Crude oil dehydration method organically combining electric field and swirling flow field

A technology of crude oil dehydration and flow field, which is applied in the direction of electric/magnetic dehydration/emulsification, etc., can solve the problems of uneven flow rate, poor promotion effect, and short operation period of the swirl tube, so as to improve the dehydration effect and occupy The effect of small area and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings.

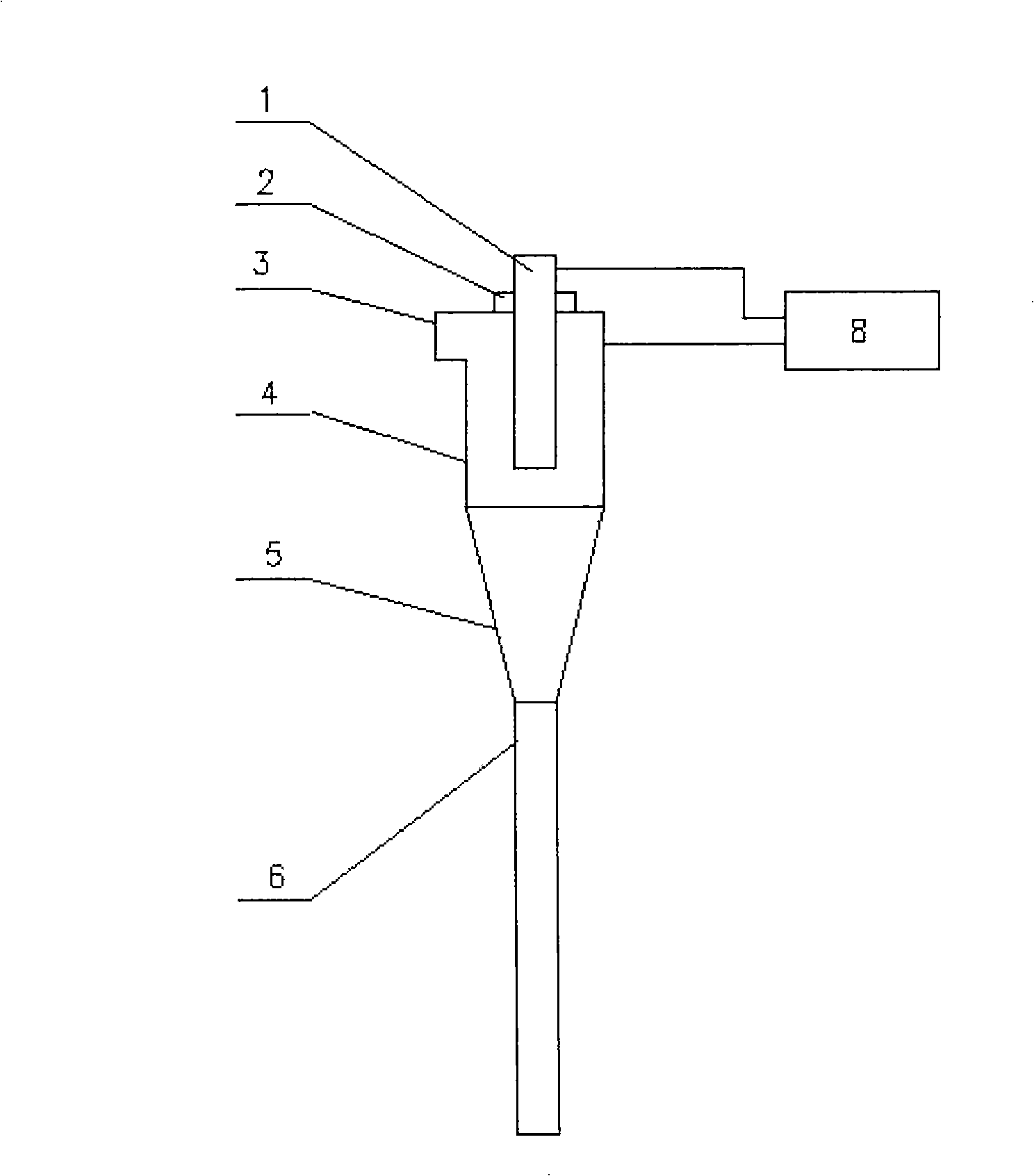

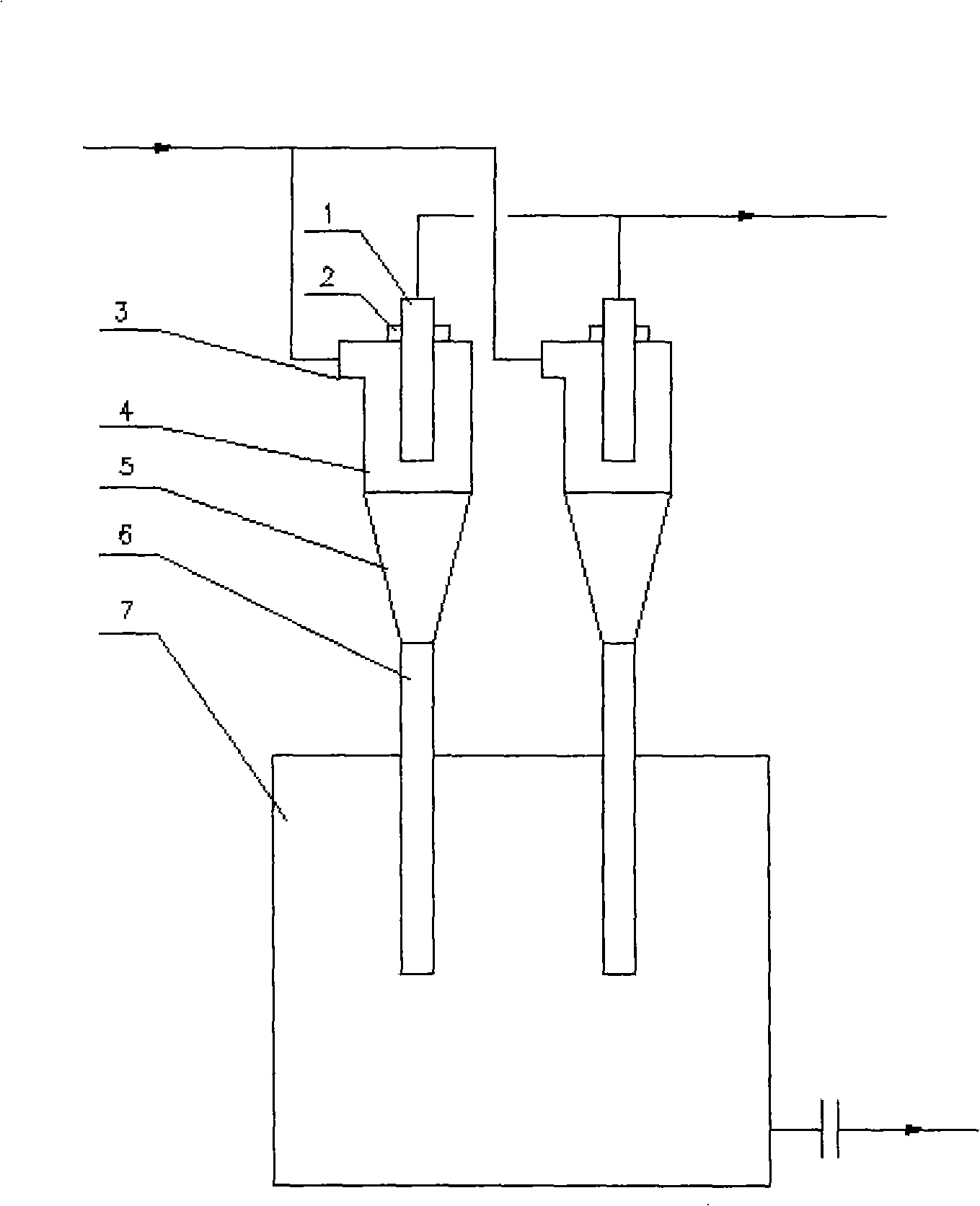

[0017] like figure 1 As shown, the vortex section 4 of the swirl tube is enlarged, the concentric diameter-reducing section 5 and the parallel tail section 6 are enlarged, and the swirler composed of many swirl tubes is set as the swirl device of a single swirl tube; The oil outlet pipe of the hydrocyclone is extended, inserted vertically into the vortex section as the high-frequency pulse dehydration electrode 1, and an insulating layer 2 is set at the connection between the oil outlet pipe and the oil delivery pipe and the connection between the oil outlet pipe and the vortex section 4; or directly dehydration The electrode 1 is inserted into the vortex section 4 along the center of the oil outlet pipe, and an insulating layer 2 is provided at the connection between the oil outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com