Sedimentation, classified reverse filtering and dewatering and dry stacking method for fine grained tailings

A technology for fine-grained tailings and tailings is applied in the field of treatment and disposal of fine-grained tailings. , The effect of less equipment maintenance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

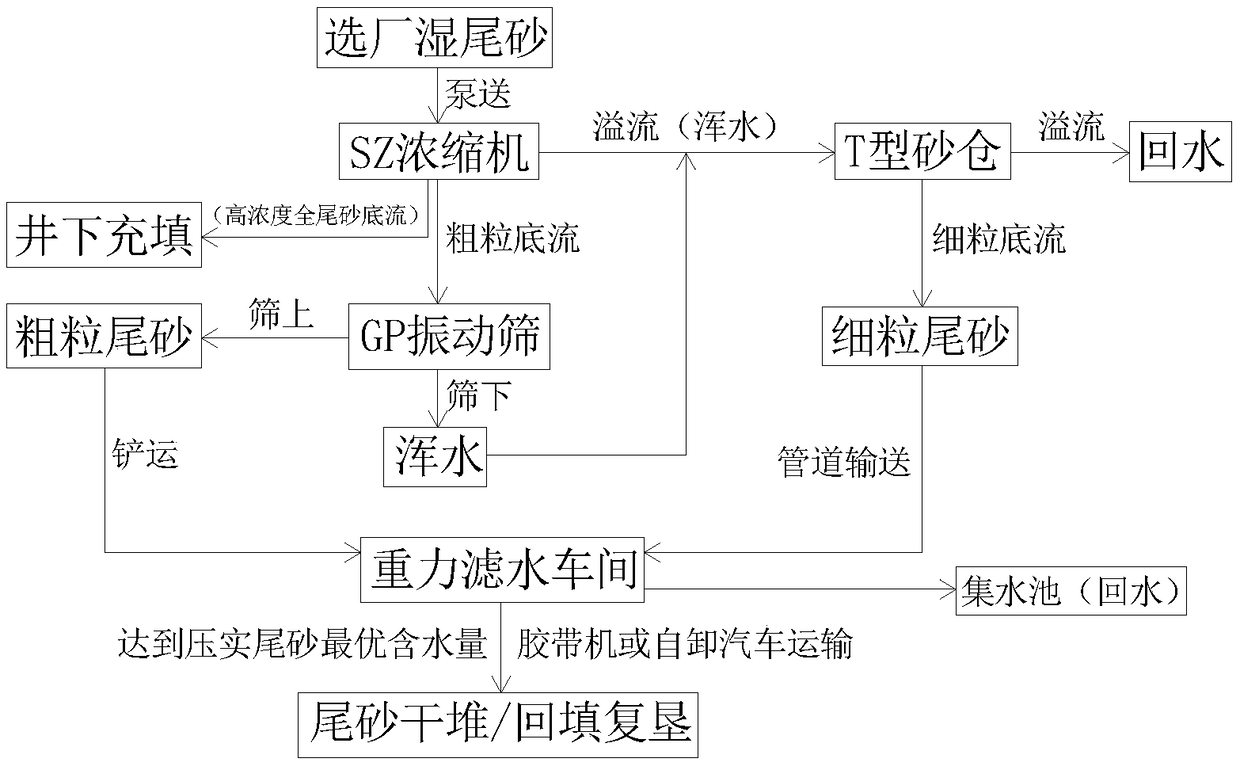

[0024] In order to further describe the present invention, the comprehensive disposal method of dry stacking, backfill reclamation or underground filling of fine tailings of the present invention will be further described in detail in conjunction with the accompanying drawings and examples.

[0025] Depend on figure 1 The principle process flow chart of the comprehensive disposal method of the dry stacking, backfill reclamation or underground filling of the fine-grained tailings shown in the present invention finds out that the fine-grained tailings settlement classification reverse filtration dehydration dry stacking method of the present invention adopts the following steps:

[0026] (1) The whole tailings (weight concentration ~ 20%) discharged from the dressing plant with a moisture content of ~ 80% are pumped through pipelines to the SZ concentrator (i.e. deep cone concentrator, below) for concentration and dehydration. The SZ concentrator There are 2 ore discharge pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com