Patents

Literature

42results about How to "Simplify the dehydration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing polyphenyl thioether

The invention relates to a process for producing polyphenyl thioether, comprising the following steps of:, mixing hydrogenous sodium sulfide, lithium chloride and N-methyl pyrrolidone in the weight ratio of (20-25): (2-6): (70-80), co-boiling the mixture and inert gases at 150-210 DEG C for distilling and dehydrating; separating solvent by refining; respectively adding santochlor, solvent and lithium chloride in anhydrous sodium sulfide, separating after complete reaction to obtain polyphenylene sulfide; compositely washing the polyphenylene sulfide to obtain pure polyphenylene sulfide; and reclaiming the lithium chloride by filtering, reclaiming the solvent and flashly evaporating dimethylbenzene solution in a two-period mode and cooling and crystallizing. The invention has the advantages of low cost, simple process, excellent performance of synthetic resin and high solvent recovering rate.

Owner:DUNHUANG XIYU MINING & CHEM

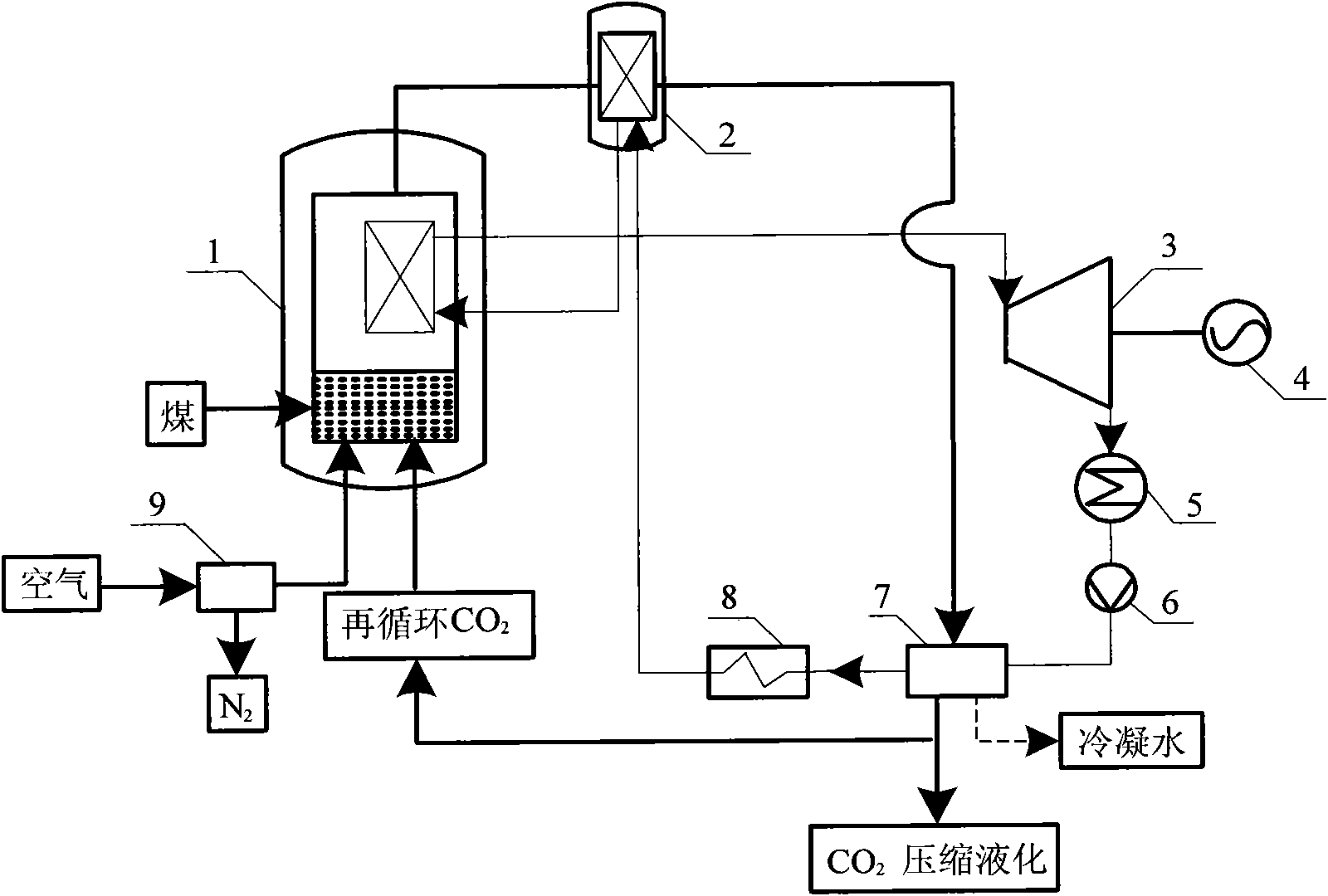

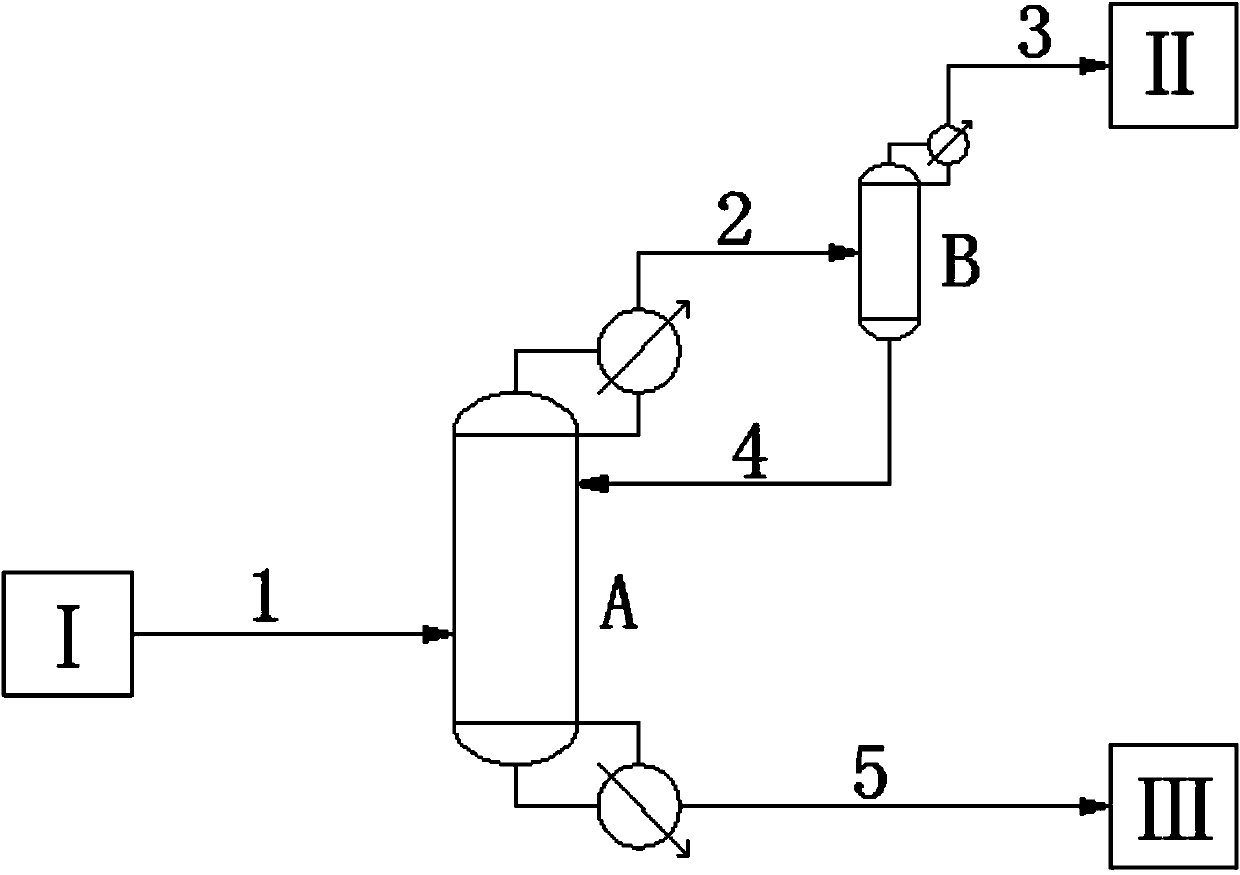

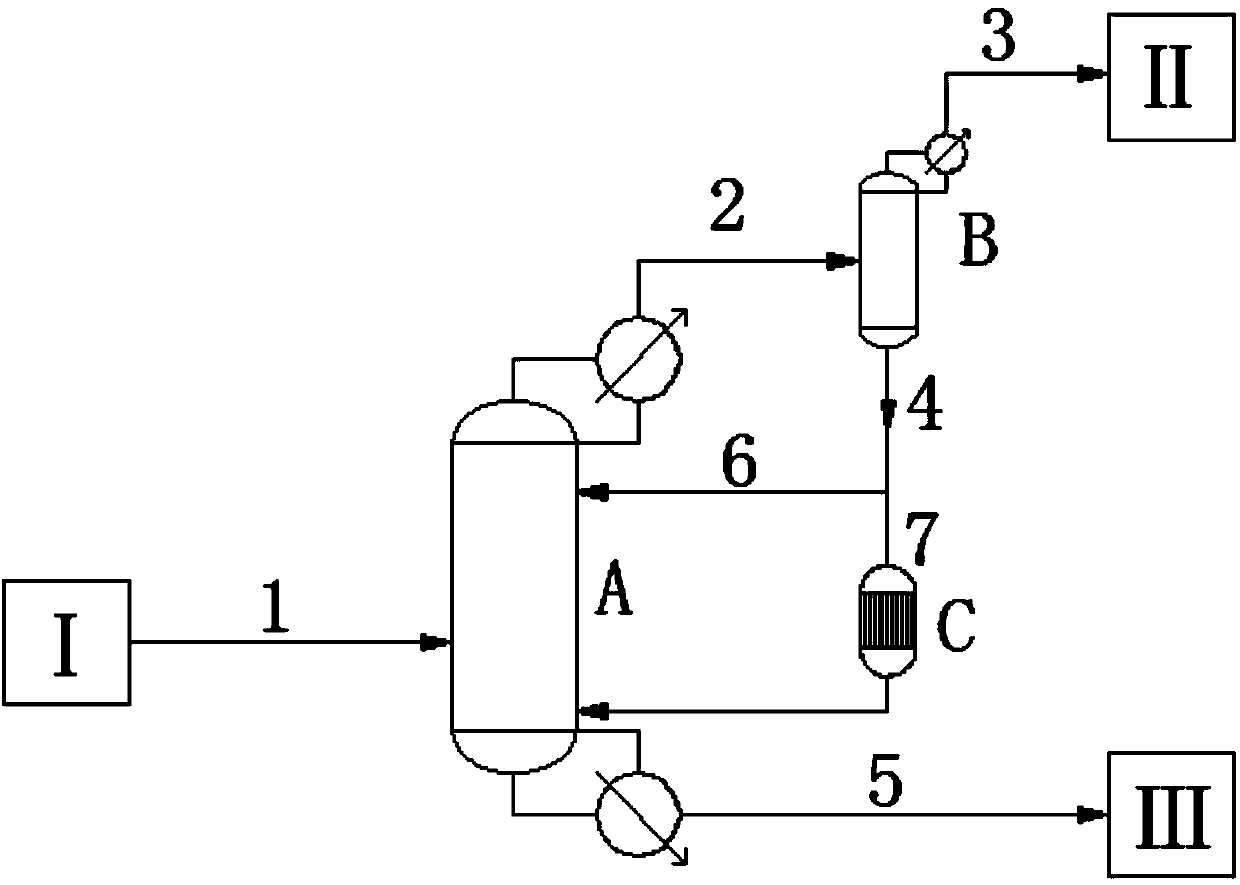

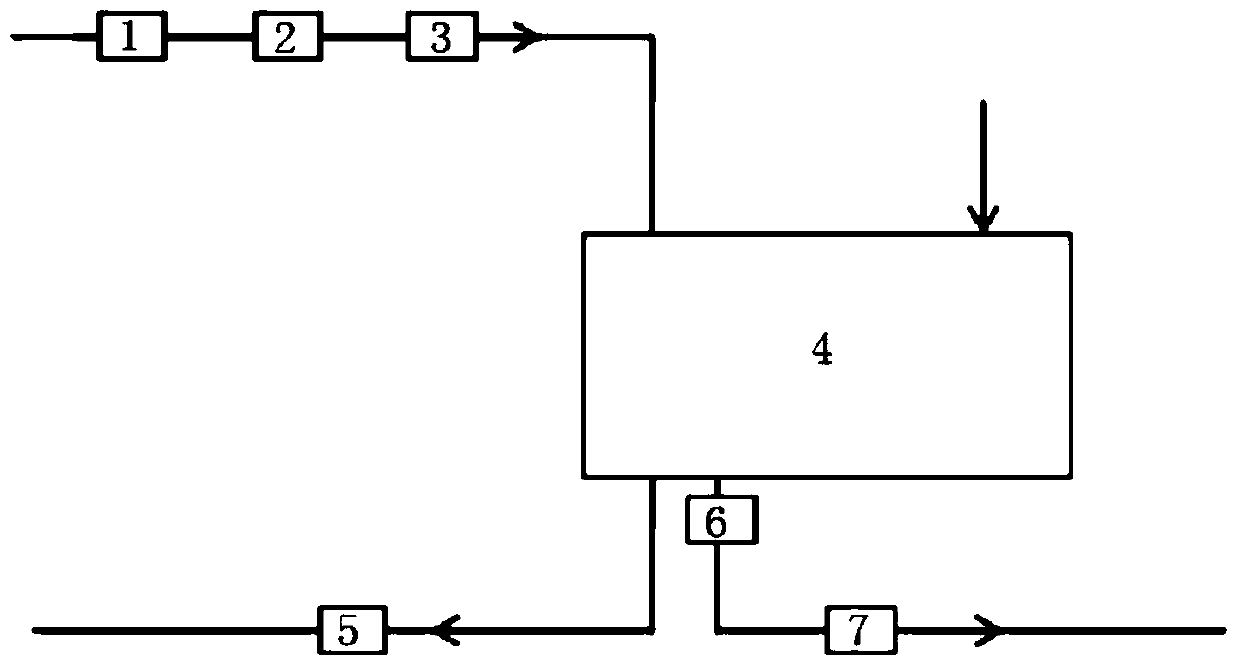

Reclaiming system for condensation heat of flue gas during pressurized oxy-coal combustion

InactiveCN101858592ASimplify the dehydration processGreat effortFeed water supplySteam engine plantsWater vaporHigh pressure

The invention discloses a reclaiming system for condensation heat of flue gas during pressurized oxy-coal combustion, and belongs to the field of energy technology application and CO2 capture. In the technology, by utilizing the characteristic that the condensation temperature of flue gas moisture under high pressure is improved to about 200 DEG C, the condensation heat of the flue gas moisture heats condensation water of a steam turbine, the condensation process is performed in a high-pressure flue gas condenser, the flue gas generated during pressurized oxy-coal combustion enters the high-pressure flue gas condenser, steam in the flue gas is cooled and releases latent heat of vaporization to heat the condensation water of the steam turbine, and the discharged flue gas is continuously compressed and liquefied to fulfill the aim of capturing CO2. Through the technology, the condensation heat of the flue gas moisture is fully utilized, the smoke discharge loss is reduced, the output of the steam turbine is improved, the energy consumption for capturing the CO2 is reduced, and the thermal economy of the pressurized oxygen enriched combustion generating system is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

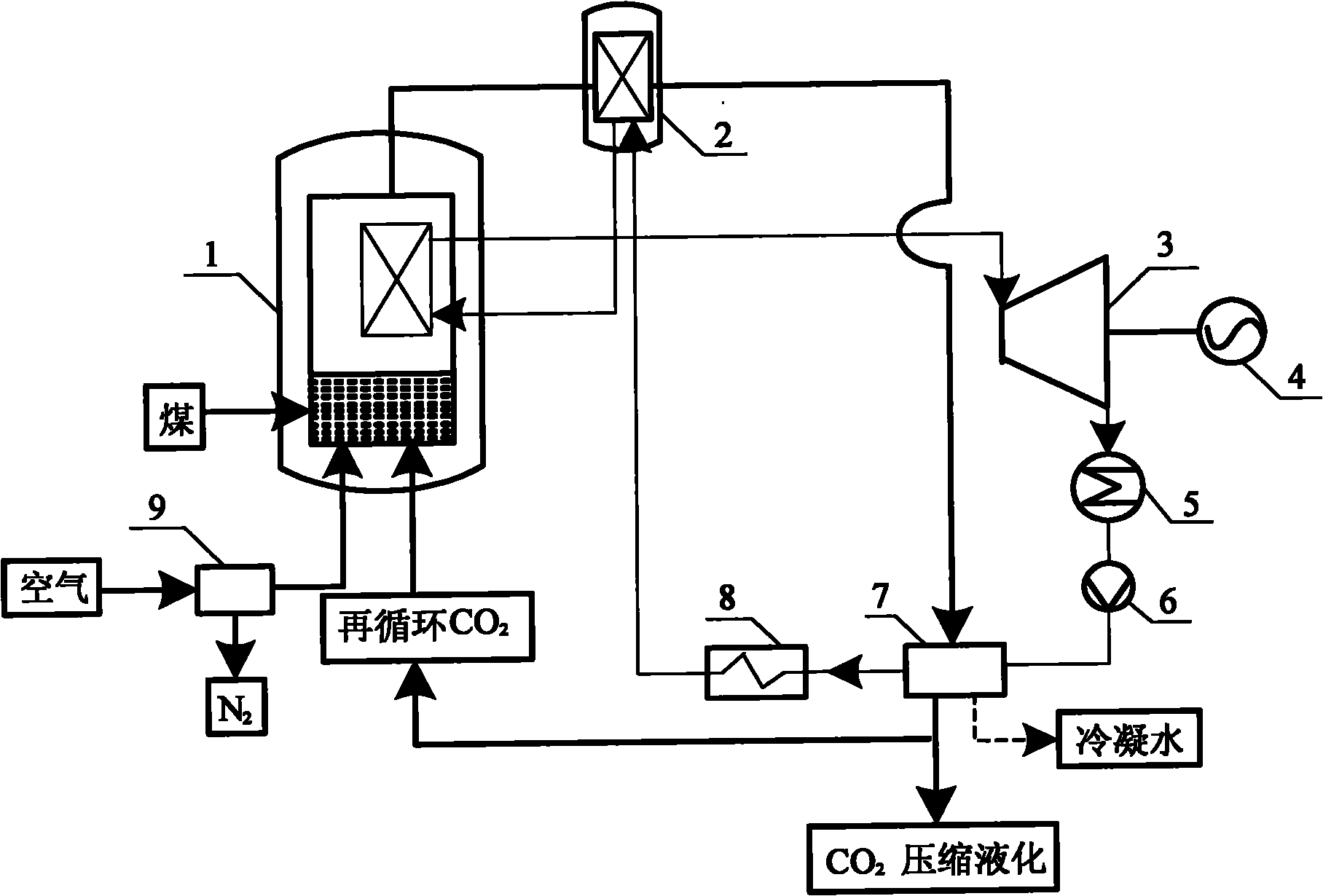

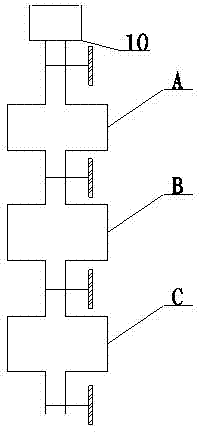

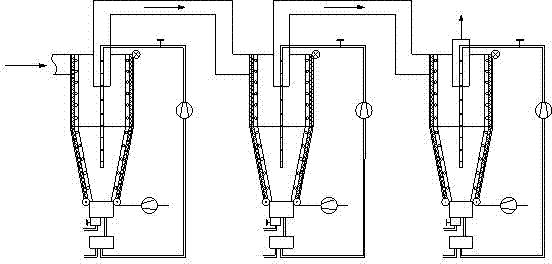

Sludge modified diaphragm compressed deep dehydration process and system

InactiveCN108947185ASimplify the dehydration processLess investmentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesActivated sludgeTransport system

The invention discloses a sludge modified diaphragm compressed deep dehydration process and system. The process comprises the following steps: (1) metering sludge, and entering an elliptical cascade sludge pre-thickening system for thickening and dehydration; (2) enabling the thickened sludge to directly enter a sludge conditioning tank for conditioning, sequentially adding a conditioner a and a conditioner b to be uniformly stirred, and modifying the sludge; and (3) enabling the modified sludge to enter a special sludge compressed dehydration equipment system for performing deep compressed dehydration treatment, and enabling the finally obtained cake sludge to enter an outwards sludge transport system. The improved process is simple and convenient to operate, and the moisture content of the treated sludge is 60% or less. The invention further provides a sludge modified diaphragm compressed deep dehydration system. According to the system, the dehydration efficiency of a filter press can be improved, the sludge volume is reduced, the cost is reduced, the land utilization efficiency is improved, the low-cost goal of the sludge is achieved, and convenience is brought to subsequent resource treatment.

Owner:四川欧美华环境工程有限公司

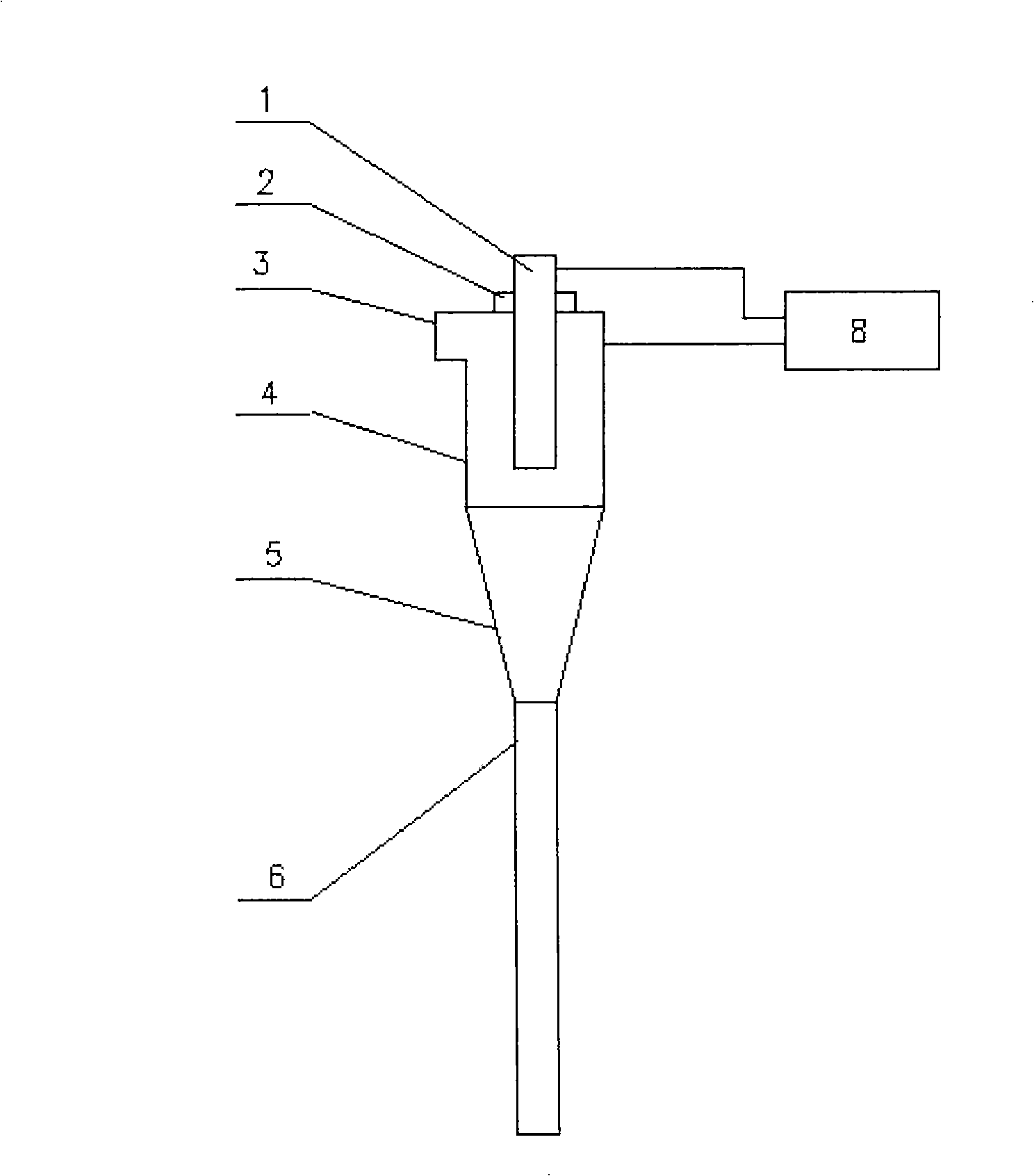

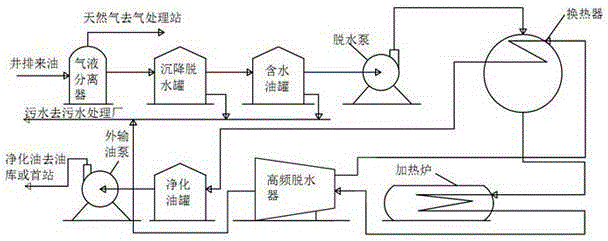

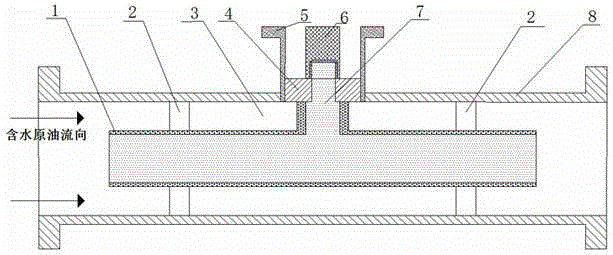

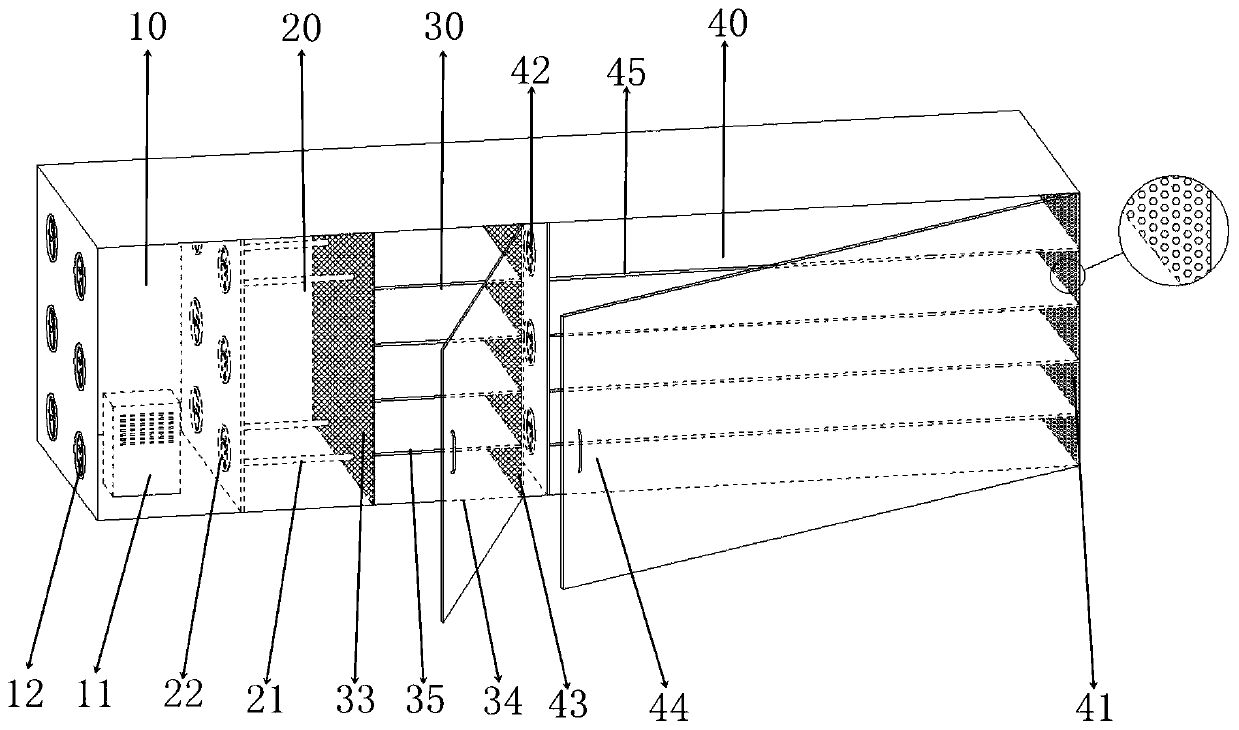

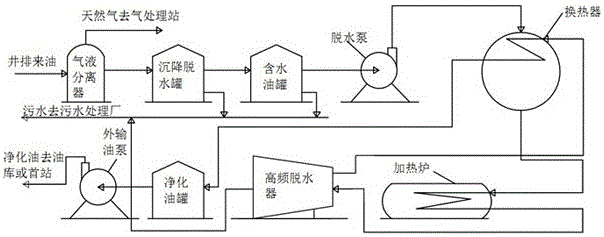

Crude oil dehydration method organically combining electric field and swirling flow field

ActiveCN101638587BSimple structureSimplify the dehydration processDewatering/demulsification with electric/magnetic meansSewagePulse electric field

The invention relates to a crude oil dehydration method organically combining an electric field and a swirling flow field, which is achieved by a crude oil dehydration process consisting of a swirler,a high-frequency pulse dehydration power supply device or other power supply devices, a dehydration electrode and a sewage settling tank, and is characterized by comprising the following steps: enlarging a vortex section, a concentric drawing-down section and a parallel end section of a swirling flow pipe in the same proportion, and setting the swirler consisting of a plurality of swirling flow pipes as a swirler with a single swirling flow pipe; extending an oil outlet pipe of the single swirling flow pipe, vertically inserting the oil outlet pipe into the vortex section as a high-frequencypulse dehydration electrode, or inserting the dehydration electrode into the middle-lower part of the vortex section along the center of the oil output pipe, wherein the output end of the high-frequency pulse dehydration power supply device is connected with the oil outlet pipe or the dehydration electrode through a conducting wire, a crude oil feed pipeline is connected with the inlet of the swirler, and the oil outlet pipe is connected with an oil conveying pipe or a good oil tank; and connecting the parallel end section with the sewage settling tank to form the crude oil dehydration processorganically combining a high-frequency pulse electric field and the swirling flow field.

Owner:SINOPEC PETROLEUM ENG DESIGN

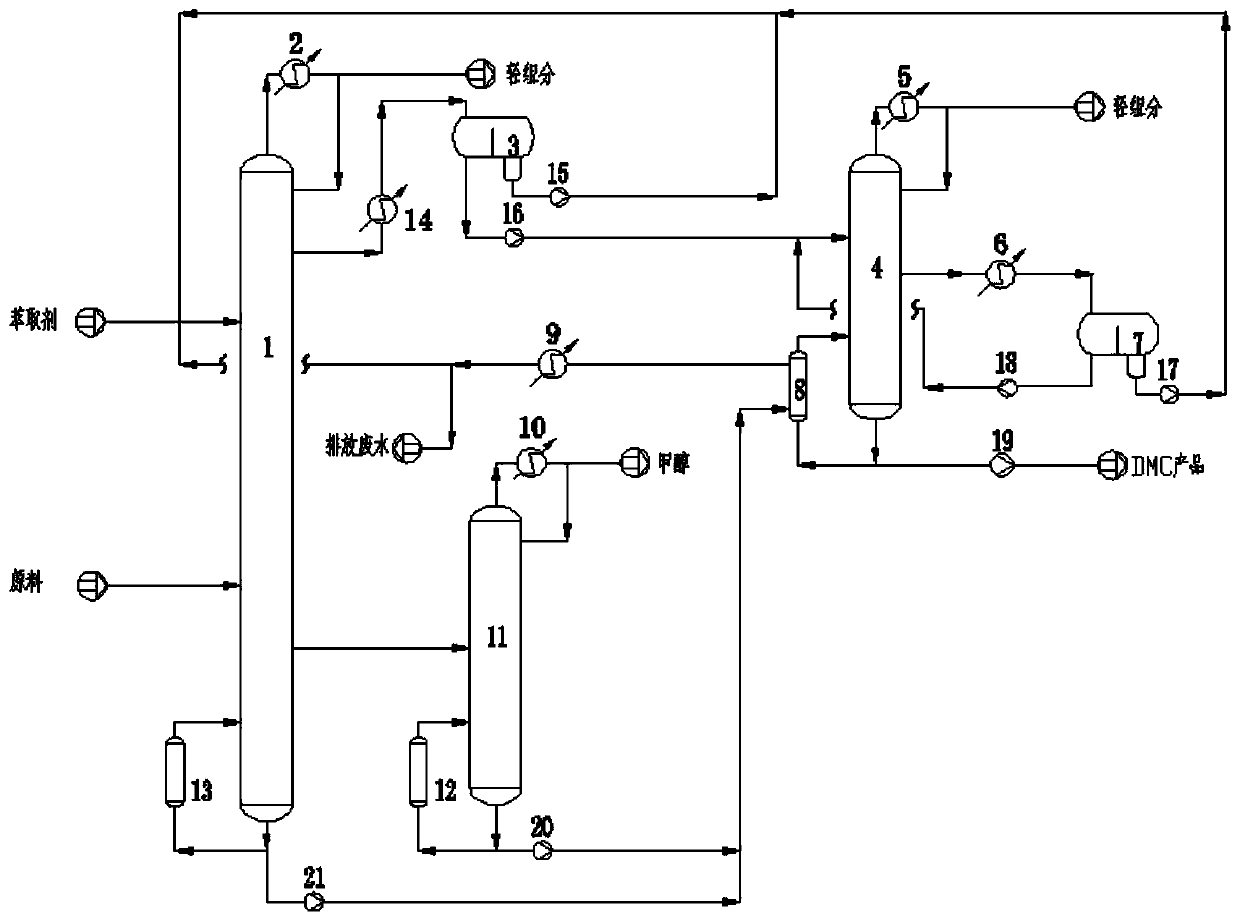

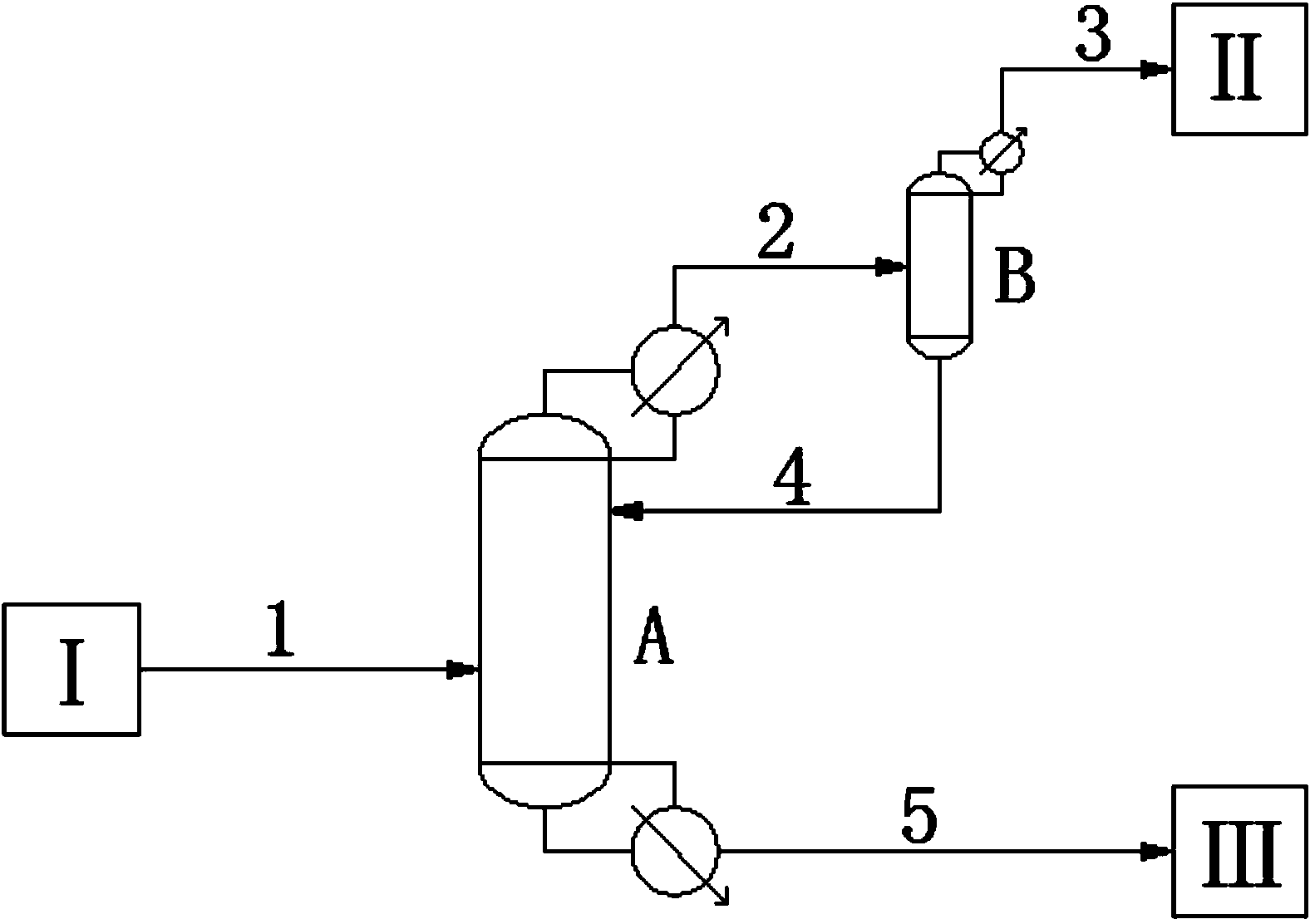

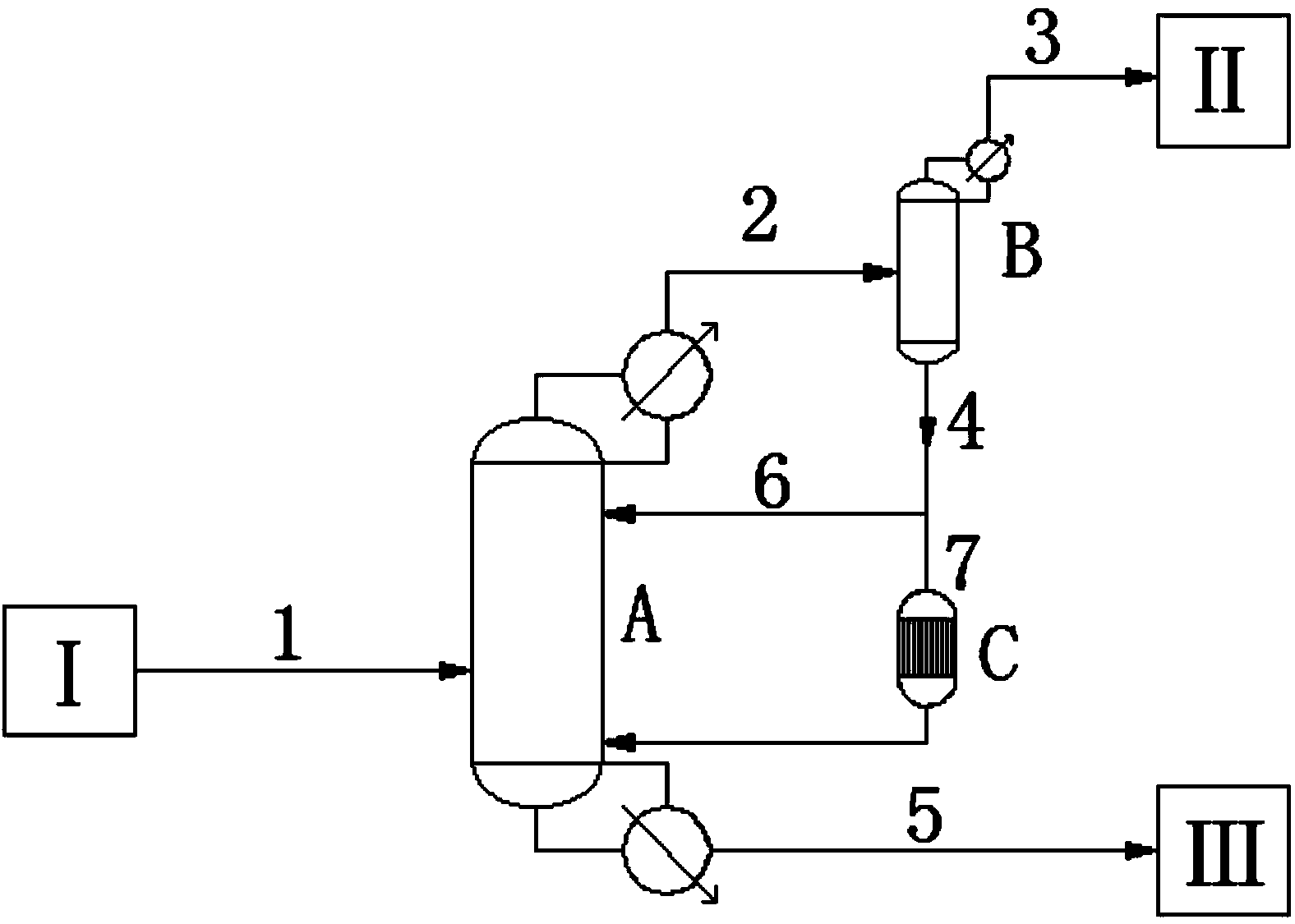

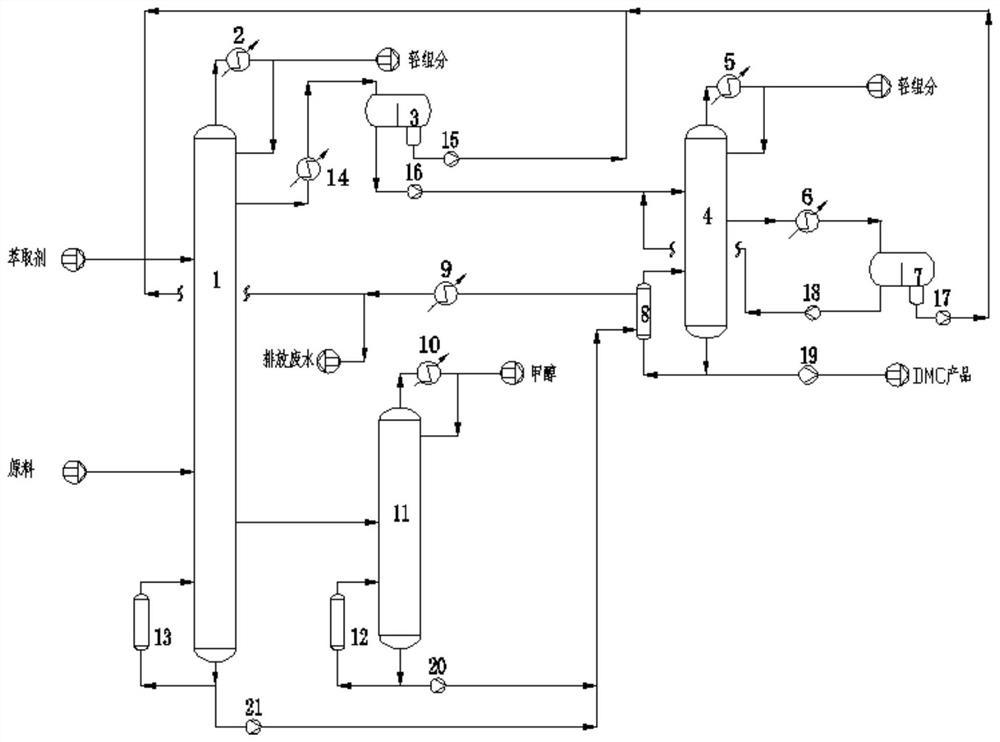

Separation purification process of dimethyl carbonate

ActiveCN110372512AImprove applicabilityAvoid backmixingOrganic compound preparationChemical industryExtractive distillationReboiler

The invention discloses a separation purification process of dimethyl carbonate. The separation purification process uses a crude product of a coal-prepared glycol by-product or a dimethyl carbonate crude product synthesized by methanol oxidative carbonyl as a raw material, and a separation device comprises an extractive distillation column with a material stream extraction side line, two phase splitters, a methanol distillation column, a dimethyl carbonate dehydration tower with a material stream extraction side line, a plurality of condensers and a plurality of reboilers; and the refined dimethyl carbonate, a light component product containing methylal and methyl formate and methanol are finally obtained through the continuous operation steps of the three separation units of extractive distillation-methanol distillation-dimethyl carbonate dehydration and an extraction agent recycling unit. The purification process of the dimethyl carbonate is high in applicability, simple in processflow and obvious in energy-saving effect through heat coupling.

Owner:TAIYUAN UNIV OF TECH

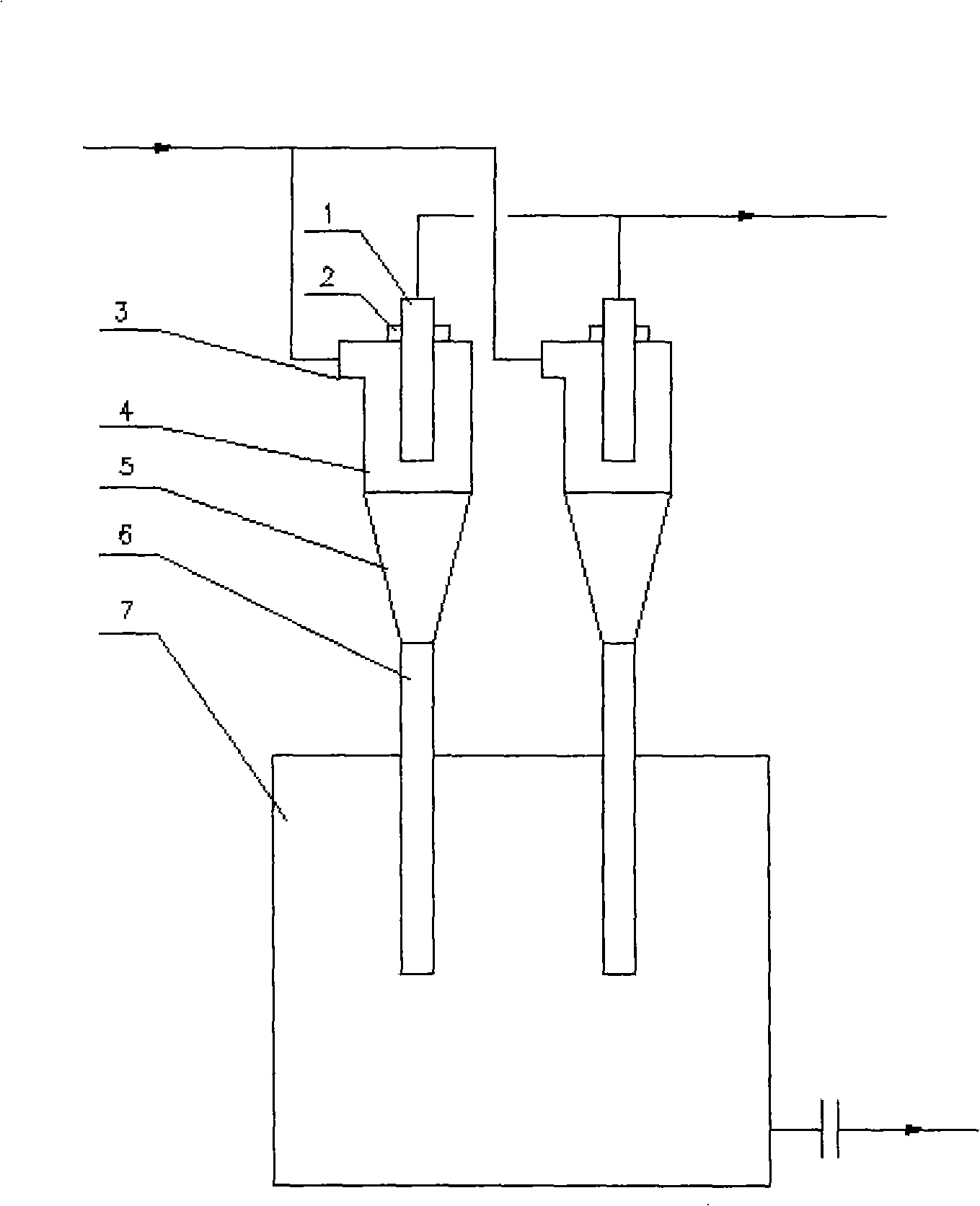

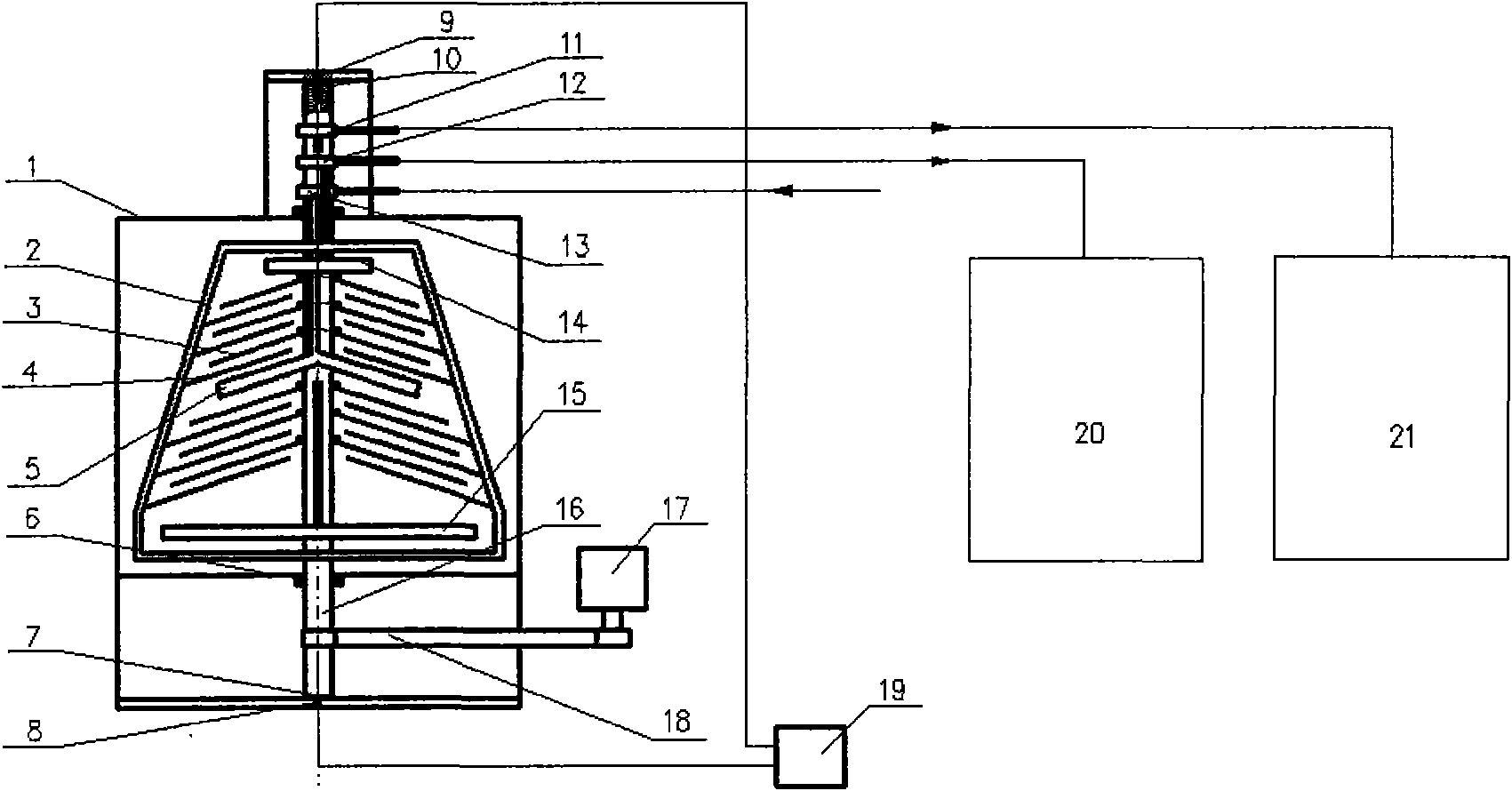

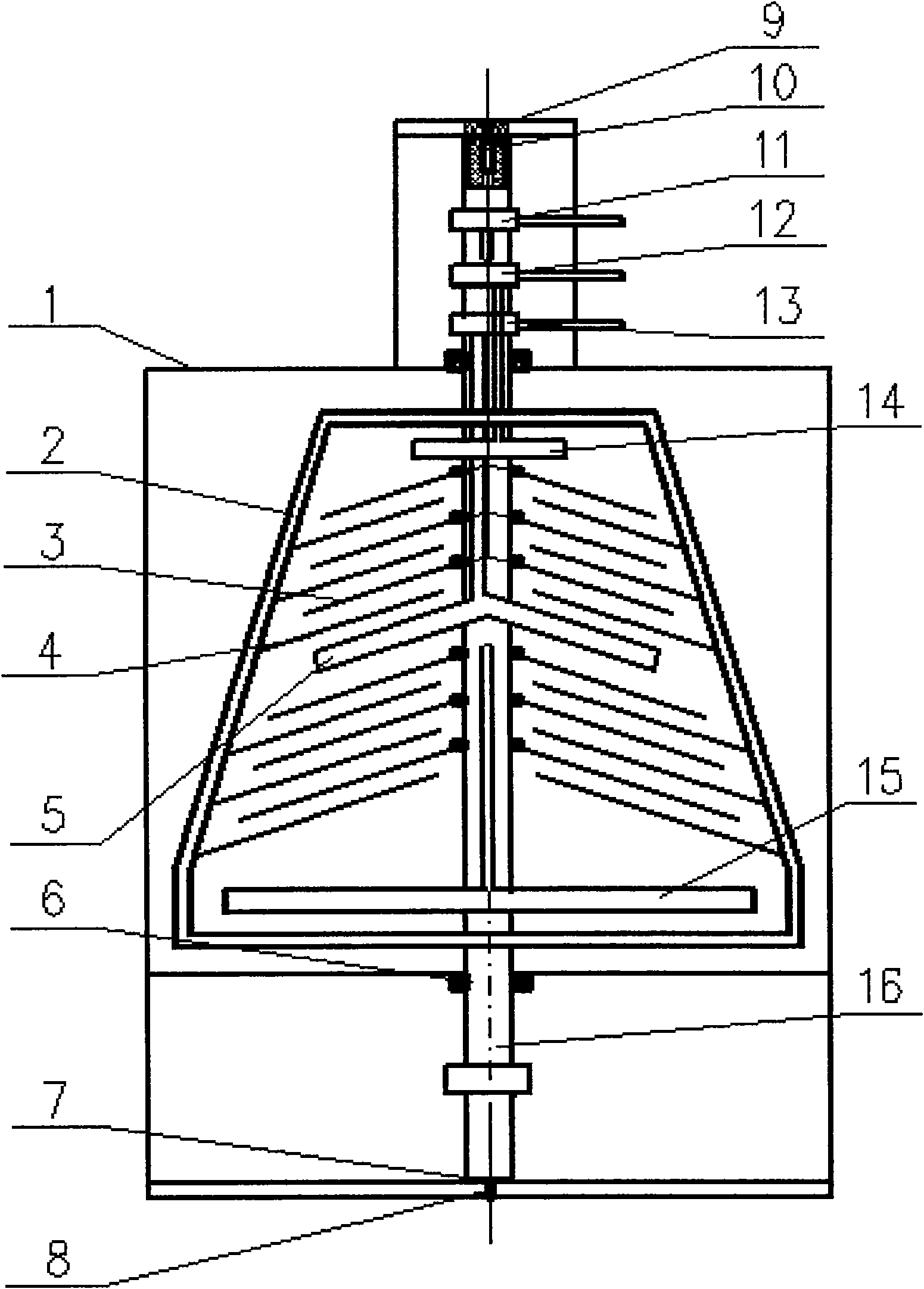

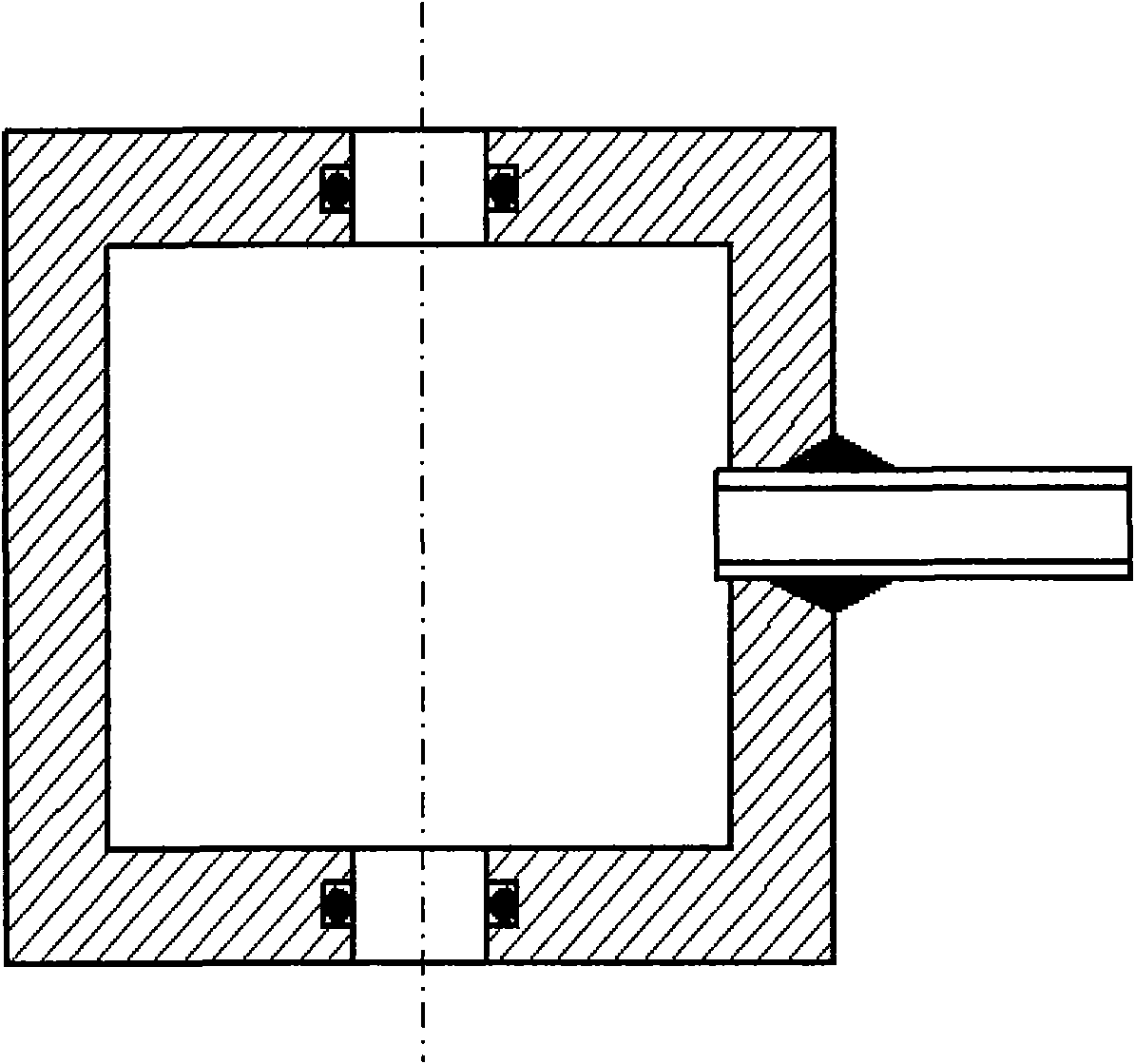

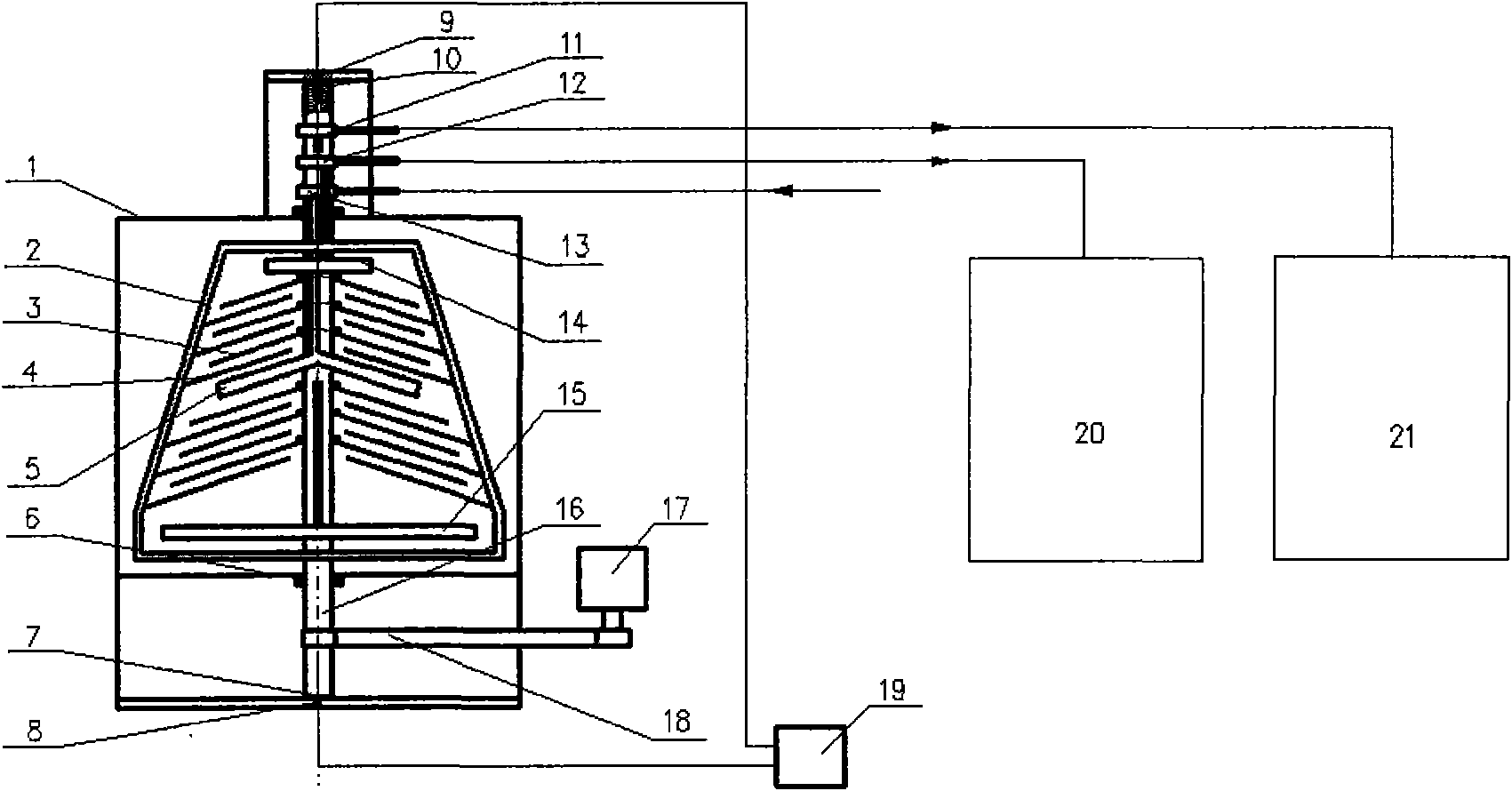

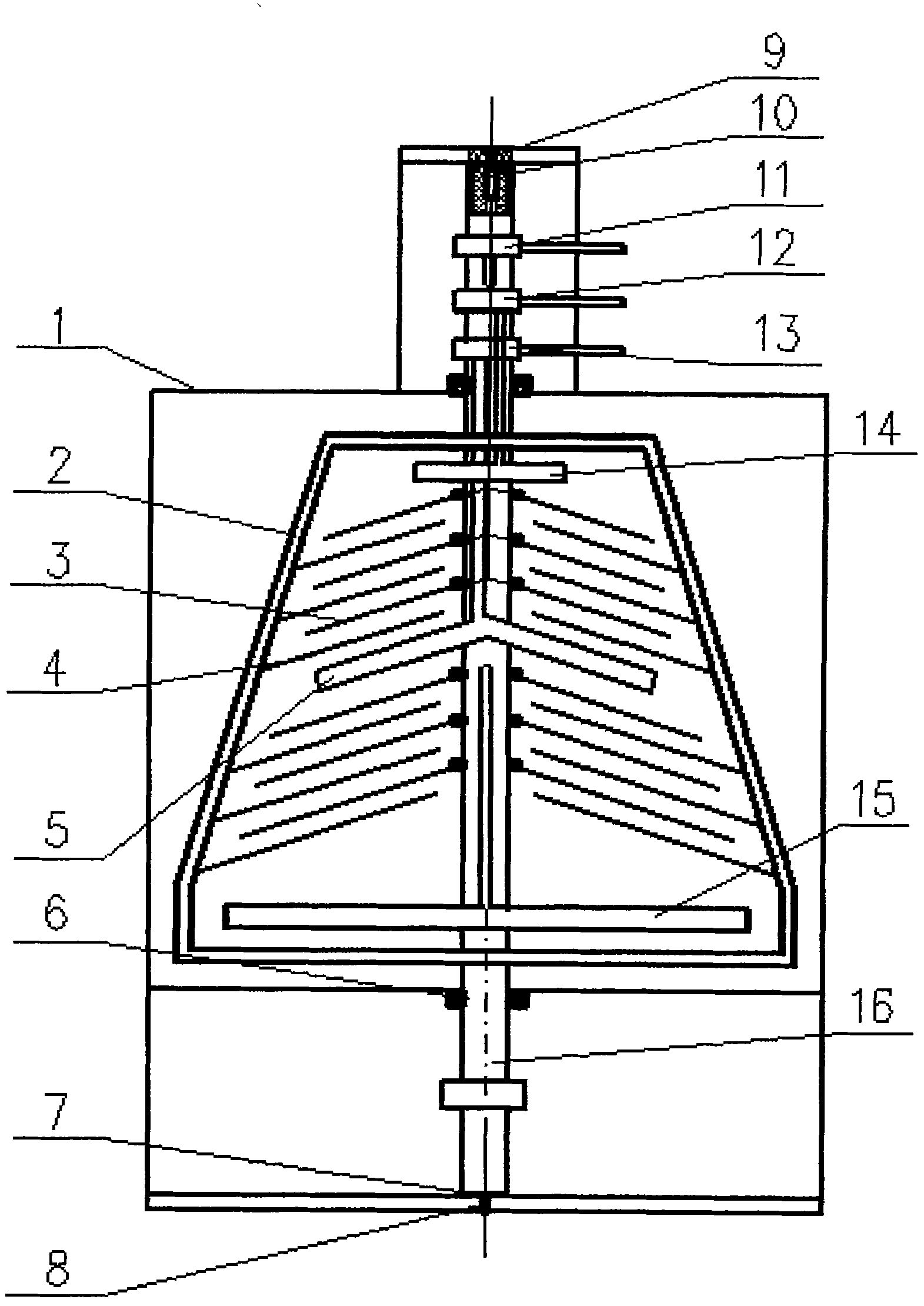

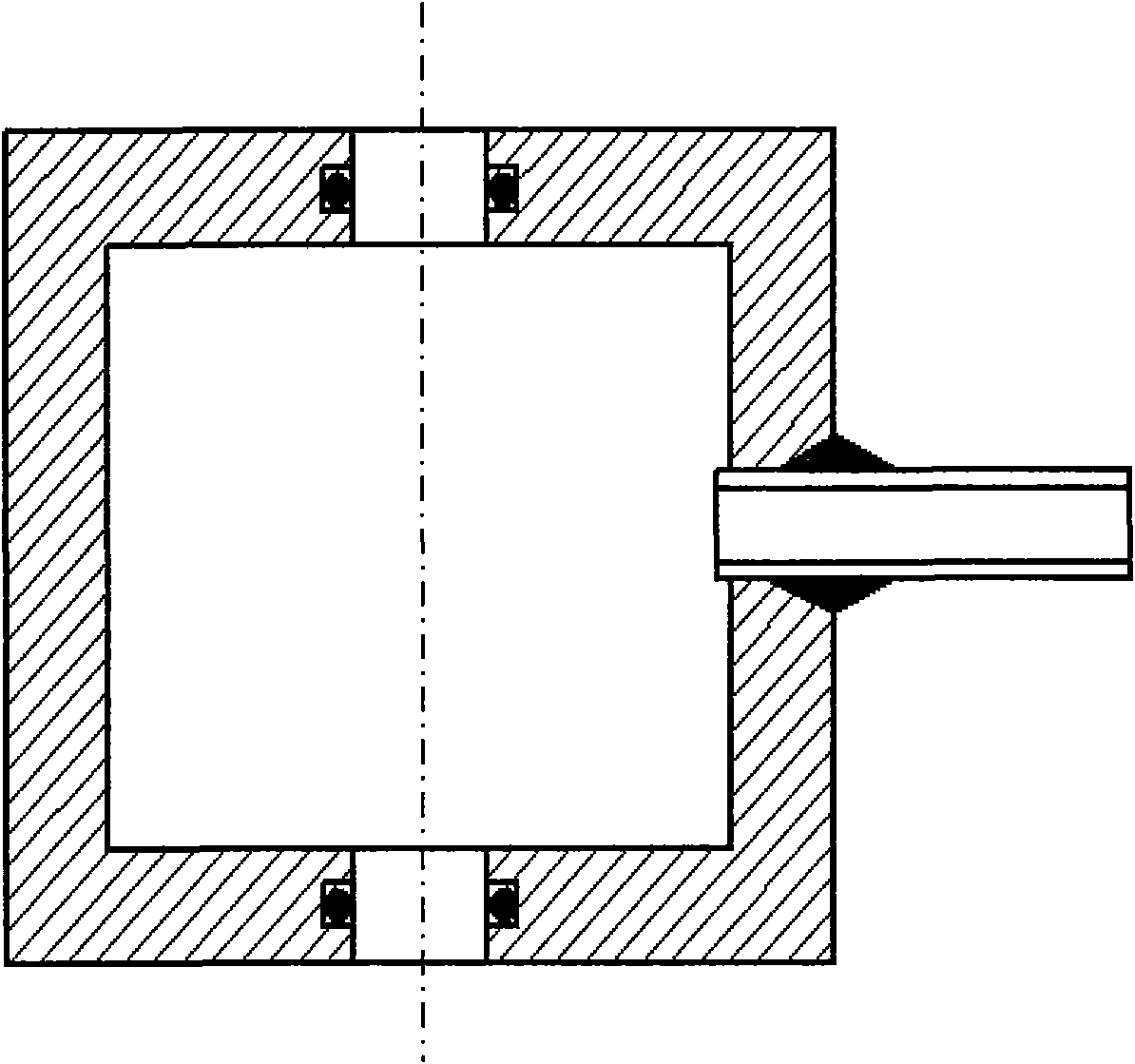

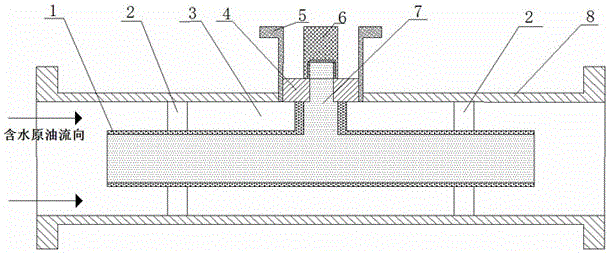

Crude oil dehydrating device combing electric field and centrifugal field

ActiveCN101564605ASimple structureSimplify the dehydration processLiquid separation by electricityElectric fieldEngineering

The invention relates to a crude oil dehydrating device combing an electric field and a centrifugal field, which consists of a shell, an electric field and centrifugal field integral structure, a motor, a pulley, a triangle leather belt, a dehydrating power supply device, an oil tank and a sewage tank. A centrifugal field structure consists of a hollow shaft, a liquid inlet pipe, a water outlet pipe, an oil outlet pipe, a sealed taper centrifugal cavity, an oil collector, a liquid distributor, a water collector, and sealing joints of the water outlet pipe, the oil outlet pipe and the liquid inlet pipe, wherein the hollow shaft is arranged in the vertical center of the shell; the liquid inlet pipe, the water outlet pipe and the oil outlet pipe are arranged in the hollow shaft; the sealed taper centrifugal cavity is arranged in the middle of the hollow shaft; the oil collector is arranged on the upper part in the hollow shaft; the liquid distributor is arranged in the middle of the hollow shaft; the water collector is arranged on the lower part of the hollow shaft; and the sealing joints are arranged on the upper part of the hollow shaft and do not rotate. An electric field structure consists of a disk-shaped electrode plate, the other disk-shaped electrode plate, moving electrodes and fixed electrodes, wherein the disk-shaped electrode plate is arranged between the oil collector and the liquid distributor; the other disk-shaped electrode plate is arranged on the centrifugal cavity and staggered with the electrode plate of the hollow shaft; the moving electrodes are arranged at both ends of the hollow shaft; and the fixed electrodes are arranged at the upper end and the lower end of the shell and correspondingly and movably contact the moving electrodes. The upper fixed electrode and the lower fixed electrode are connected with the dehydrating power supply device; and a motor pulley is connected with the pulley on the lower part of the hollow shaft through the.

Owner:SINOPEC SSC +1

Crude oil dehydrating device combining electric field and centrifugal field

ActiveCN101564605BSimple structureSimplify the dehydration processLiquid separation by electricityEngineeringSewage

The invention relates to a crude oil dehydrating device combing an electric field and a centrifugal field, which consists of a shell, an electric field and centrifugal field integral structure, a motor, a pulley, a triangle leather belt, a dehydrating power supply device, an oil tank and a sewage tank. A centrifugal field structure consists of a hollow shaft, a liquid inlet pipe, a water outlet pipe, an oil outlet pipe, a sealed taper centrifugal cavity, an oil collector, a liquid distributor, a water collector, and sealing joints of the water outlet pipe, the oil outlet pipe and the liquid inlet pipe, wherein the hollow shaft is arranged in the vertical center of the shell; the liquid inlet pipe, the water outlet pipe and the oil outlet pipe are arranged in the hollow shaft; the sealed taper centrifugal cavity is arranged in the middle of the hollow shaft; the oil collector is arranged on the upper part in the hollow shaft; the liquid distributor is arranged in the middle of the hollow shaft; the water collector is arranged on the lower part of the hollow shaft; and the sealing joints are arranged on the upper part of the hollow shaft and do not rotate. An electric field structureconsists of a disk-shaped electrode plate, the other disk-shaped electrode plate, moving electrodes and fixed electrodes, wherein the disk-shaped electrode plate is arranged between the oil collectorand the liquid distributor; the other disk-shaped electrode plate is arranged on the centrifugal cavity and staggered with the electrode plate of the hollow shaft; the moving electrodes are arrangedat both ends of the hollow shaft; and the fixed electrodes are arranged at the upper end and the lower end of the shell and correspondingly and movably contact the moving electrodes. The upper fixed electrode and the lower fixed electrode are connected with the dehydrating power supply device; and a motor pulley is connected with the pulley on the lower part of the hollow shaft through the.

Owner:中石化石油工程技术服务有限公司 +1

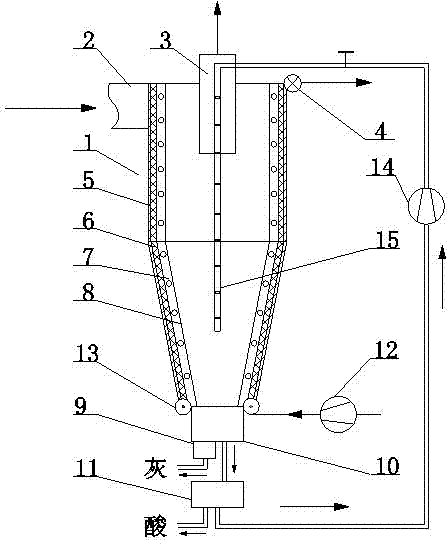

Method for smoke discharge, condensation and dust removal of supercharged oxygen-enriched coal-fired boiler

InactiveCN102287841ASimplify the dehydration processImprove economyIndirect carbon-dioxide mitigationSolid removalHigh pressure waterHigh pressure

The invention relates to a method for smoke discharge, condensation and dust removal of a supercharged oxygen-enriched coal-fired boiler. The method comprises the following steps of: introducing smoke into a high-pressure water cooling cyclone dust removal and condensation device; exchanging heat between the smoke and a water cooling wall in the device and condensing; dumping dust and liquid dropin the smoke to an inner wall of the water cooling wall; downwards flowing a liquid film formed by condensation under the action of gravity and washing the dust on an inner wall surface; condensing sulfuric acid steam in the smoke and flowing the sulfuric acid steam to the bottom part of a conical chamber arranged on the lower part of the device; discharging the treated smoke through an air outlet pipe; discharging ash gathered on the bottom part of the device through an ash discharging valve; discharging acid liquid to an acid liquid treatment and recovery device for separation of dilute sulphuric acid; sending separated water to a spraying pipe of the dust removal and condensation device; blowing the ash from the dust removal and condensation device; sending cooling water subjected to heat exchange to a water feeding heating system of the boiler. The method is characterized in that: equipment is simple and reliable, energy consumption is low, a CO2 collection process is simplified, and a good effect of smoke dehydration and dust removal can be achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

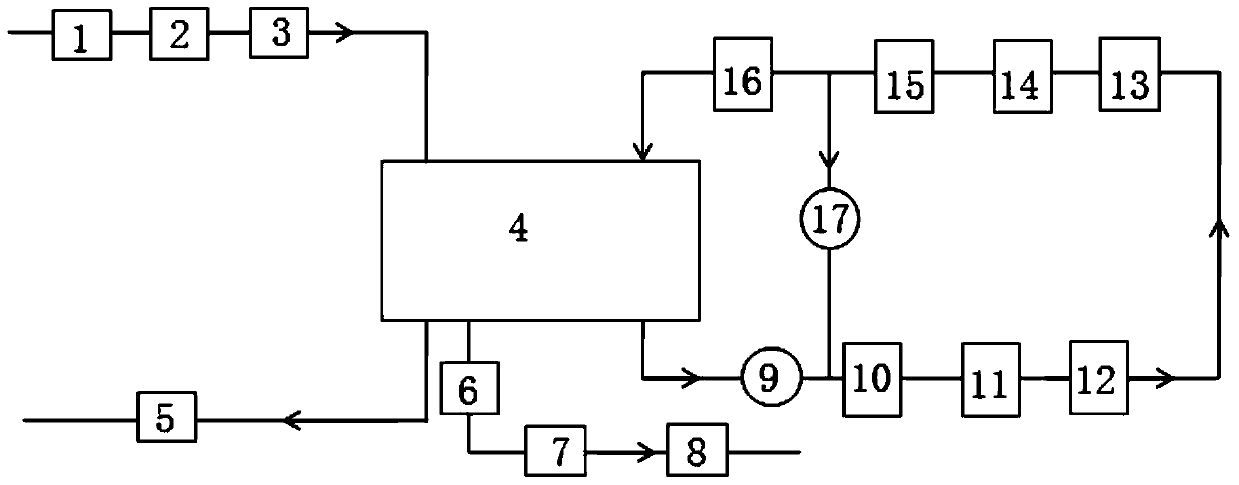

Dehydration method during production process of toluene diisocynate

ActiveCN103724229AEfficient removalReduce corrosionOrganic compound preparationPreparation from carbamatesPhosgeneCarbamoyl chloride

The invention belongs to the field of toluene diisocynate production technology and relates to a dehydration method during the production process of toluene diisocynate. Toluenediamine and phosgene have cold light gasification reaction to obtain a mixture flow of carbamyl chloride, amidogen hydrochloride and hydrogen chloride; the mixture flow flows into a phosgenation reaction tower; carbamyl chloride and amidogen hydrochloride react to produce toluene diisocynate and the by-product hydrogen chloride; at the bottom of a hydrogen chloride rectifying tower, the mixture flow of amidogen and hydrogen chloride is divided into two parts, most of the mixture flow returns to the top of the phosgenation reaction tower and serves as the backflow, and the rest of the mixture flow enters into a drain sump containing activated carbon as the catalyst; water and phosgene in the mixture flow react to produce hydrogen chloride and carbon dioxide to remove water in the mixture flow under the function of the activated carbon catalyst; the dehydrated mixture flow enters into the bottom of the phosgenation reaction tower for further rectification and is discharged from the bottom of the phosgenation reaction tower for next step. The dehydration technology is simple and environmentally friendly, the cost is low, and the dehydration effect is excellent.

Owner:QINGDAO UNIV OF SCI & TECH +1

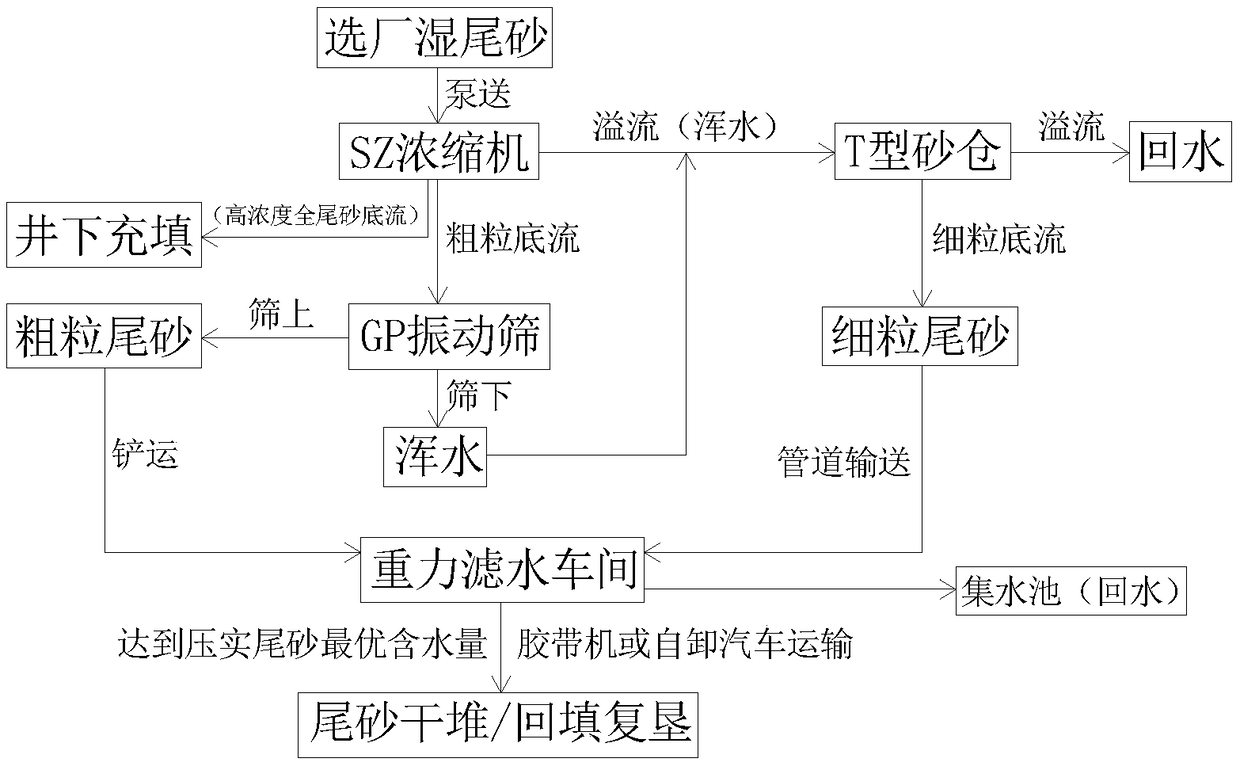

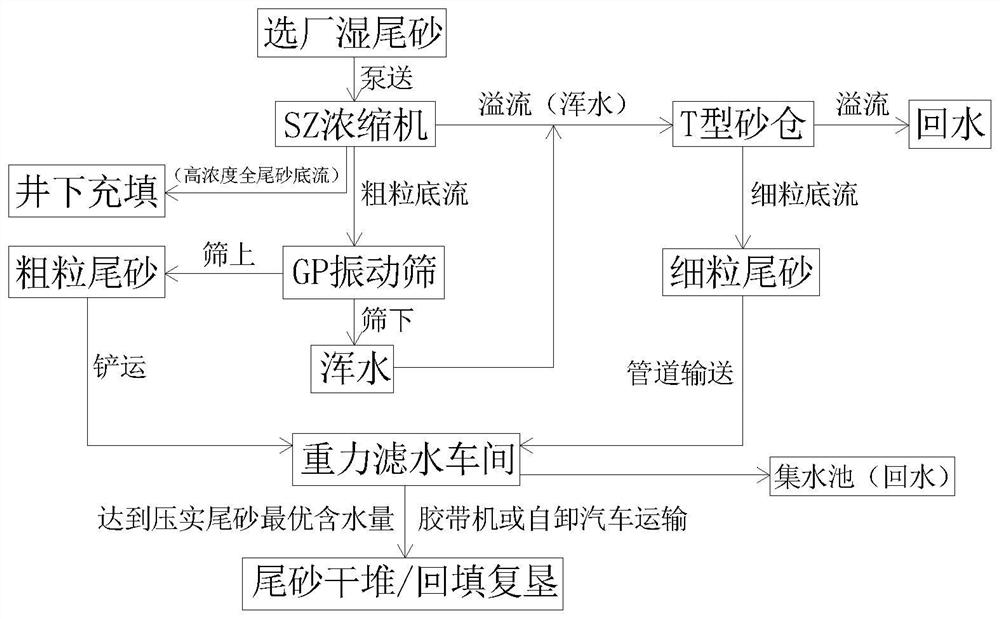

Sedimentation, classified reverse filtering and dewatering and dry stacking method for fine grained tailings

ActiveCN109432878ASimplify the dehydration processShort processFiltration circuitsMining engineeringWater filter

The invention discloses a sedimentation, classified reverse filtering and dewatering and dry stacking method for fine grained tailings. Total tailing pulp discharged from a concentration plant is concentrated and dewatered by a deep cone thickener, underflow flows to a high-frequency vibrating screen, coarse grained tailings on the screen slide to a funnel of a sealing-tape machine or a bucket ofa scraper, and the coarse grained tailings are conveyed to a sand pool of a gravity water filtering workshop by the sealing-tape machine or the scraper; a bottomed rectangular filtering sand tank is defined on the workshop floor by the coarse grained tailings in the sand pool with a grab machine, and concentrated underflow in a T-shaped sand bin is conveyed into the filtering sand tank; overflow of the T-shaped sand bin serves as back water; a coarse grained tailing mixture in the filtering sand tank is reversely loaded to the funnel of the sealing-tape machine or a dump truck by the scarper,conveyed to a tailing dry stacking yard or a backfill reclamation site and compacted layer by layer. The method is used for dry stacking, backfill reclamation or downhole filling of the fine grained tailings and infrastructure construction of tailing dewatering, equipment investment is reduced by 50%, energy consumption is reduced by 85%, efficiency is increased by 70%, cost is reduced by 60%, andoperation management is simple.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

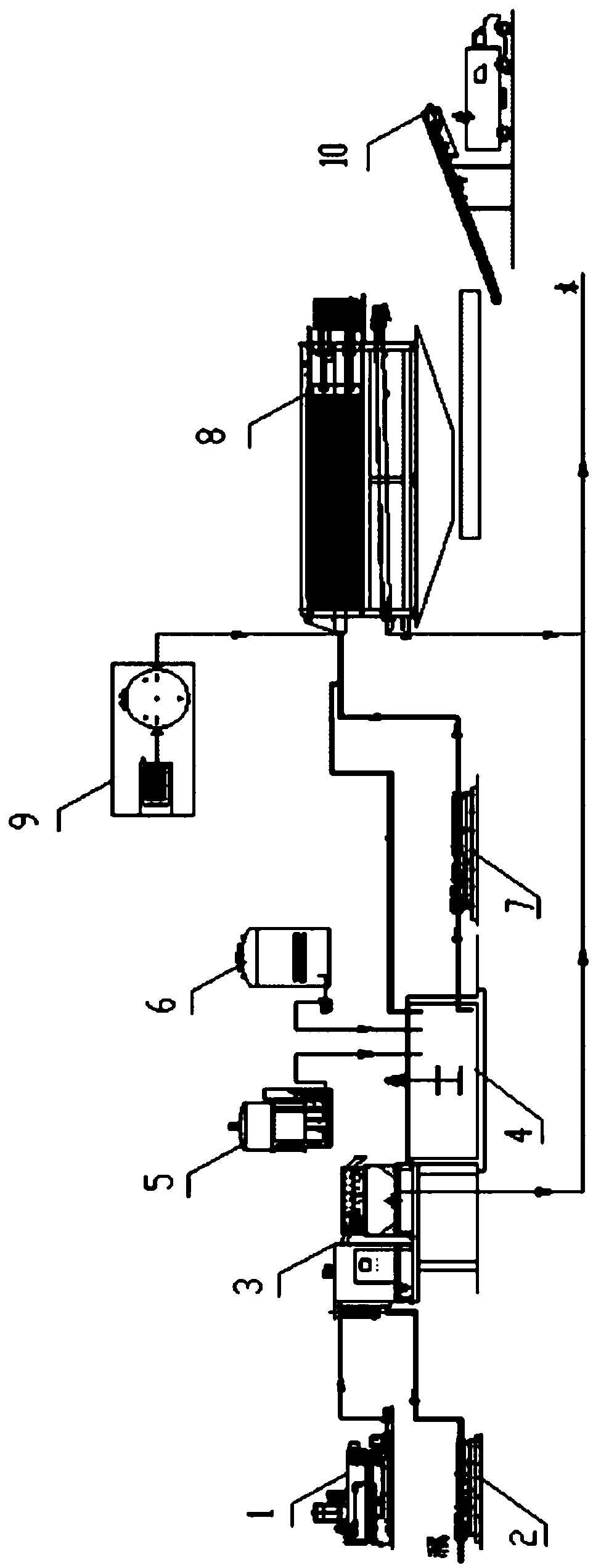

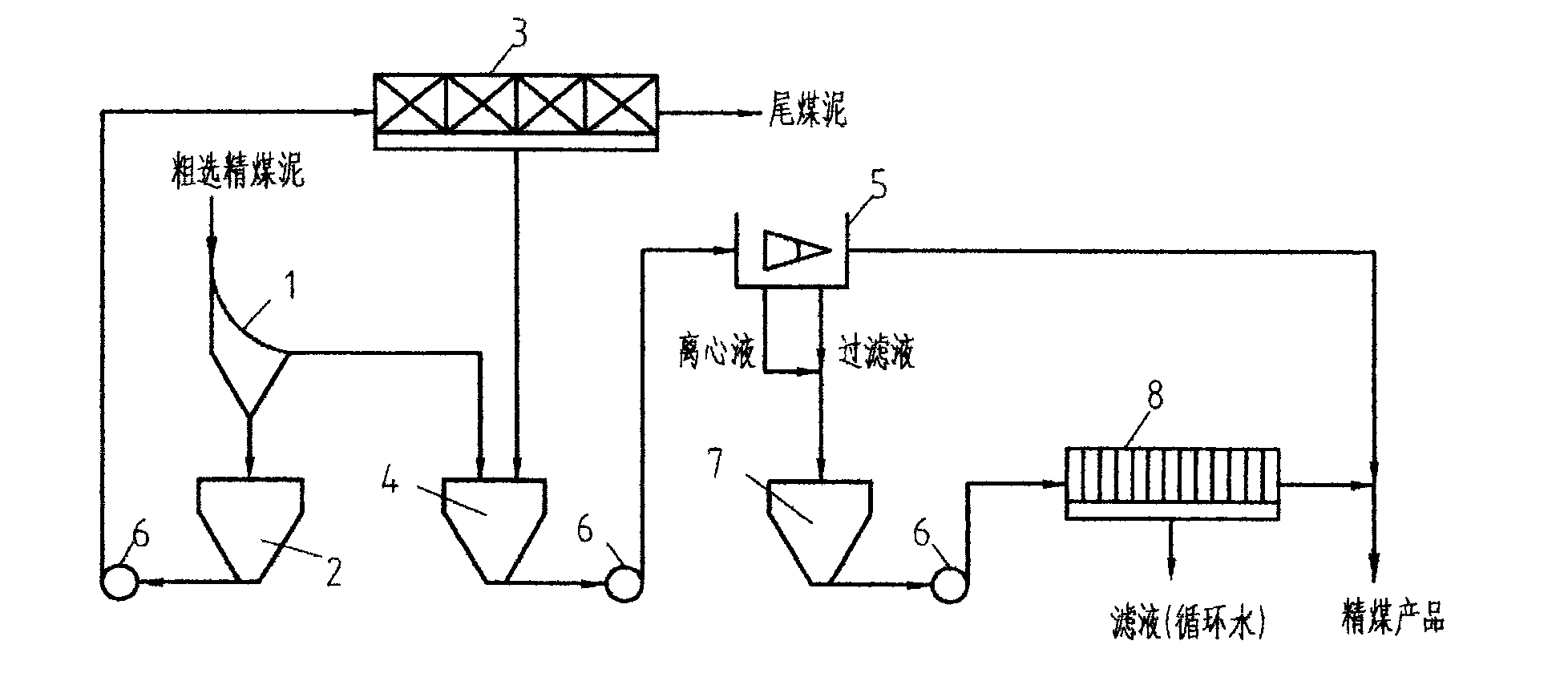

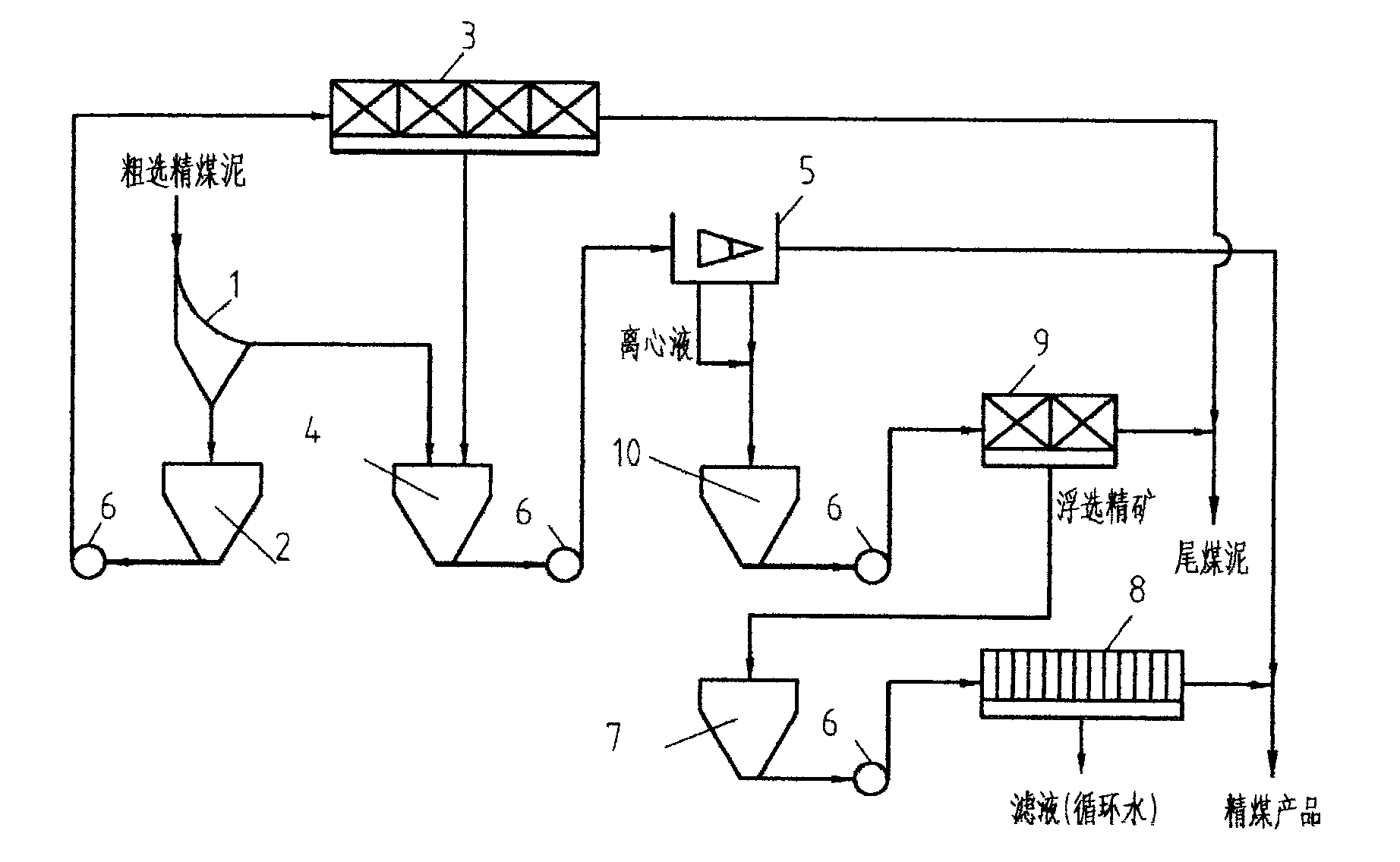

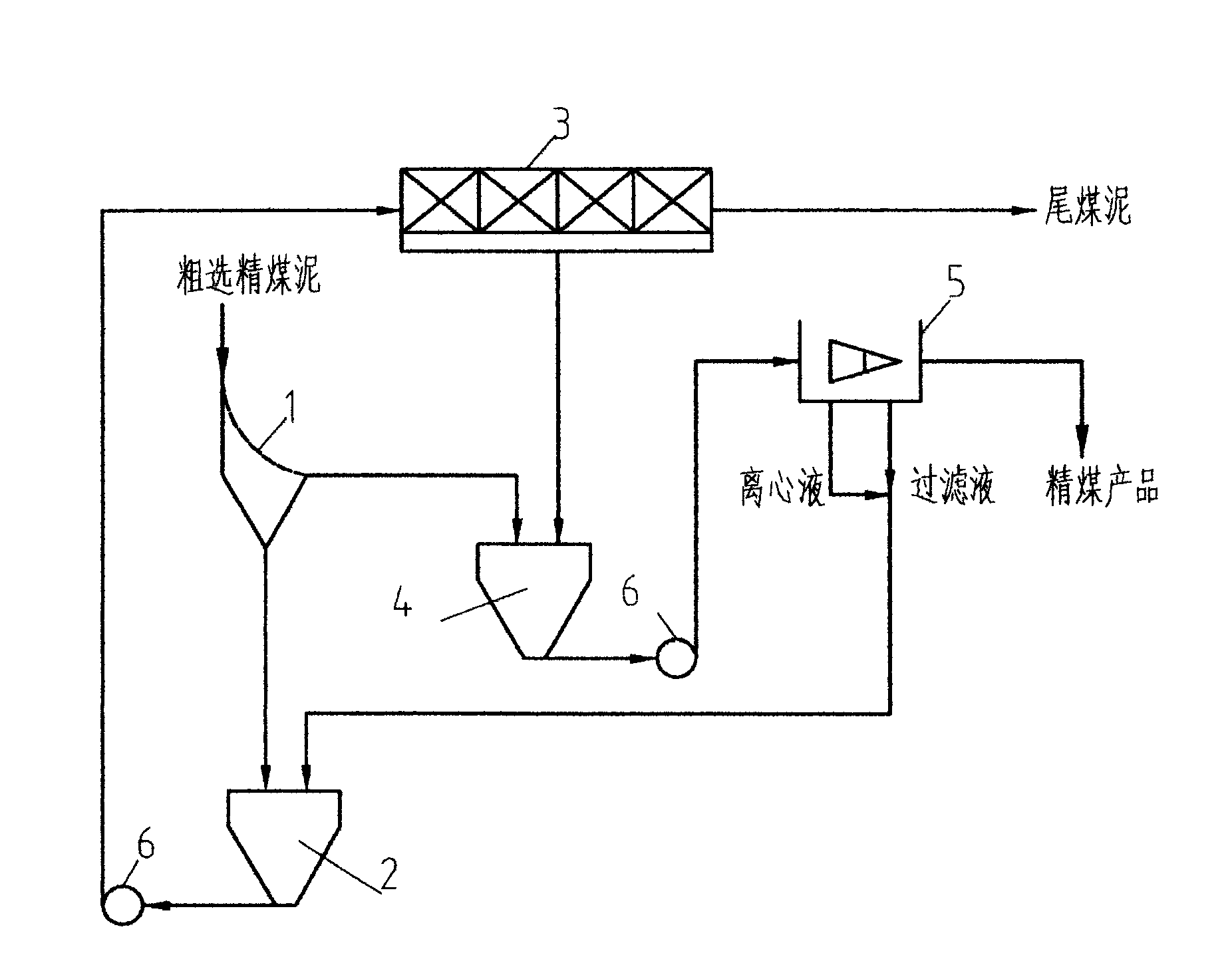

Cleaned coal dehydration process and equipment combination for realizing same

The invention relates to a coal preparation process, in particular to a floatation-cleaned-coal dehydration process and simultaneously relates to a set of equipment combination for realizing same. The dehydration process is characterized by comprising the following steps of: leading floatation cleaned coal to automatically flow into a settling and filtering centrifuge for dehydration or pumping the floatation cleaned coal into the settling and filtering centrifuge by using a pump for dehydration, wherein the dehydrated floatation cleaned coal is directly used as a final product; and leading centrifugate and filtrate of the settling and filtering centrifuge to return to the step of floatation feeding, namely participating in floatation operation again. The equipment combination is characterized by being provided with no filter press and no secondary floatation machine, and the settling and filtering centrifuge is used as only equipment for dehydrating the floatation cleaned cola. The process and the equipment combination, provided by the invention, are favorable for greatly saving construction cost and reducing maintaining expenses and product cost, not only can ensure that the moisture index of a floatation cleaned-coal product is qualified, but also can simultaneously ensure the uniformity of quality indexes, such as ash content and the like, of the floatation cleaned-coal product.

Owner:烟台金华选煤工程有限公司

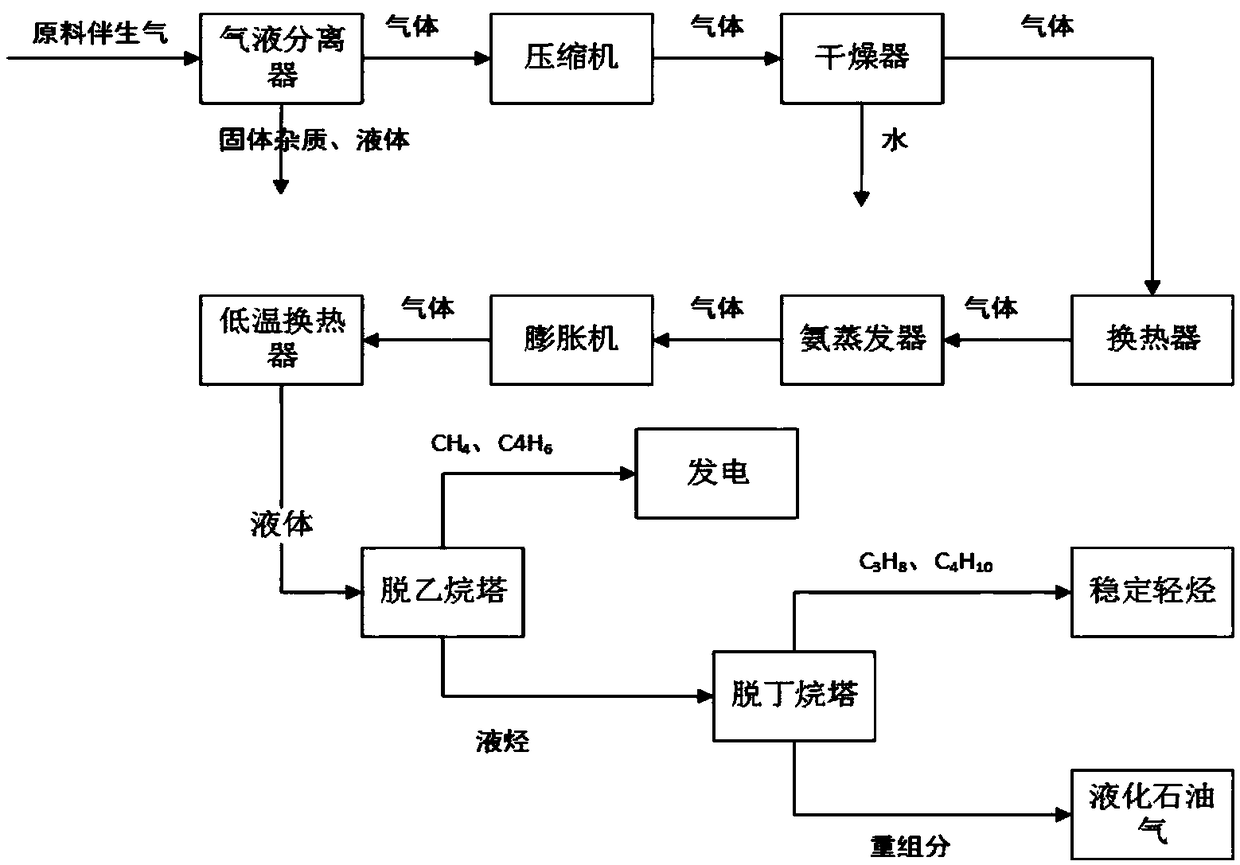

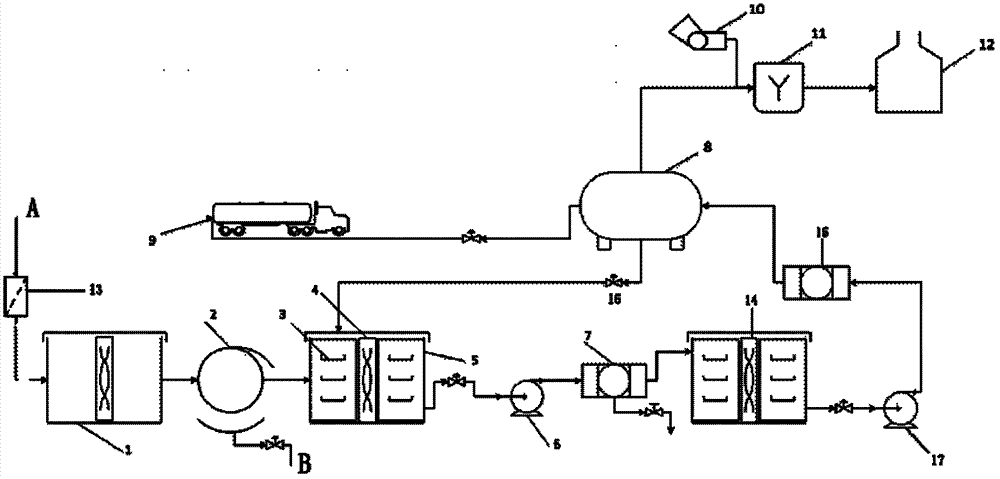

Treatment technology for petroleum associated gas

ActiveCN109321297APrevent liquefactionConducive to liquefactionGaseous fuelsComposite filmDistillation

The invention discloses a treatment technology for petroleum associated gas, and belongs to the technical field of treatment of petroleum associated gas. The treatment technology comprises the following steps of compression of the associated gas, drying, pre-cooling by ammonia, refrigerating by an expansion machine, distillation of product, and dry gas power generation; in the drying process, a composite film is used for drying and dewatering; the composite film is a double-layer composite film which is prepared by mixing and weaving stainless steel fibers and glass fibers into a net-shaped bottom film, pressing a thin film into a blank, firing and forming. The treatment technology for the petroleum associated gas has the advantages that the petroleum associated gas is treated and is usedfor dry gas power generation; the operation is simple, and the treatment steps are concise; a film drying technique is used for dewatering, the dewatering speed is high, the permeation amount of gas is high, and the secondary pollution due to production of dust is avoided.

Owner:杭州勃扬能源设备有限公司

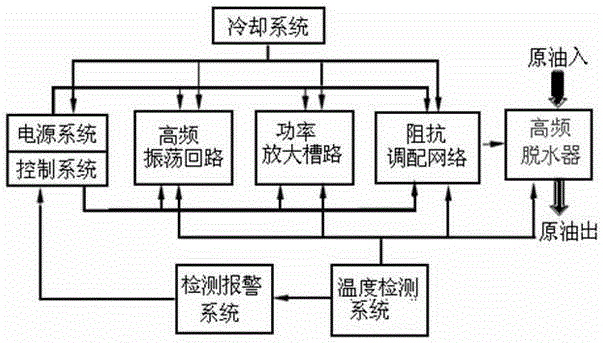

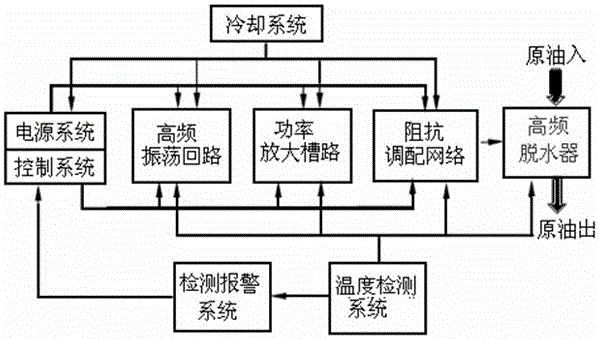

High-frequency crude oil dehydrator

ActiveCN105199777ALow viscosityEasy to separateHydrocarbon oil dewatering/demulsificationThermodynamicsControl system

The invention discloses a high-frequency crude oil dehydrator. A high-frequency dehydrator is connected with an impedance allocating network; a high-frequency radiator is connected with a temperature detection system; the temperature detection system is respectively connected with the impedance allocating network, a power amplification tank circuit, a high-frequency oscillation circuit and a detection and alarm system; the detection and alarm system is connected with a control system of a power supply system; the control system of the power supply system, the high-frequency oscillation circuit, the power amplification tank circuit and the impedance allocating network are all connected with a cooling system; a radial high-frequency electric field is generated by the high-frequency dehydrator at the high frequency; the orientation polarization is generated under the action of the electric field; two ends of water droplets induce and generate opposite charges to form an induction electric field; dipole coalescence is generated between the similar water droplets; the water droplets are condensed to form large water droplets; the large water droplets are demulsified and settled; the high-frequency electric field accelerates polar molecules to rotate at high speed and cause charge neutralization; when liquid globules lose the action of double electric layers, the liquid globules collide and gather, so that the oil and the water are separated. The high-frequency crude oil dehydrator has the characteristics of low operation cost, dehydration simplicity, high dehydration efficiency, stability and safety in dehydration, and green and environment-friendly performance.

Owner:XI'AN PETROLEUM UNIVERSITY

Cyclone electric dehydration device with driving impeller

InactiveCN104560129BReduce volumeImprove dehydration efficiencyDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansDrive wheelConical tube

Owner:承德石油高等专科学校

Process for producing polyphenyl thioether

The invention relates to a process for producing polyphenyl thioether, comprising the following steps of:, mixing hydrogenous sodium sulfide, lithium chloride and N-methyl pyrrolidone in the weight ratio of (20-25): (2-6): (70-80), co-boiling the mixture and inert gases at 150-210 DEG C for distilling and dehydrating; separating solvent by refining; respectively adding santochlor, solvent and lithium chloride in anhydrous sodium sulfide, separating after complete reaction to obtain polyphenylene sulfide; compositely washing the polyphenylene sulfide to obtain pure polyphenylene sulfide; and reclaiming the lithium chloride by filtering, reclaiming the solvent and flashly evaporating dimethylbenzene solution in a two-period mode and cooling and crystallizing. The invention has the advantages of low cost, simple process, excellent performance of synthetic resin and high solvent recovering rate.

Owner:DUNHUANG XIYU MINING & CHEM

Method for processing oily sludge in oil field

InactiveCN102583915BReduce moisture contentEasy to transportWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningEmulsionSlag

The invention discloses a method for processing oily sludge in an oil field, which comprises the following steps of: carrying out filter pressing and filtering after primarily filtering; under the heating state of 90-120DEG C, filtering by a filter screen of 18-35 meshes; carrying out secondary filtering by the filter screen of 70-120 meshes; adding emulsion breaker and heating to 45-60DEG C; standing until three phases of oil, water and solid are layered; separating upper-layer liquid to obtain crude oil; separating middle-layer liquid to obtain free water; after the crude oil and the free water are obtained, naturally drying the residual slag until the moisture content is less than 40%; and mixing at the volume ratio of slag to fire coal of (2-3):10 to obtain fuel. The method for processing oily sludge in an oil field has high crude oil recovery rate, more than 50% of crude oil in the oily sludge can be recovered, the processing cost of the oily sludge is indirectly lowered, and the economic value for processing the oily sludge is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

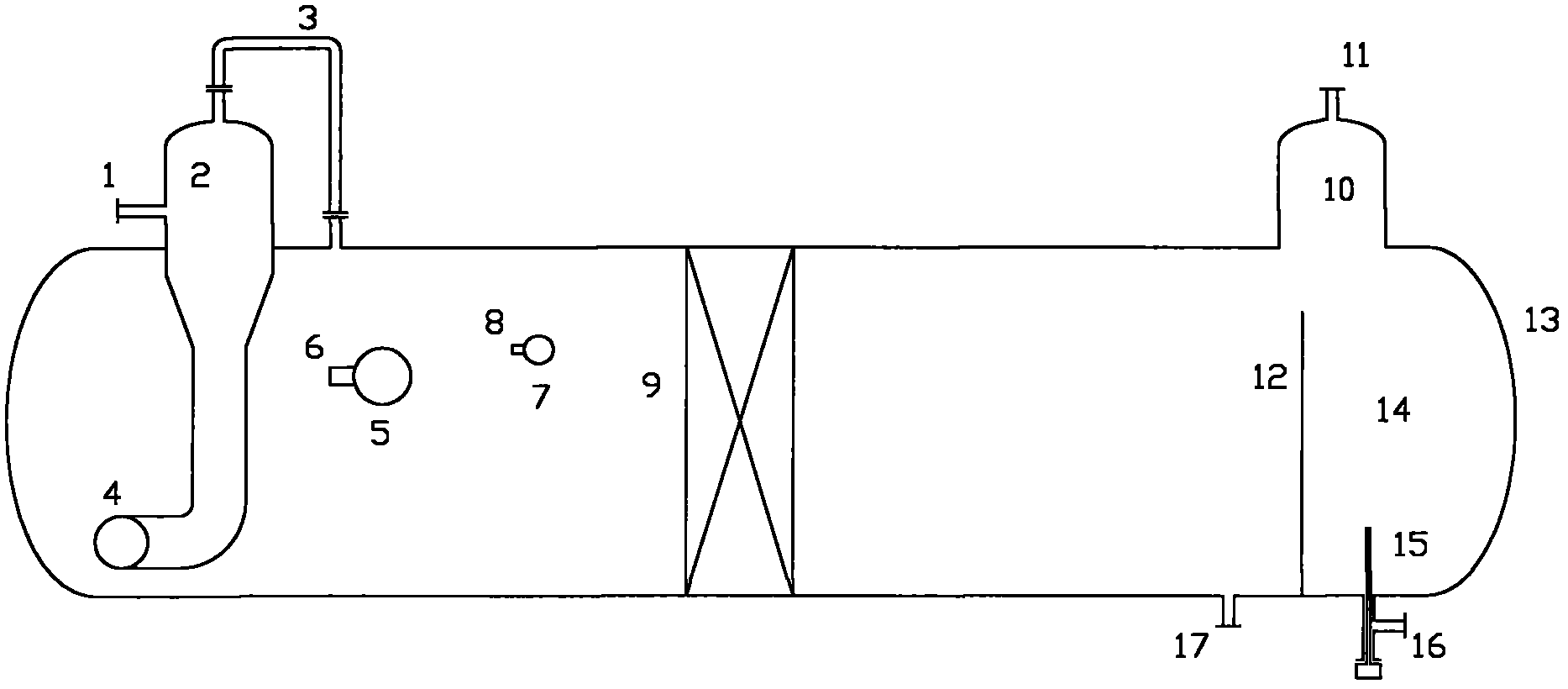

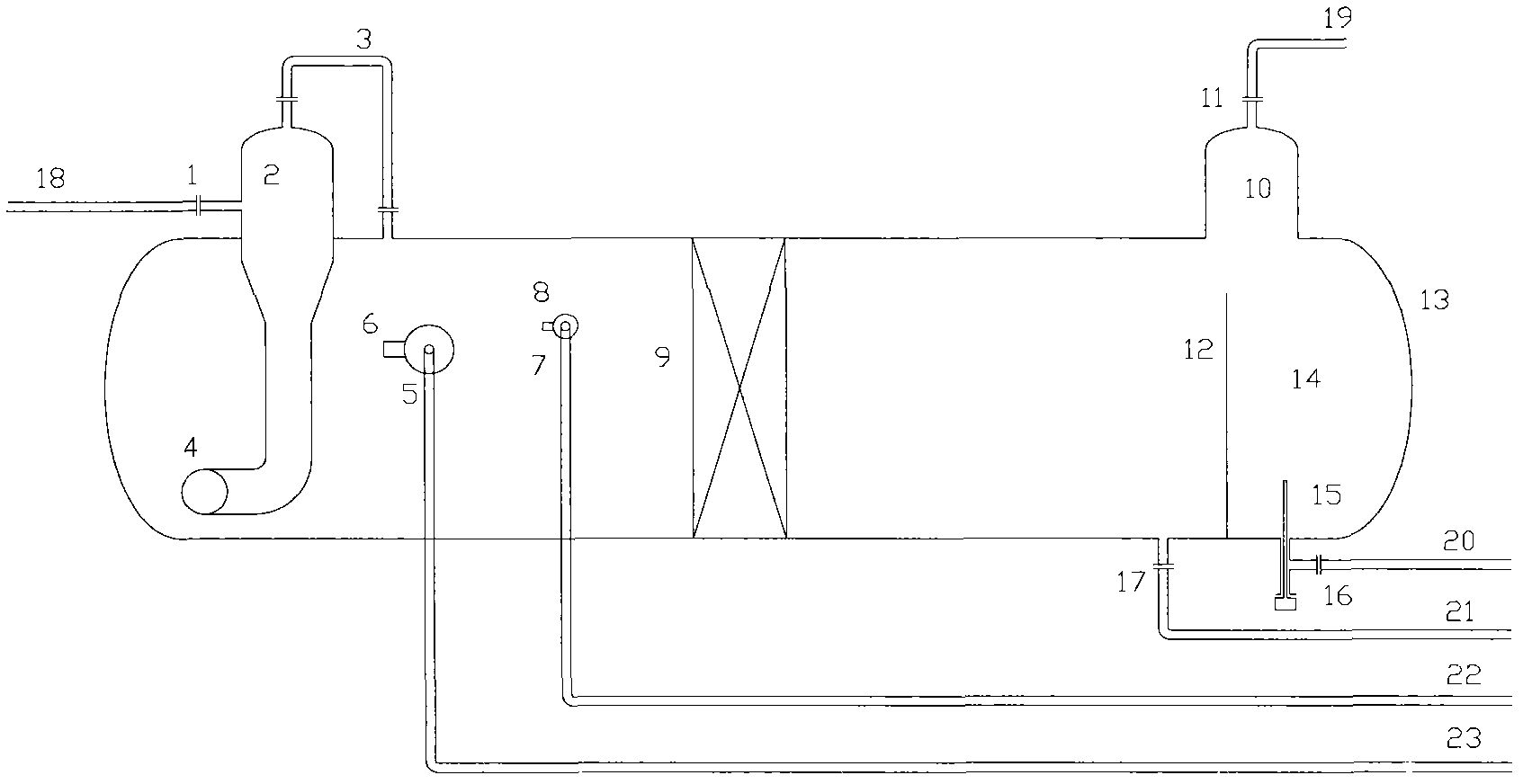

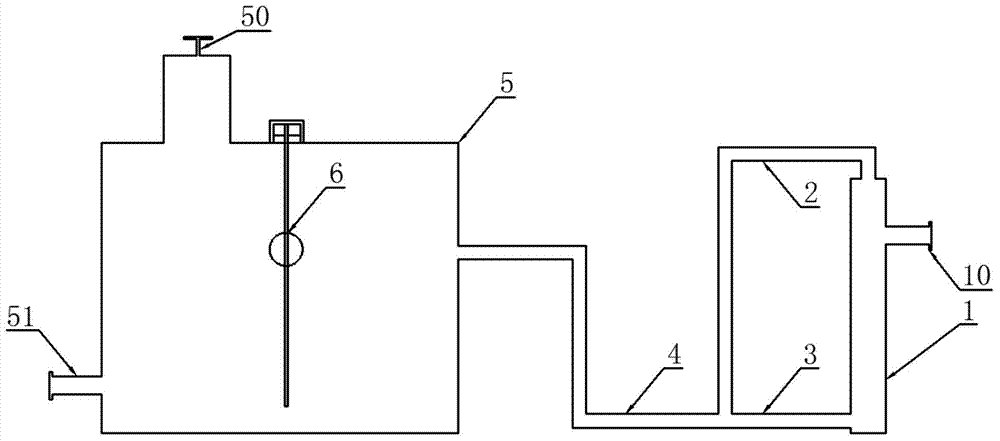

Thickened oil three-phase separator used for removing free water and combining thin oil

InactiveCN103157300ACompact structureSimplify the dehydration processDewatering/demulsification with chemical meansLiquid degasificationOil spillOil field

The invention discloses a thickened oil three-phase separator which is used for removing free water and reducing viscosity by adding thin oil and is used in oil fields and mine fields. The thickened oil three-phase separator is composed of an outer shell, a separation cavity, a gas-liquid pre-separation barrel, a liquid distributor, an inlet, a gas communication pipe, a gas outlet, a gas distribution bag, separation filler, a thin oil adding distributor, a thin oil distribution mouth, a chemical agent distributor, a chemical agent distribution mouth, an oil spilling weir plate, a water outlet, an oil outlet, an oil cavity, a thickened oil and thin oil mixer, and the like. A thin crude oil distributor and a thin oil distributor are arranged in the separator, and then thin oil is enabled to permeate into a certain position inside the separation cavity, and then the viscosity of thickened oil is reduced after the free water is removed. The chemical agent distributor and the chemical agent distribution mouth are arranged in the separator, chemical agents are enabled to permeate into a certain position inside the separation cavity, and chemical demulsification is carried out on the thickened oil after the free water is removed. The thickened oil and thin oil mixer is arranged at the position of the oil cavity of the oil outlet of the separator, mixing degree of the thickened oil and the thin oil is increased with methods such as a mechanical vibration method, and the thickened oil is enabled to be discharged out of the separator smoothly.

Owner:SINOPEC PETROLEUM ENG DESIGN

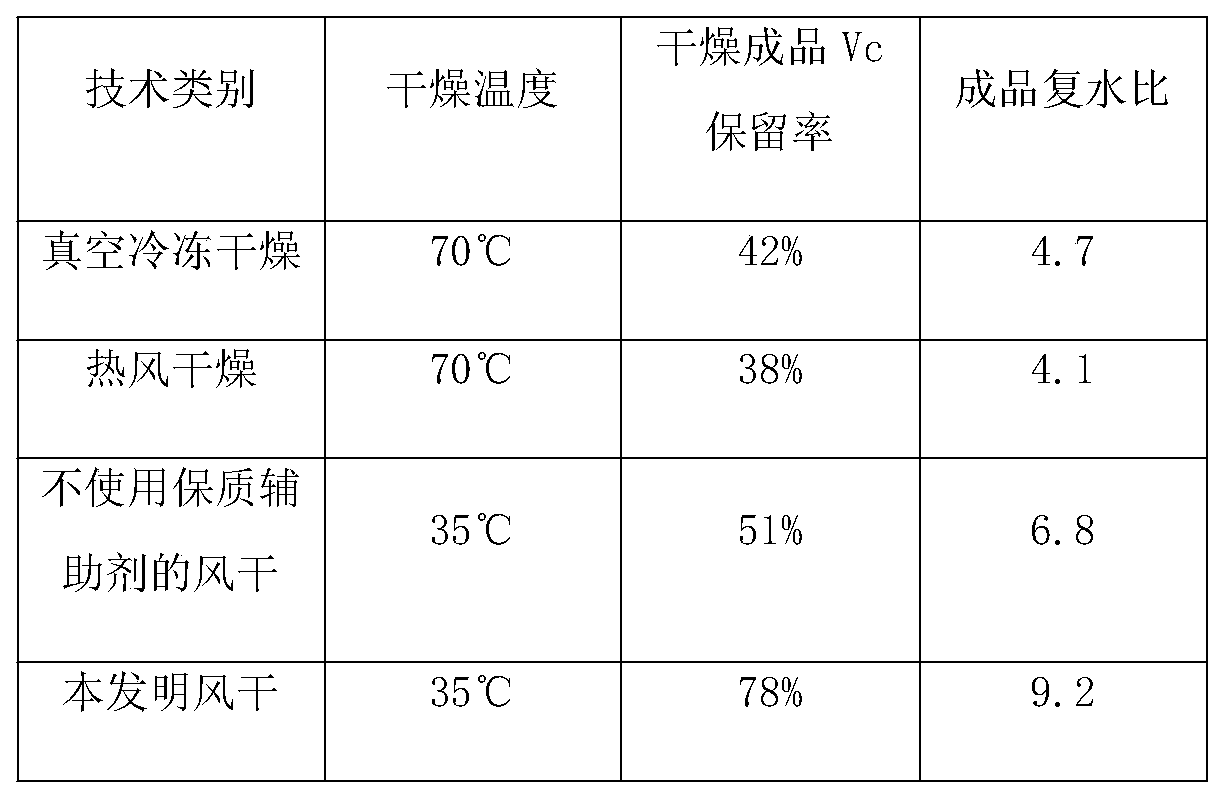

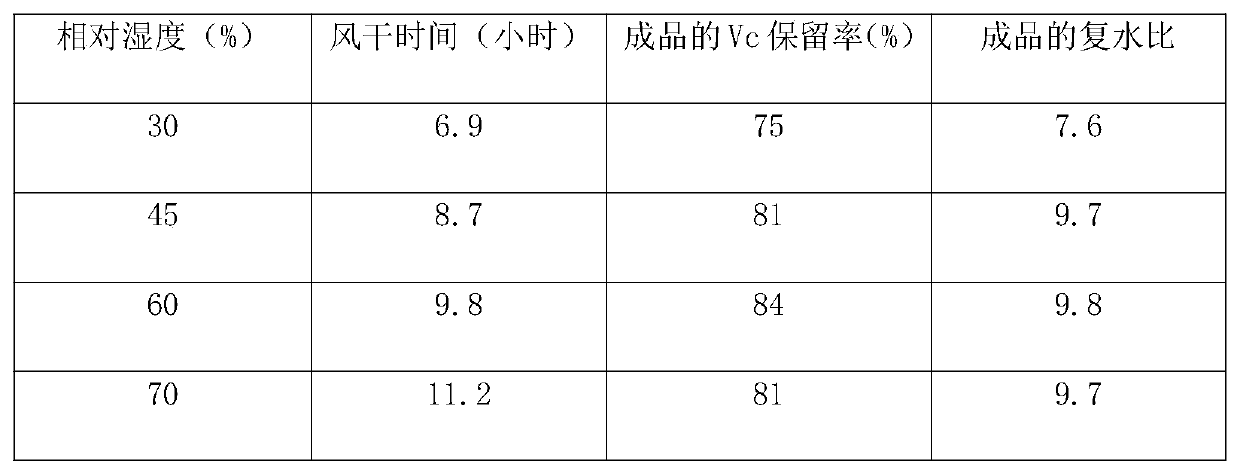

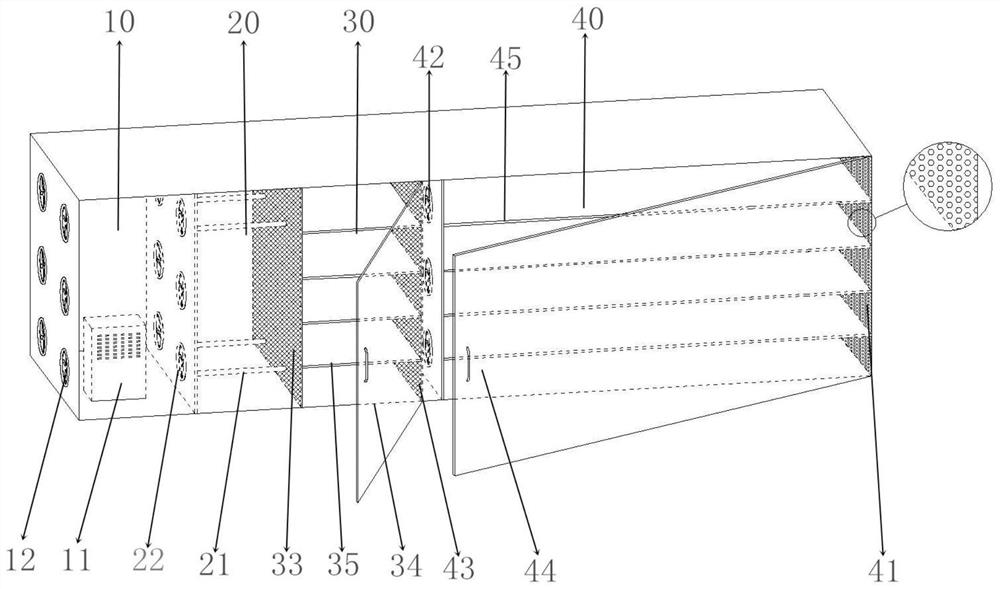

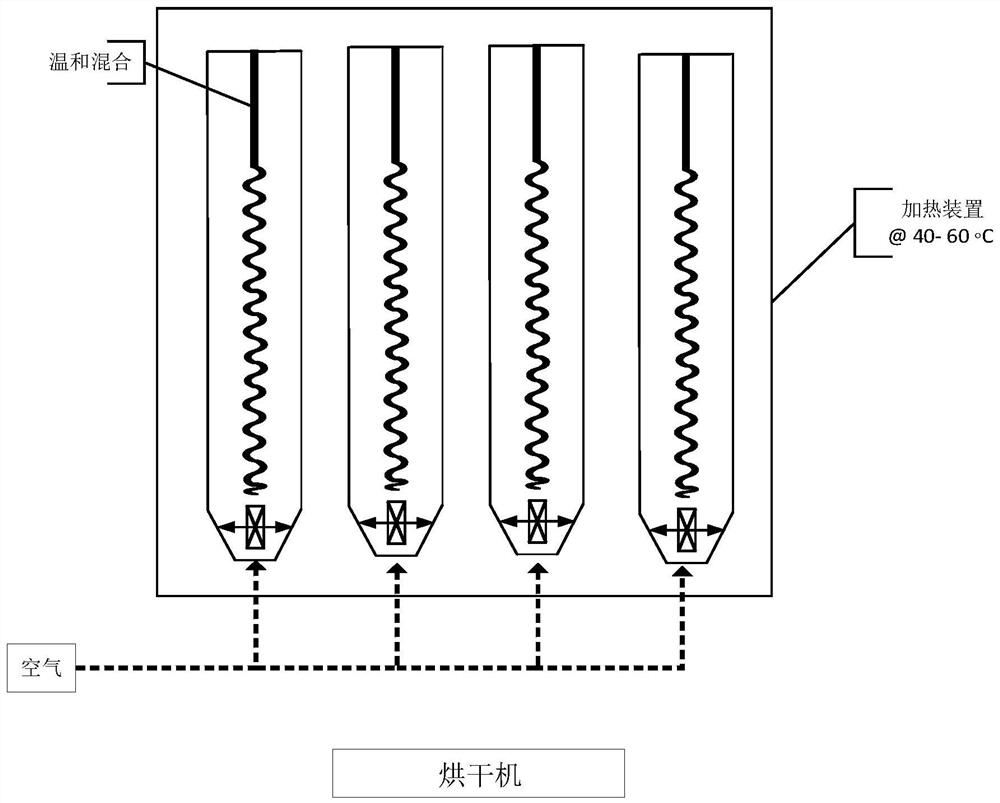

Food air drying method

ActiveCN110024853AClever useMaintain nutrientsFruits/vegetable preservation by irradiation/electric treatmentFood processingChemistryFlavor

The invention provides a food air drying method. The food air drying method comprises the steps of a method for preparing an air drying quality guaranteeing auxiliary agent and a method for performingair drying, wherein the method for preparing the air drying quality guaranteeing auxiliary agent comprises the steps of taking fresh lemons, performing squeezing to obtain juice, removing residues, taking juice for standby application, crushing dried aromatic hydrocarbon containing plants to obtain powder, pouring the powder into the lemon juice, performing sufficient stirring while pouring the powder until the powder is viscous and does not have dry powder, so that the air drying quality guaranteeing auxiliary agent is prepared and placed in a sterilized sealed box namely that the quality guaranteeing auxiliary agent is loaded into the box; and the method for performing air drying comprises the steps of taking fresh air, performing dampness removal, ultraviolet irradiation and aseptic filtration so as to obtain clean air having temperature being 18-30 DEG C and humidity being 45-70%, introducing the clean air into an adjunct room, enabling the clean air to flow past the quality guaranteeing auxiliary agent to be injected into an air drying room, enabling the air to flow past the fruit and vegetable raw materials for air drying, and then discharging the air out of the air drying room. The air drying method disclosed by the invention can maintain the flavor of foods to the maximum extent, the foods can be really reduced, the working procedures are simple, the equipment is simple, batched production is easy to realize, and the air drying method is suitable for cooked foods or fresh foods.

Owner:龙岩安萍科技有限公司

Method used for improving waste active sludge dehydration performance through adding of bacterial broth

ActiveCN110104921AAdaptableImprove stabilitySludge treatment by de-watering/drying/thickeningBiological sludge treatmentMicrobial inoculationResource utilization

The invention discloses a method used for improving waste active sludge dehydration performance through adding of bacterial broth. According to the method, aspergillus niger, Pseudomonas aeruginosa, Streptococcus thermophilus, and Rhodococcus rhodococcus are adopted, a fermentation culture solution is prepared from a waste molasses diluted solution and waste active sludge; the fermentation culturesolution is inoculated with the above four microbes respectively at certain ratios, fermentation is carried out for 2 to 5d at 25 to 35 DEG C 160-180r / min so as to obtain a composite bacterial broth;the composite bacterial broth is added into waste active sludge, stirring reaction is carried out for 4h, dehydration is carried out, and after conditioning, sludge water content is reduced to be lower than 50%. The bacterial broth is excellent in adaptability on temperature and pH value, and excellent in flocculation capability, dehydration effect is improved obviously; the method is simple; cost is low; sludge obtained through dehydration treatment can be taken as a plantation substrate or a microbial fertilizer; and sludge resource utilization is promoted.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

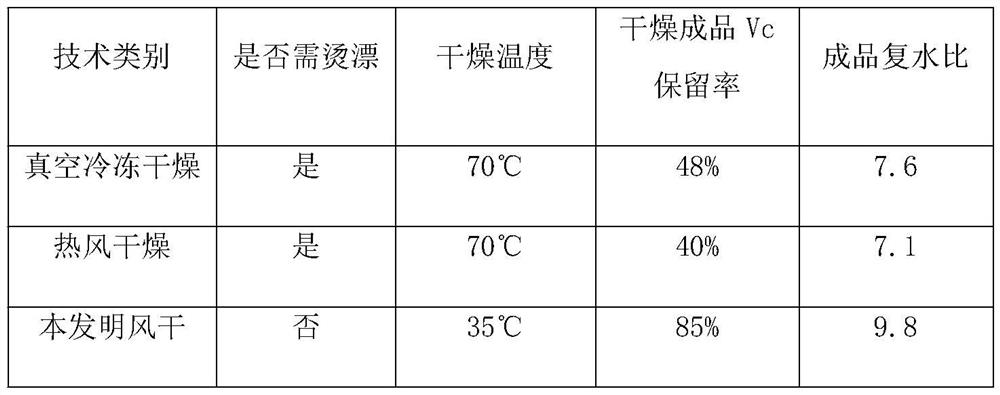

A kind of preparation method of reducible fruit and vegetable dehydrated product

ActiveCN110024852BKeep shapeMaintain textureFruits/vegetable preservation by irradiation/electric treatmentFood processingFood additiveHorticulture

The invention relates to the technical field of agricultural product processing, in particular to a method for preparing reducible dehydrated fruit and vegetable products. The method comprises: fruit and vegetable raw material selection, fruit and vegetable pretreatment, preparation of quality preservation auxiliary agent and fruit and vegetable air-drying process. With this method, the quality preservation auxiliary agent is made of natural raw materials, and the fruit and vegetable raw materials do not need to be treated at high temperature, which realizes real low-temperature drying. It is in the state of fresh fruits and vegetables, and the preparation process is simple, no food additives are added at all, and the preparation cost is low.

Owner:龙岩安萍科技有限公司

A high frequency crude oil dehydrator

ActiveCN105199777BLow viscosityEasy to separateHydrocarbon oil dewatering/demulsificationElectricityControl system

The invention discloses a high-frequency crude oil dehydrator. A high-frequency dehydrator is connected with an impedance allocating network; a high-frequency radiator is connected with a temperature detection system; the temperature detection system is respectively connected with the impedance allocating network, a power amplification tank circuit, a high-frequency oscillation circuit and a detection and alarm system; the detection and alarm system is connected with a control system of a power supply system; the control system of the power supply system, the high-frequency oscillation circuit, the power amplification tank circuit and the impedance allocating network are all connected with a cooling system; a radial high-frequency electric field is generated by the high-frequency dehydrator at the high frequency; the orientation polarization is generated under the action of the electric field; two ends of water droplets induce and generate opposite charges to form an induction electric field; dipole coalescence is generated between the similar water droplets; the water droplets are condensed to form large water droplets; the large water droplets are demulsified and settled; the high-frequency electric field accelerates polar molecules to rotate at high speed and cause charge neutralization; when liquid globules lose the action of double electric layers, the liquid globules collide and gather, so that the oil and the water are separated. The high-frequency crude oil dehydrator has the characteristics of low operation cost, dehydration simplicity, high dehydration efficiency, stability and safety in dehydration, and green and environment-friendly performance.

Owner:XI'AN PETROLEUM UNIVERSITY

Rotational flow coarse graining sedimentation dehydration device and method thereof

ActiveCN104711013AReduced time required for gravity differentiationEasy to separateTreatment with plural serial refining stagesLiquid separationMiniaturizationOil water

The invention discloses a rotational flow coarse graining sedimentation dehydration device which comprises a coarse graining processor and a precipitator, wherein the coarse graining processor comprises a swirler; a liquid inlet, an overflow port and a bottom flow port are formed in the swirler; the overflow port and the bottom flow port are externally connected with an overflow pipe and a bottom flow pipe respectively; the tail ends of the overflow pipe and the bottom flow pipe are connected with each other to be connected with a mixing liquid pipe; the other end of the mixing liquid pipe is connected onto a precipitator. In addition, the invention further discloses a method of dehydration by utilizing the rotational flow coarse graining sedimentation dehydration device. The method comprises performing coarse graining treatment on oil-water mixing liquid and performing sedimentation on the oil-water mixing liquid subjected to the coarse graining treatment. According to the invention, three separation methods are integrated in a manner of having advantages and removing disadvantages; the dehydration method is simpler compared with a coarse grinding separation method, easier to control compared with a swirler separation method, and more efficient compared with a thermochemistry sedimentation method, so that the miniaturization of the dehydration device is ensured, the stability of production operation is met, the construction cost of a separation facility is reduced, and the operating cost is decreased.

Owner:崔斌

Dehydration method during production process of toluene diisocynate

ActiveCN103724229BEfficient removalReduce corrosionOrganic compound preparationPreparation from carbamatesPhosgeneCarbamoyl chloride

Owner:QINGDAO UNIV OF SCI & TECH +1

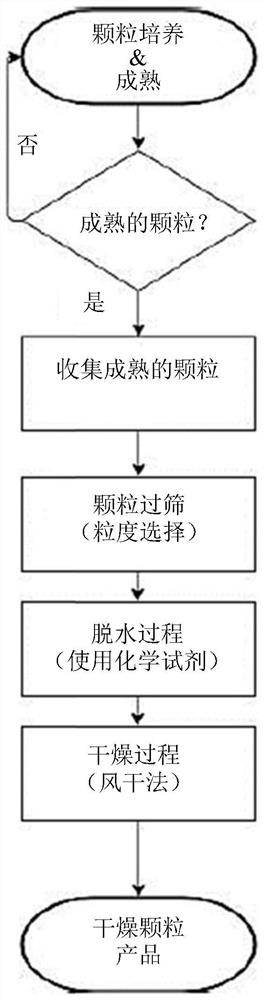

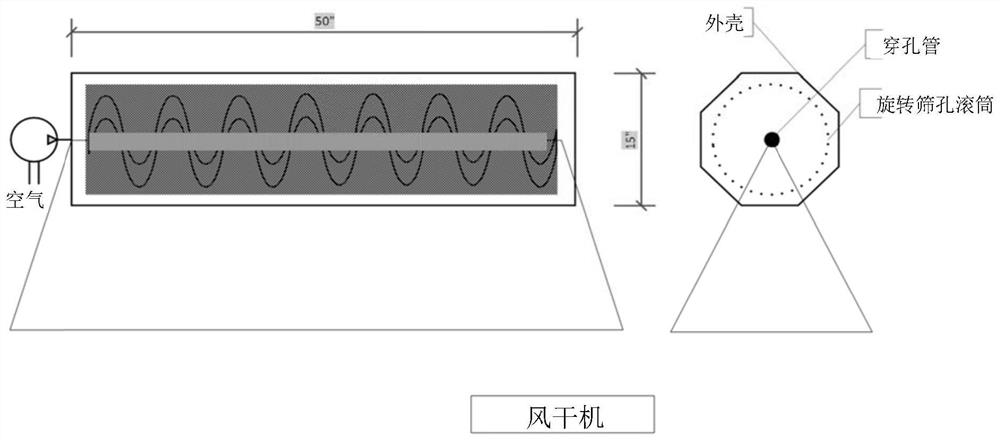

Simple method for desiccation and reactivation of aerobic granules

PendingCN114072225ABreach of integritySimplify the dehydration processBacteriaTreatment using aerobic processesDehydrationFood science

A method of producing desiccated aerobic granules, comprising: (a) subjecting aerobic granules to a size selecting step; (b) subjecting the size selected aerobic granules from (a) to a dehydration step; (c) subjecting the dehydrated size selected aerobic granules from (b) to a drying step.

Owner:鑫颗生物科技私人有限公司

Dry stacking method for fine-grained tailings sedimentation classification reverse filtration dehydration

ActiveCN109432878BSimplify the dehydration processShort processFiltration circuitsMining engineeringWater filter

The invention discloses a sedimentation, classified reverse filtering and dewatering and dry stacking method for fine grained tailings. Total tailing pulp discharged from a concentration plant is concentrated and dewatered by a deep cone thickener, underflow flows to a high-frequency vibrating screen, coarse grained tailings on the screen slide to a funnel of a sealing-tape machine or a bucket ofa scraper, and the coarse grained tailings are conveyed to a sand pool of a gravity water filtering workshop by the sealing-tape machine or the scraper; a bottomed rectangular filtering sand tank is defined on the workshop floor by the coarse grained tailings in the sand pool with a grab machine, and concentrated underflow in a T-shaped sand bin is conveyed into the filtering sand tank; overflow of the T-shaped sand bin serves as back water; a coarse grained tailing mixture in the filtering sand tank is reversely loaded to the funnel of the sealing-tape machine or a dump truck by the scarper,conveyed to a tailing dry stacking yard or a backfill reclamation site and compacted layer by layer. The method is used for dry stacking, backfill reclamation or downhole filling of the fine grained tailings and infrastructure construction of tailing dewatering, equipment investment is reduced by 50%, energy consumption is reduced by 85%, efficiency is increased by 70%, cost is reduced by 60%, andoperation management is simple.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

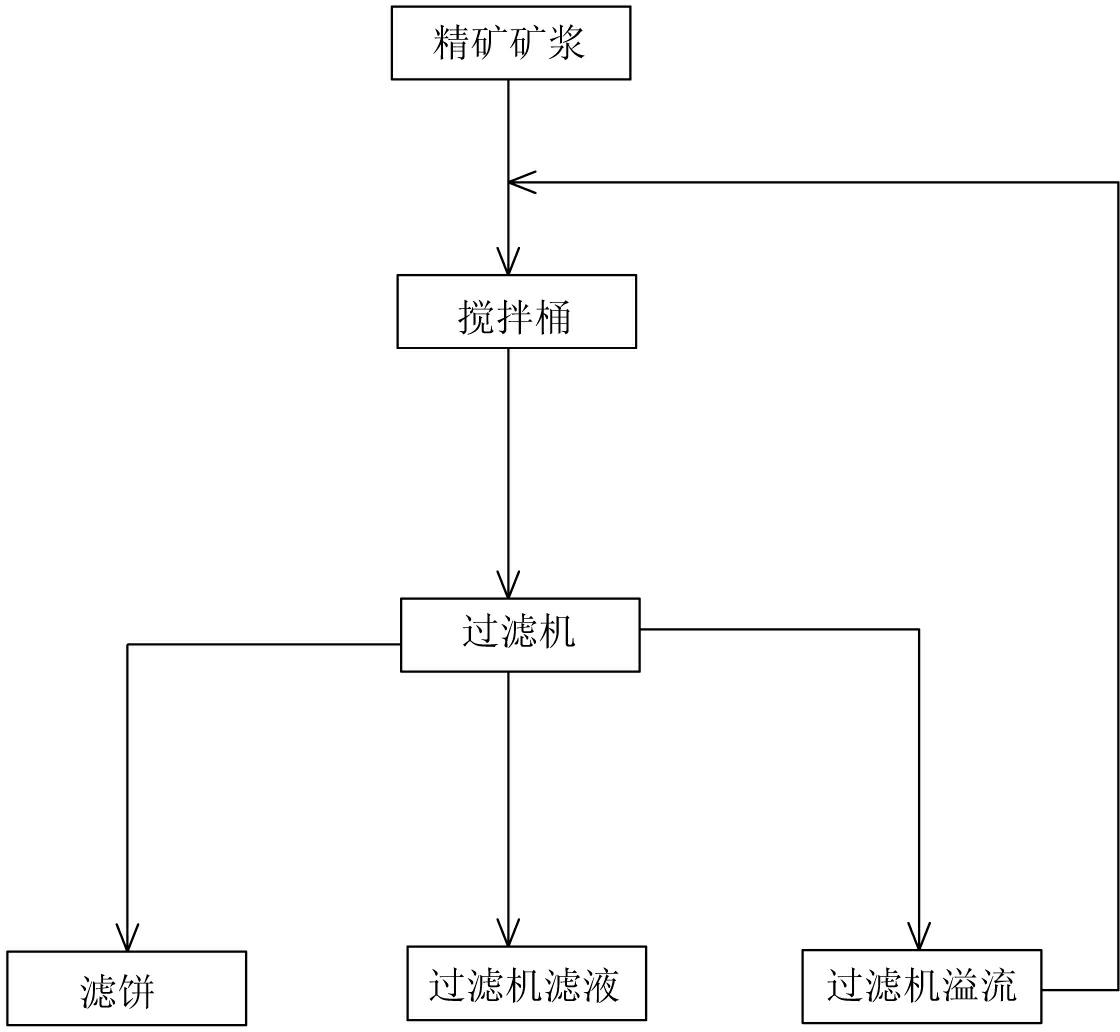

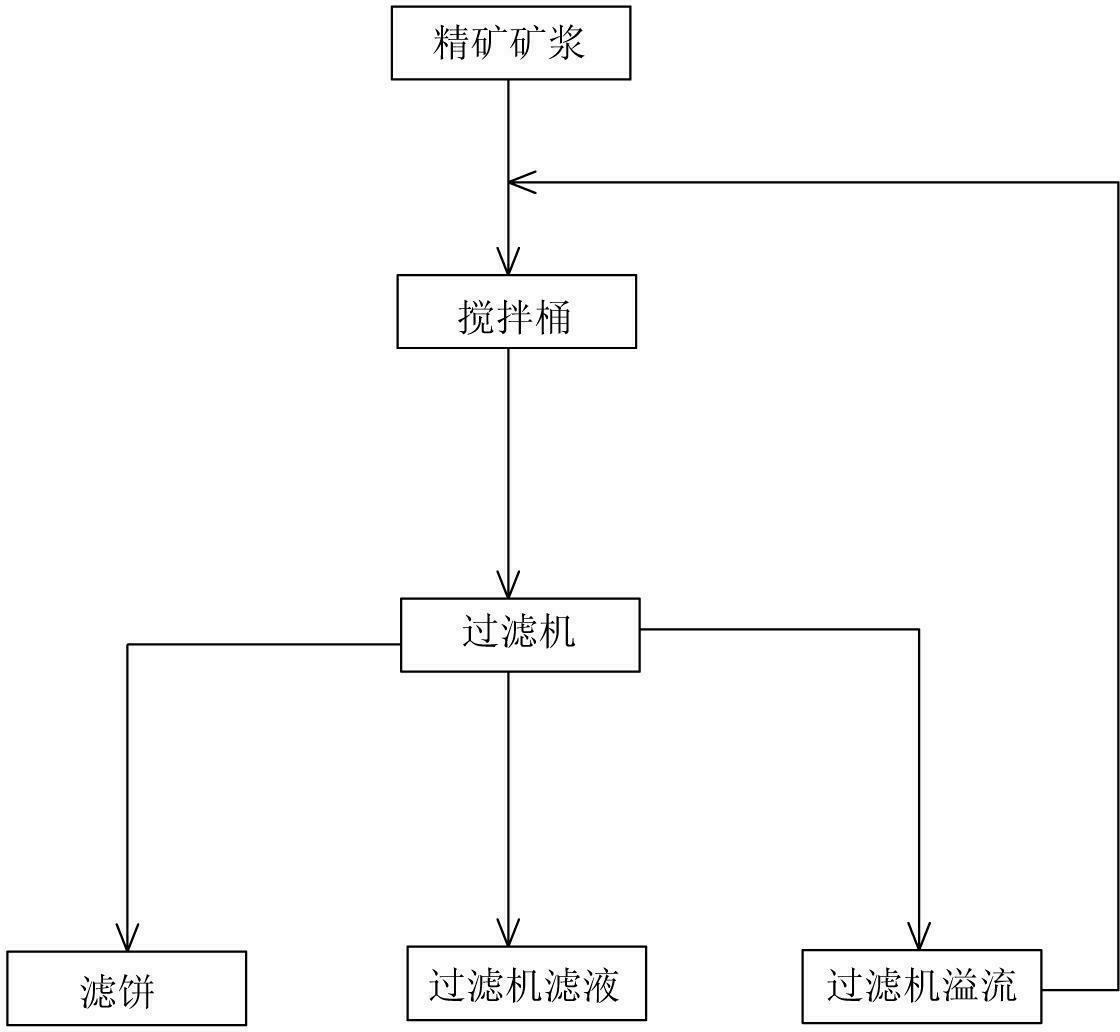

New process for concentrating and dehydrating iron concentrate

InactiveCN102614712AReduce in quantitySimplify the dehydration processMoving filtering element filtersWater treatment systemWater content

The invention discloses a new process for concentrating and dehydrating an iron concentrate. The process is characterized by comprising the following steps of: (a) feeding 55 to 70 percent iron concentrate pulp into a stirring barrel for stirring; (b) feeding the iron concentrate pulp into a filtering machine for dehydrating by using an underflow pump; and (c) obtaining a final product, namely an iron concentrate filter cake with the water content of 8.5 to 9.5 percent, discharging 0.3 to 0.5 percent filtrate into a filtrate pump tank, recycling by using a water treatment system in a dressing plant, and returning 45 to 65 percent overflow of the filtering machine to the stirring barrel to form a closed cycle. The filtrate and the overflow from the filtering machine are treated respectively, so that the process link of concentrating by using a concentrator is eliminated, the process for concentrating and dehydrating the concentrate is simplified, the number of pumps and pipelines and maintenance cost are reduced, and production cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

A kind of separation and purification process of dimethyl carbonate

ActiveCN110372512BImprove applicabilityAvoid backmixingOrganic compound preparationChemical industryExtractive distillationGlycol synthesis

The invention discloses a separation and purification process of dimethyl carbonate. The separation and purification process uses the crude product of coal-based ethylene glycol by-product or the crude product of dimethyl carbonate synthesized by oxidative carbonylation of methanol as raw material. The separation equipment includes belt material Extractive distillation column with side draw of stream stream, two phase separators, methanol distillation column, dimethyl carbonate dehydration column with side draw of material stream stream, several condensers and several reboilers, through extractive distillation-methanol distillation ‑Dimethyl carbonate dehydration three separation units and the continuous operation steps of extractant recycling unit, finally get refined dimethyl carbonate, light component products containing methylal and methyl formate and methanol. The dimethyl carbonate purification process of the present invention has strong raw material applicability, simple process flow, and obvious energy-saving effect through heat coupling.

Owner:TAIYUAN UNIV OF TECH

A kind of dehydration process of water celery

ActiveCN103478216BKeep the green lookPreserve the flavorFruits/vegetable preservation by dehydrationAdditive ingredientFood flavor

The invention relates to the technical field of food processing and preservation and discloses a dewatering process of water cress. The dewatering process comprises the following steps of (1) taking materials; (2) cleaning; (3) secondarily cleaning; (4) disinfecting and protecting color; (5) drying; and (6) weighing and packaging. The dewatering process disclosed by the invention has the advantages that the process is simple, the water in the water cress can be removed by a belt type drying machine, the taste of the old water cress is improved, the dewatered water cress can be stored for one year and is convenient to eat for people; and the green appearance and the original flavor as well as nutritional ingredients of the water cress are retained to greatest extent.

Owner:TONGCHENG GUNIUBEI AGRI DEV

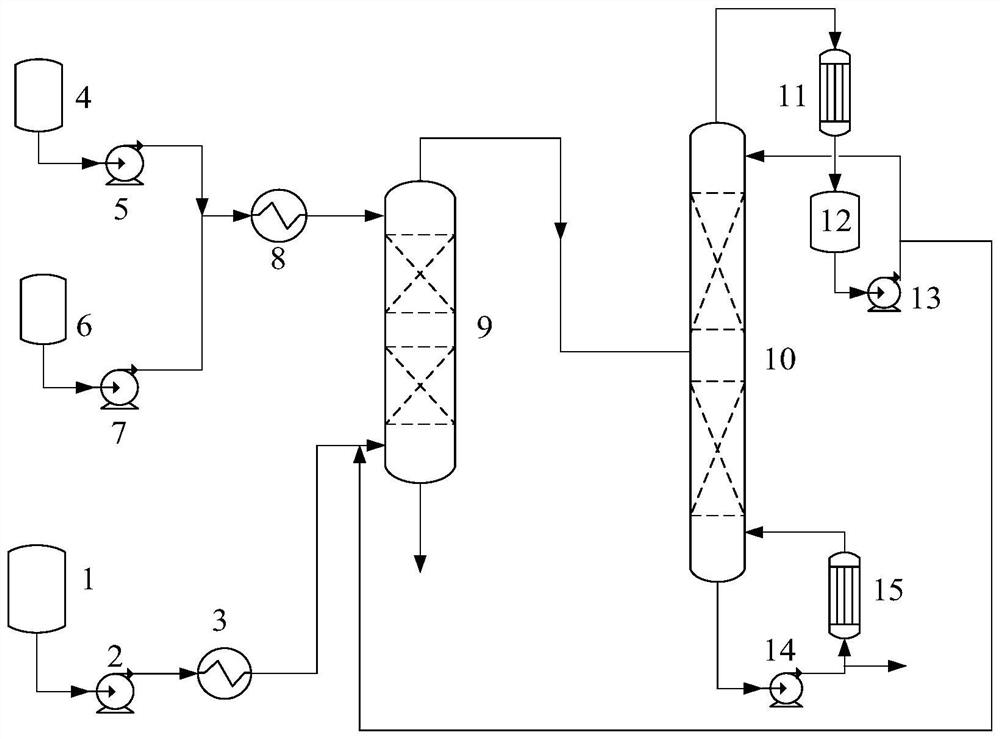

Device system and method for continuously producing alkoxy propane

PendingCN114160050ABreak balance limitImprove conversion rateOrganic chemistryOrganic compound preparationPtru catalystSolid acid

The invention provides a device system and method for continuously producing alkoxy propane, and the method comprises the following steps: carrying out condensation reaction on a raw material solution in a filler reaction extraction tower under the action of a solid acid catalyst, and then carrying out countercurrent contact on the raw material solution and an extraction agent to obtain an extraction phase; and carrying out azeotropic distillation on the extract phase in a product refining tower to obtain a target product. According to the method, modified solid acid is used as a catalyst and is matched with an extracting agent, in-situ separation and removal of byproduct water and promotion of right shift of balance are realized through countercurrent contact, the retention time is short, and the conversion per pass can be improved; besides, in the rectification process, due to the existence of the extraction agent, the product separation process is greatly simplified, the number of equipment and energy consumption are remarkably reduced, and the extraction agent is low in price, easy to obtain, capable of being directly recycled and reused, free of subsequent treatment, green and environmentally friendly and has great market competitive advantages.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

Built-in oil tank heating oil quality control system and quality control method

ActiveCN105480607BRealize automatic monitoringAvoid lostLarge containersTank wagonsWater detectorHeating oil

Owner:SHANDONG PULILONG PRESSURE VESSEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com