Functional lubricating grease and preparation thereof

A lubricating grease and functional technology, applied in the field of functional lubricating grease and its preparation, can solve the problems of complex production process and high production cost, and achieve the effect of simple refining process, low cost and improved structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

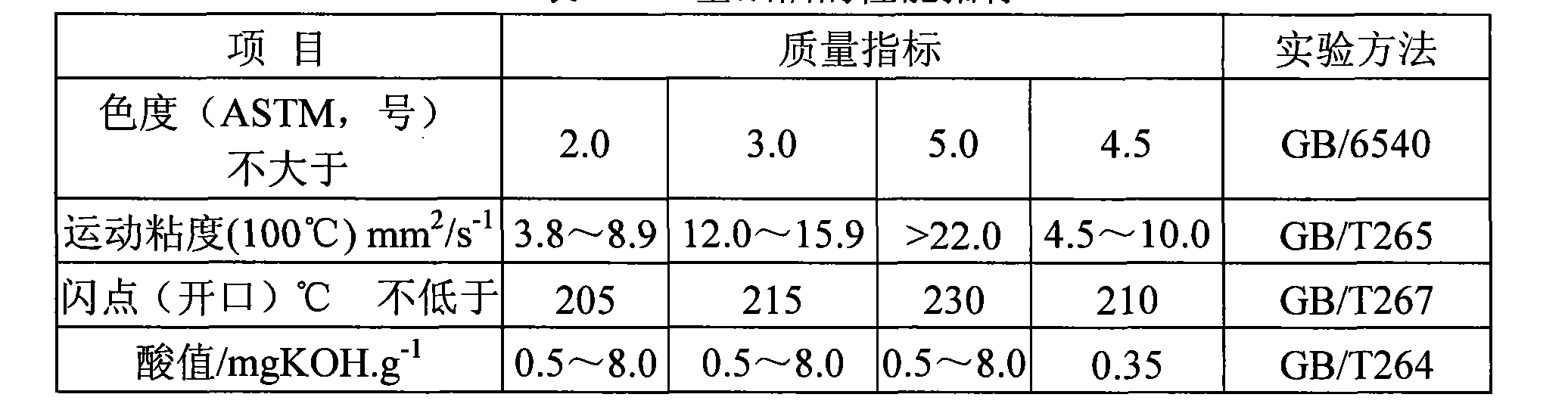

Examples

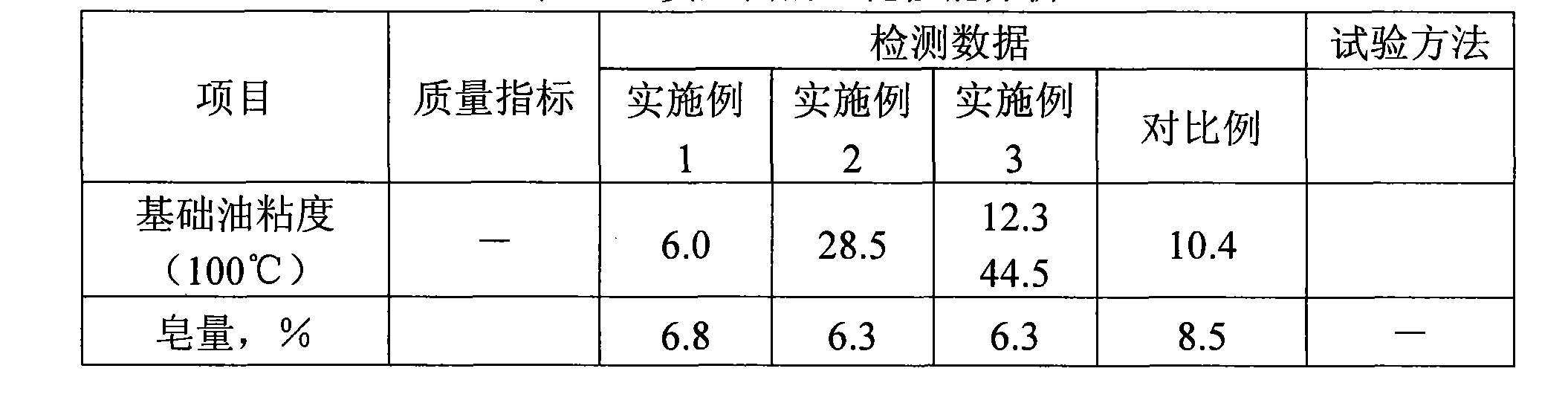

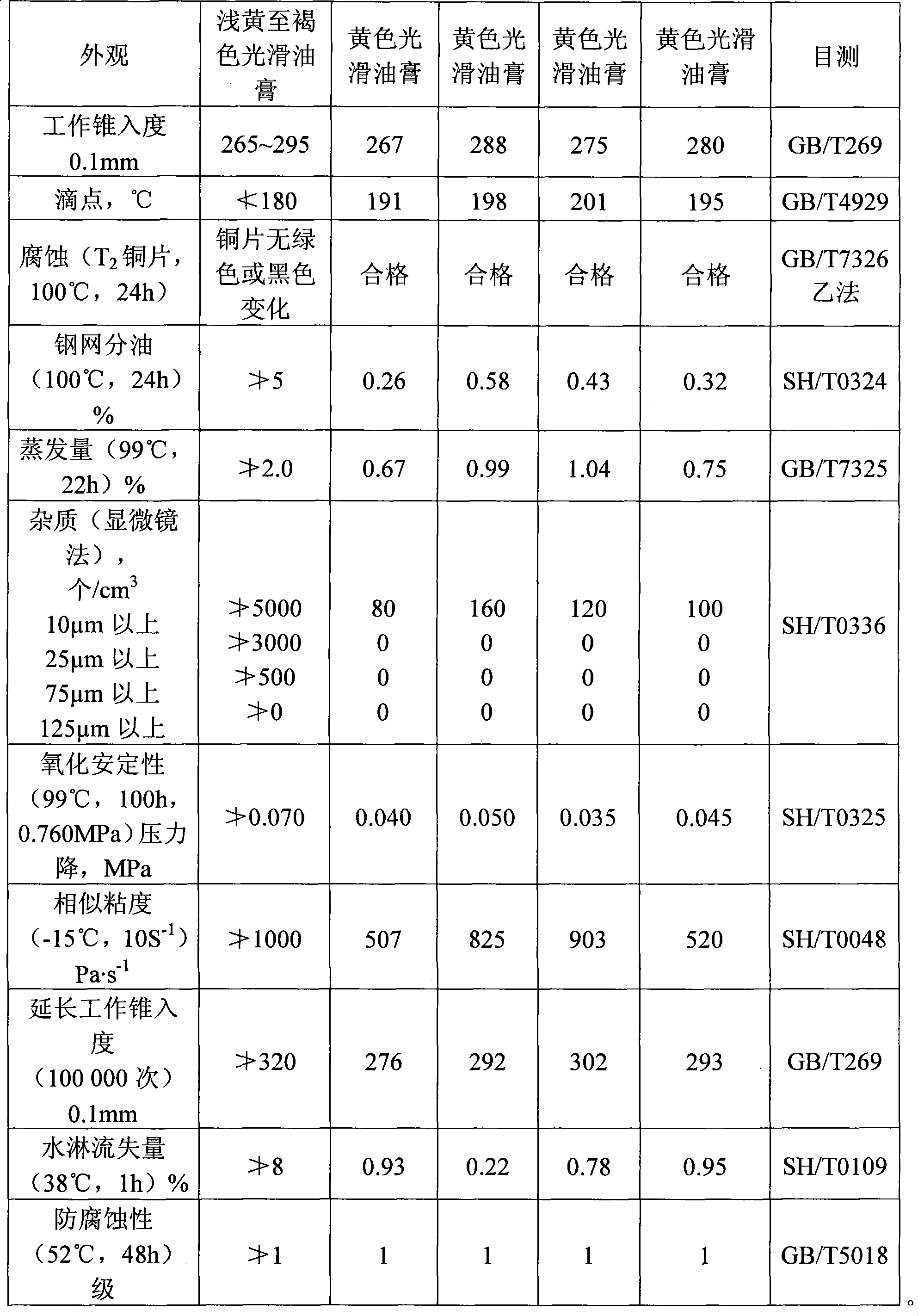

Embodiment 1

[0014] Embodiment 1, preparation functional lubricating grease

[0015] In a normal-pressure reactor with a volume of 100L and heating, cooling and stirring, add 42kg of 100°C viscosity 16.1mm 2 / s base oil, 3.48kg 12-hydroxystearic acid, heated to 80°C, added 0.507kg lithium hydroxide, 2.51kg water, heated to react, heated to 202°C, and then 16.52kg100°C viscosity 16.1mm 2 / s Base oil is added to the kettle, the temperature of the material in the reactor is lowered to 180°C, stirred, circulated and cooled, and then lowered to 110°C, circulated, filtered, homogenized, and degassed to become a product. The test results are listed in Table 1 and Table 2.

Embodiment 2

[0016] Embodiment 2, preparation functional lubricating grease

[0017] In a normal-pressure reactor with a volume of 100L and heating, cooling and stirring, add 35kg of 100°C viscosity 9.6mm 2 / s base oil, 3.15kg 12-hydroxystearic acid, heated to 82°C, added 0.459kg lithium hydroxide, 2.3kg water, heated to react, heated to 202°C, and then 21.85kg100°C viscosity 9.6mm 2 / s Base oil is added to the kettle, the temperature of the material in the reactor is lowered to 180°C, stirred, circulated and cooled, and then lowered to 110°C, circulated, filtered, homogenized, and degassed to become a product. The test results are listed in Table 1 and Table 2.

Embodiment 3

[0018] Embodiment 3, preparation functional lubricating grease

[0019] In a normal-pressure reactor with a volume of 100L and heating, cooling and stirring, add 35kg of 100°C viscosity 12.3mm 2 / s base oil, 3.15kg12-hydroxystearic acid, heated to 82°C, added 0.459kg lithium hydroxide, 2.3kg water, heated to react, heated up to 202°C, and then 21.85kg100°C viscosity 44.5mm 2 / s base oil is added to the kettle, and the temperature of the material in the reactor is lowered to 180°C, stirred, circulated and cooled, and continued to drop to 110°C, circulated, filtered, homogenized, and degassed to become a product. The test results are listed in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com