Process for production of diaryl oxalate

A technology of diaryl oxalate and dialkyl oxalate, which is applied in the direction of carbonate/haloformate preparation, organic chemical methods, chemical instruments and methods, etc., can solve the problems of increased impurities, reduced selectivity, and material Thinning and other issues, to achieve the effect of increased selectivity, improved reaction efficiency, and simplified manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0190] The present invention is illustrated in detail by way of examples below. However, the present invention is not limited to the following examples at all.

Synthetic example 1

[0192] Synthesis of tetraphenoxytitanium

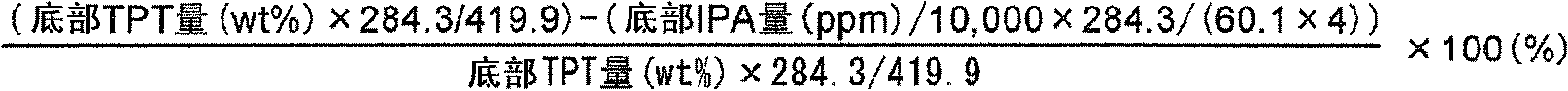

[0193] 300 ml of phenol was charged at the bottom of a flat-bottomed flask with an inner diameter of 32 mm and an Oldershaw type reactive distillation column (hereinafter referred to as "reactive distillation column for catalyst synthesis") having a volume of 1 L, and heated with an oil bath to raise the temperature. After the temperature distribution in the reactive distillation tower for catalyst synthesis was stabilized while maintaining the total reflux state, phenol was fed at a flow rate of 342.4g / h, and titanium tetraisopropoxide (TIPT) was fed at a flow rate of 21.6g / h . The ratio of the number of moles of phenol fed to the number of moles of Ti atoms in the TIPT (phenol / Ti) was 48. Keeping the reflux ratio at 5 the distillate from the top was withdrawn. In addition, it was continuously withdrawn from the bottom of the reaction distillation column for catalyst synthesis so that the liquid level at the bottom was maintained a...

Synthetic example 2~4

[0198] Synthesis of tetraphenoxytitanium

[0199] The same experiment as in Synthesis Example 1 was performed by changing some of the conditions shown in Table 1, and the results are shown in Table 1.

[0200] In addition, in the reaction solution of Synthesis Example 4, TPT was partially separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com