Thickened oil three-phase separator used for removing free water and combining thin oil

A three-phase separator and free water technology, which is applied in the direction of separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of affecting the separation effect, high viscosity of heavy oil, affecting production, etc., and achieves a simple dehydration process and an The floor area is small and the effect of improving the dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

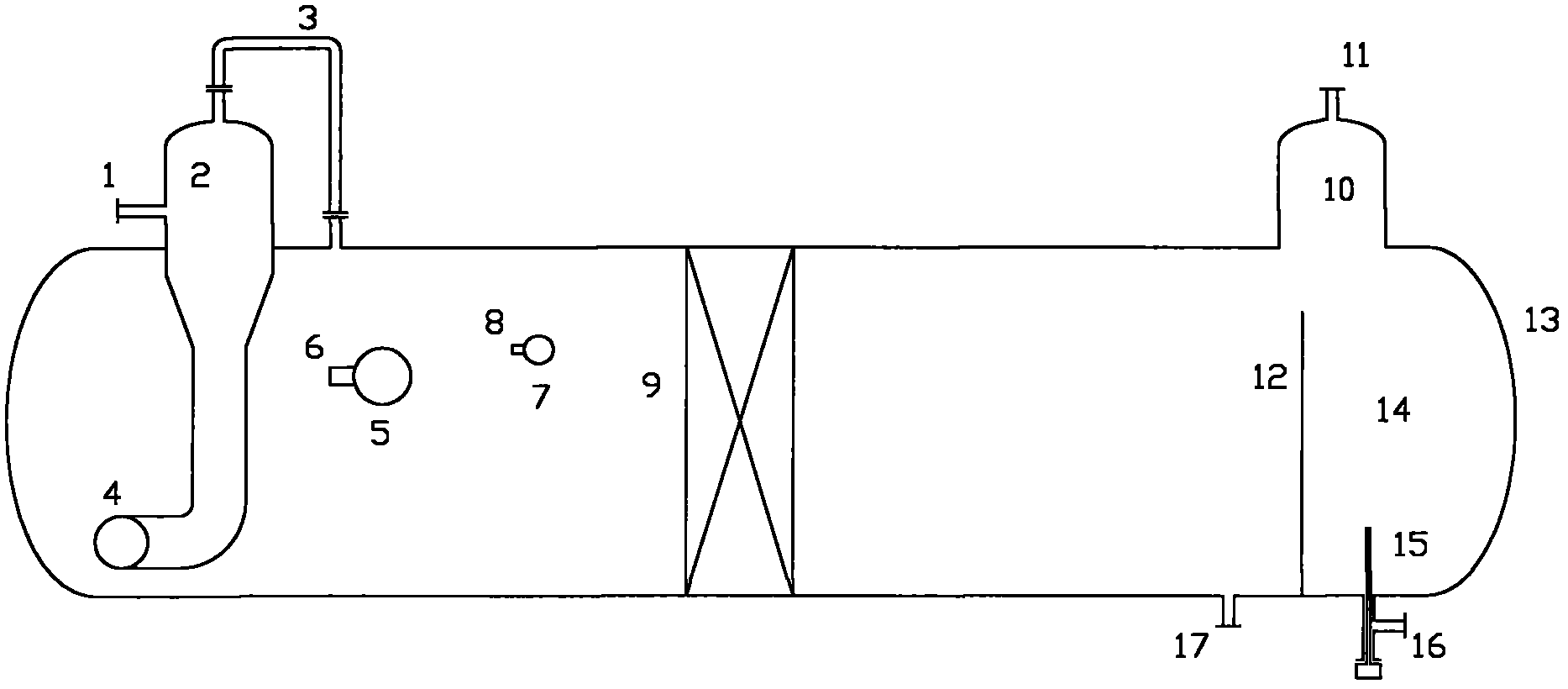

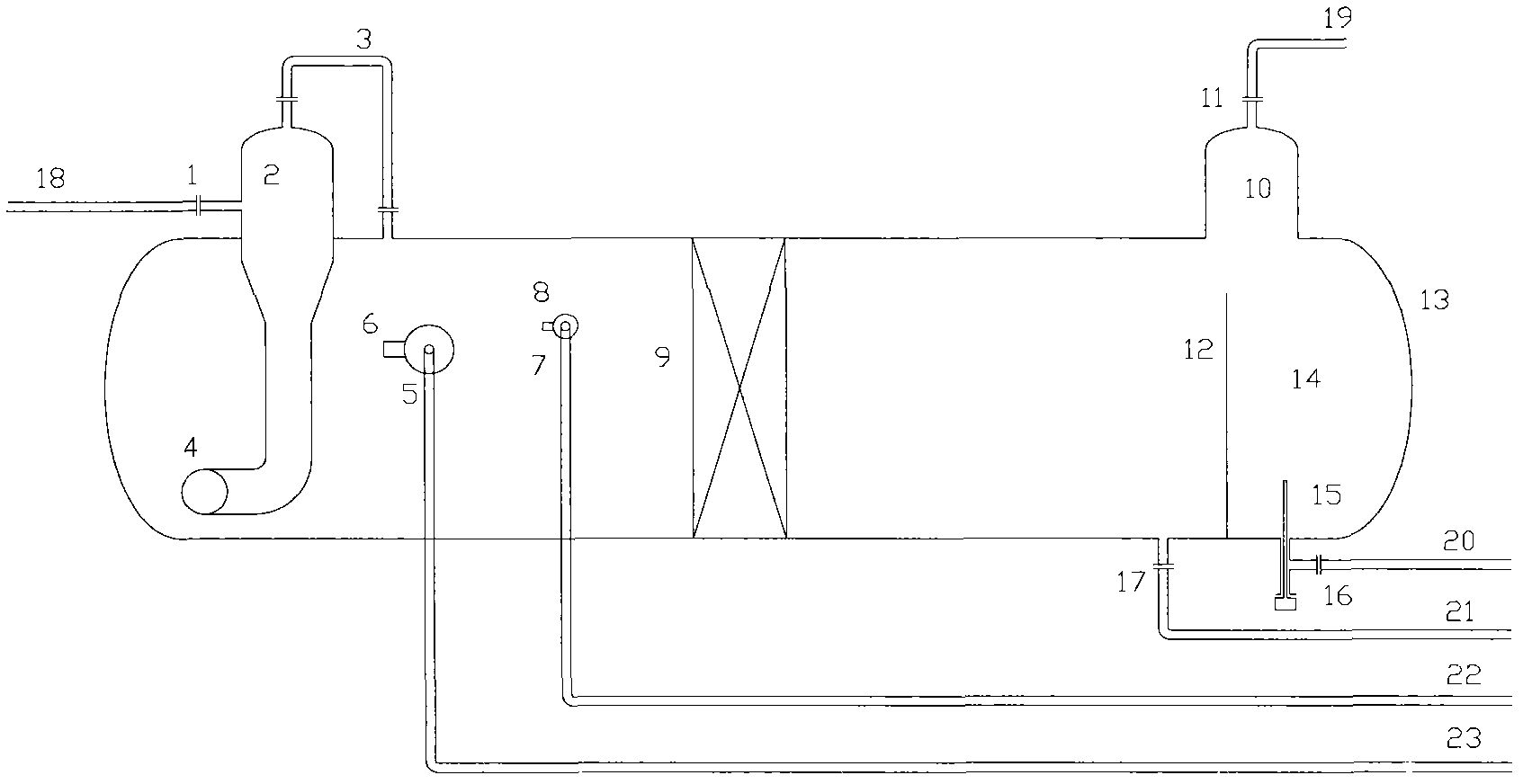

[0015] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the incoming liquid of heavy oil enters the gas-liquid-liquid separation cylinder 2 through the inlet 1, and the incoming liquid is pre-separated by gas-liquid swirl in the gas-liquid-liquid separation cylinder 2, and the separated natural gas enters the upper part of the separation chamber through the gas communication pipe 2, After gas separation, the heavy oil enters the lower part of the separation chamber through the liquid distributor 4 for oil-water separation. After the free water is separated, the heavy oil and sewage will be separated. In the low water content heavy oil layer, a thin oil distributor 5 is installed, and a number of thin oil cloth liquid ports 6 are arranged on the liquid distributor 5, so that the thin oil can be evenly mixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com