Simple method for desiccation and reactivation of aerobic granules

An aerobic granulation and drying technology, which is applied in the direction of granulation of raw materials, drying of granular materials, chemical instruments and methods, etc., can solve the problems of time-consuming, expensive seed granules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Aerobic particles are dense aggregates of microorganisms that self-immobilize without the need for a carrier medium. The aerobic granular sludge process is increasingly recognized as a promising wastewater treatment technology, which has shown advantages in terms of high treatment capacity and significantly reduced equipment footprint and operating costs. However, the relatively long start-up phase remains one of the main challenges of this new technology. Shipping of seed pellets is expensive and time-consuming, especially when the seed pellets are to be transported to another country.

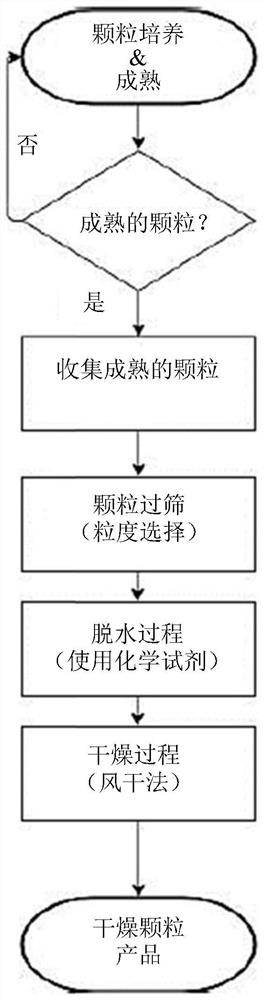

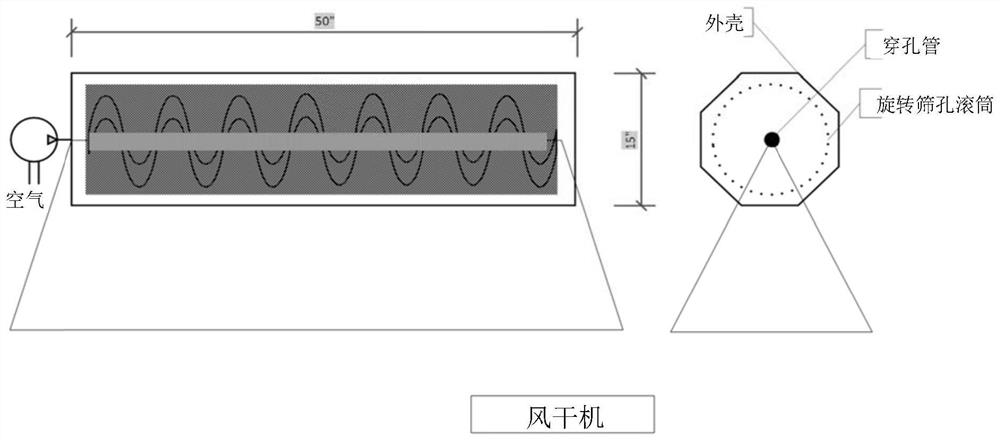

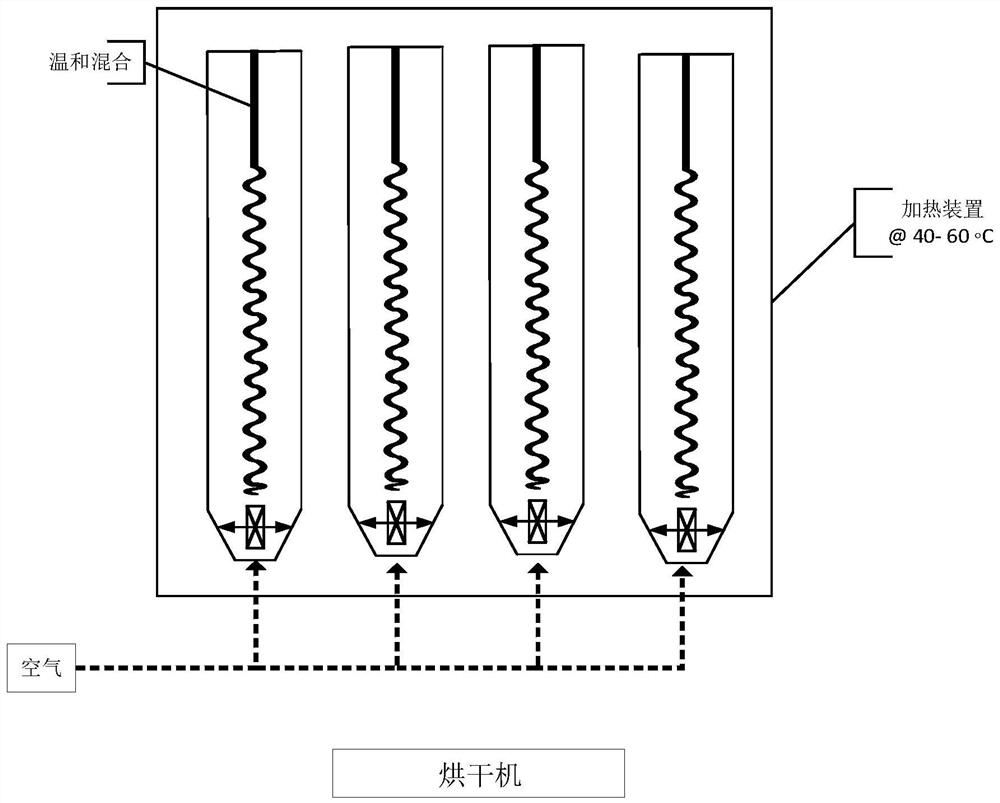

[0029] This article describes a method for drying aerobic granules. In some embodiments, the drying process takes only a few hours. Dried granules are easier to transport and are storage stable for at least 5 months. The drying process is designed to be scalable and to maximize the preservation of the microbial community in the aerobic granules, especially the major functional group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com