Device system and method for continuously producing alkoxy propane

A technology of alkoxypropane and feeding device, which is applied in separation methods, chemical instruments and methods, distillation separation, etc., can solve the problems of inability to directly obtain high-purity products, lower single-pass conversion rate, and high requirements for heat transfer equipment, and achieve Avoid ultra-low temperature or high vacuum operating conditions, high selectivity, low equipment investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

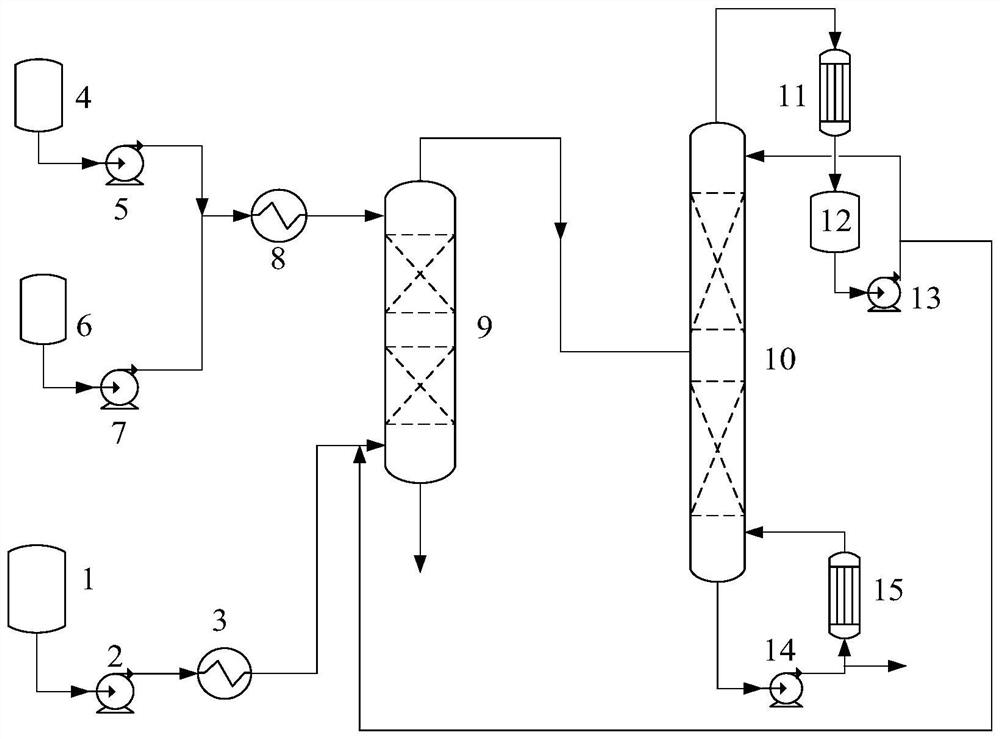

[0094] This embodiment provides a figure 1 The device system for the continuous production of alkoxypropane shown, the device system includes a feed unit connected in sequence, a packing reaction extraction tower 9 and a product refining tower 10;

[0095] The feeding unit includes an extraction agent feeding device and a raw material feeding device;

[0096] The extractant feeding device is connected with the extractant inlet at the bottom of the packing reaction extraction tower 9 towers;

[0097] The raw material feeding device is connected with the raw material inlet at the top of the packed reactive extraction tower 9;

[0098] The material outlet of the packing reactive extraction tower 9 is connected with the material inlet of the product refining tower 10 .

[0099] The extractant feeding device comprises an extractant storage tank 1, an extractant delivery pump 2 and an extractant heat exchanger 3 connected in sequence; the outlet of the extractant heat exchanger 3 ...

Embodiment 2

[0106] This embodiment provides a device system for the continuous production of alkoxypropane. The device system is the same as that of Embodiment 1 except that the number of theoretical plates of the plate distillation column is replaced by 55.

Embodiment 3

[0108] This embodiment provides a device system for the continuous production of alkoxypropane. In the device system, the plate rectification tower is changed to a packed rectification tower, and the number of theoretical plates of the packed rectification tower is changed to 50 , all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com