Flexible methanol rectification method and device capable of producing both MTO-grade and AA-grade methanol

A methanol rectification and flexible technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as inability to generate benefits, complicated operation, and inability to produce AA grade methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

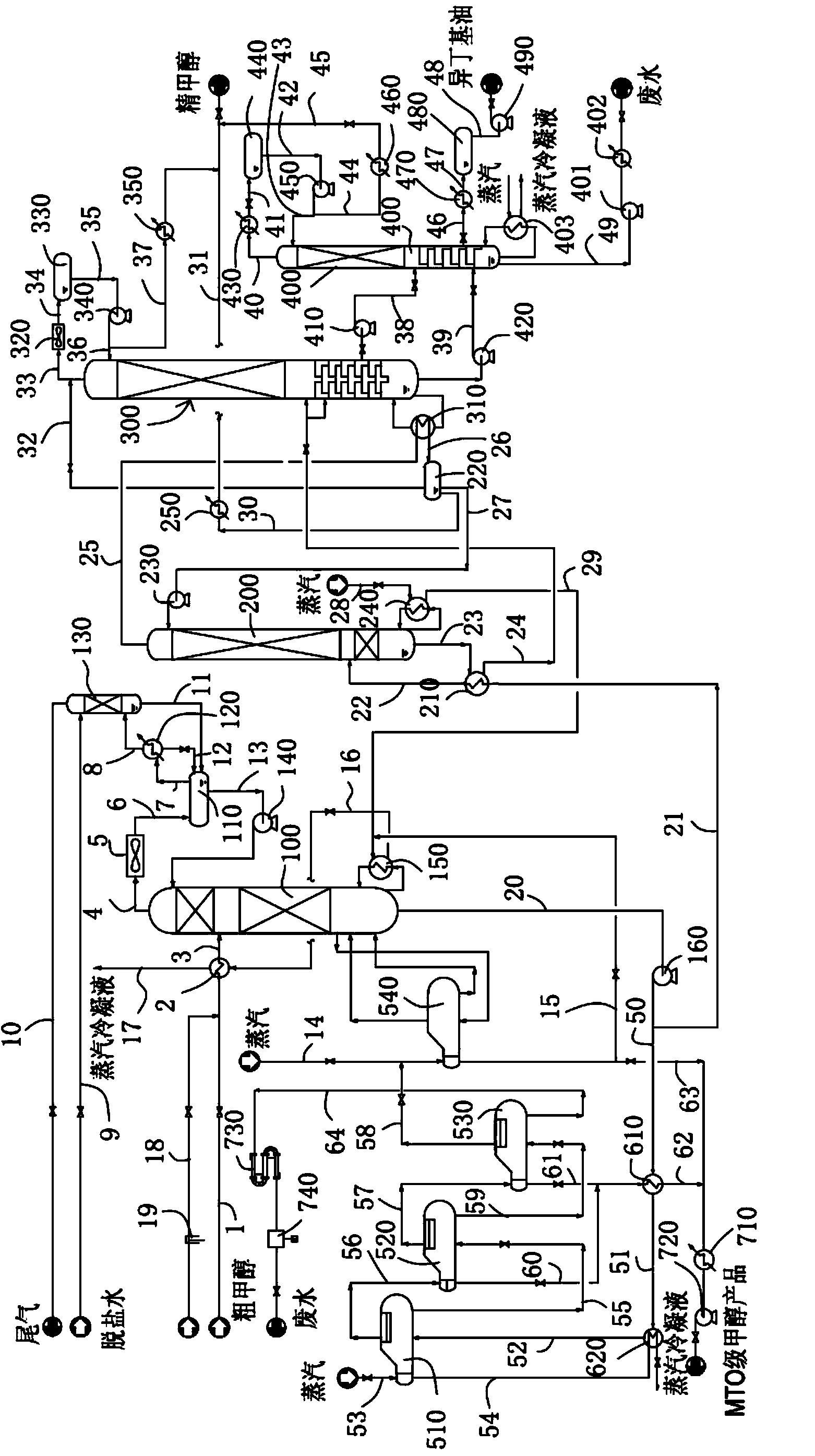

[0053] see figure 1 , a flexible methanol rectification device and process that can produce both MTO grade and AA grade methanol is shown in the figure, including a stabilizing tower 100, a pressurized rectification tower 200, an atmospheric rectification tower 300, and a recovery tower 400 methanol four-tower rectification device and also includes the first effect evaporator 510, the second effect evaporator 520, the third effect evaporator 530, the fourth effect evaporator 540 and the first column tank methanol preheater 610, The methanol preheater 620 in the second column tank and the fourth effect evaporator 540 can be shared as a steam reboiler. The pressurized rectification column 200 is a fully structured packing column.

[0054] When preparing AA grade methanol, the equipment configuration process is as follows:

[0055] The crude methanol from the crude methanol storage tank or the methanol synthesis circuit is sent to the crude methanol preheater 2 through the pipe...

Embodiment 2

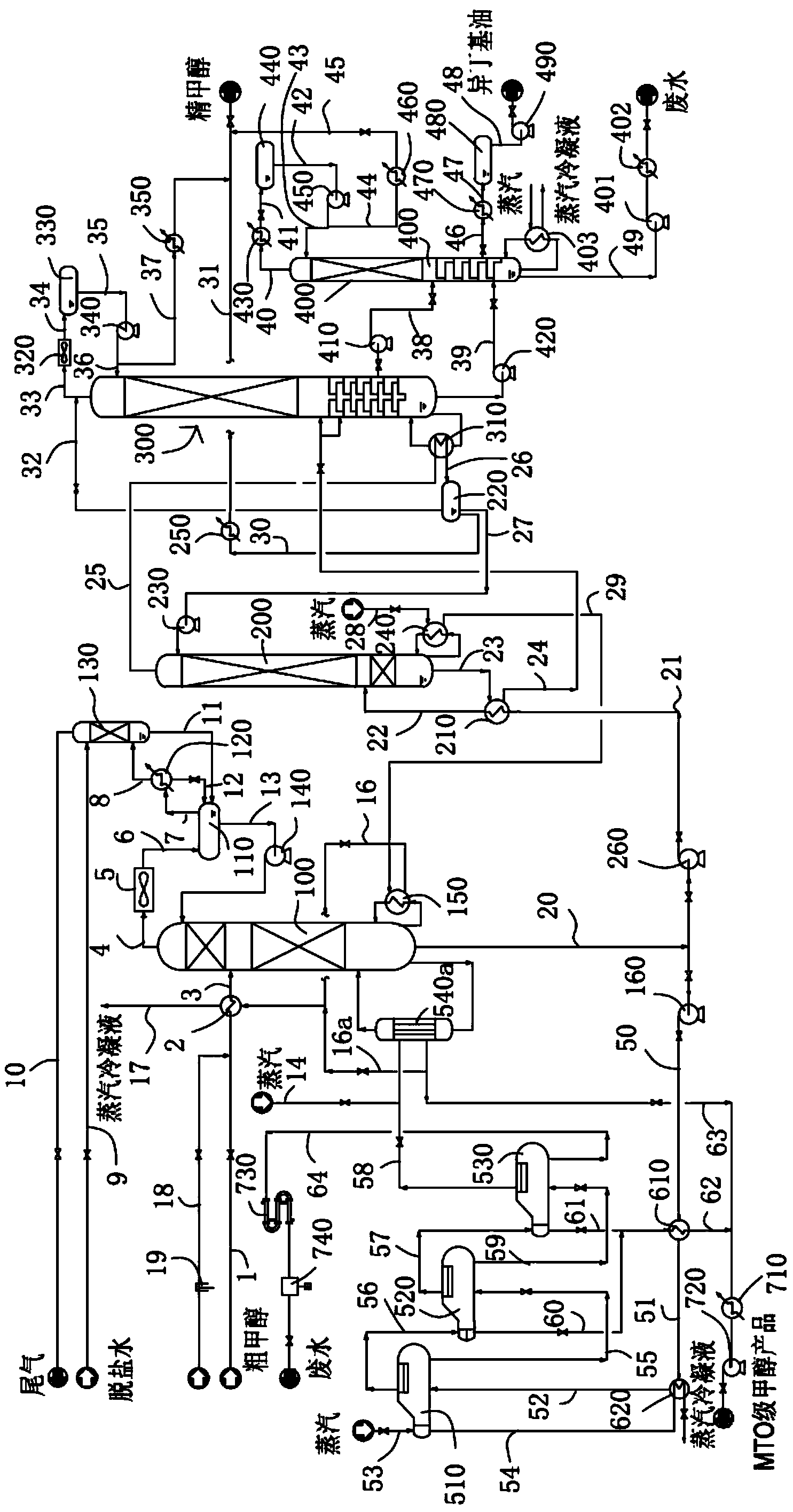

[0075] see figure 2 , a flexible methanol rectification device and process that can produce both MTO grade and AA grade methanol is shown in the figure, including a stabilizing tower 100, a pressurized rectification tower 200, an atmospheric rectification tower 300, and a recovery tower 400 methanol four-tower rectification device and also includes the first effect evaporator 510, the second effect evaporator 520, the third effect evaporator 530, the pre-column reboiler 540a and the first column tank methanol preheater 610, The methanol preheater 620 in the second column tank. The pressurized rectification column 200 is a fully structured packing column.

[0076] The crude methanol from the crude methanol storage tank or the methanol synthesis circuit is sent to the crude methanol preheater 2 through the pipeline 1 for preheating, and the crude methanol preheated by the crude methanol preheater 2 enters the upper part of the stabilization tower 100 through the pipeline 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com