Built-in oil tank heating oil quality control system and quality control method

A technology for controlling system and oil quality, applied to tank cars, transport passenger cars, railway car body parts, etc., can solve problems such as user losses, environmental pollution, leakage, etc., achieve automatic monitoring, simplify the dehydration process, and save losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

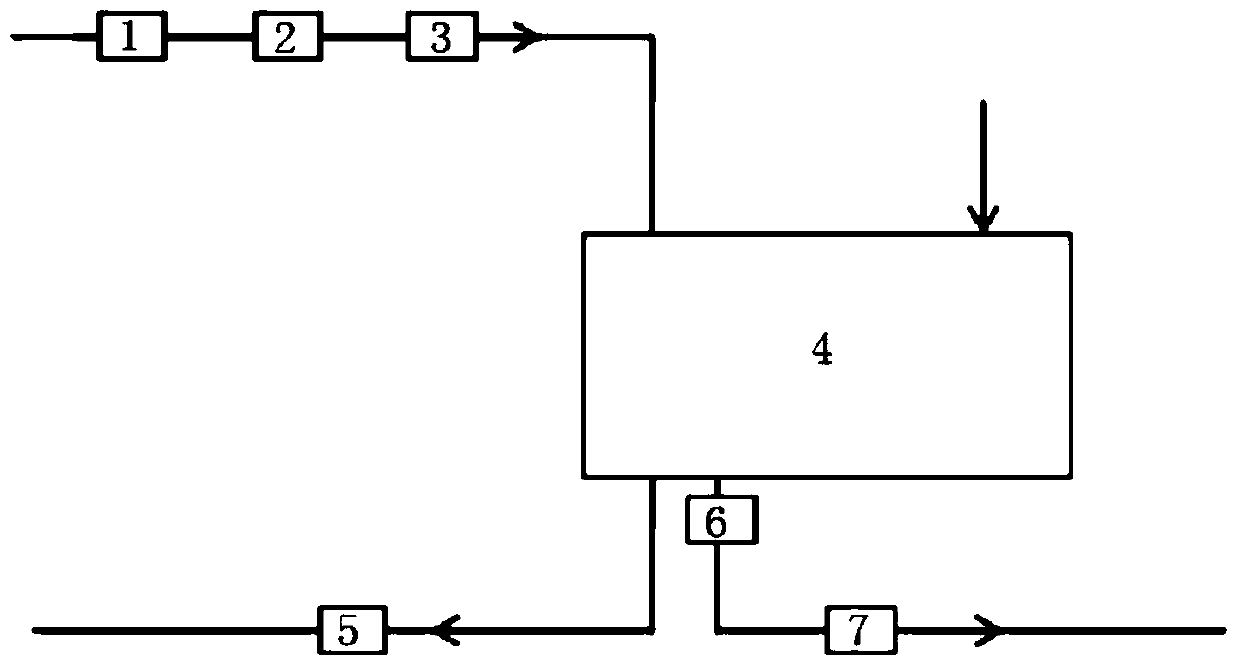

[0042] A built-in oil tank heating oil quality control system, including a storage tank 4, a heater arranged inside the storage tank 4, a steam inlet pipe and a steam outlet pipe connected to the heater, and an oil inlet pipe connected to the storage tank 4 And the oil outlet pipeline, the steam on-off valve 1 is arranged on the steam inlet pipeline, the oil on-off valve 6 is arranged on the oil inlet pipeline of the storage tank 4, and the first moisture detector 8 is arranged on the oil outlet pipeline; the steam on-off valve 1, the first moisture detector Instrument 8 and oil switch valve 6 are all connected with the control system.

[0043] The steam inlet pipeline is also provided with a flow regulating valve 2, and the oil outlet of the storage tank 4 is provided with a temperature sensor 7, and both the flow regulating valve 2 and the temperature sensor 7 are connected to the control system.

[0044]The heater heats the lubricating oil in the storage tank 4, and when he...

Embodiment 2

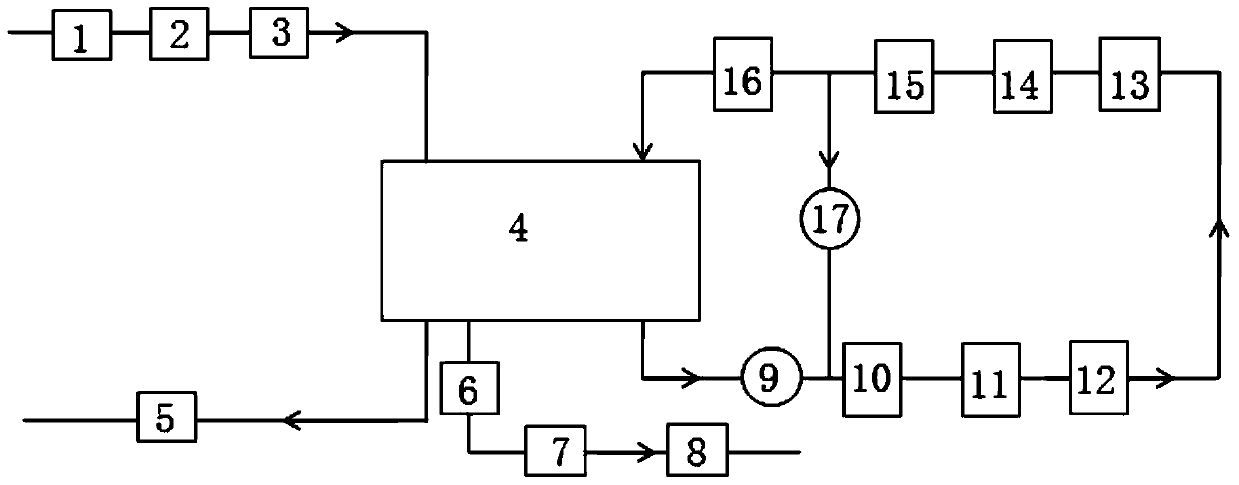

[0049] Such as figure 2 As shown, the above-mentioned built-in oil tank heating oil quality control system also includes a lubricating oil dehydration treatment system, including a first oil pump 11, a heater 12 and a demulsification dehydration separator 13 connected in sequence, the first oil pump 11 and The demulsification and dehydration separators 13 are all in communication with the interior of the storage tank 4 . The switch valve 9, the second moisture detector 10, and the first oil pump 11 are connected with the control system. The third moisture detector 14, the second oil pump 15, the valve one 16, and the valve two 17 are connected with the control system. The demulsification and dehydration separator 13 is equipped with a liquid level gauge, which is connected with the control system.

[0050] When the moisture in the oil detected by the third moisture detector 14 has not reached the standard, the control system starts the second oil pump 15, closes the valve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com