Patents

Literature

82results about How to "The refining process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

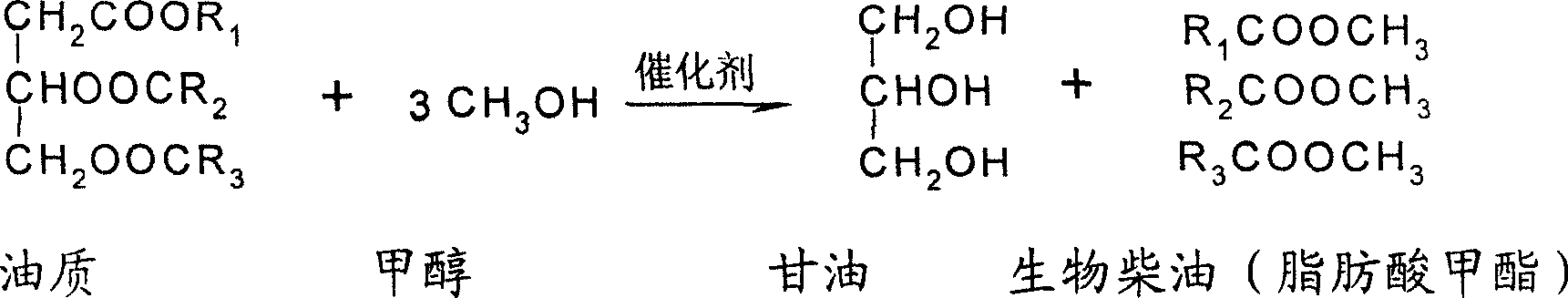

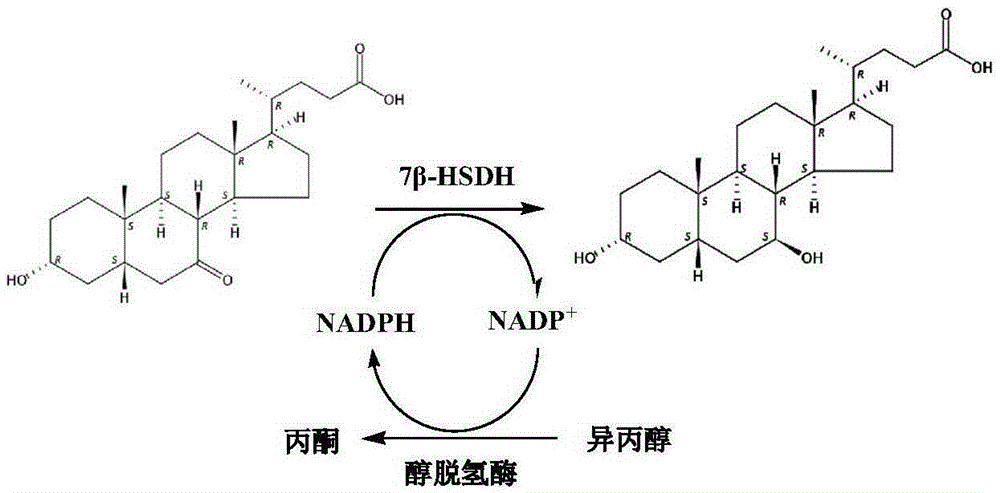

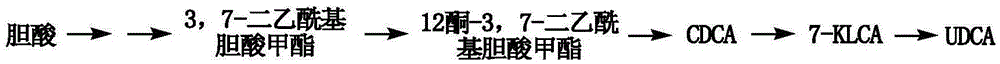

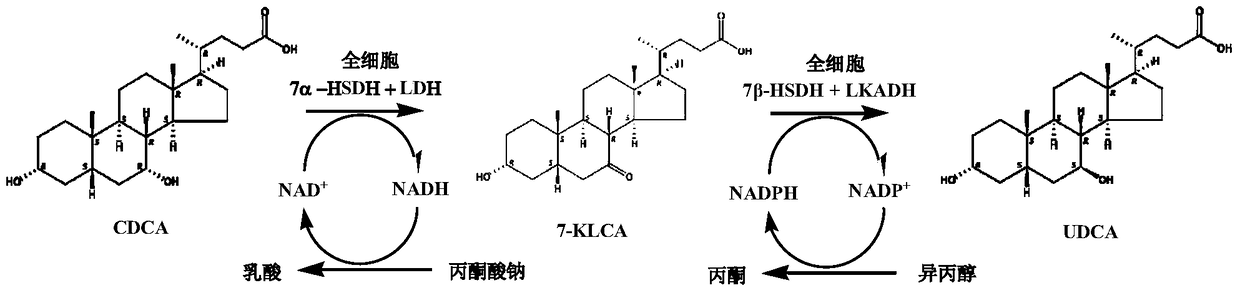

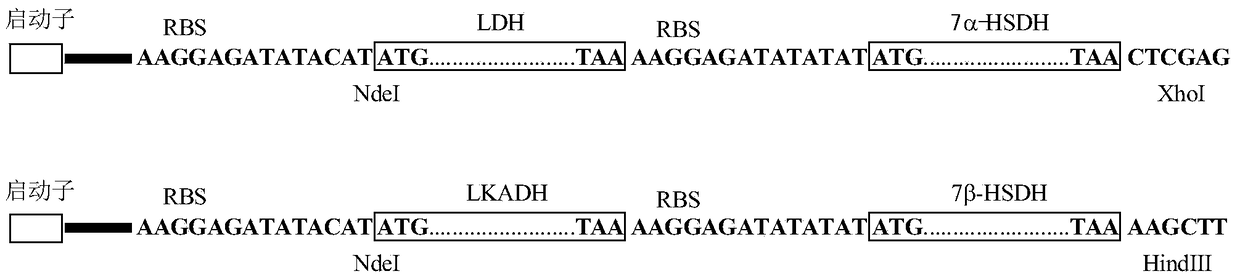

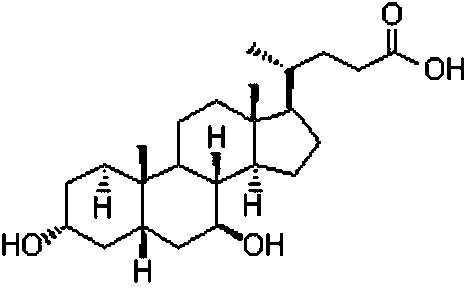

Method for catalyzing chenodeoxycholic acids to compound ursodesoxycholic acids through efficient whole-cells

ActiveCN105368828AFermentation methods are cheap and readily availableSuitable for industrial productionBacteriaMicroorganism based processesChemical synthesisLactate dehydrogenase

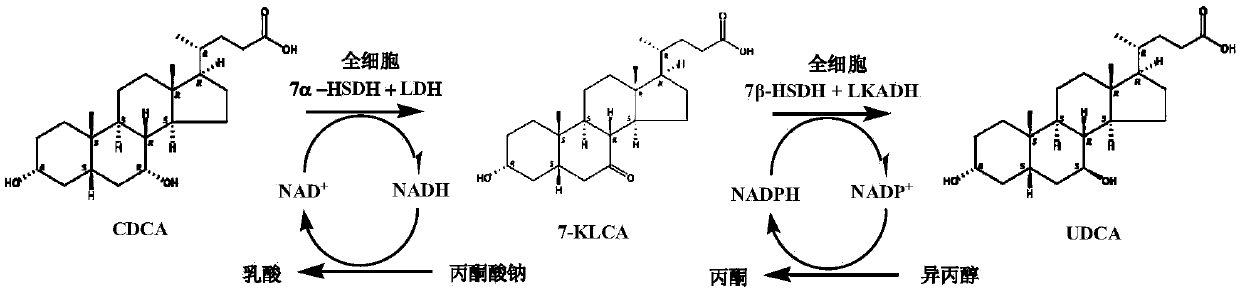

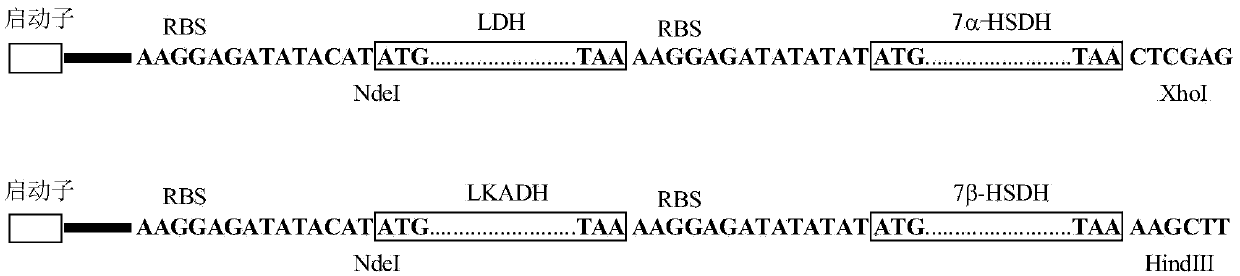

The invention provides a method for catalyzing chenodeoxycholic acids to compound ursodesoxycholic acids through efficient whole-cells. A 7a-hydroxysteroid dehydrogenase (7a-HSDH) and a lactic dehydrogenase (LDH) for regeneration of coenzyme nicotinamide adenine dinucleotide (NAD) are efficiently co-expressed in escherichia coli, escherichia coli whole cells are used to catalyze chenodeoxycholic acids (CDCA) to generate 3 alpha (Alpha)-hydroxyl-7-oxo-5bata (Beta)- cholanic acids (7-KLCA), and a reaction liquid which is obtained by catalyzing the chenodeoxycholic acids through whole cells is adjusted to be 7-KLCA crude products. Reconstitution cells can be easily obtained in low cost through a fermentation process, are better than a chemical synthesis method in production cost and product quality, and are suitable for commercial process.

Owner:苏州天绿生物制药有限公司

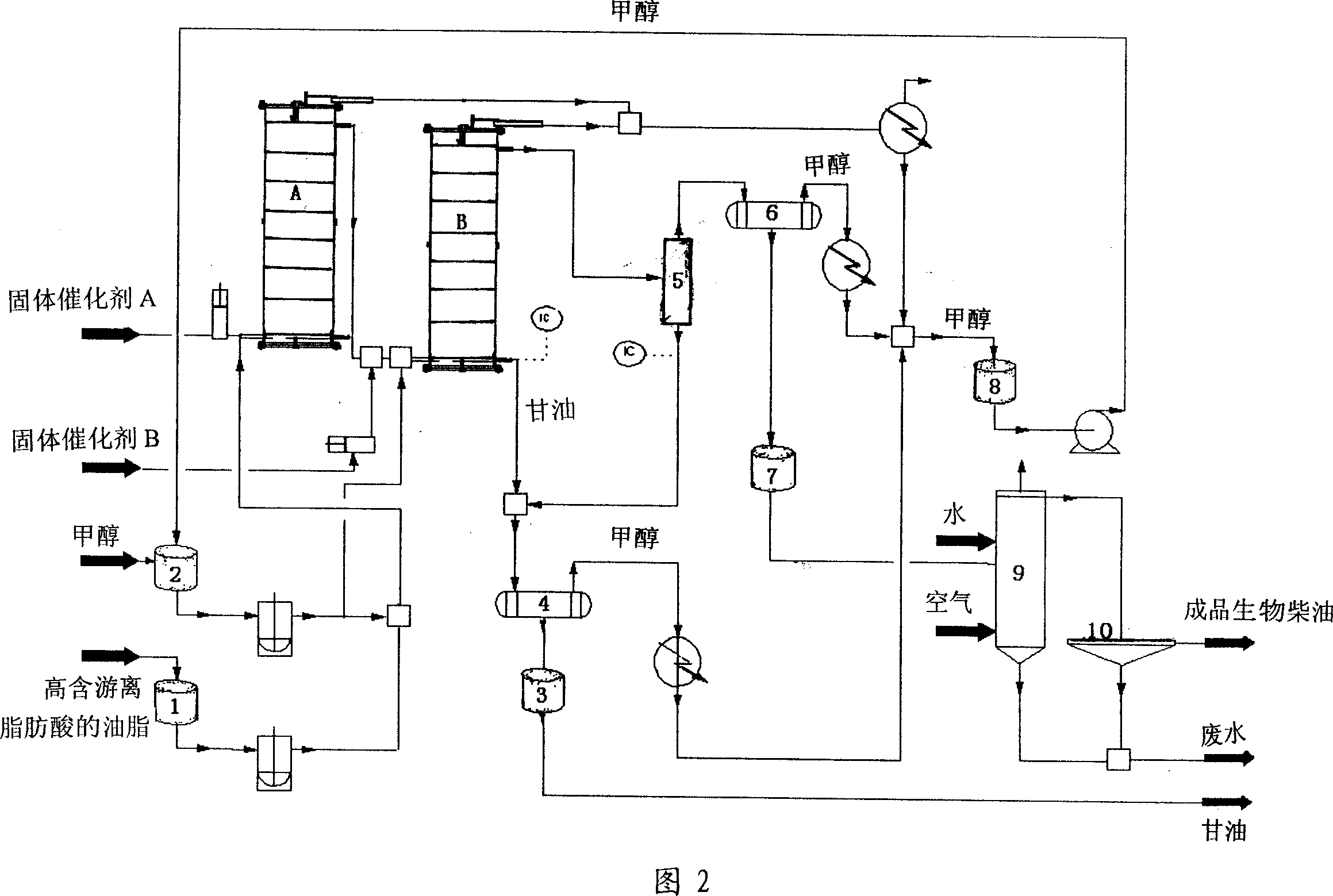

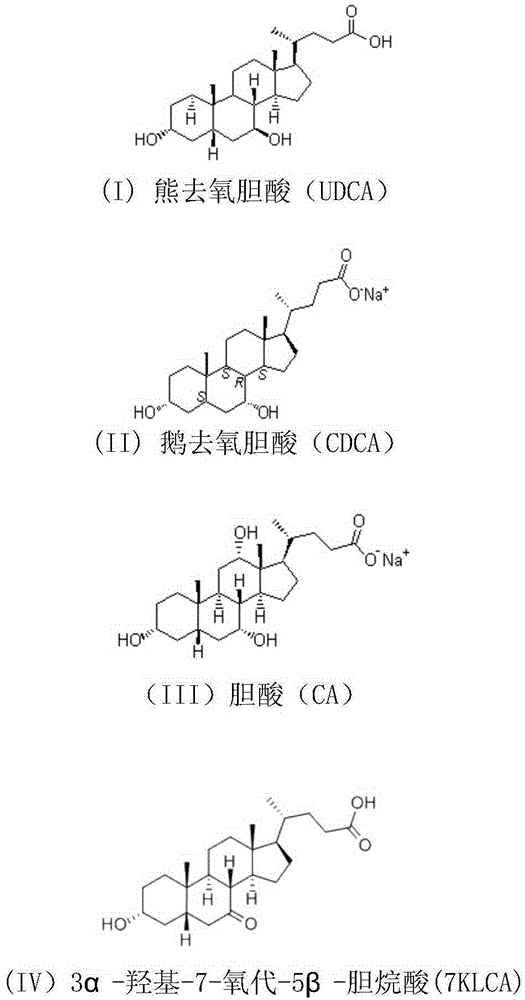

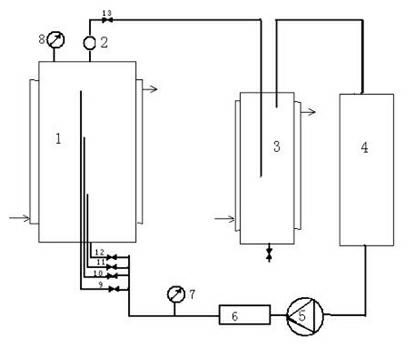

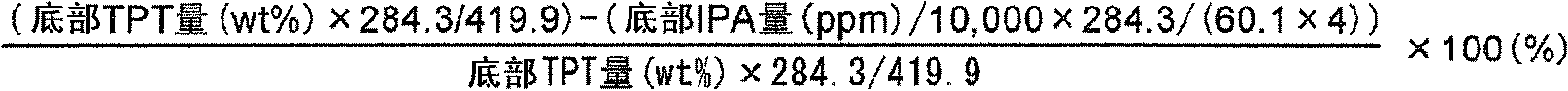

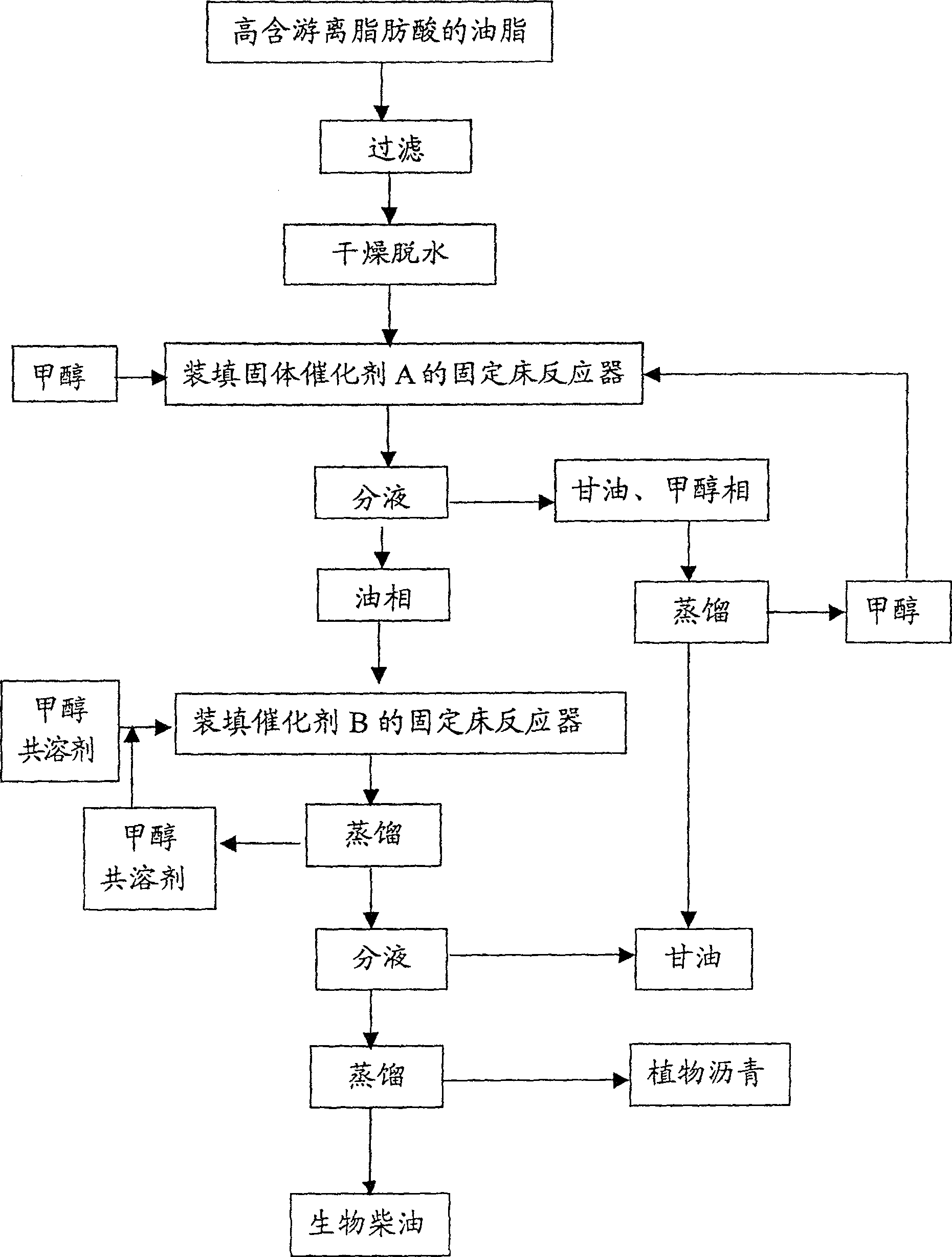

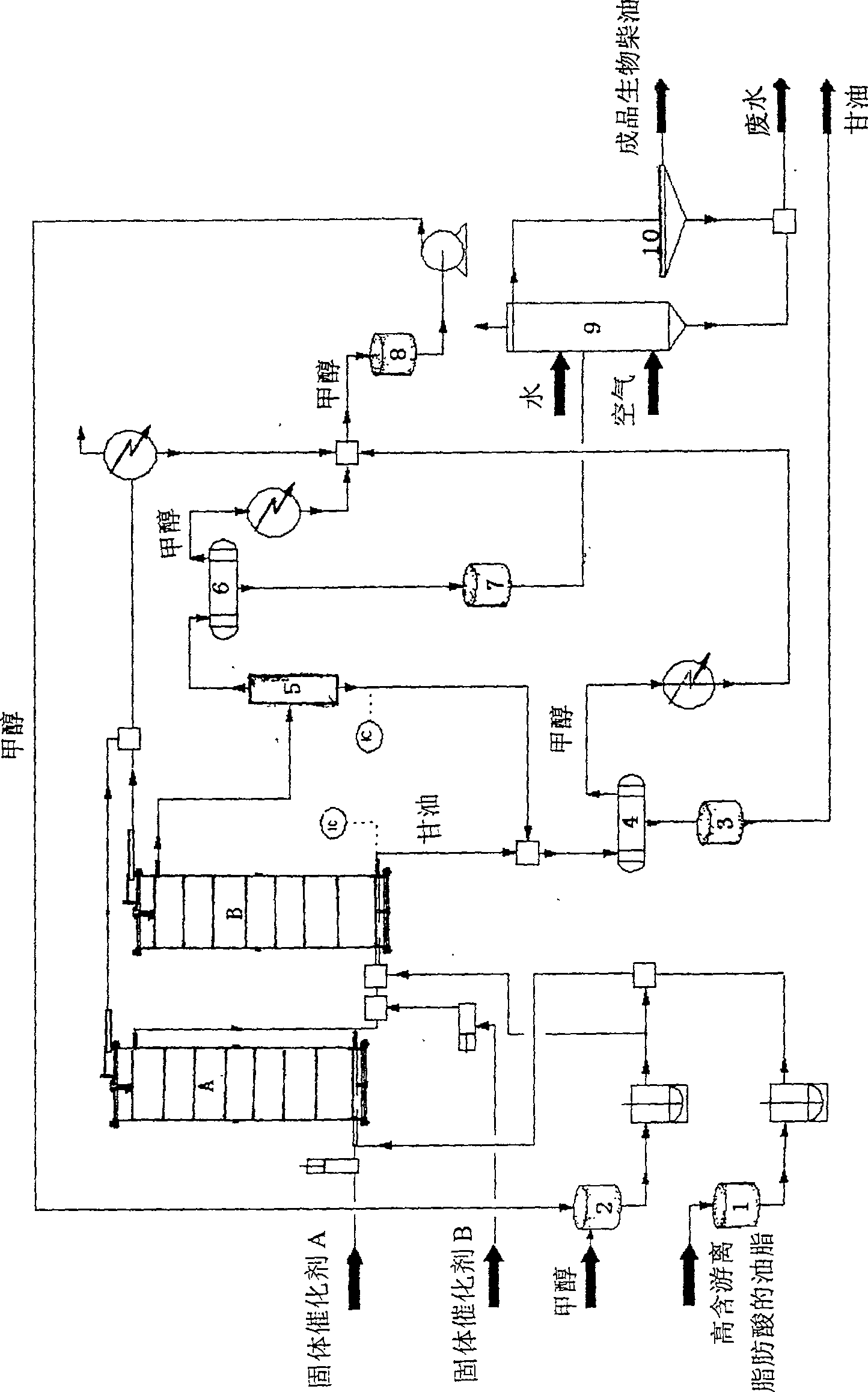

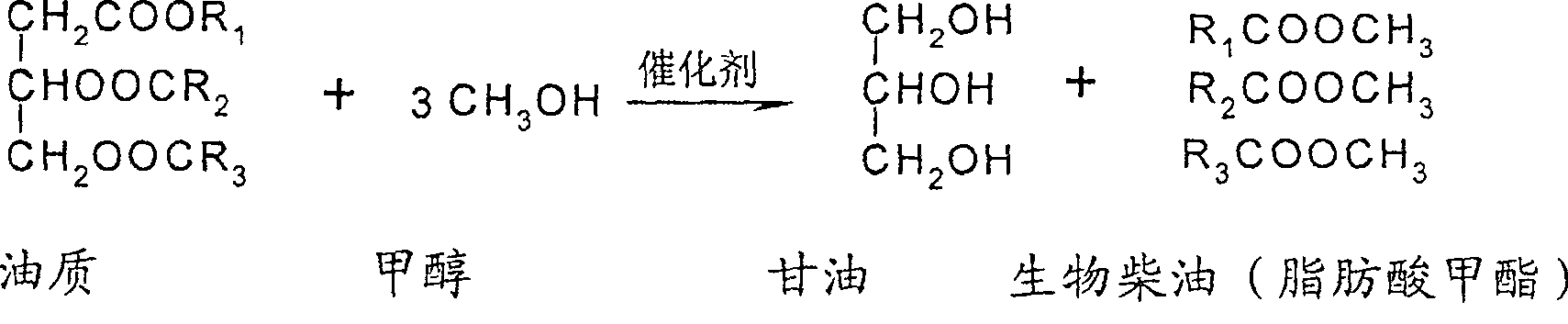

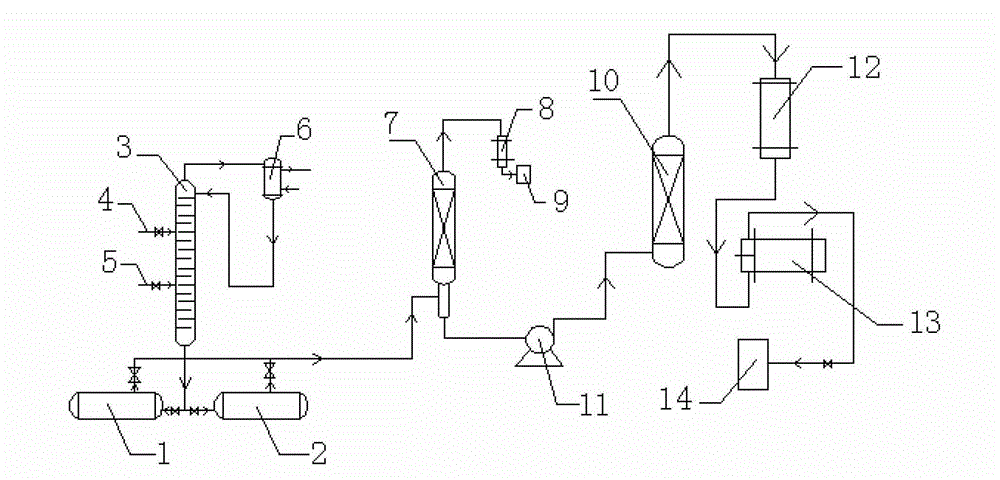

Preparation method of biological diesel oil

InactiveCN1928016AHigh catalytic activityLower activation energyBiofuelsLiquid hydrocarbon mixture productionSolventGlycerol

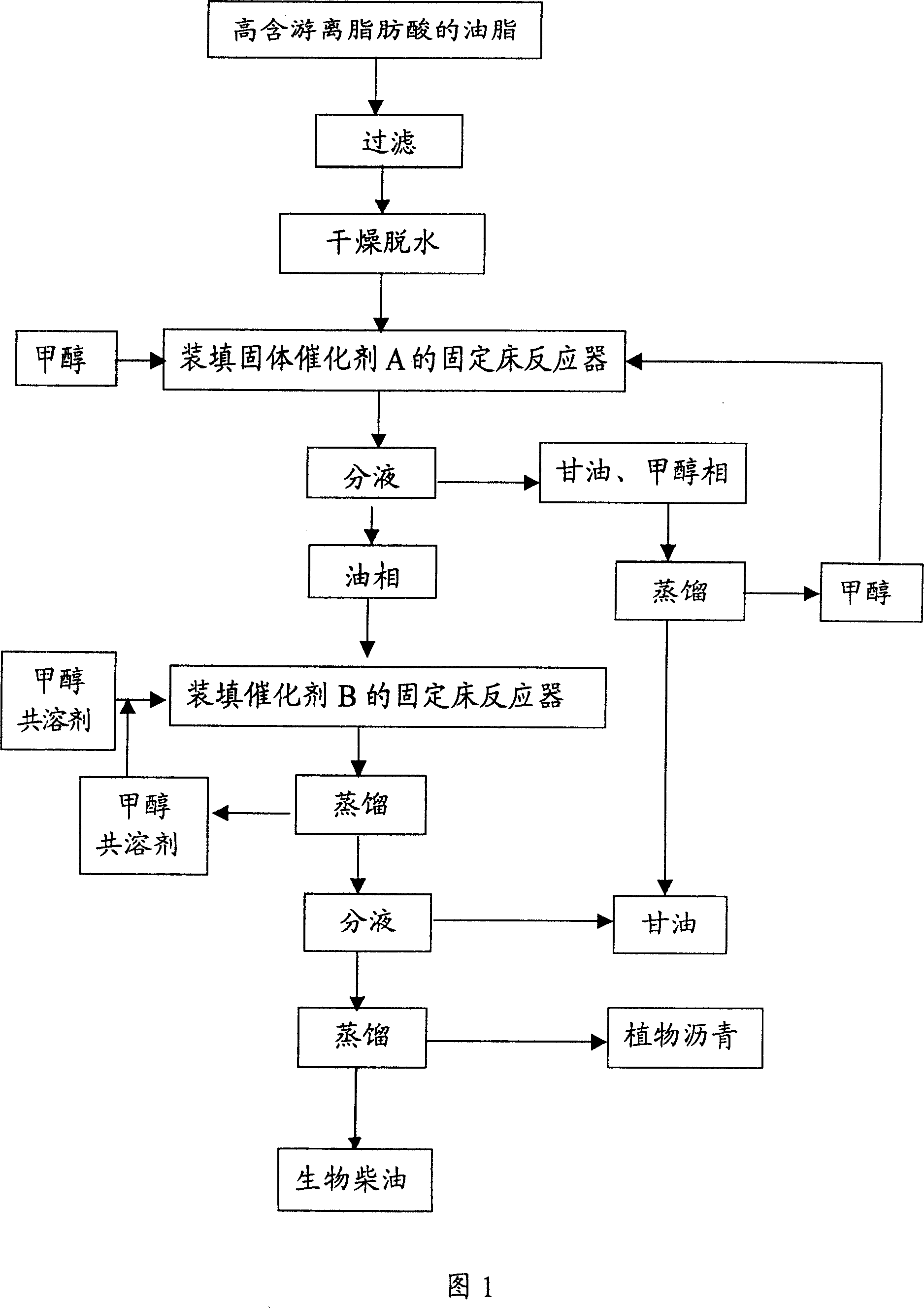

The present invention relates to biodiesel oil preparing process, and provides one biodiesel oil preparing process with solid acid and solid alkali as catalyst to lower the activating energy and raise the reaction speed. The biodiesel oil preparing process includes the following steps: reacting dried grease with high free fatty acid content, methanol or ethanol, and cosolvent in the molar ratio of 1 to 6-1 to 6.05 in the first fixed bed reactor with solid catalyst A at 60-65 deg.c for about 3 hr; separating the oil phase from others; reacting the oil phase in the second fixed bed reactor with solid catalyst B with methanol or ethanol and cosolvent at 60-65 deg.c for about 3 hr; distilling out methanol or ethanol and cosolvent; separating the biodiesel oil from glycerin phase; and distilling the biodiesel oil phase to obtain biodiesel oil product. The catalyst of the present invention has high catalytic activity and can lower the activating energy and raise the reaction speed.

Owner:张海军

Mutant of 7 beta-hydroxyl steroid dehydrogenase, application of mutant and synthesis method

ActiveCN105274070ASuitable for industrial productionEasy to controlOxidoreductasesFermentationChemical synthesisCholic acid

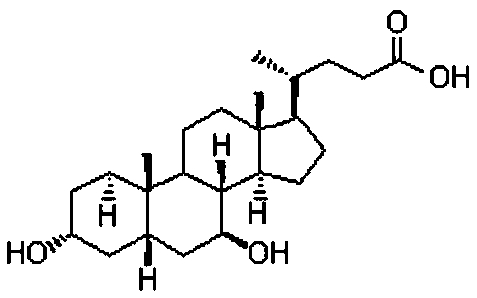

The invention provides a mutant of 7 beta-hydroxyl steroid dehydrogenase, application of the mutant and a synthesis method. The mutant of the 7 beta-hydroxyl steroid dehydrogenase is characterized in that amino acid sequences of the mutant are Seq ID NO:4, and coded nucleotide sequences are Seq ID NO:3; or amino acid sequences of the mutant are Seq ID NO:6, and coded nucleotide sequences are Seq ID NO:5. The mutant, the application and the synthesis method have the advantages that cholic acid compounds, particularly ursodeoxycholic acid, can be catalytically synthesized by the efficient 7 beta-hydroxyl steroid dehydrogenase, mutant enzymes of the 7 beta-hydroxyl steroid dehydrogenase and coenzyme regeneration systems, accordingly, the substrate concentration can reach 100 g / L, the conversion rate is 99.2-99.5%, and the weight yield can reach 94-96%; and the enzymes can be inexpensively and easily obtained by the aid of a fermentation process, accordingly, the production cost and the product quality are superior to the production cost and the product quality of chemical synthesis methods, and the mutant and the synthesis method are applicable to industrial production.

Owner:苏州天绿生物制药有限公司

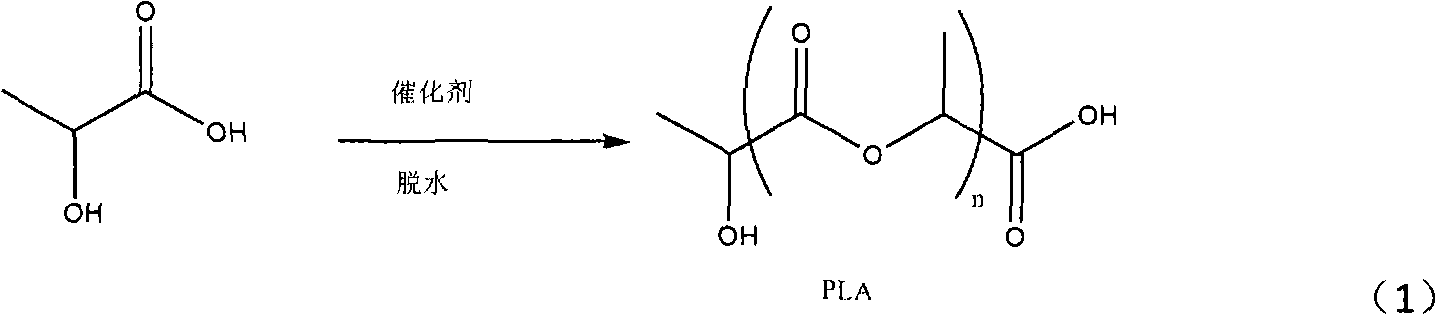

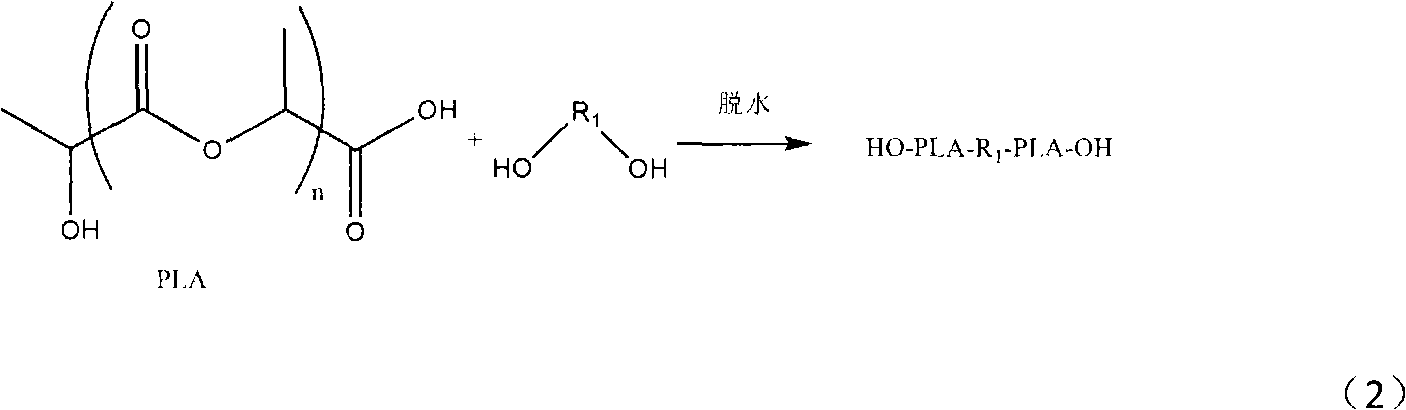

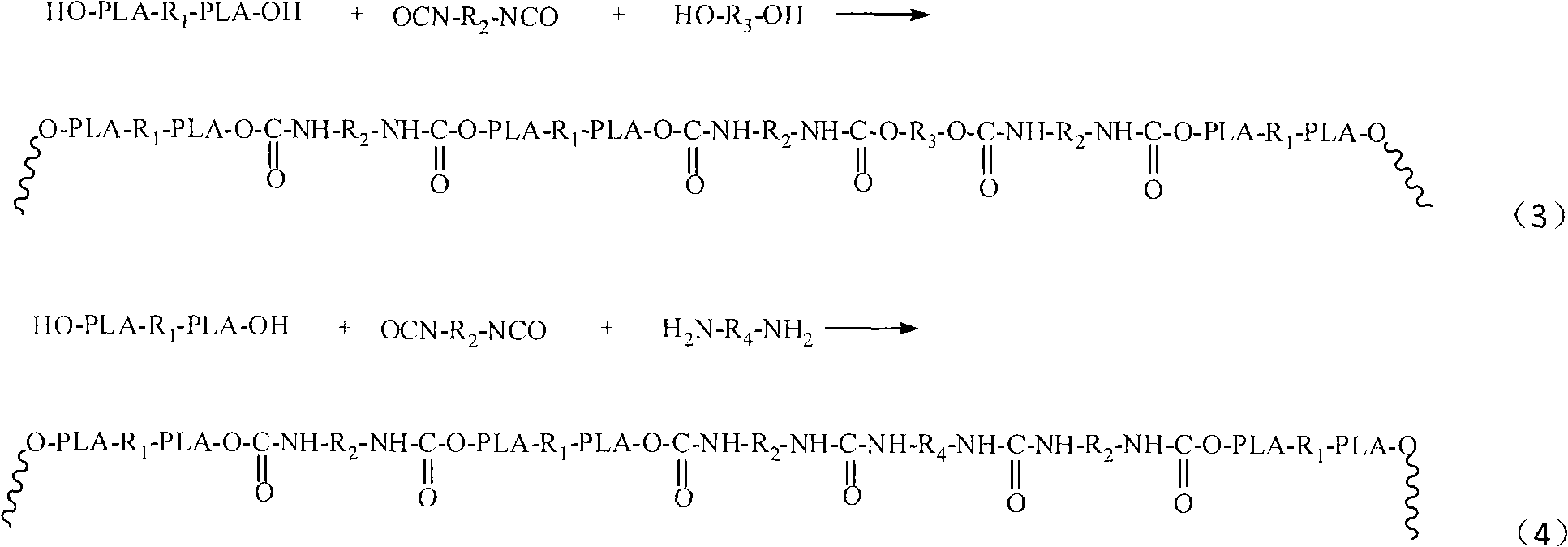

Method for preparing polylactic acid-based high-elasticity copolymer

The invention belongs to the field of high molecular materials, in particular relates to a method for preparing a polylactic acid-based high-elasticity copolymer, which comprises the following specific steps of: the preparation of a polylactic acid matrix; the preparation of a copolymer prepolymer; and chain extension reaction of the copolymer prepolymer. In the method, due to the adoption of abundant and readily available lactic acid, polymer polyols, isocyanate, polyalcohol and polyamine, the complex refining process during the use of lactide is simplified, and the industrial production is convenient; a flexible chain segment of the polymer polyols is introduced into a molecular chain of polylactic acid, the ductility of the polylactic acid is improved, and the application field of materials is expanded; end groups of the synthesized prepolymer are hydroxyl, and diisocyanate and the polyalcohol (the polyamine) are subjected to chain extension to improve the efficiency of the chain extension greatly; and the polyalcohol or the polyamine is added into a system, so the polymer after the chain extension forms a micro-crosslinked structure easily, and the heat resisting property of the polylactic acid-based copolymer is improved greatly.

Owner:TONGJI UNIV

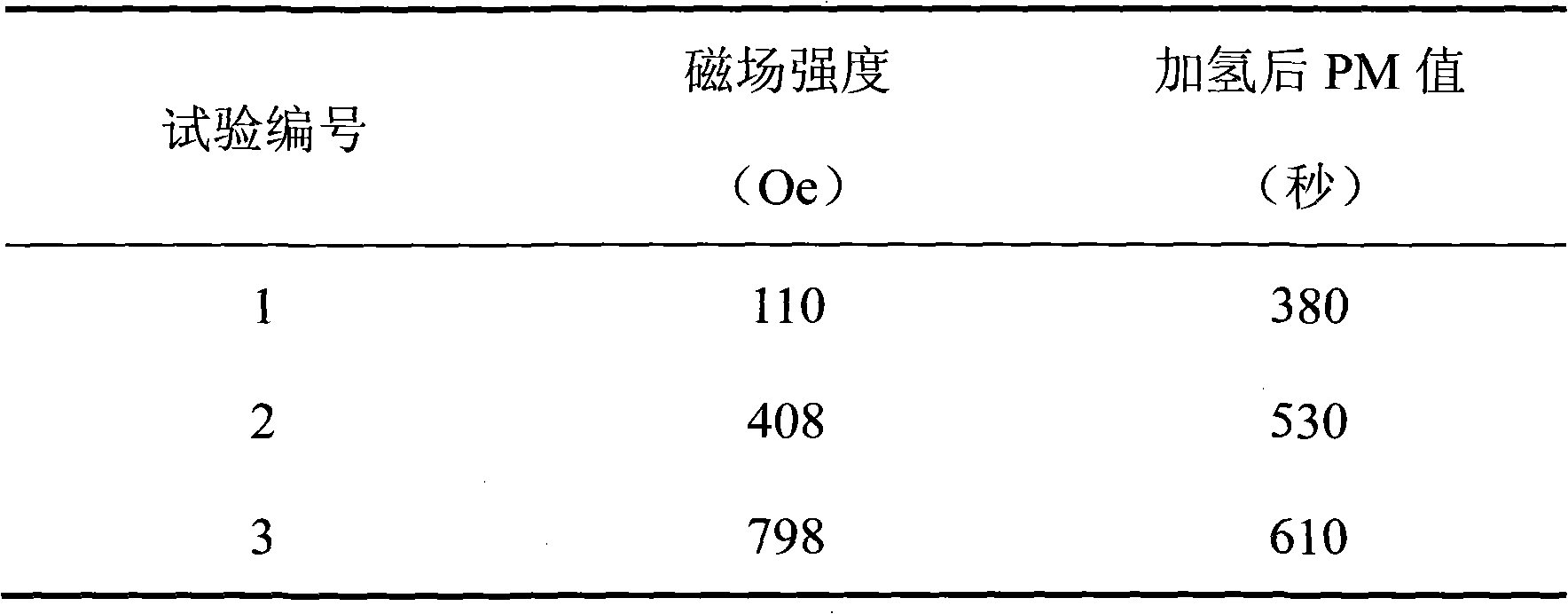

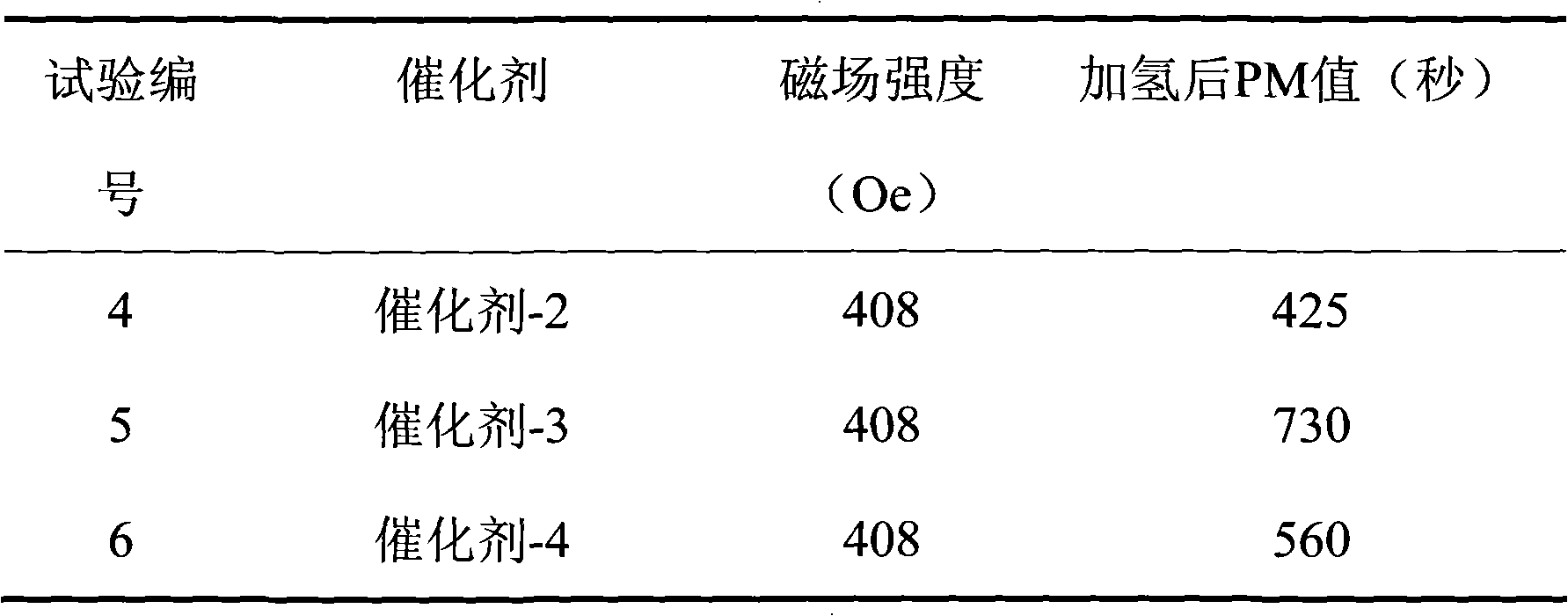

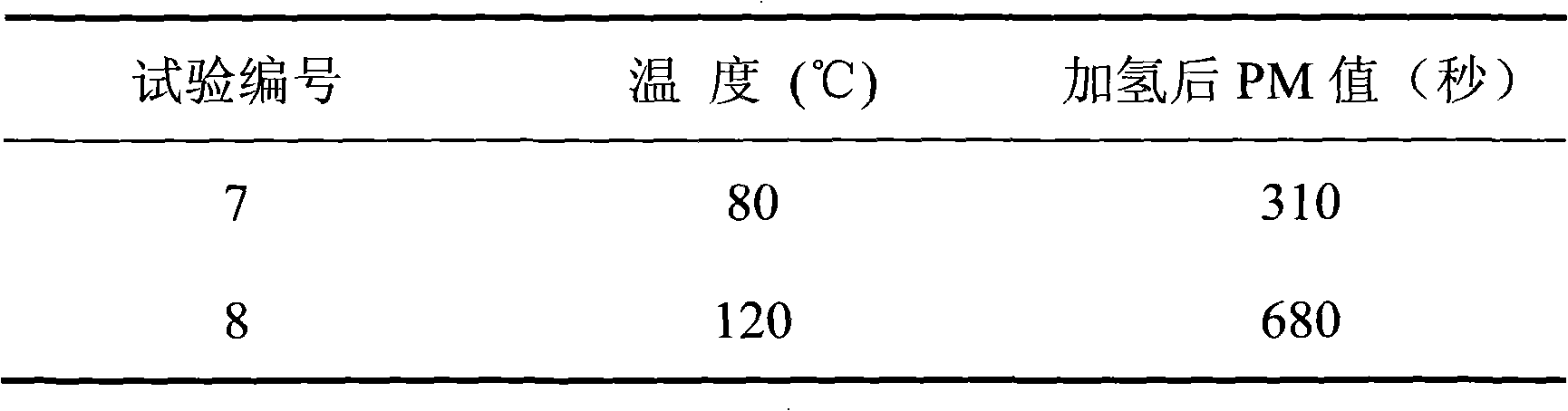

Method for hydrofining caprolactam in magnetically stabilized bed

ActiveCN102050783ARealize the operationReduce pollutionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsEvaporationCaprolactam

The invention relates to a method for hydrofining caprolactam in a magnetically stabilized bed. The method comprises the following steps: the acidamide oil is extracted and distilled with benzene / cyclohexane to obtain the caprolactam crude product; in a magnetically stabilized bed reactor, the hydrogenation reaction is carried out under the action of a catalyst formed by active components such as platinum or / and palladium and a magnetic spherical carrier, so that the unsaturated substance in the liquid caprolactam crude product reacts with hydrogen to generate a saturated substance; and then the saturated substance is rectified to obtain the caprolactam product. The active components in the catalyst occupy 0.01-5 percent (wt); and the hydrogenation reaction conditions are as follows: temperature: 80 DEG C to 140 DEG C, pressure: 0.5 to 3.0 MPa, air speed: 2 to 60h-1, and magnetic field intensity: 10 to 1500 oersteds. Compared with the prior art, the method has the advantages that the procedures of water re-extraction and dehydration by evaporation are reduced, the refining process is greatly simplified, and the refining operation process is optimized; and the method is favorable for reducing energy consumption and environmental pollution and enhancing the processing capacity of the device.

Owner:CHINA PETROLEUM & CHEM CORP +3

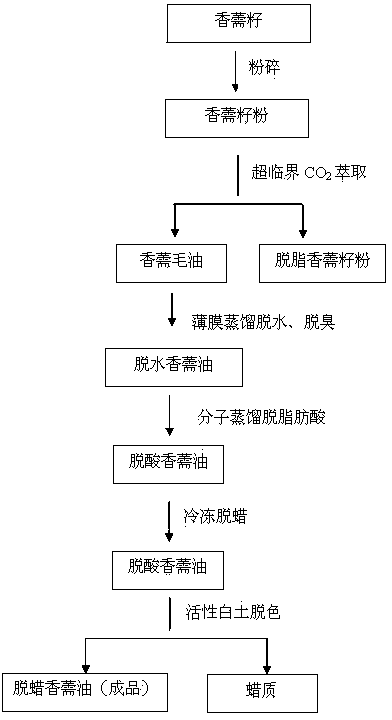

Preparation method of herbal elsholtzia essential oil

ActiveCN103409241AControl freezing temperatureImprove oil yieldEssential-oils/perfumesEngineeringFatty acid

The invention provides a preparation method of herbal elsholtzia essential oil, which is characterized by comprising the following steps: (1) extraction of supercritical CO2: smashed herbal elsholtzia seed power is added to a supercritical feed cylinder and placed in an extraction kettle for extraction of supercritical CO2, so that herbal elsholtzia crude oil can be obtained; (2) dehydration and degassing through thin-film distillation: dehydration and deodorization are performed on the herbal elsholtzia crude oil through the thin-film distillation; (3) fatty acid removal through molecular distillation: the herbal elsholtzia crude oil after dehydration and deodorization is continuously moved to a molecular still, so that deacidification herbal elsholtzia oil and a secondary product free fatty acid can be obtained; (4) activated clay decoloration: the herbal elsholtzia oil after deacidification is decolored via an activated clay decoloration column; (5) freezing and dewaxing: the freezing temperature is controlled, and the herbal elsholtzia oil stands still, or is stirred at intervals, crystallized, settled, filtered or centrifuged and dewaxed, so that faint yellow liquid namely the herbal elsholtzia essential oil can be obtained. According to the preparation method, the herbal elsholtzia essential oil has high oil production and excellent linolenic acid maintenance, the production is safe, the technology is simple, the operation is convenient, and the continuous large-scale production is facilitated.

Owner:丽江先锋食品开发有限公司

Solanesol refining method

InactiveCN1676502AThe refining process is simpleHigh product yieldOrganic compound preparationHydroxy compound preparationPre treatmentChemistry

This invention provides a solanesol refining method, including pre-treatment of solanesol crude cream with zymolysis and alkali saponification, and making eater key formed from solanesol and organic acid break off. Its characteristics also include: supercritical extraction purifying, decompressing separation purifying, modified extraction purifying. This invention greatly simplifies the refining procedure and improves the yield of products in order to lower the cost and overcomes many weak points of present techniques, and greatly decreases the exhaustion of industrial residues to aim the low cost, high efficiency, scalization and environmental protection. It is a method with high industrial value.

Owner:杨群力 +1

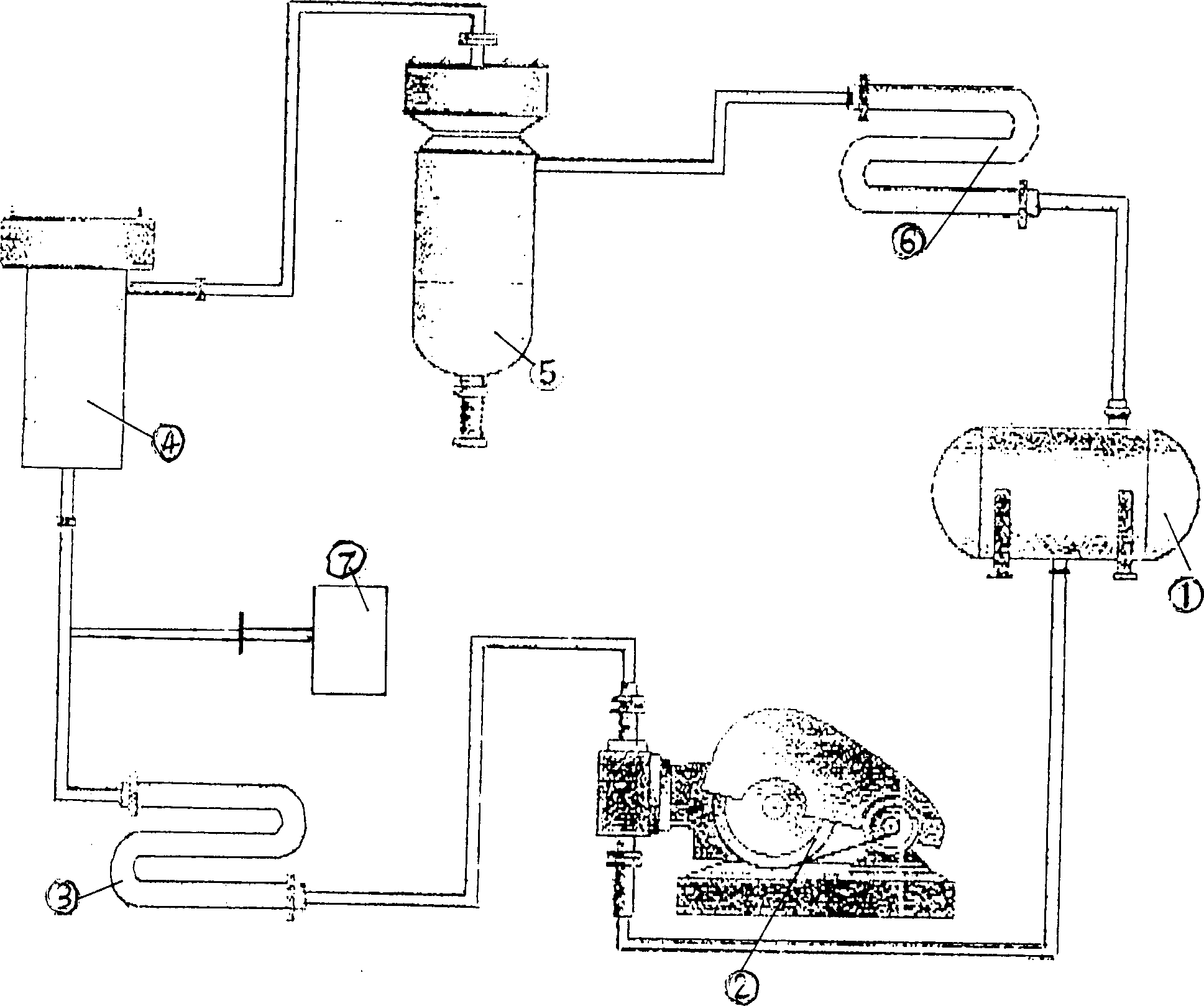

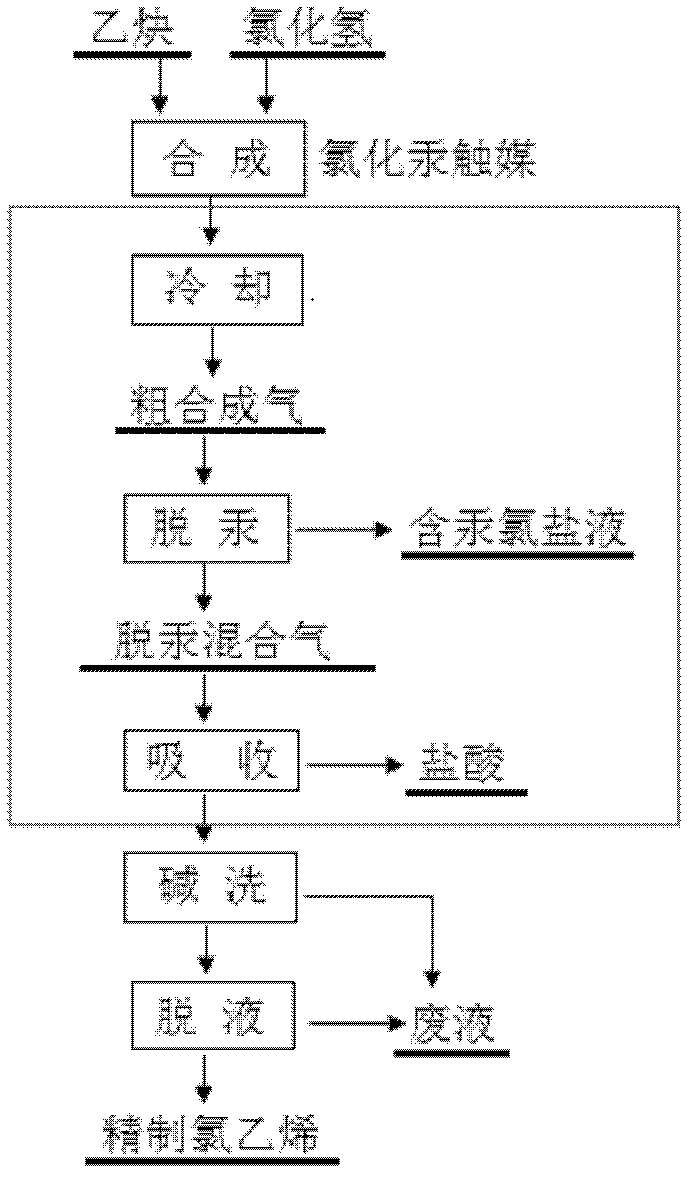

Comprehensive processing method of vinyl chloride synthetic gas

ActiveCN102516022AHigh removal rateShort processChlorine/hydrogen-chloridePreparation by halogen halide additionHigh concentrationSyngas

The invention discloses a comprehensive processing method of vinyl chloride synthetic gas. Under the effect of a mercuric chloride catalyst, acetylene gas and hydrogen chloride are subject to a reaction, such that crude vinyl chloride synthetic gas is produced; the crude vinyl chloride synthetic gas is subject to mercury removing by using a high-concentration chloride containing hydrochloric acid; hydrogen chloride is absorbed by using water; the crude vinyl chloride synthetic gas is then subject to steps such as alkali washing and dehydration, such that refined vinyl chloride is obtained, and requirements of mercury recovering, qualified industrial hydrochloric acid production and vinyl chloride refining are directly achieved.

Owner:CENT SOUTH UNIV

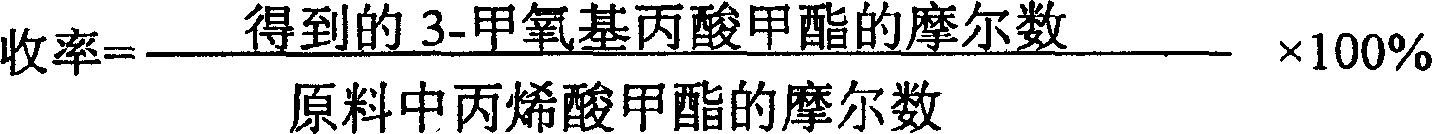

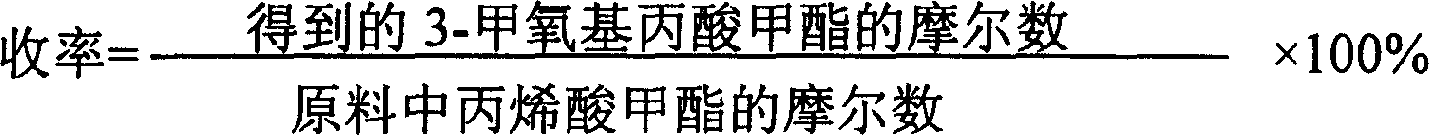

Method for preparing 3-methoxy methyl propionate

InactiveCN1660767AReduce dosageHigh yieldOrganic compound preparationPreparation by ester-hydroxy reactionPotassiumPhosphoric acid

A process for preparing 3-methyl methoxypropionate includes proportionally adding methanol and sodium (or potassium) methoxide as catayst to reactor, stirring while reaction, adding MA, continuous reaction, cooling, stirring while adding concentrated sulfuric acid (or phosphonic acid ) to neutralize catalyst, and refining.

Owner:CNPC JILIN CHEM GROUP CORP +1

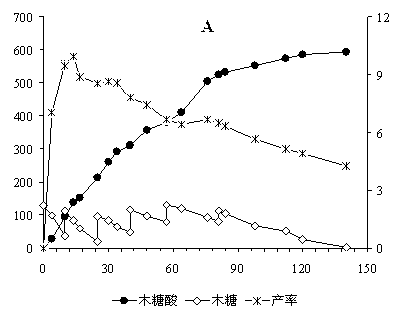

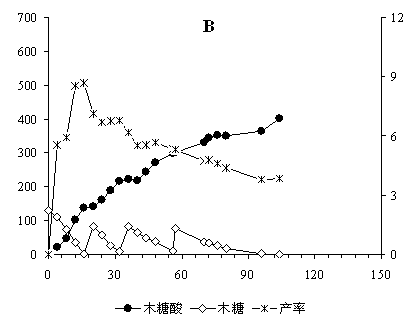

Method for producing xylosic acid through xylose whole-cell catalysis by direct oxygen introduction and pressurization

ActiveCN103215317AImprove oxygen transfer efficiencyReduce ventilationMicroorganism based processesFermentationChemistryHigh concentration

The invention discloses a method for producing xylosic acid through xylose whole-cell catalysis by direct oxygen introduction and pressurization. The method comprises the following steps that: oxygen is directly introduced into a xylose liquid deep reaction system for air replacement in the mixing condition, the gluconobacter oxydans is then inoculated into the system, the sealed reaction system is pressurized to 0.01-0.10MPa with oxygen to carry out xylose whole-cell catalysis for the production of the xylosic acid; the carbon dioxide content generated by the neutralization reaction of the reaction system is monitored, when the carbon dioxide concentration in the waste gas exceeds 5%, mixing intensity is reduced, the reaction system is started, the waste gas in the reaction system is replaced through the oxygen, then the reaction system is again sealed, and the stirring strength is recovered to continue the reaction. By adopting the method disclosed by the invention, the severe foam problem caused by direct air introduction in the production process can be completely solved, no defoamer needs to be added, product refining procedure is greatly simplified, product quality is improved, the product concentration of the xylosic acid and the yield of the unit system are respectively improved by 50% and 66% due to the high concentration oxygen introduction, the xylosic acid product concentration reaches 600g / L, and xylose utilization rate is higher than 98%.

Owner:NANJING FORESTRY UNIV

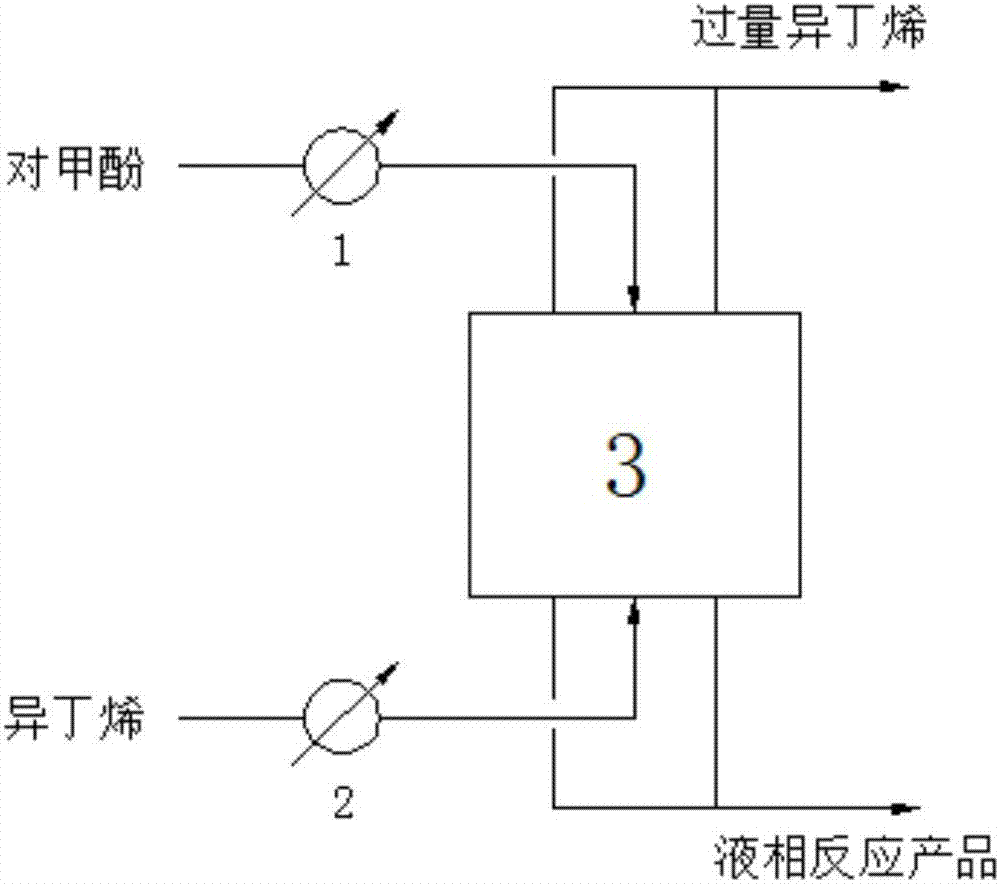

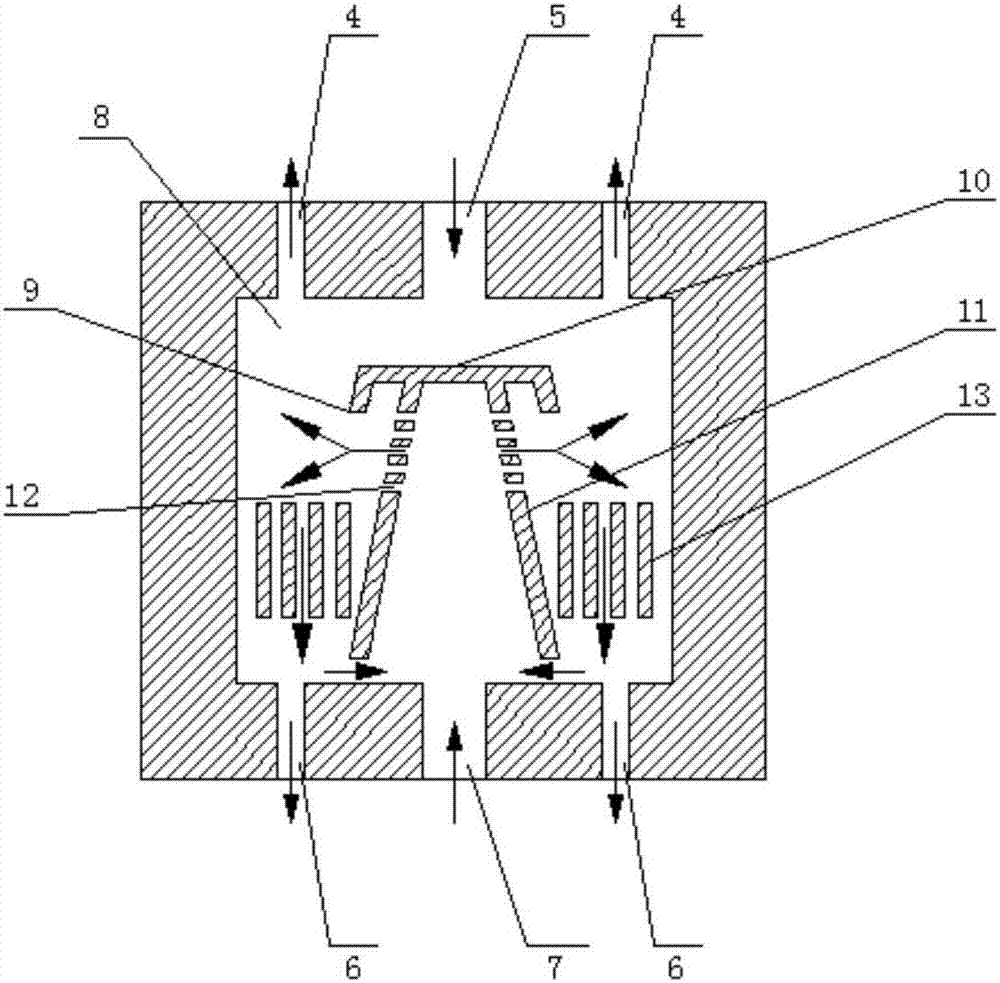

Method for preparing 2,6-ditertbutyl-4 methylphenol by using micro-reaction rectifying plate and device thereof

InactiveCN106866380AImprove conversion rateAvoid flying temperatureOrganic chemistryOrganic compound preparationChemistryBoiling point

The invention relates to a technology method for preparing 2,6-ditertbutyl-4 methylphenol by using a micro-reaction rectifying plate. The method comprises the following steps of preheating p-cresol to 70 to 90 DEG C by a first preheater, and sending into the micro-reaction rectifying plate via an upper center passage; meanwhile, preheating isobutene to 70 to 90 DEG C by a second preheater, and sending into the micro-reaction rectifying plate via a lower center passage; enabling the p-cresol and the isobutene to react in the micro-reaction rectifying plate, so as to generate a liquid-phase product; discharging via a lower side passage of the micro-reaction rectifying plate, and rectifying and separating the liquid-phase reaction product, so as to obtain the 2,6-ditertbutyl-4 methylphenol; crystallizing again, and drying, so as to obtain a finished product; discharging the excessive isobutene and a low-boiling point product from an upper side passage of the micro-reaction rectifying plate. The technology method has the advantages that the conversion rate of the p-cresol is high, the yield rate of the 2,6-ditertbutyl-4 methylphenol is high, the reaction temperature is low, and the temperature runaway is avoided.

Owner:HEBEI UNIV OF TECH

Method for reducing sulphur content of strontium carbonate product

InactiveCN102153122AReduce free sulfur contentImprove quality and added valueCalcium/strontium/barium carbonatesCalcium EDTAEnvironmental chemistry

The invention relates to a method for reducing sulphur content of a strontium carbonate product. The method includes the steps as follows: (1) mixing strontium carbonate power with water according to a solid-liquid mass ratio of 1:6-10 and stirring the mixture to form uniform slurry; (2) at the stirring state, adding a desulphurizing agent in the slurry, raising temperature to 90-105 DEG C and keeping the temperature for 30-120min, and obtaining desulphurized slurry; and (3) separating the desulphurized slurry to obtain mother liquor and a filter cake, precipitating or settling the mother liquor by lime milk to obtain thiosulfate precipitate of calcium and pure water, wherein the pure water returns to the production stage of strontium carbonate, and the thiosulfate precipitate of the calcium is stacked as waste residue; and washing and drying the filter cake to obtain desulphurized strontium carbonate product. The method can effectively reduce consumption during treatment processes, avoid pollution, convert solid free sulphur to dissolvable thiosulfate, not only lower the content of the free sulphur in the product, but also improve the quality and the additional value of the strontium carbonate product.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

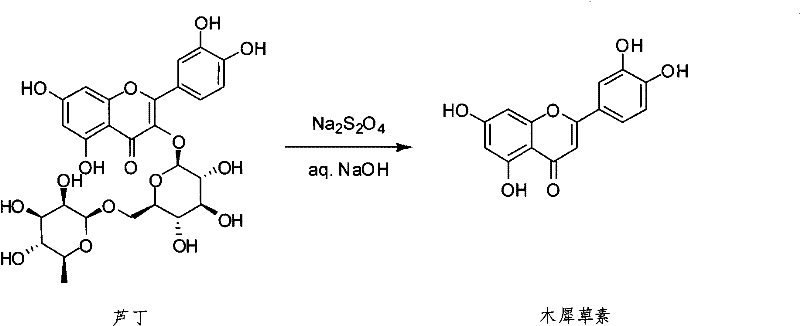

Method for synthesizing luteolin

The invention discloses a method for synthesizing luteolin, comprising the following steps of: adding rutin at the room temperature of 20-30DEG C in alkali water and stirring for dissolving; adding a reducing agent of sodium hydrosulfite with equivalent weight of 6.3 once, continuously heating up to 100DEG C and stirring for 12 hours; after the HPLC (High Performance Liquid Chromatography) monitoring reaction is finished, cooling, adding dilute hydrochloric acid or dilute sulfuric acid, adjusting the pH to be 3-4, standing for 24 hours for separating out a solid and filtering; washing a filtering cake with water twice to remove salts contained in the product; and drying to obtain a crude product, continuously crystalizing with ethanol to obtain a pure product with the purity being more than 95 percent. Compared with the prior art, the invention has the advantages of high synthetic efficiency, high yield, low energy consumption, low pollution, greenness, environmental protection and the like and is easy for industrialized production.

Owner:西安炎黄经方医药研发有限公司

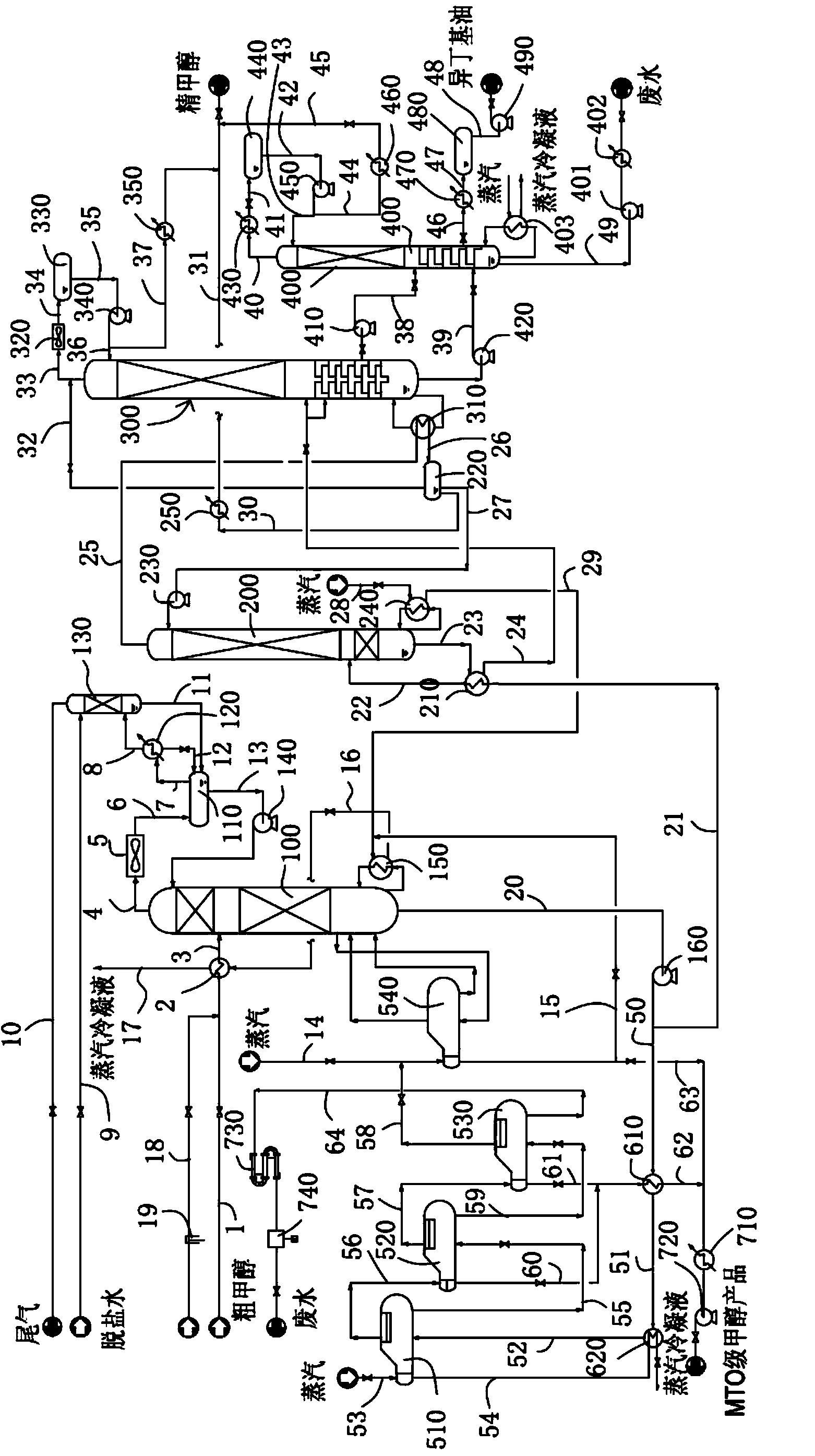

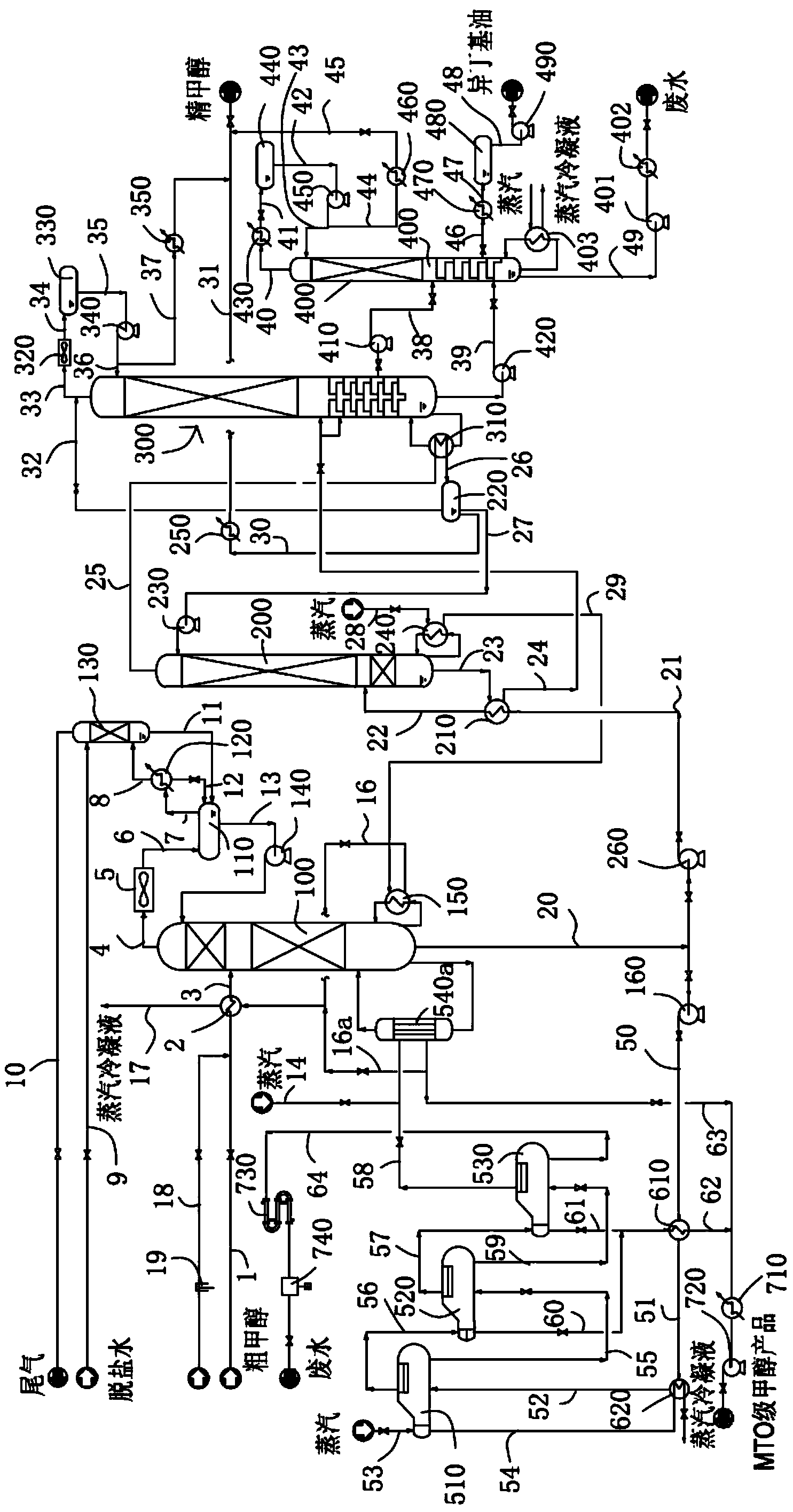

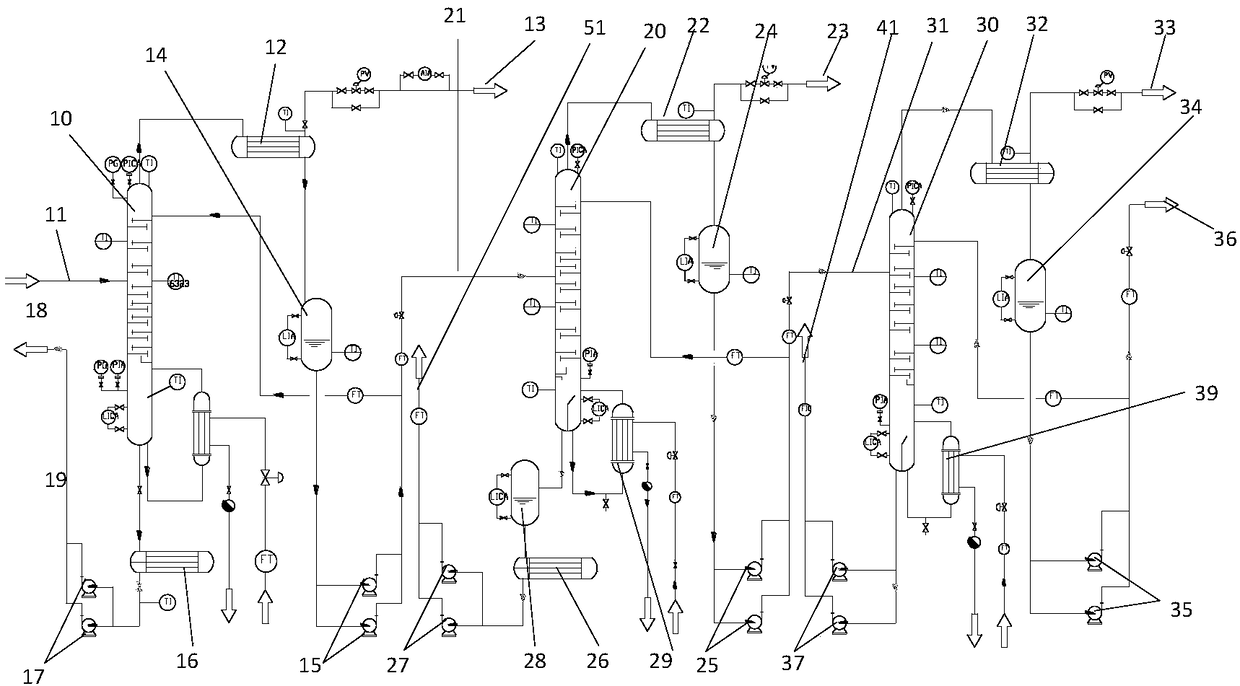

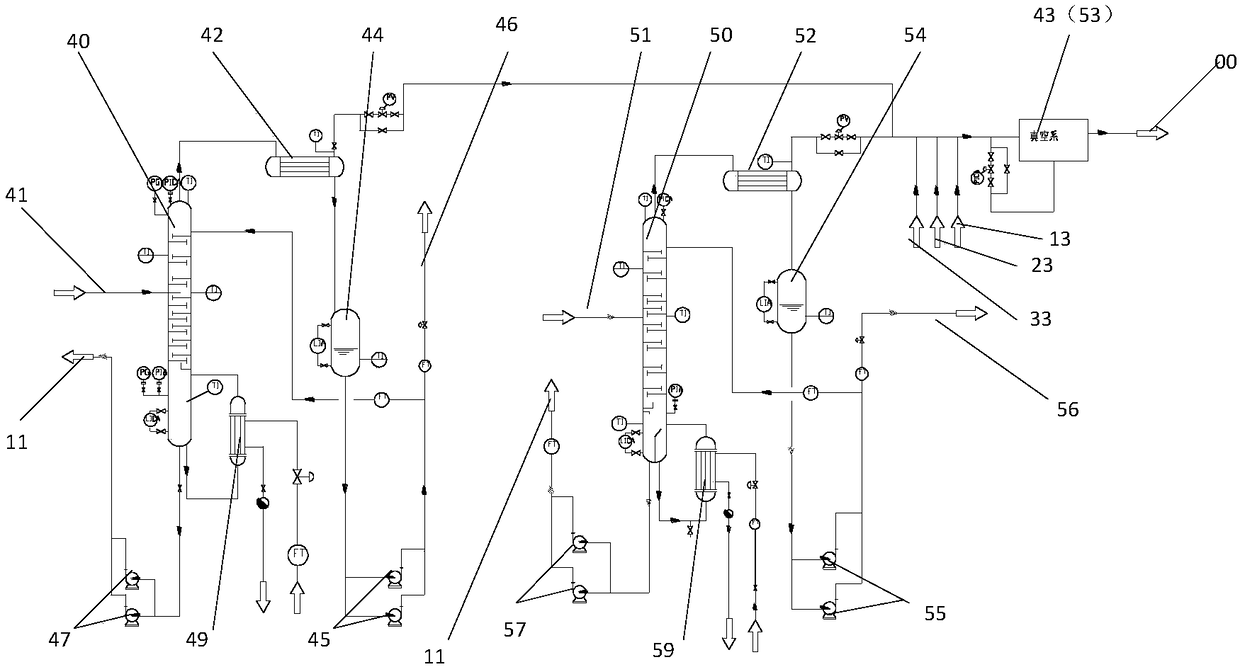

Flexible methanol rectification method and device capable of producing both MTO-grade and AA-grade methanol

InactiveCN104370697AReduce investmentThe refining process is simpleOrganic compound preparationChemical industryTowerEnergy expenditure

The invention discloses a flexible methanol rectification method and device capable of producing both MTO-grade and AA-grade methanol. The raw material crude methanol firstly enters a common stabilizer to remove light components; the crude methanol subjected to light component removal can enter a multi-effect evaporator to be heated and evaporated so as to generate alkali-metal-free methanol vapor, and the alkali-metal-free methanol vapor is condensed to generate the MTO-grade methanol; and the crude methanol subjected to light component removal can also enter a multi-effect rectifier composed of a pressurization tower, an atmospheric tower and a stabilizer to produce the AA-grade methanol by multi-effect rectification. The device is additionally provided with a crude methanol preheater, a first and second tower bottom methanol preheaters, a pressurization tower feed preheater and other units besides the multi-effect evaporator and multi-effect rectifier main body so as to perform repeated preheating, thereby saving the energy consumption. The stabilizer bottom discharging pump can be driven by a variable-frequency motor to satisfy the operation demands for two working conditions for producing the AA-grade methanol and MTO-grade methanol.

Owner:SHANGHAI INT ENG CONSULTING

Method for reducing residual fat of almond cakes by dipping and pressing

InactiveCN101558795AExudation path shortenedReduce resistanceEdible oils/fatsForeign matterOil processing

The invention discloses a method for reducing residual fat of almond cakes by dipping and pressing, and belongs to the oil processing technical field. The method comprises the following steps: firstly crushing almond cakes obtained by squeezing at low temperature, adding 15-30 parts of 95%-99% ethanol and 5-10 parts of dried protein-free almond to every 100 parts of the almond cakes, evenly mixing and wetting for 10-30min, then filling in an oil press, regulating pressing pressure to 8-12MPa and pressing for 3min, and increasing pressure to 40-50MPa, and ending the pressing after 5min pressing. By material changing produced by refilling of materials, increased liquid composition and reduced viscosity caused by dissolving the ethanol in the oil, softening of the cakes by the ethanol and assisted filtering of the dried almond, porosity of the cakes is reduced during further pressing, the empty cavities holding residual oil reduce, oil drainage passages increase, oil drainage resistance reduces, and residual oil rate of the almond cakes is further reduced, and the dried almond is taken as a filter aid without other foreign matters, thus avoiding raw material pollution.

Owner:CHINA AGRI UNIV

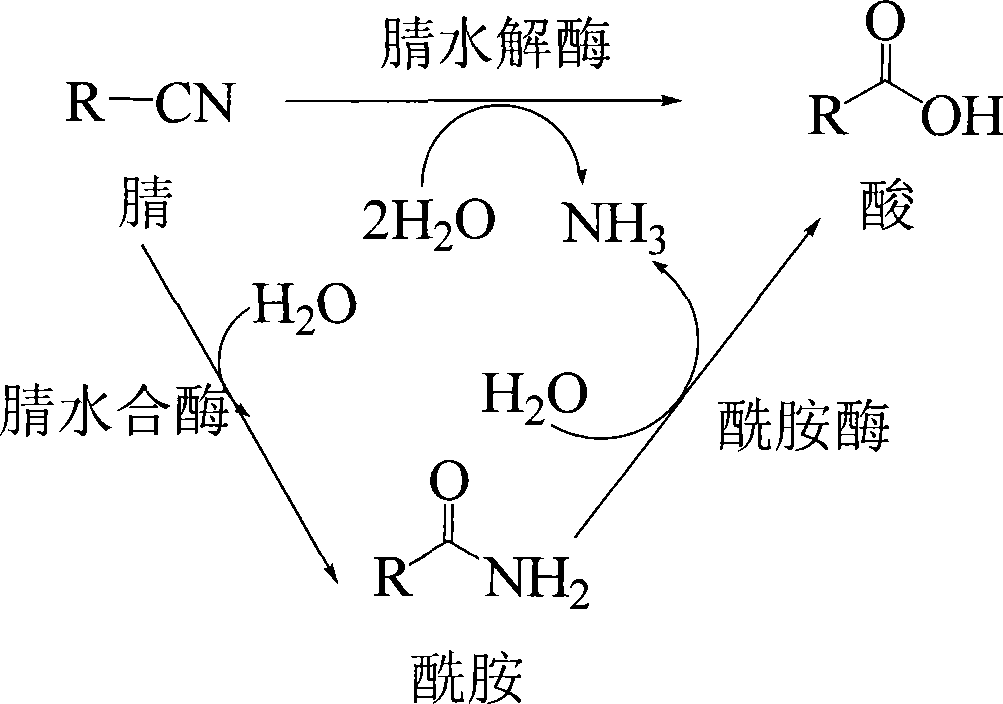

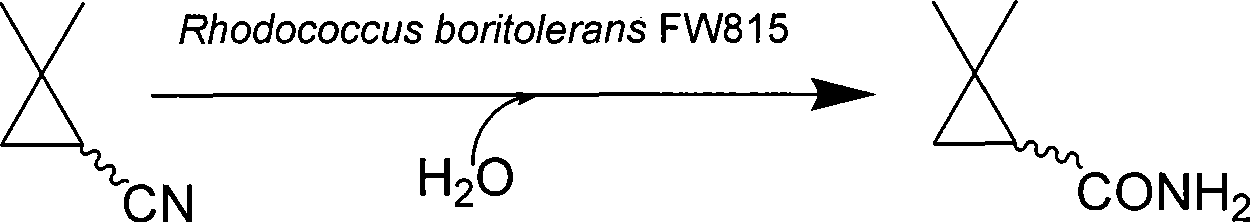

Method for preparing 2,2-dimethyl cyclopropanecarboxamide and bacterial strain thereof by biological catalysis

ActiveCN101481665ASimple compositionHigh biocatalytic efficiencyBacteriaMicroorganism based processesSewageFormamide

The invention provides a Rhodococcus boritolerans FW815 enriched in soil and sewage and sieving high nitrile hydratase active mircoorganism strain, and a process that applies the strain to biological catalysis methods for the preparation of 2,2-dimethyl cyclopropane formamide. The 2,2-dimethyl cyclopropane formamide is prepared by converting 2,2-dimethyl cyclopropane formonitrile via the nitrile hydratase generated by the strain, wherein, the reaction medium is water, constituents of the reaction system are simple, the biological catalysis efficiency is high, the conversion time is short, the conversion rate for substrates is high, the yield of the 2,2-dimethyl cyclopropane formamide product is high and the extraction and purification processes are simple.

Owner:ZHEJIANG UNIV OF TECH

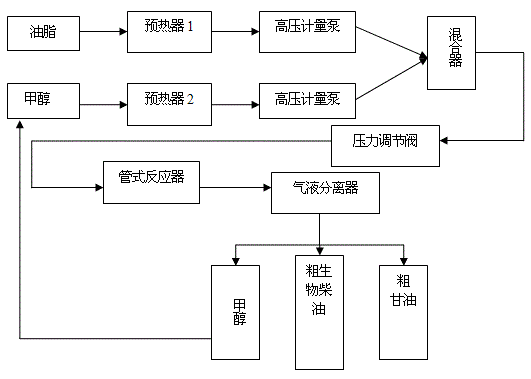

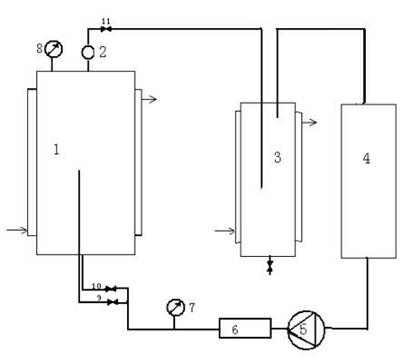

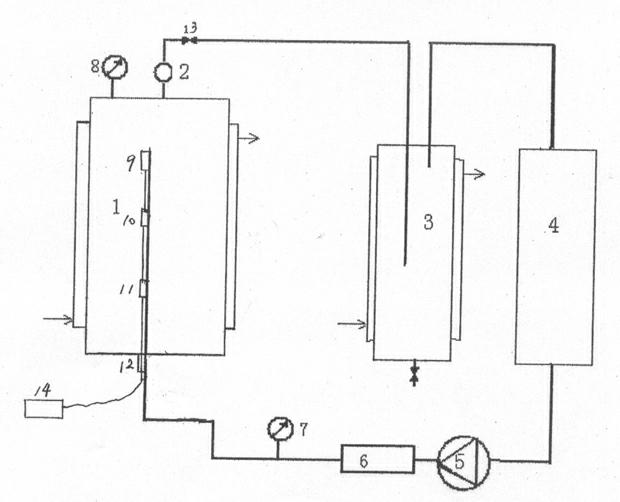

Method utilizing supercritical catalysis process to continuously prepare biodiesel

InactiveCN103981033AImprove reaction efficiencyLower reaction operating conditionsFatty acid esterificationBiofuelsBiodieselVapor–liquid separator

The invention discloses a method utilizing a supercritical catalysis process to continuously prepare biodiesel, and relates to a preparation method of biodiesel. The method uses a solid catalysis fixed-bed reactor to carry out continuous biodiesel production. The ester exchange reaction is carried out at a temperature of 260 to 330 DEG C under a pressure of 10 to 19 MPa, and the alcohol / oil mole ratio is in a range of 35:1 to 70:1. The ester exchange reaction is carried out for 1.5 to 3 minutes in the reaction tube of the fixed-bed reactor in the presence of a catalyst, the reaction product is transported to a gas / liquid separator to carry out primary separation, the upper layer methanol is recycled, the middle layer and the lower layer are coarse biodiesel and coarse glycerine, and the coarse biodiesel and the coarse glycerine are respectively subjected to post refining treatments. Through detection, people find that the grease conversion rate is 90% to 100%. Advantages of conventional supercritical methanol method for preparing biodiesel are all preserved, furthermore, a fixed-bed catalyst and a continuous production technology are used, and thus the difficult conditions of supercritical reactions are greatly improved. Moreover, no impurity is introduced into the system during the reaction process, so the biodiesel post-treatment is largely simplified.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

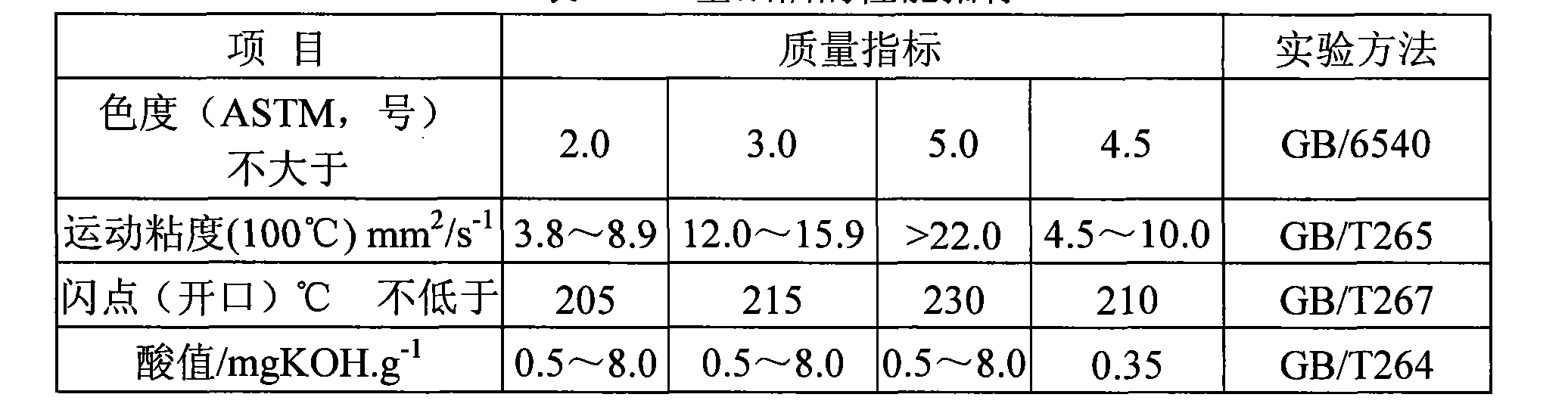

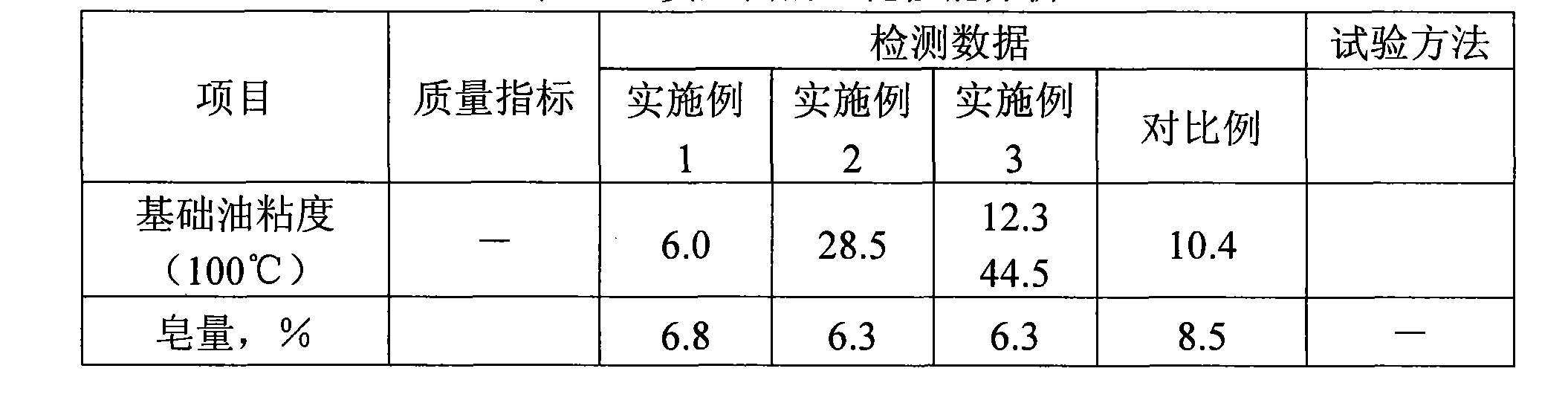

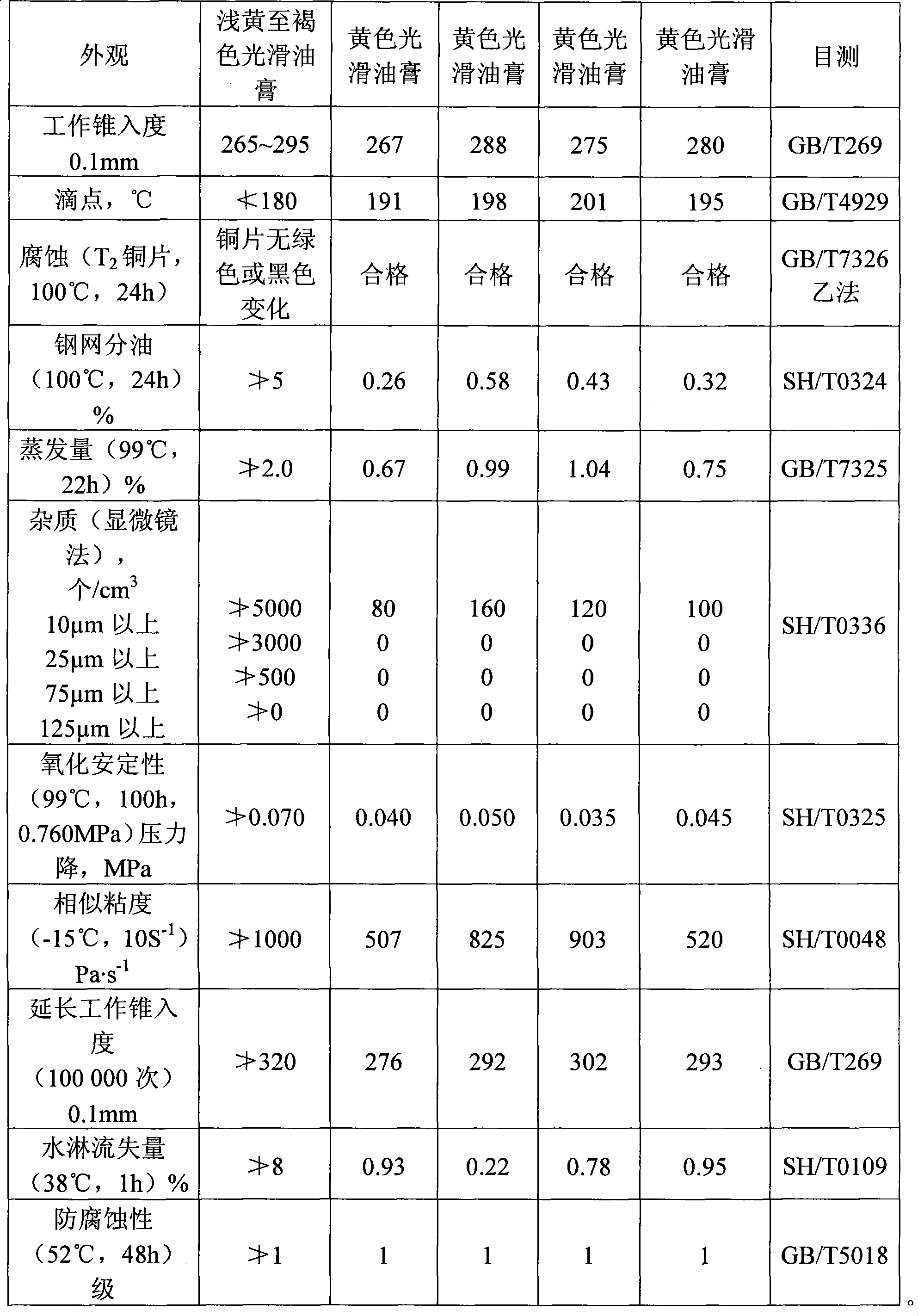

Functional lubricating grease and preparation thereof

The invention discloses a functional grease lubricant and a preparation method thereof. In the preparation method, fraction oil obtained through high-acid naphthene base crude oil is used as the base oil of the grease lubricant and is reacted with 12 hydroxy stearic acid, lithium hydroxide and water for obtaining the finished product of the functional grease lubricant. The viscidity of the fraction oil under the temperature of 100 DEG C is 9.5 to 44.5mm<2>s and is preferably to be 9.5 to 16.5mm<2>s and is more preferably to be 9.5 to 44.5mm<2>s; the acidity is equal to or more than 0.5mgKOH / g; the weight portion ratio of the base oil of the grease lubricant to the 12 hydroxy stearic acid, lithium hydroxide and water is 49 to 65: 3.0 to 3.6: 0.45 to 0.53 : 2.2 to 2.6. The preparation method provided by the invention can reduce the consumption of a thickening agent, improve the structure of the grease lubricant and reduce the production cost. The produced grease lubricant meets the index requirements of the National Standard GB7324-94.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Device and method for extracting oil-tea camellia seed oil at low temperature by taking liquefiable gas as solvent

InactiveCN102093930AReduce the problem of excessive pressure differenceAvoid differential pressureFatty-oils/fats productionEdible oils/fatsEngineeringSolvent

The invention relates to a device and a method for extracting oil-tea camellia seed oil at low temperature by taking a liquefiable gas as a solvent, which are used for extracting the oil-tea camellia seed oil. The inner side of an extracting container is at least provided with a group of more than two equal-distance or unequal-distance inlets capable of being opened and closed; the inlets are connected with a pump for inputting a solvent gas through a pipeline; the equal distance or unequal distance refers to a distance from a port end of the pipeline inserting to the inner side of the extracting container to the inner bottom surface of the extracting container; and the inlets capable of being opened and closed are connected with the pump for inputting the solvent gas through different pipelines or the same pipeline. The invention has the advantages that: the utilization rate of the camellia seed oil can be improved, the quality of crude oil is improved, a refining step is eliminated, the production period is shortened and the loss of nutrient substances in the camellia seed oil is reduced.

Owner:广州绿和缘生物科技有限公司 +1

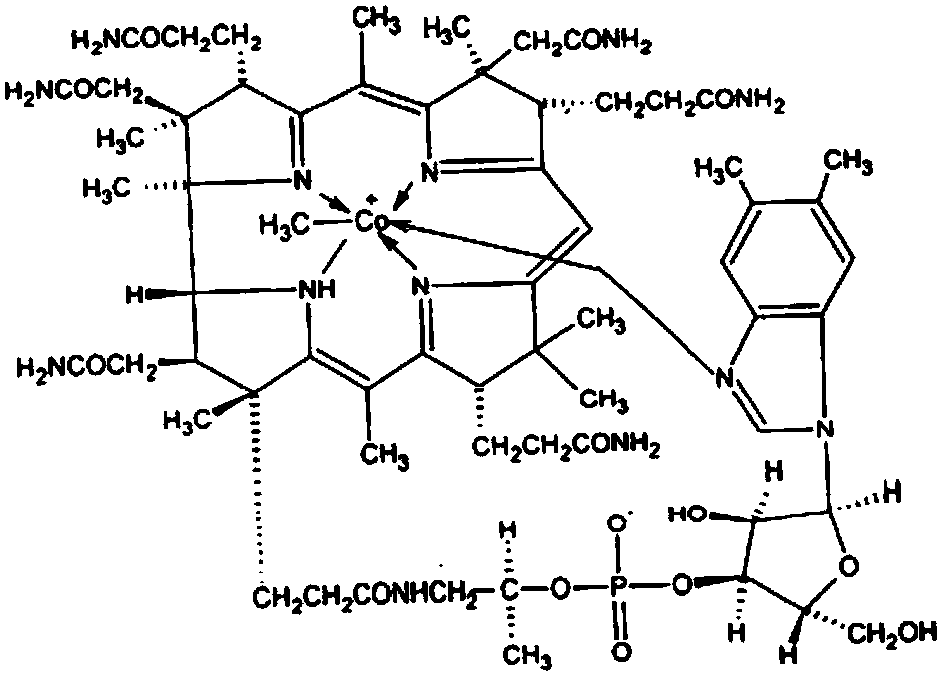

Method used for preparing mecobalamin

ActiveCN107698642AShort reaction timeThe methylation reaction is completeSugar derivativesSugar derivatives preparationButanoneSodium borohydride

The invention discloses a method used for preparing mecobalamin. The method comprises: dissolving cyanocobalamin, butanone and cobalt chloride hexahydrate in purified water, adding a sodium borohydride solution drop by drop for a reduction reaction, adding trimethylsulfoxonium iodide drop by drop for a methylation reaction to generate mecobalamin, and refining mecobalamin through a crystallizationmethod to obtain high-purity mecobalamin. The provided method is simple and easy, is simple to operate, complete in reaction, mild in condition, high in yield and high in purity, and is particularlysuitable for massive production.

Owner:广州普星药业有限公司

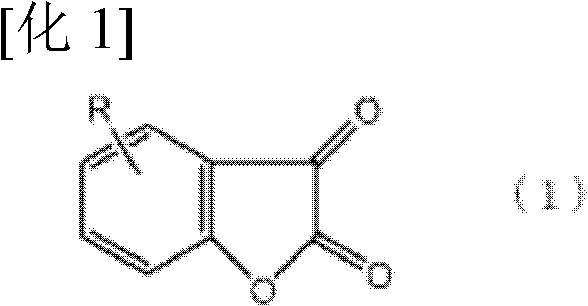

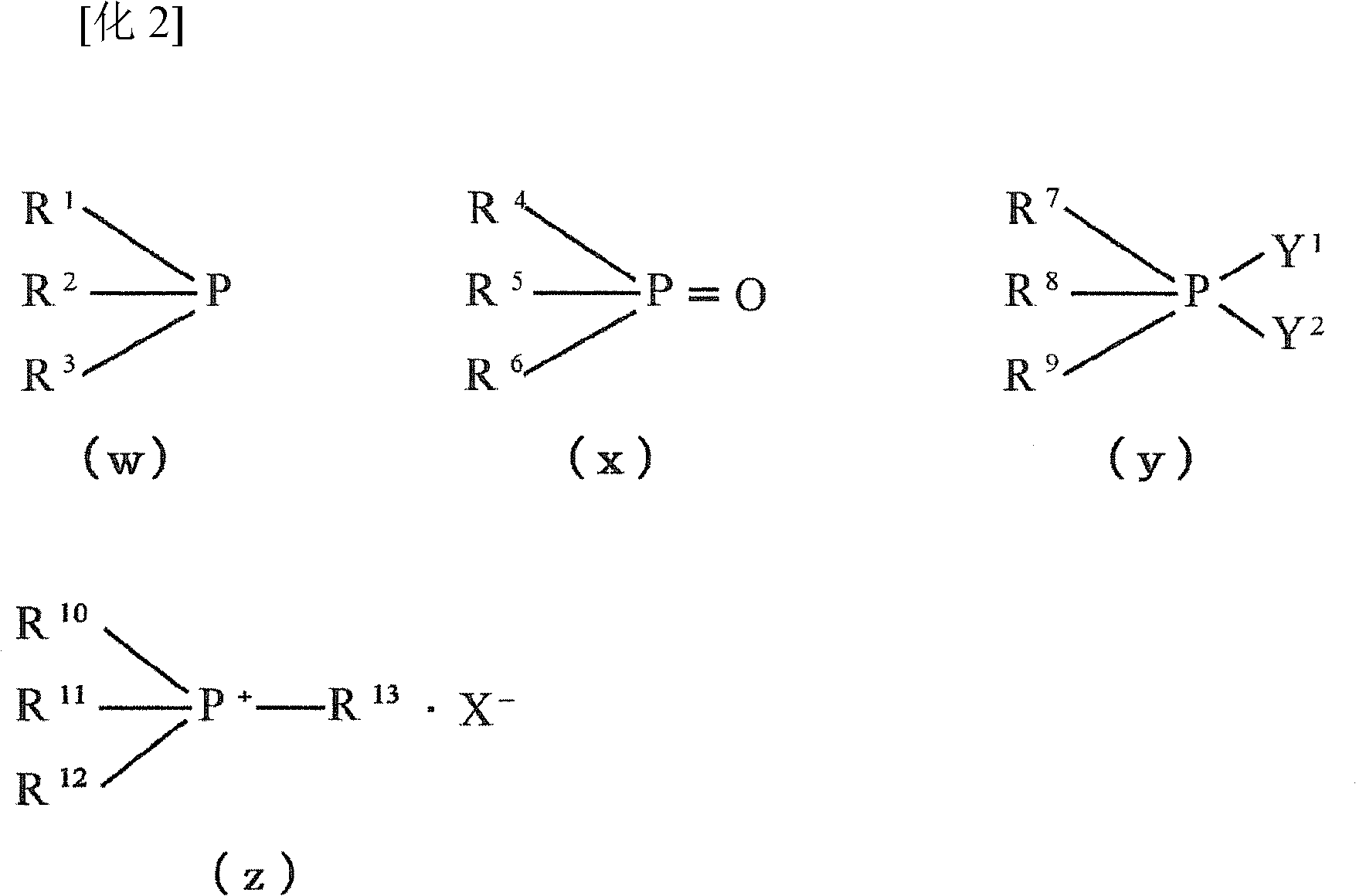

Process for production of diaryl oxalate

ActiveCN102712564AImprove conversion rateSimple processOrganic compound preparationPreparation by ester-hydroxy reactionOxalateAryl

Disclosed is a process for producing a diaryl oxalate, which involves a step of carrying out the transesterification reaction of a dialkyl oxalate or / and an alkylaryl oxalate with an aryl alcohol in the presence of a tetra(aryloxy)titanium that serves as a catalyst. The process is characterized in that the tetra(aryloxy)titanium is supplied to a reaction system to be used for the transesterification reaction in the form of a solution of the tetra(aryloxy)titanium in an aryl alcohol, wherein the solution is produced by reacting an tetraalkoxytitanium with an excess amount of the aryl alcohol and removing an alkyl alcohol that is produced as a byproduct.

Owner:UBE IND LTD

Preparation method of biological diesel oil

InactiveCN100513521CHigh catalytic activityNo emissionsBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

Owner:张海军

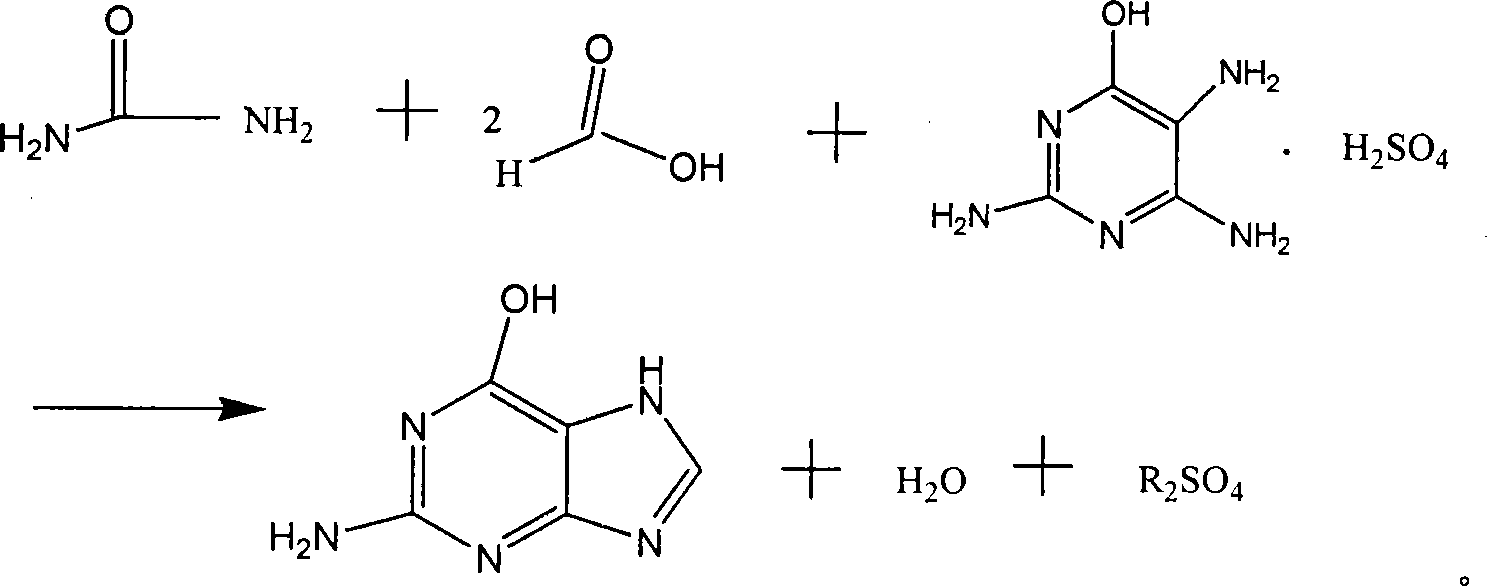

Method for synthesizing guanine from urea

The invention discloses a process for synthesizing guanine with urea, which comprises firstly reacting urea with formic acid, adding 2, 4, 5- triamino-6-hydroxy pyrimidine sulphate and further adding formic acid to react continuously, finally obtaining guanine. The invention has the advantages of simple operation, low device demand and stable product yield, less raw material consumption, low cost and raw material cost, high product yield and excellent product quality, which does not generate inorganic salt in the reaction process, and is easy to be refined.

Owner:江苏八巨药业有限公司

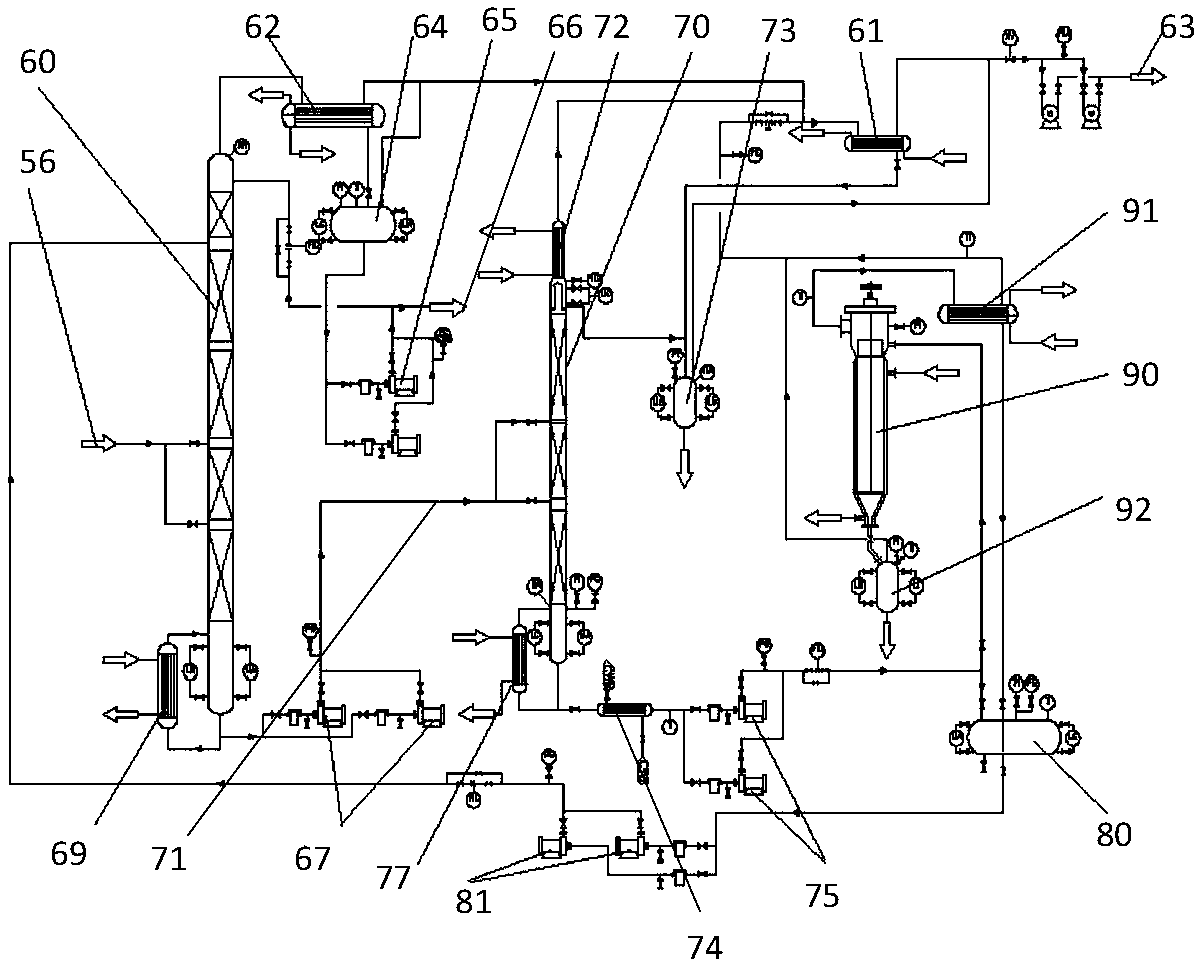

Deep processing device and method for chloropropene co-product

InactiveCN108484354AAchieve separationMeet pharmaceutical grade standardsOrganic chemistry methodsHalogenated hydrocarbon separation/purificationProcess engineeringTower

The invention discloses a deep processing device and method for a chloropropene co-product. The deep processing device for the chloropropene co-product comprises a rectification tower 1, a rectification tower 2, a rectification tower 3, a rectification tower 4 and a rectification tower 5; and a continuous vacuum rectification separation device is adopted, and a DD mixed agent is used as a raw material, so that separation of trans-1,3-dichloropropene and cis-1,3-dichloropropene is achieved, and a concentration of the obtained cis-1,3-dichloropropene can reach 98% and meets a pharmaceutical grade standard. The device disclosed by the invention adopts vacuum operation, can greatly reduce energy consumption, and improve a product yield.

Owner:BEFAR GROUP CO LTD

Method for preparing 3-methoxy methyl propioniate

InactiveCN1258518CReduce dosageHigh yieldOrganic compound preparationPreparation by ester-hydroxy reactionPropionatePotassium

Owner:CNPC JILIN CHEM GROUP CORP +1

Method for preparing high-purity white 2-hydroxy quinoxaline crystal

InactiveCN102010377AReduce dosageThe refining process is simpleOrganic chemistryQuinoxalinePotassium borohydride

The invention discloses a method for preparing 2-hydroxy quinoxaline by condensing glyoxylic acid and o-phenylenediamine. The method is characterized by comprising the following steps of: condensing industrial glyoxylic acid solution and dry ice-precooled o-phenylenediamine at the temperature of between -6 and 0 DEG C to obtain a crude product of the 2-hydroxy quinoxaline; heating and refluxing a colored crude product for 1 to 4 hours in a mixed solvent of N,N-dimethylformamide, diethylene glycol or N-methyl pyrrolidone and methanol in the presence of a reducing agent such as sulfur dioxide, sodium hypophosphite or potassium borohydride; dissolving impurities in the mixed solvent; converting a fine-powder crude product into white crystals; and filtering, washing and drying to obtain a refined product of the 2-hydroxy quinoxaline. Through liquid chromatography measurement, the content is 99.5 percent, the melting point is 270 to 272 DEG C and the refining yield is 97.5 percent. The 2-hydroxy quinoxaline has a simple refining process; a high-purity white crystal product can be obtained; the refining yield is high; the dosage of refining solvent is less; and the solvent can be recycled for use by heating, refluxing and discoloring by using activated carbon.

Owner:TIANJIN VOCATIONAL INST

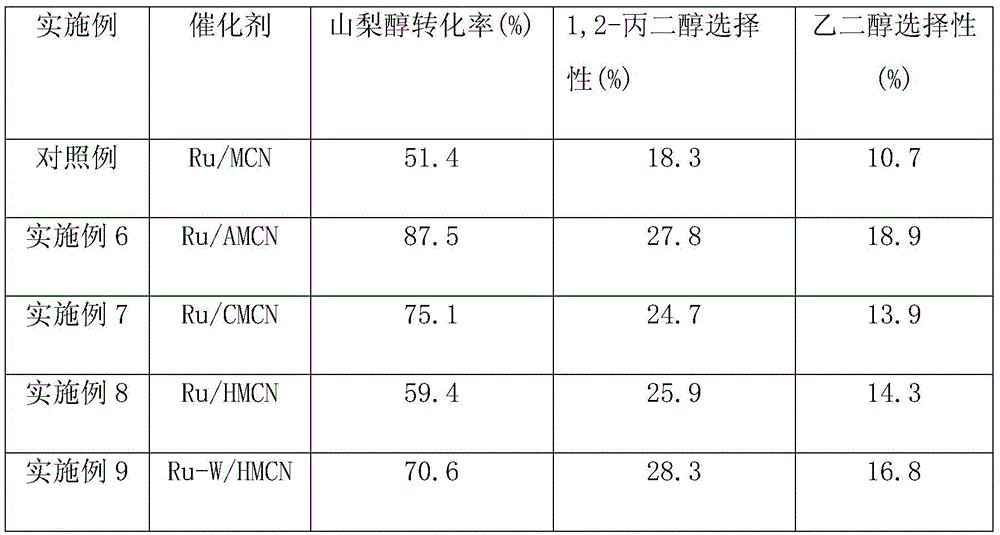

Catalyst with functionalized carbon nanotubes as carrier, and preparation method and application thereof

InactiveCN105478111AImprove stabilityEvenly dispersedOrganic compound preparationHydroxy compound preparationAlcohol sugarsCarbon nanotube

The invention provides a catalyst. The catalyst adopts functionalized carbon nanotubes as a carrier, metal ruthenium is supported on the carrier, and the load capacity of the metal ruthenium is 3-5%. The invention also provides a preparation method of the catalyst. The method comprises the following steps: isopyknically dipping the functionalized carbon nanotubes in a ruthenium compound solution, carrying out ultrasonic treatment, carrying out constant temperature stirring, ageing the obtained mixture at room temperature overnight, an drying the aged mixture to obtain a metal ruthenium supported catalyst; and carrying out reducing activation on the metal ruthenium supported catalyst at 250-350DEG C in H2 atmosphere for 2-6h to obtain the reduced and activated metal ruthenium supported catalyst. The invention provides an application of the catalyst in a sugar alcohol hydrogenolysis reaction for preparing ethylene glycol and propylene glycol. Compared with traditional catalysts, the catalyst with the functionalized carbon nanotubes to support ruthenium has the advantages of uniform metal dispersion, excellent catalysis performance and selectivity in intermittent sugar alcohol hydrogenolysis technologies, mild reaction conditions, and good stability.

Owner:SHANGHAI INST OF TECH

Method for adding crude anhydride in maleic anhydride production process

InactiveCN102863411AImprove economic efficiencyThe refining process is simpleOrganic chemistrySolventMaleic anhydride

The invention provides a method for adding crude anhydride in maleic anhydride production process; a refining system used for producing maleic anhydride is a continuous refining system formed by three towers and two kettles including two refining kettles, an azeotropic dehydrating tower, a solvent recovery tower and a refining tower; and the crude anhydride is directly added into the azeotropic dehydrating tower and is added from the middle part of the azeotropic dehydrating tower. The invention also provides the refining system used for the method for adding the crude anhydride in the maleic anhydride production process; the crude anhydride is directly added into the azeotropic dehydrating tower, so that the crude anhydride is completely dehydrated in the adding process, the free acid in the crude anhydride is removed, the refining yield is avoided being influenced, and the economic benefit of enterprises can be more conveniently increased; and the invention leads the refining process of the maleic anhydride to be more convenient, and has the advantages of being simple in structure, convenient to maintain, low in processing cost, high in production efficiency and the like.

Owner:TIANJIN BOHUA ZHONGHE CHEM

A method for the synthesis of ursodeoxycholic acid from chenodeoxycholic acid with high-efficiency whole-cell catalysis

ActiveCN105368828BFermentation methods are cheap and readily availableSuitable for industrial productionBacteriaMicroorganism based processesChemical synthesisLactate dehydrogenase

The invention provides a method for catalyzing chenodeoxycholic acids to compound ursodesoxycholic acids through efficient whole-cells. A 7a-hydroxysteroid dehydrogenase (7a-HSDH) and a lactic dehydrogenase (LDH) for regeneration of coenzyme nicotinamide adenine dinucleotide (NAD) are efficiently co-expressed in escherichia coli, escherichia coli whole cells are used to catalyze chenodeoxycholic acids (CDCA) to generate 3 alpha (Alpha)-hydroxyl-7-oxo-5bata (Beta)- cholanic acids (7-KLCA), and a reaction liquid which is obtained by catalyzing the chenodeoxycholic acids through whole cells is adjusted to be 7-KLCA crude products. Reconstitution cells can be easily obtained in low cost through a fermentation process, are better than a chemical synthesis method in production cost and product quality, and are suitable for commercial process.

Owner:苏州天绿生物制药有限公司

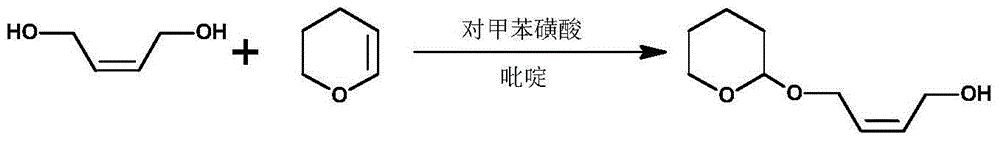

Synthetic method of cis-4-(tetrahydropyrane-2-oxy)-2-butylene-1-ol

InactiveCN105017192AThe refining process is simpleExpand sourceOrganic chemistryAddition reactionSulfonic acid ester

The invention discloses a synthetic method of cis-4-(tetrahydropyrane-2-oxy)-2-butylene-1-ol. The synthetic method comprises the following steps: performing low-temperature recrystallization and desolution by using acetone on 1,4-butendiol which is taken as a raw material to prepare high-purity cis-1,4-butendiol, then performing addition reaction with 2,3-dihydropyrane under the complex catalysis of toluene-p-sulfonic acid monohydrate and pyridine, and performing desolution to obtain a product namely cis-4-(tetrahydropyrane-2-oxy)-2-butylene-1-ol. The method does not need high-purity cis-1-4-butendiol as a raw material anymore, so that the cost is reduced, the raw material source is broadened, and convenience is provided for industrial production. Moreover, the refining process of butendiol is simple and suitable for scale production. The cis content after refining can be improved to more than or equal to 99.5%. The addition process is simple to operate, and the reaction condition is mild. Methylbenzene extraction and water scrubbing are performed, so that the residues of butendiol are greatly reduced, the product quality is improved, the non-rectification content can reach more than or equal to 80%, and the molar yield to 2,3-dihydropyrane after purification reaches more than or equal to 73%.

Owner:江苏威格瑞斯化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com