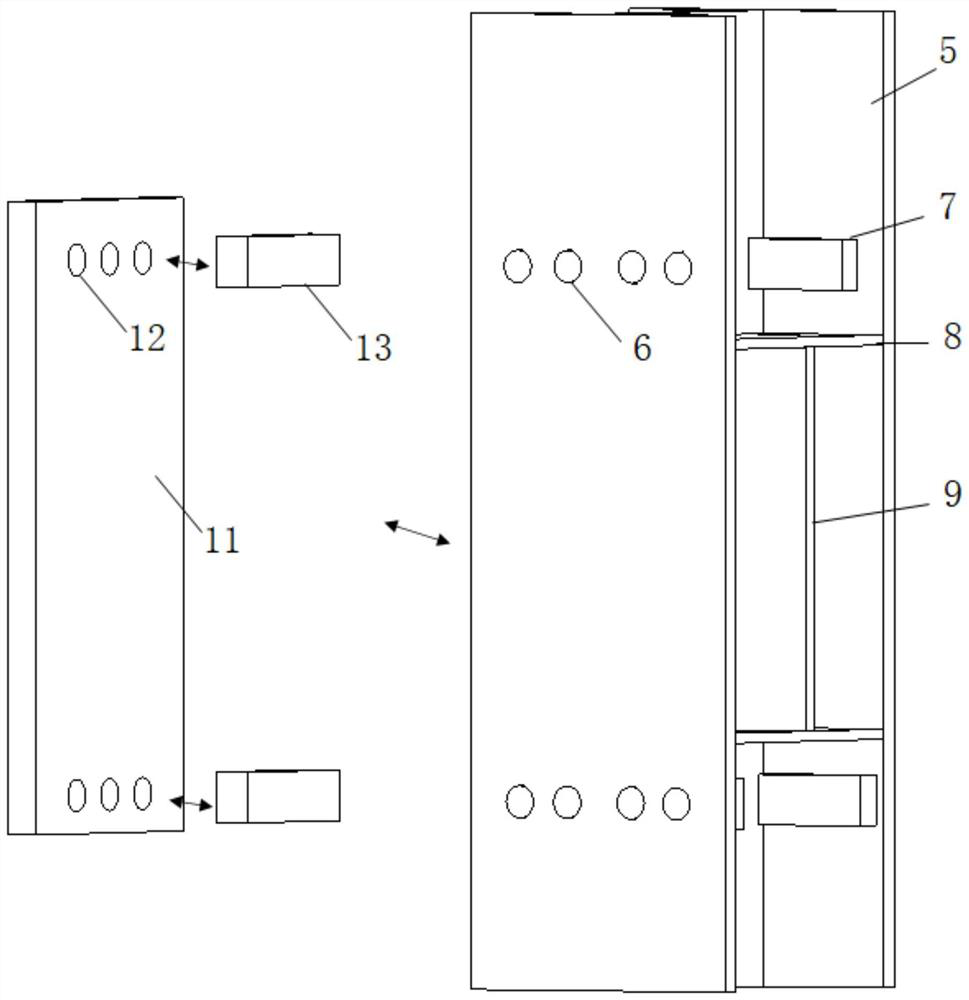

Beam-column joint for prefabricated PEC structure system and preparation method

PendingCN112411767ASimple connection structureEasy to operateBuilding constructionsStructural systemManufacturing engineering

The invention discloses a beam-column joint for a prefabricated PEC structure system and a preparation method. The beam-column joint comprises a prefabricated PEC column, a prefabricated PEC cross beam with an end plate and a prefabricated PEC longitudinal beam with an end plate. The prefabricated PEC column comprises an H-shaped steel concrete column, single-side bolt hole channels are formed inthe H-shaped steel concrete column, the single-side bolt hole channels are formed in the left flange and the right flange of the H-shaped steel concrete column and are symmetrically arranged left andright relative to a web of the H-shaped steel concrete column, and the single-side bolt hole channels are located on the outer sides of the upper flange and the lower flange of the beam. Channel steelis further arranged on the H-shaped steel concrete column and welded to the inner sides of the left flange and the right flange of the H-shaped steel concrete column, and weld joints are parallel tothe flange direction of the column. The beam-column joint for the prefabricated PEC structure system is simple in structure, convenient to operate, capable of saving materials, low in cost, capable ofachieving direct on-site assembly after a PEC member is prefabricated in a factory, capable of shortening the construction period, easy to install, capable of preventing construction waste from beingformed due to dismantled formworks at the same time, and efficient and environmentally friendly in the construction process.

Owner:ECONOMIC TECH RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

Yellow brass brazing filler metal alloy

InactiveCN106624443ALow melting pointLow costWelding/cutting media/materialsSoldering mediaAlloyTitanium

The invention provides a yellow brass brazing filler metal alloy. The alloy is prepared from, by weight, 50-55% of copper, 0.2-0.4% of tin, 2-5% of bismuth, 0.1-1% of titanium and 0.02-0.06% of germanium, and the balance being zinc. The yellow brass brazing filler metal alloy does not contain silver and cadmium, but is capable of lowering the melting point of traditional yellow brass brazing filler metal, and has the advantages of high reactivity and low cost.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

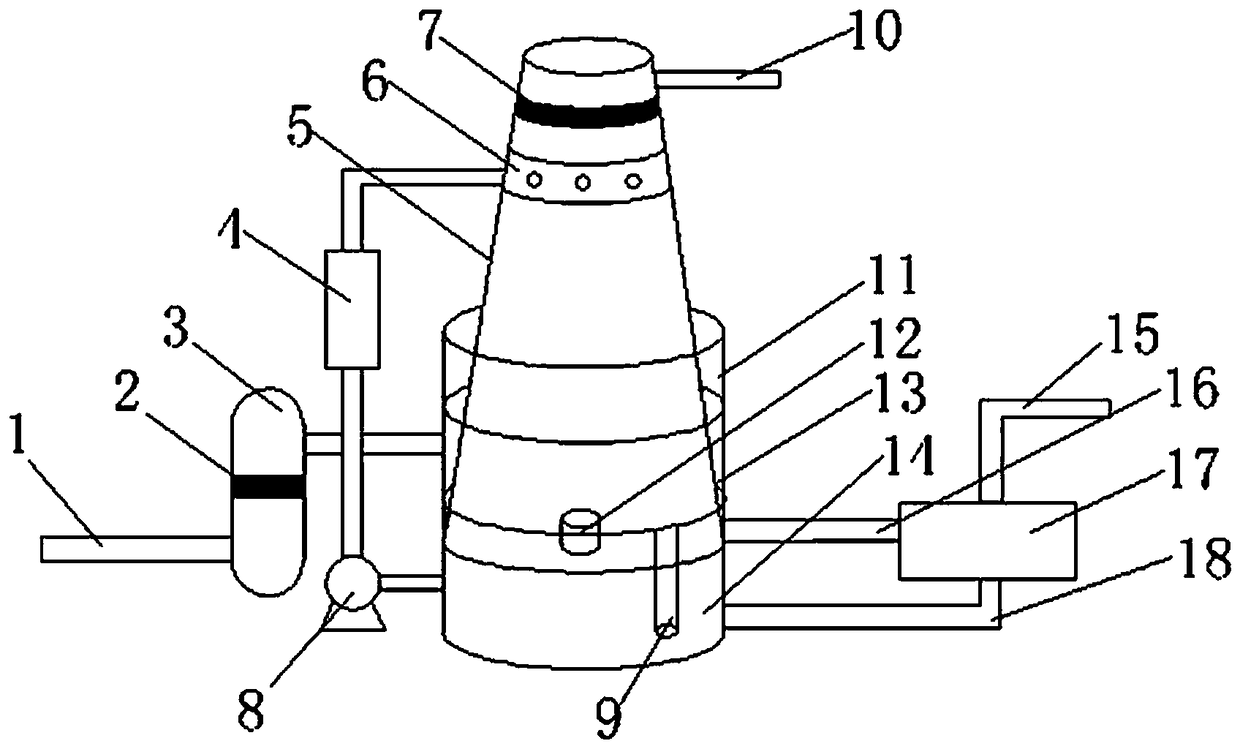

Small natural gas desulphurization device and application method thereof

The invention relates to a small natural gas desulphurization device and an application method thereof and belongs to the technical field of natural gas purification equipment. Natural gas enters a raw material separation device through a natural gas inlet pipeline, enters a natural gas storage box after being separated and purified by the raw material separation device, enters a reaction solutionstorage tank through a natural gas pipeline and reacts with a reaction solution in the reaction solution storage tank, so that a part of sulfides in the natural gas is removed; then, the natural gasenters a reaction tower through a gas pipeline, the reaction solution in the reaction solution storage tank enters an atomization device through a high-pressure pump, is sprayed into the reaction tower by a spraying device after being atomized and is subjected to a secondary reaction with the natural gas, so that sulfur is removed; the reacted natural gas is discharged through a natural gas discharging pipeline after being demisted by a wire mesh demister; the reacted reaction solution falls into the bottom of the reaction tower and enters a regeneration device through a lean amine solution pipeline; the regenerated reaction solution enters the reaction solution storage tank through a rich amine solution pipeline; and the sulfides generated in the regeneration device are collected througha waste gas outlet.

Owner:常州聚盛节能工程有限公司

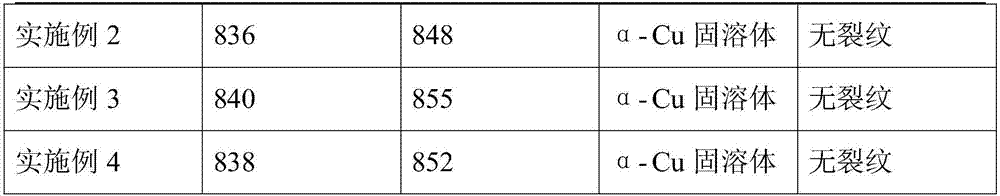

Grading method of wetland padding added with nano-carrier material

InactiveCN107399825AGood washing effectReduces the chance of wetland cloggingBiological water/sewage treatmentZeoliteSieve

The invention discloses a grading method of a wetland padding added with a nano-carrier material. A zeolite layer (3), a nanometer modified ceramsite layer (2) and a vermiculite layer (1) are filled hierarchically in sequence from bottom to top; the particle size of the padding becomes smaller in sequence from bottom to top; the filling height ratio of the zeolite layer to the nanometer modified ceramsite layer to the vermiculite layer is 1 to 1 to 1. A delamination sieve is filled with a hierarchical filling material, a zeolite layer filling screen (4) is filled with zeolite of the zeolite layer (3), a nanometer modified ceramsite layer hierarchical filling screen (5) is filled with nanometer modified ceramsite of the nanometer modified ceramsite layer (2), and a vermiculite layer filling screen (6) is filled with vermiculite of the vermiculite layer (1). The artificial wetland padding is filled hierarchically from bottom to top, and the particle size of the padding becomes smaller in sequence from bottom to top, so that the probability of blockage of an upstream vertical flow wetland can be lowered, a substrate can be flushed successfully, and a good flushing effect is achieved in a back-flushing process.

Owner:JIANGXI ACADEMY OF SCI

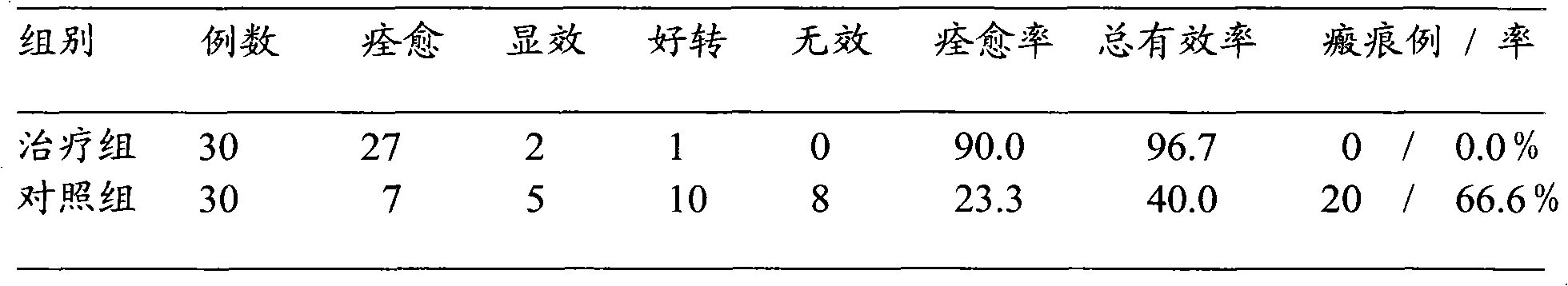

Medicament for treating trichoepithelioma and preparation method thereof

ActiveCN101869623AConvenient treatmentWill not formUnknown materialsDermatological disorderMyrrhTrichoepithelioma

The invention discloses a medicament for treating trichoepithelioma. The medicament comprises the following raw materials in part by weight: 100 parts of bezoar, 5 to 15 parts of rehmanniae praeparatum, 4 to 16 parts of root of red-rooted salvia, 2 to 8 parts of frankincense, 2 to 8 parts of myrrh and 100 to 180 parts of solvent. The invention also discloses a preparation method of the medicament. The medicament has the effects of softening hardness to dissipate stagnation, eliminating rash and promoting tissue regeneration and dispelling the trichoepithelioma.

Owner:兰吉如

Pre-tensioned sand core

InactiveCN101065200AReduce breakageIncrease productionFoundry mouldsFoundry coresPre stressCasting mold

Provided are methods of replacing drilling holes in castings by pre-tensioning sand cores. This methods are used in long cylindrical shaped sand cores in cold core box processes. The urethane sand core is placed in compression to increase the core strength during handling, placing inside of the mold. The pre-tensioned urethane sand core is set in a casting mold so as to form a cavity in the casting mold. The molten metal is poured to form the cavity inside of the casting. The pre-tensioned urethane sand core maintains its initial shape during casting.

Owner:马丁·佐尔丹

Silver-free brass soldering flux

InactiveCN107052614AImprove liquidityLow melting pointWelding/cutting media/materialsSoldering mediaIndiumSoldering

The invention proposes a silver-free brass solder, which is made of the following raw materials according to weight percentage: 52-58% copper, 0.8-1.2% tin, 0.6-1.8% bismuth, 0.16-0.36% silicon, 0.02-0.02% indium 0.2%, and germanium 0.02-0.06%, the balance is zinc. The silver-free brass solder can not only reduce the melting point of traditional brass solder, but also solve the problem of microcracks caused by adding Si.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

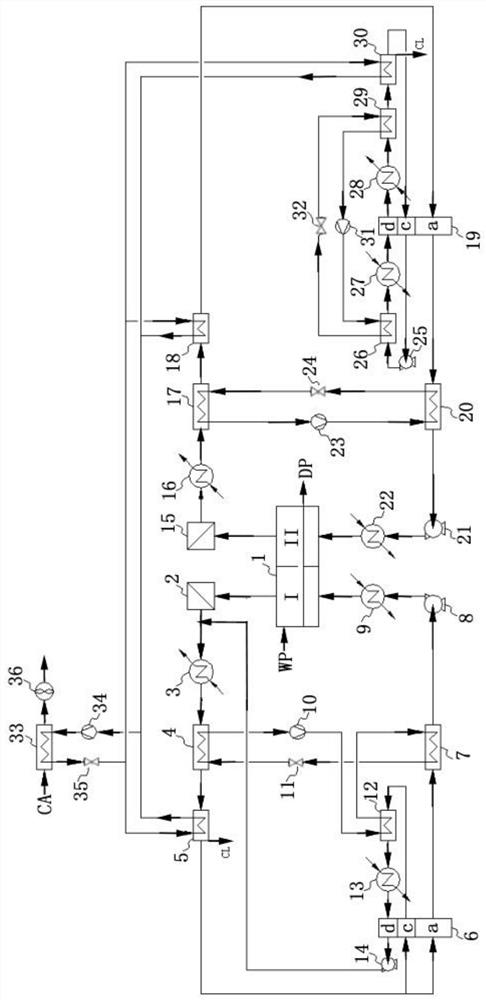

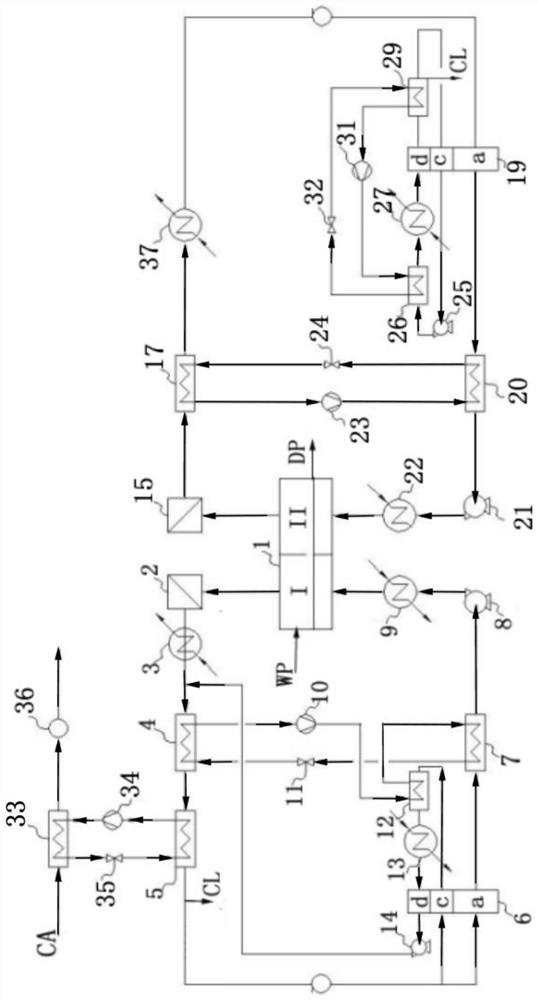

Heat-sensitive material closed loop adsorption dehumidification two-stage drying system

ActiveCN111780494AGuaranteed activityReduce energy consumptionHeat pumpsDrying solid materials with heatEvaporatorEngineering

The invention discloses a heat-sensitive material closed loop adsorption dehumidification two-stage drying system. The heat-sensitive material closed loop adsorption dehumidification two-stage dryingsystem comprises a dryer, the dryer comprises a first drying zone and a second drying zone, one top air outlet of the first drying zone communicates with a first gas-solid separator, one air outlet ofthe first gas-solid separator is connected with one air inlet of a second evaporator by one pipeline through a first precooler and a first evaporator in sequence, one air outlet of the second evaporator is divided into two paths, and one path is connected with one bottom air inlet of the first drying zone by one pipeline through an adsorption dehumidification zone of a first-stage dehumidification rotating wheel, a first condenser for preheating, a first cycle air fan and a first heater to form a first-stage drying gas circulation loop. By means of the heat-sensitive material closed loop adsorption dehumidification two-stage drying system, a two-path closed loop system is adopted, when heat-sensitive materials are dried, the activity of the heat-sensitive materials is maintained, and a good drying effect is also achieved.

Owner:ZHEJIANG UNIV OF TECH +1

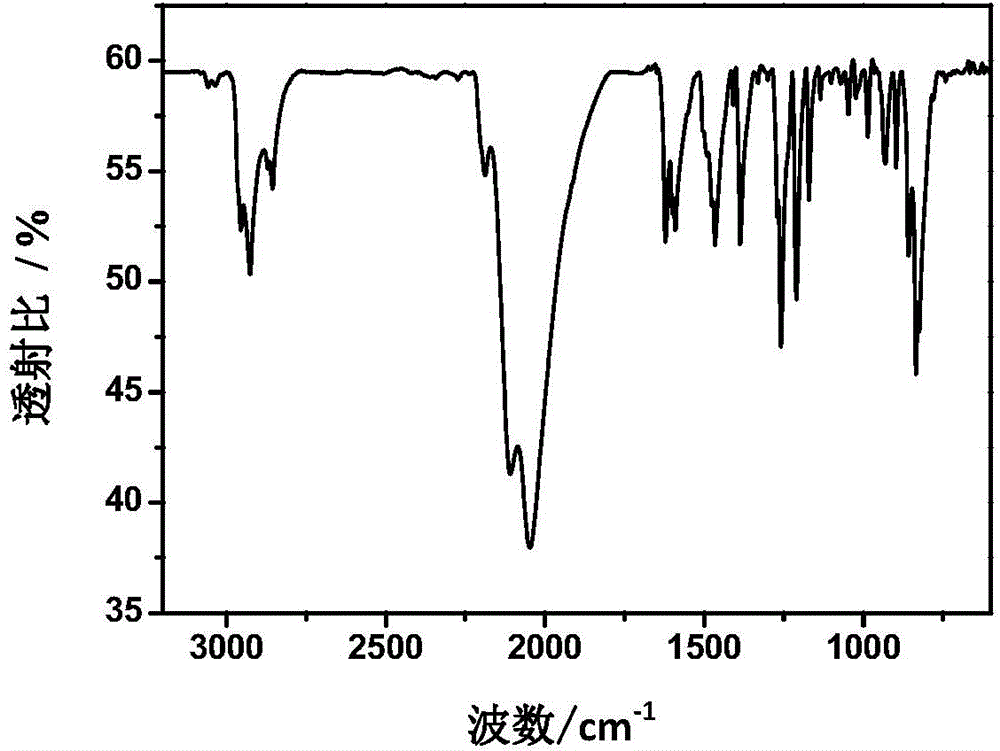

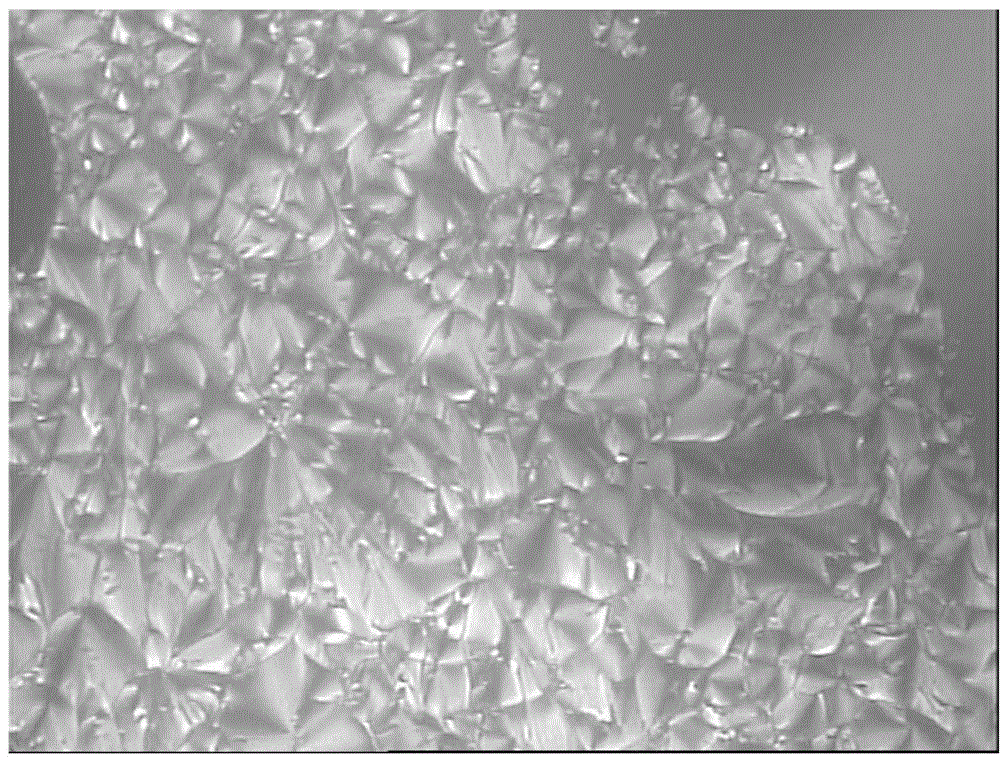

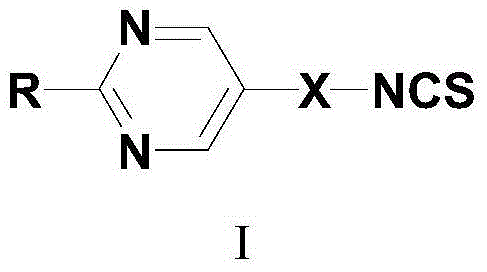

Pyrimidine liquid crystal compound with high birefringence and preparation method thereof

InactiveCN104130196AHigh birefringenceHigh voltage retentionLiquid crystal compositionsOrganic chemistryEnd-groupRefractive index

The invention discloses a pyrimidine liquid crystal compound with high birefringence and a preparation method thereof. The compound has a structure as shown a formula I, wherein R represents one of alkoxy, alkyl phenyl, alkoxyl phenyl, alkylbenzene acetylene, and alkoxy phenylacetylene; and X is one of phenyl, phenyl acetylene, biphenyl and biphenyl acetylene. The compound has the advantages of a long pi-electron conjugated system, introduction of isothiocyano group to the end group, lower dipole moment and viscosity than cyano group, high resistivity and voltage conservation rate, weak interactions of the internal molecules, and prevention of the formation of bipolymer. The compound of the present invention has high birefringence rate and is a liquid crystal material and optical material with excellent performance.

Owner:PEKING UNIV

Silicon carbide crystal growth device and method

ActiveCN113622016ASimple structureEasy to set upPolycrystalline material growthFrom frozen solutionsCarbide siliconCrucible

The invention relates to the technical field of crystal growth, and concretely relates to a silicon carbide crystal growth device and method. The silicon carbide crystal growth device comprises a crucible and a net-shaped piece; the net-shaped piece is arranged in a crucible body of the crucible, and the periphery of the net-shaped piece abuts against the inner wall of the crucible body; the net-shaped piece is in a concave shape towards the bottom of the crucible body; and the bottom of the crucible is configured to be used for containing raw material powder, the net-shaped piece is configured to be attached to and cover the raw material powder, and the surface, facing the top face of the crucible body, of the raw material powder is provided with a concave shape matched with the net-shaped piece. The thermal field can be effectively utilized by changing the concave-convex degree of the charge level, so that the internal stress of the crystal is reduced, the nitrogen doping is more uniform, the occurrence of SF is solved from two aspects, and the density of BPD is reduced as much as possible.

Owner:FUJIAN NORSTEL MATERIAL TECH CO LTD

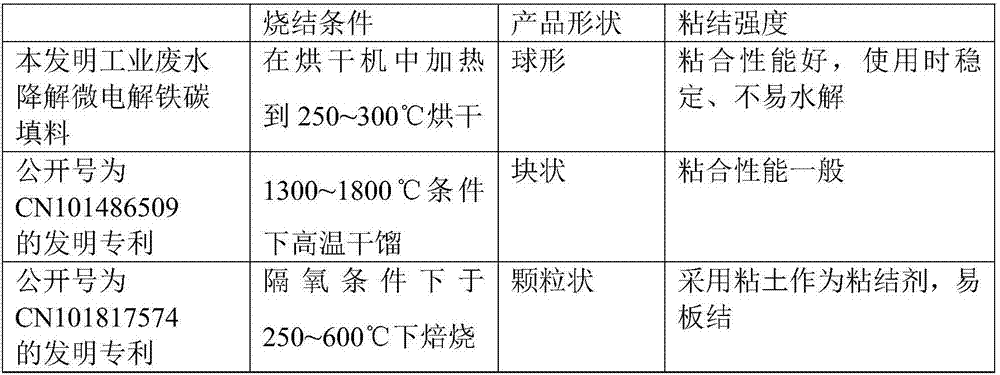

Preparation method of micro-electrolytic iron-carbon filler for degrading industrial wastewater

ActiveCN104724794BImprove adhesionEasy to useWater/sewage treatmentIndustrial waste waterElectrolysis

The invention discloses a method for preparing industrial waste water degraded micro-electrolytic iron-carbon filler, which comprises the following steps: (1) preparing a binder: mixing sodium silicate, calcium chloride and hydroxypropyl cellulose uniformly by weight, That is to get the binder; (2) mixing: put iron powder, activated carbon and binder into the mixer according to the weight ratio and mix evenly; (3) into balls: put the raw materials mixed in step (2) into the Form into balls in a ball machine; (4) Drying and molding: heat the balls obtained in step (3) to 250-300°C in a dryer to dry, and then they can be molded to obtain industrial wastewater degradable micro-electrolytic iron-carbon fillers . The preparation method is simple and reasonable, can be prepared in conventional equipment, and the conditions are mild; the micro-electrolytic iron-carbon filler for industrial pollutant wastewater degradation is spherical, has a large contact surface with sewage, and has good pollutant treatment effect. Industrial wastewater degrades micro-electrolytic iron-carbon fillers without hardening or passivation; the binder used is stable and not easy to hydrolyze.

Owner:WUHAN STEEL NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com