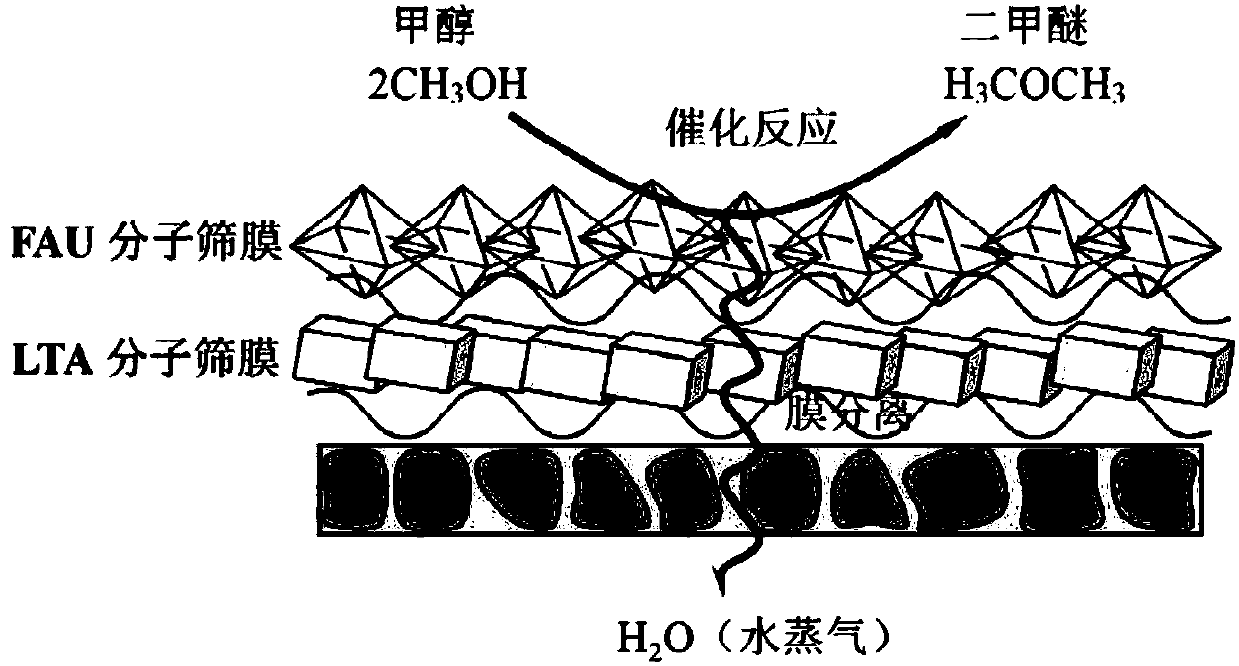

A kind of reaction separation bifunctional catalytic membrane reaction device for catalyzing methanol dehydration to prepare dimethyl ether and its application

A technology of dual-functional catalysis and reaction device, which is applied in the dehydration of hydroxyl-containing compounds to prepare ethers, chemical/physical/physical-chemical fixed reactors, ether preparations, etc., which can solve the problem of dual-functional coupling and single reaction that cannot be satisfied at the same time. or issues like separating functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

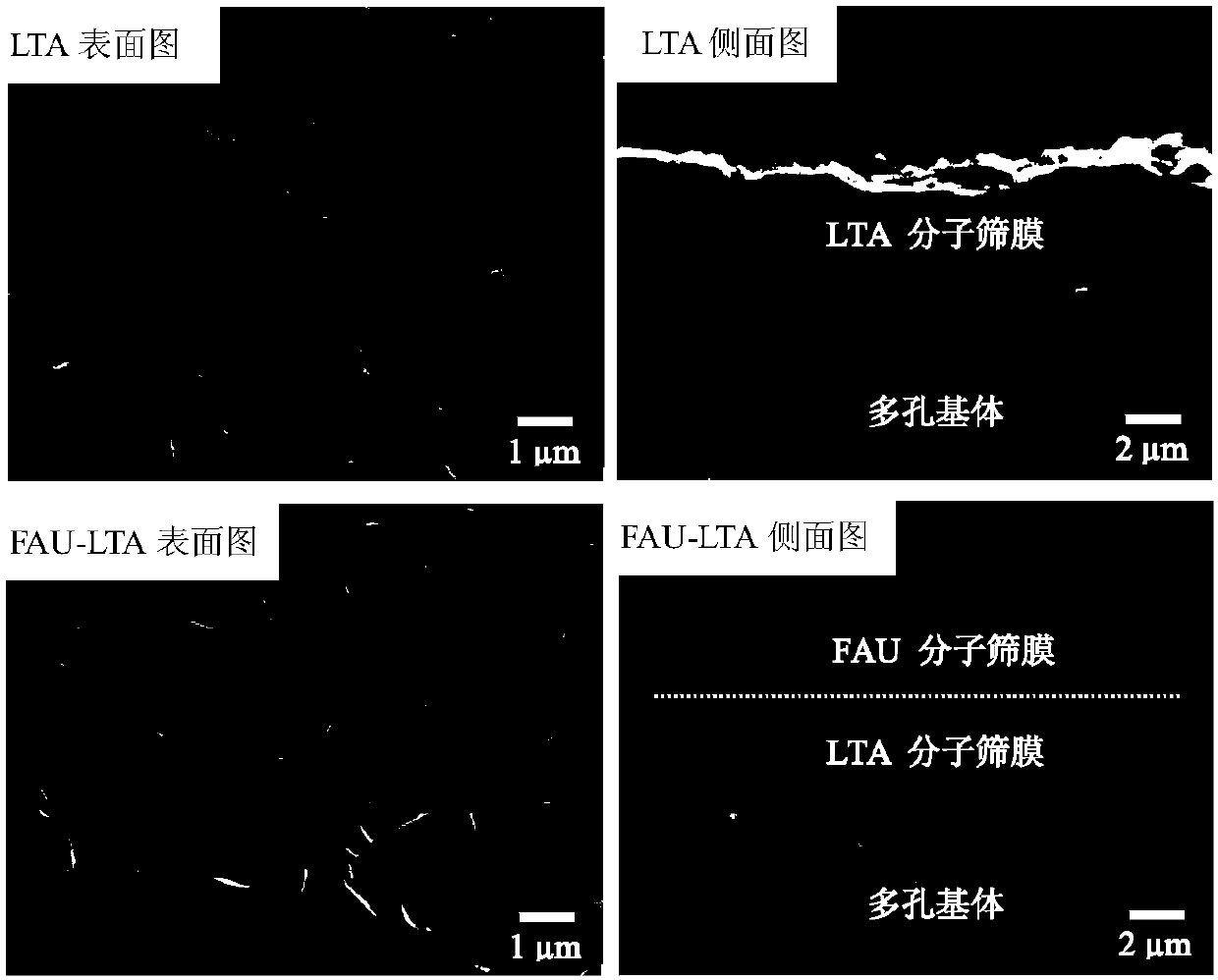

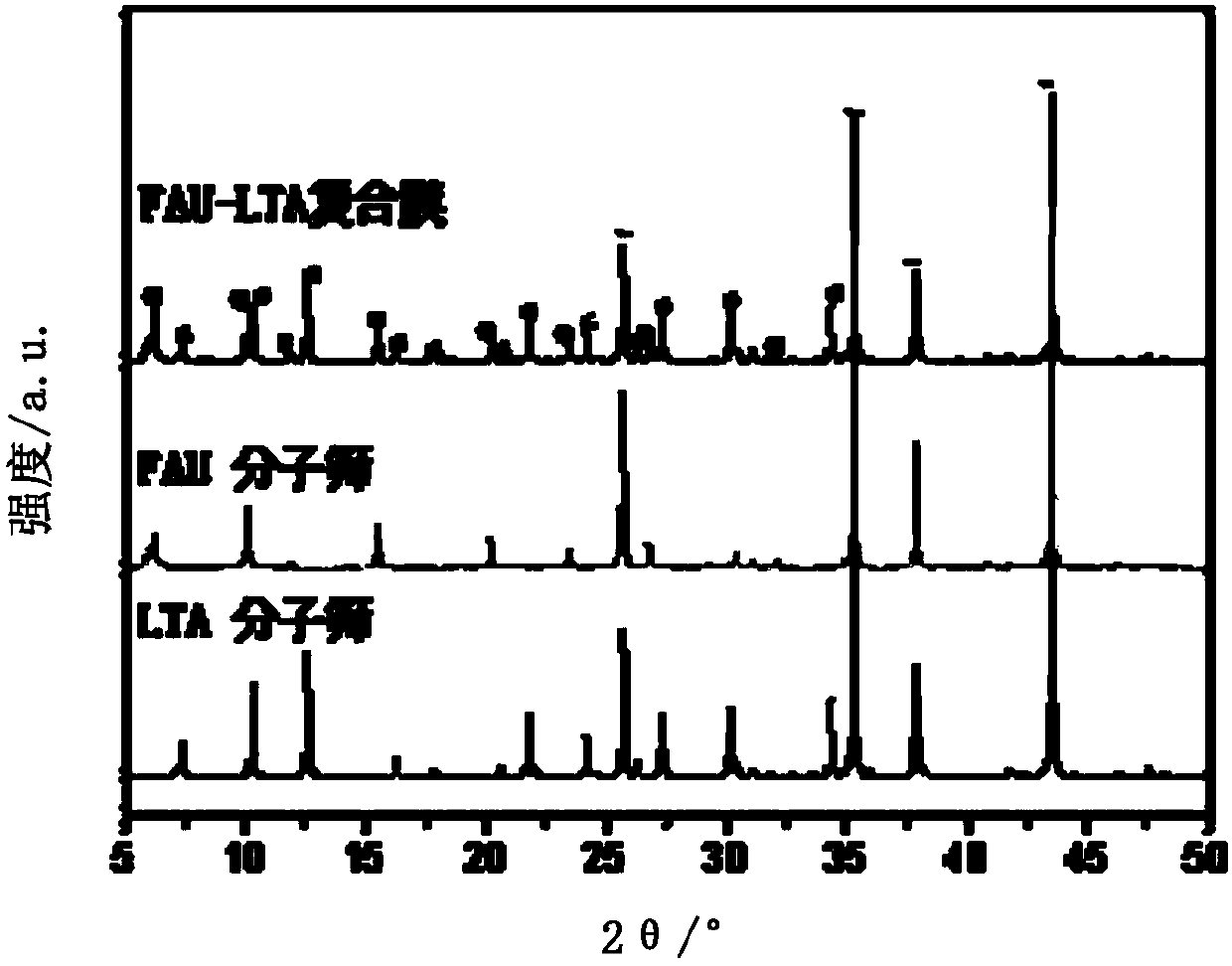

[0124] Embodiment 1FAU-LTA molecular sieve membrane catalytic reactor 1

[0125] making process

[0126] Step 1. Functional modification of porous matrix

[0127] The substrates of synthetic molecular sieve membranes such as porous alumina ceramics, porous titania ceramics, porous stainless steel and stainless steel mesh were respectively placed in 0.2 mol / L organic solvents such as APTES, DICB, CPTMS, CPTCS, CPDMS, CPCS, BPTMS, BPPCS and IPTMS. In the toluene solution of silane, react at 110°C for 0.5~3h, so as to introduce -NH on the surface of the substrate 2 , -NCO, -Cl, -Br and -I and other organic functional groups to form a functionally modified porous matrix for molecular sieve membrane synthesis.

[0128] Step 2, prepare the synthetic solution of molecular sieve membrane

[0129] Weigh a certain amount of NaOH and dissolve it in distilled water, add aluminum foil after clarification, and stir to form an aluminum solution; measure a certain amount of silica sol and ...

Embodiment 2

[0148] Embodiment 2FAU-LTA molecular sieve membrane catalytic reactor 2

[0149] The preparation process is the same as in Example 1, except that the ion exchange time in step 6 is 36 hours.

[0150] The performance testing process is the same as that in Example 1, except that the raw material flow rate is 0.20 g / h.

Embodiment 3

[0151] Embodiment 3FAU-LTA molecular sieve membrane catalytic reactor 3

[0152] The preparation process is the same as in Example 1, except that the ion exchange time in step 6 is 48 hours.

[0153] The performance testing process is the same as in Example 1, except that the flow rate of the raw material is 0.25 g / h, and the long-term stability of the catalyst is tested at 280°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com