Patents

Literature

33results about How to "Inhibition of thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

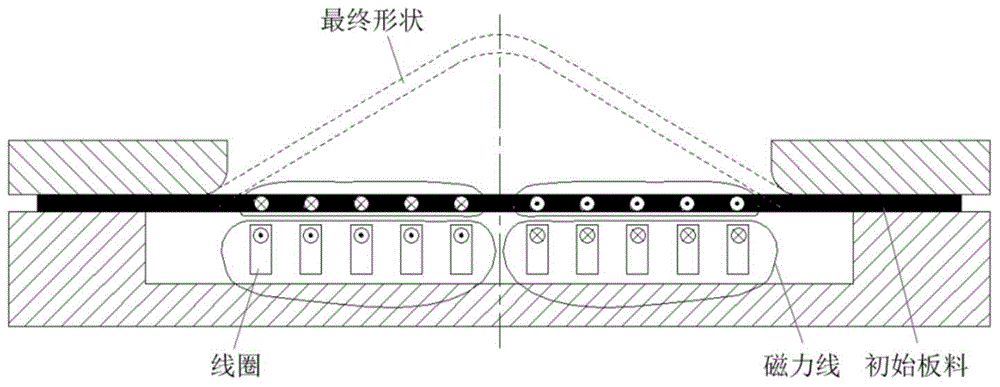

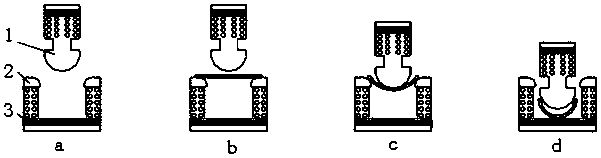

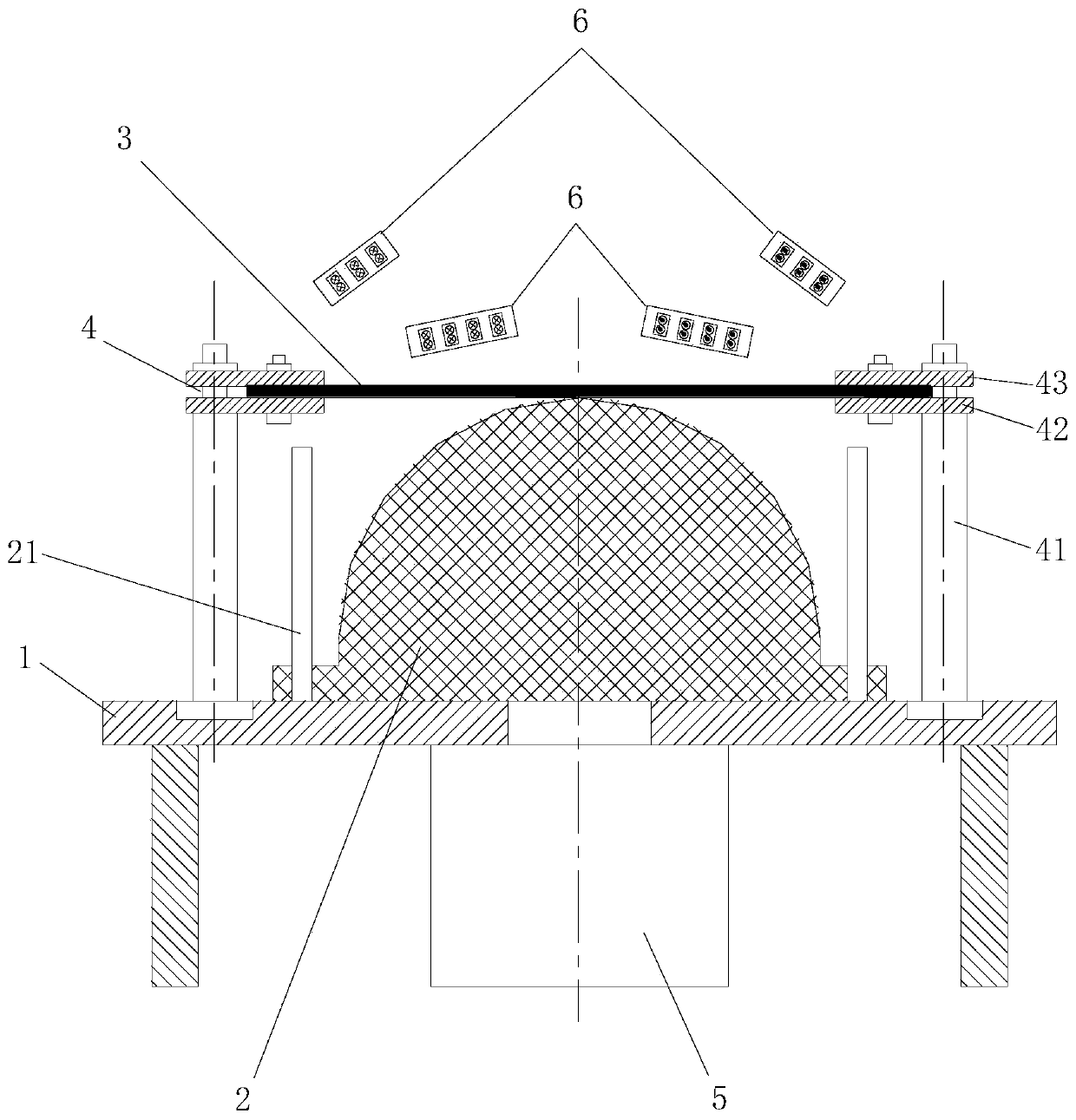

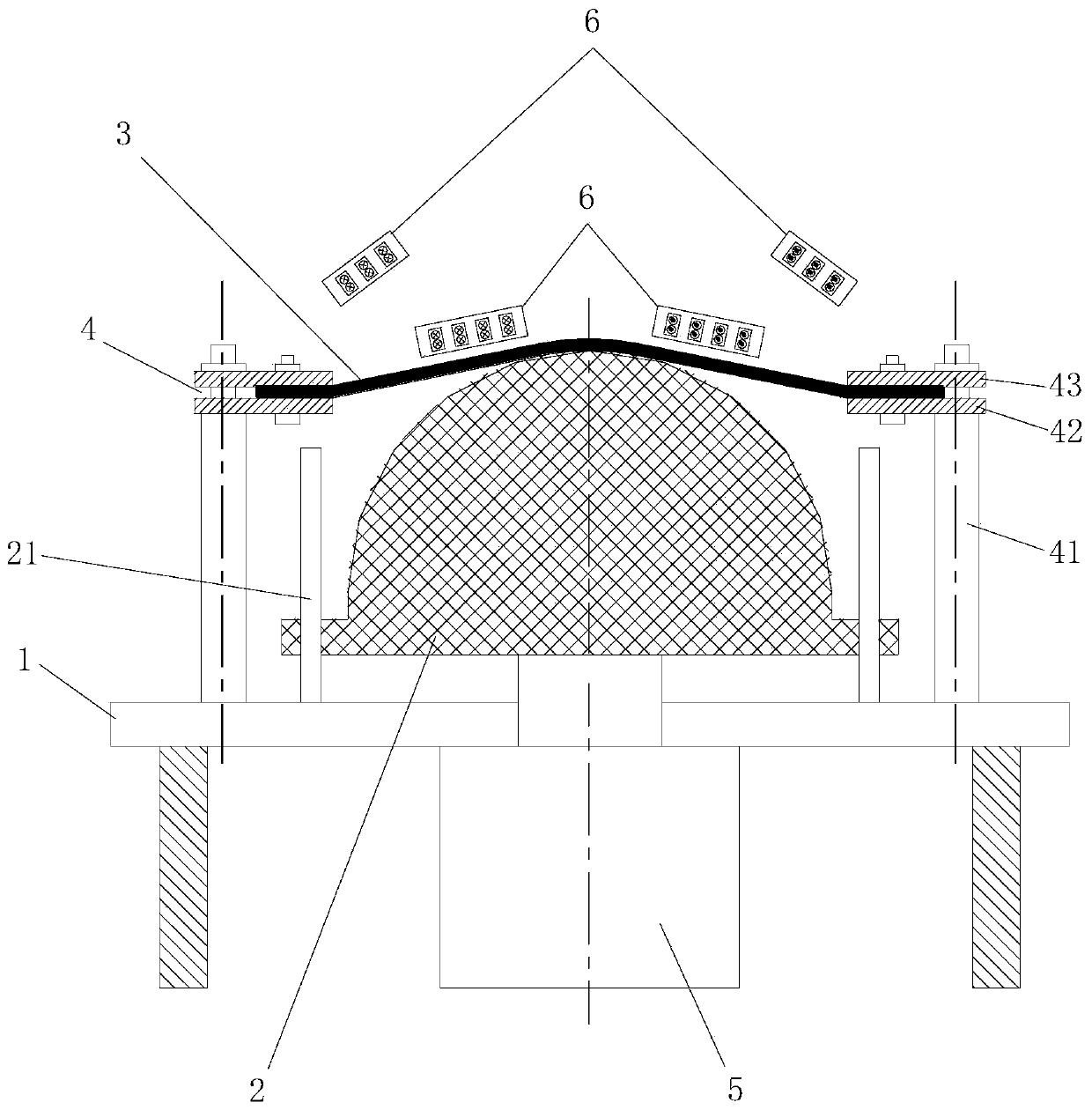

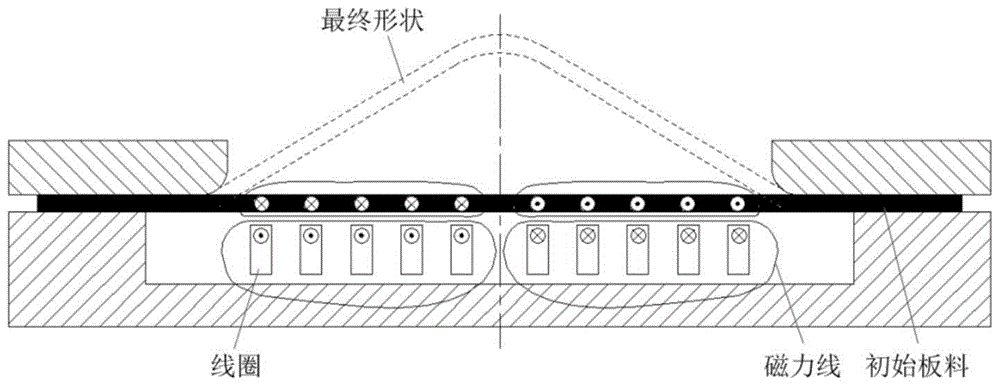

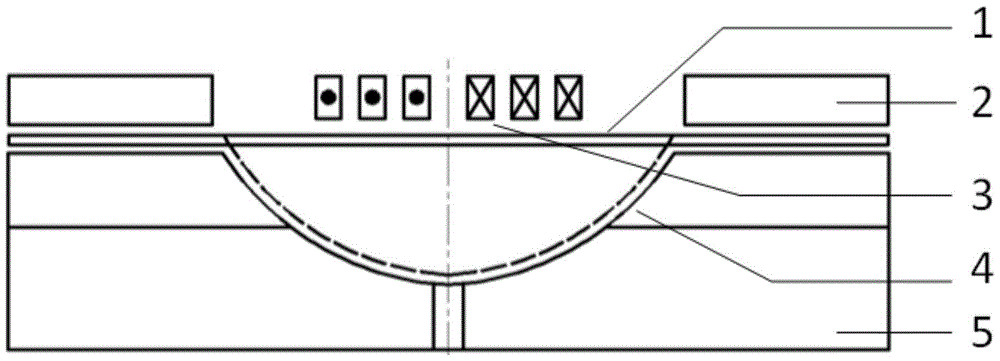

Stretch-forming and electromagnetic combining incremental forming method and device of large thin-wall part

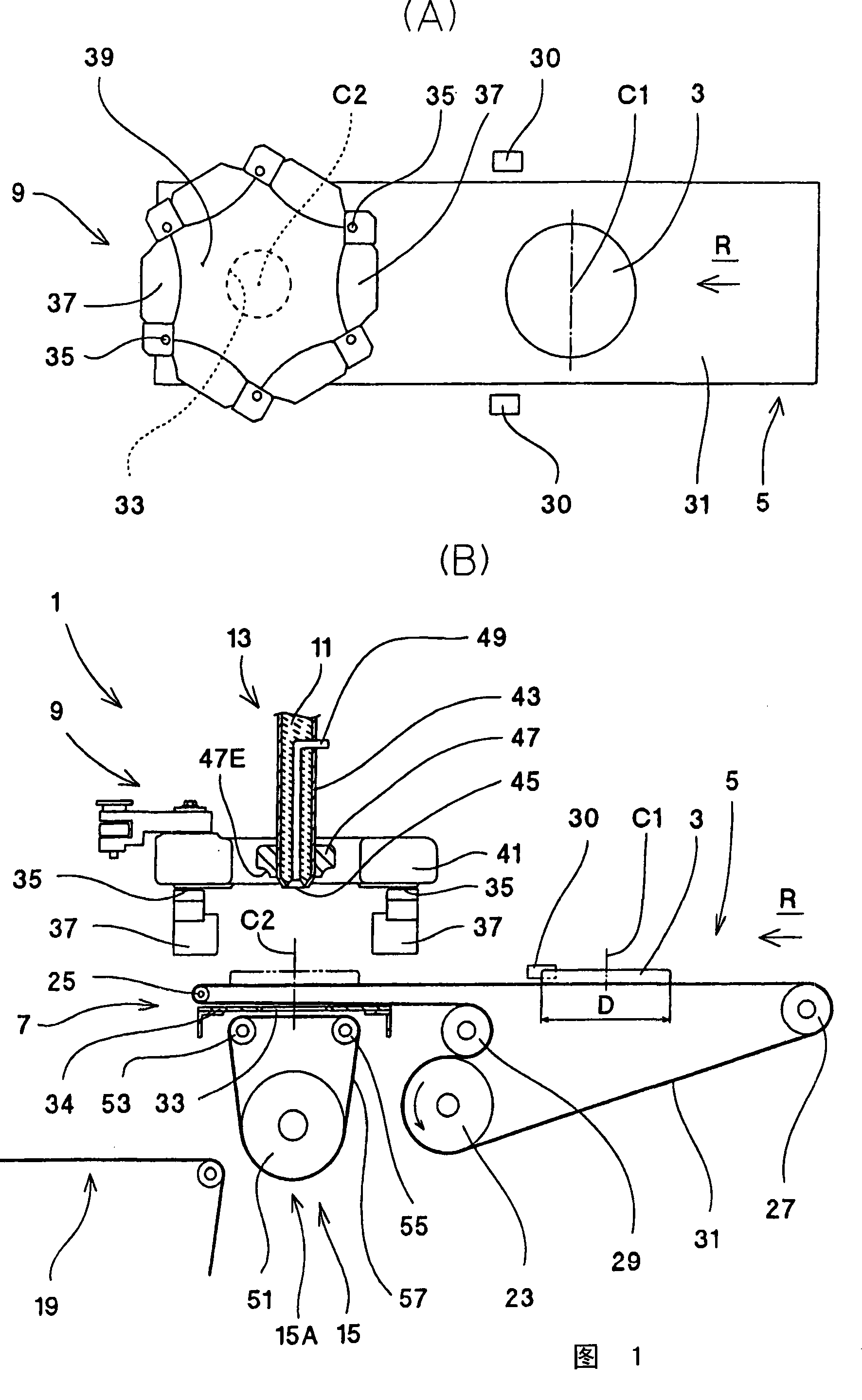

The invention discloses a stretch-forming and electromagnetic combining incremental forming method and device of a large thin-wall part. The method comprises the steps that a driving plate is arranged above a plate to be deformed, the driving plate and the plate to be deformed are clamped by a pressing plate and a supporting plate, and a lifting oil cylinder drives the supporting plate to move, so that the driving plate and the plate to be deformed are stretch-bent and tightened preliminarily, and the stretch-forming process is achieved; the position of an electromagnetic coil is adjusted, the electromagnetic coil is made to exactly face the driving plate to be deformed to discharge electricity, the coil rotates on the surface of the driving plate for a circle around the axis of a male die, and the plate to be deformed is attached to the male die at the same height; then, the oil cylinder descends again to stretch-bend the plate, the coil discharges electricity to deform the plate to be deformed again, the plate to be deformed is attached to the male die, and the alternate forming process of stretch-forming, discharging, re-stretch-forming and re-discharging of the plate is achieved in the same way till deformation of the plate is finished. The flowing evenness of materials can be improved, the thinning ratio of the plate can be reduced, and flexible processing and precise plastic manufacturing of large plates hard to deform can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

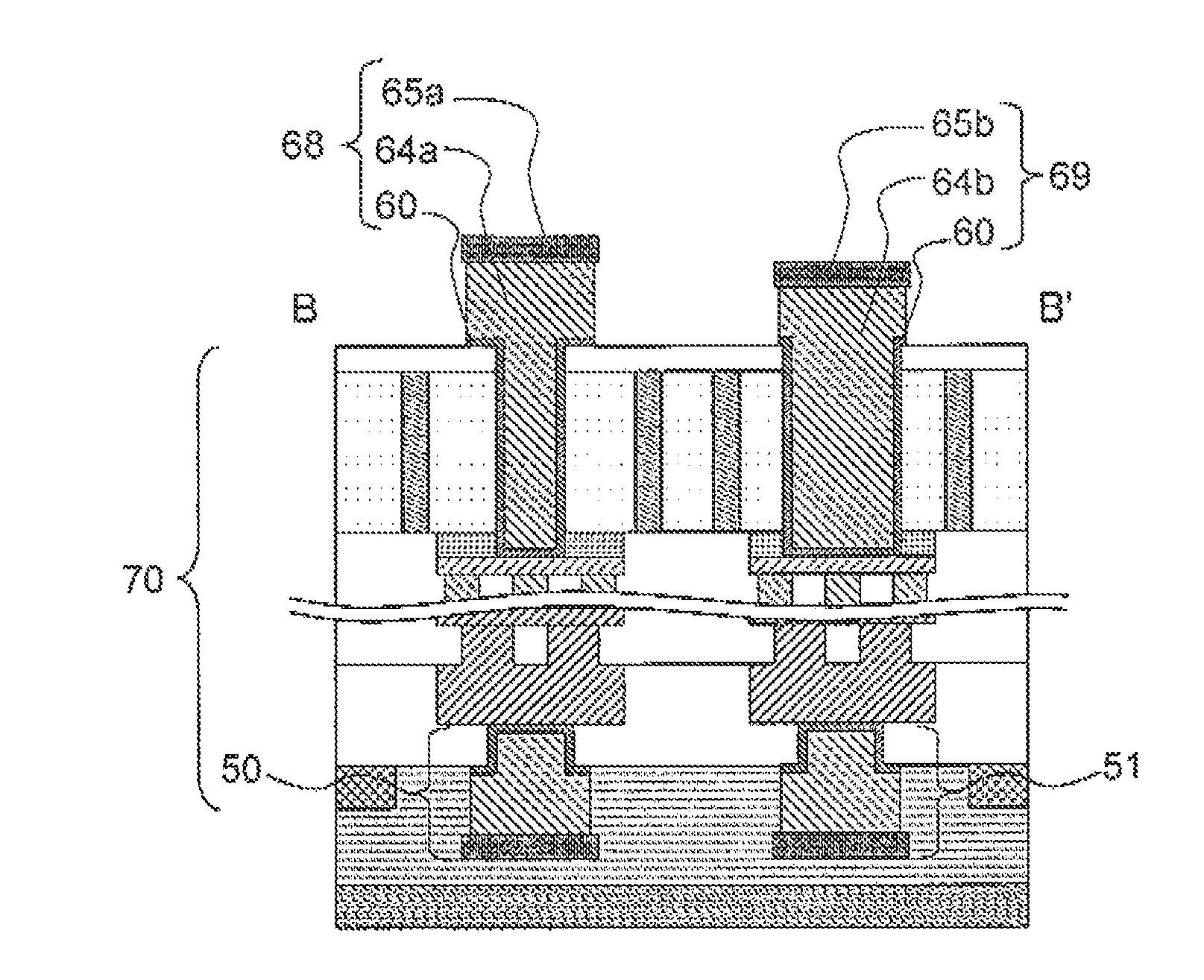

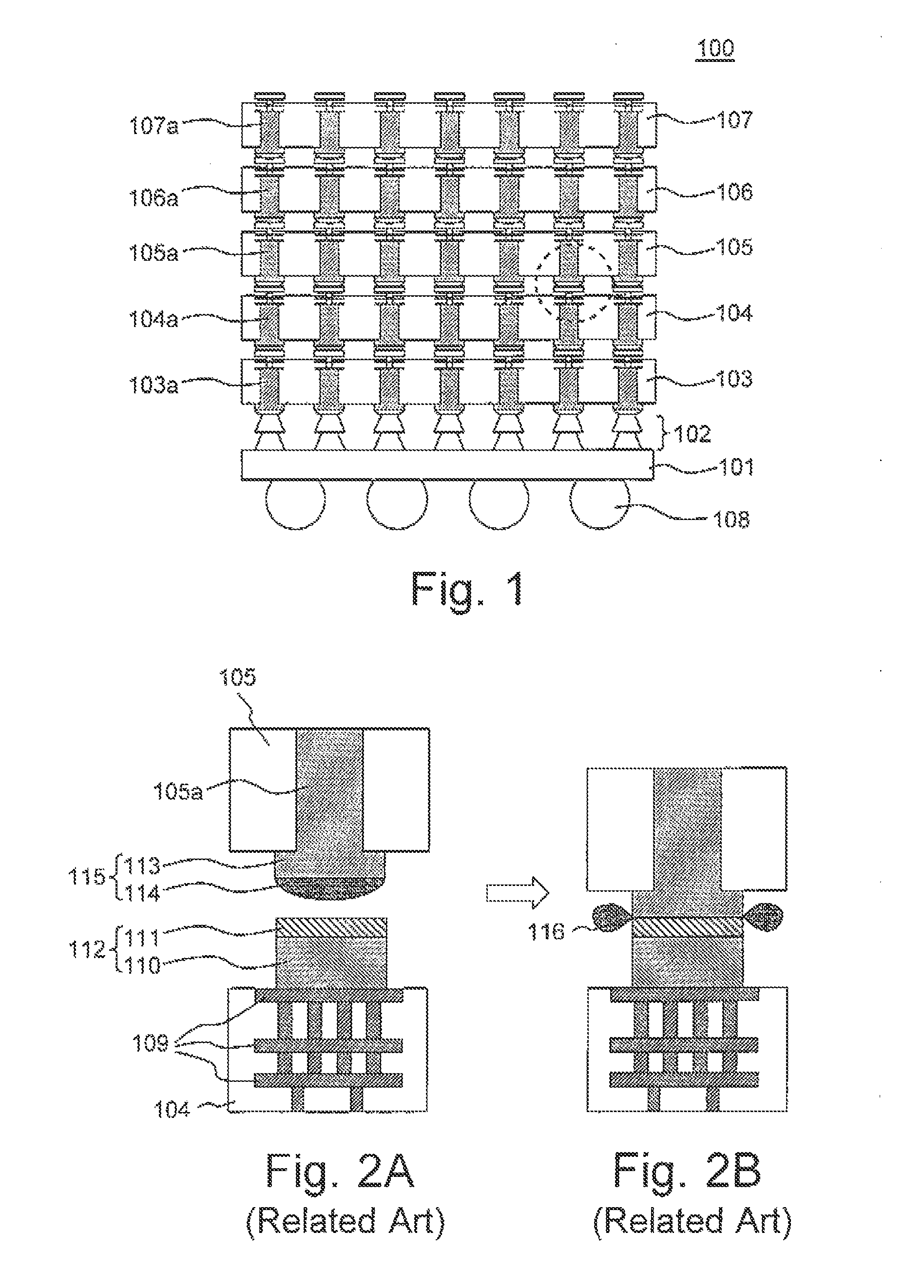

Semiconductor device

InactiveUS20130082382A1Inhibition of thinningSecure marginSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

First and second sub-bumps are provided on both surfaces of each substrate along with a usual bump structure (first and second main bumps), and at least one of the first and second sub-bumps is made greater in height than the first and second main bumps, so that the sub-bumps come into contact with one another earlier than the main bumps at the time of joining semiconductor chips, thereby securing margins of joint among the main bumps and suppressing the thin-filming of a layer, such as a solder layer, to be fluidized by heating.

Owner:PS4 LUXCO SARL

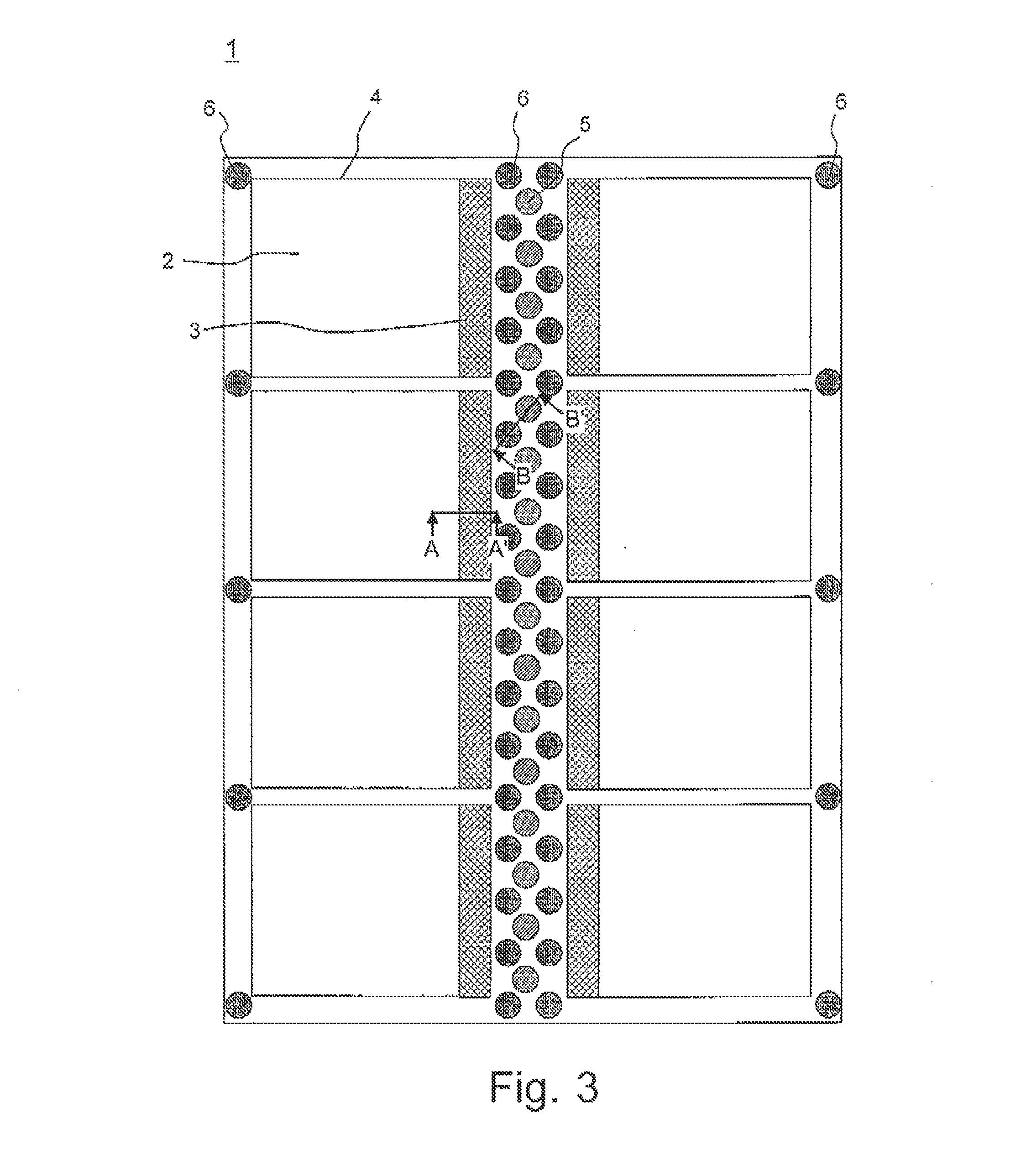

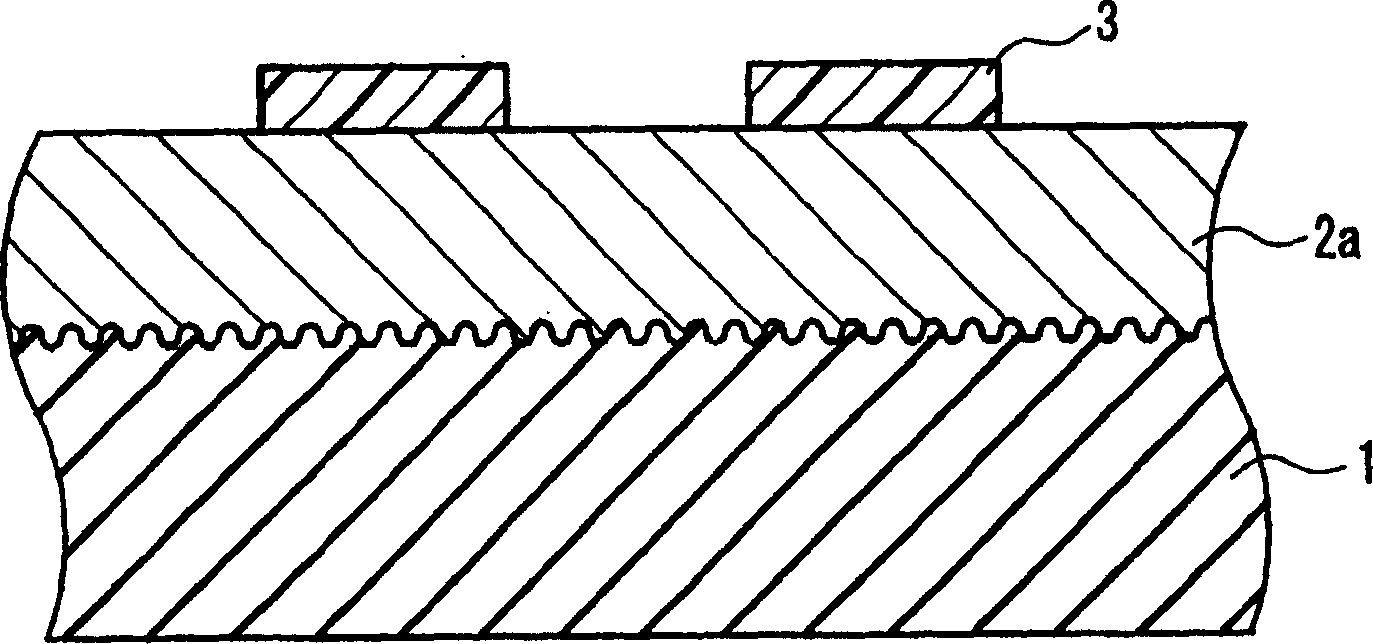

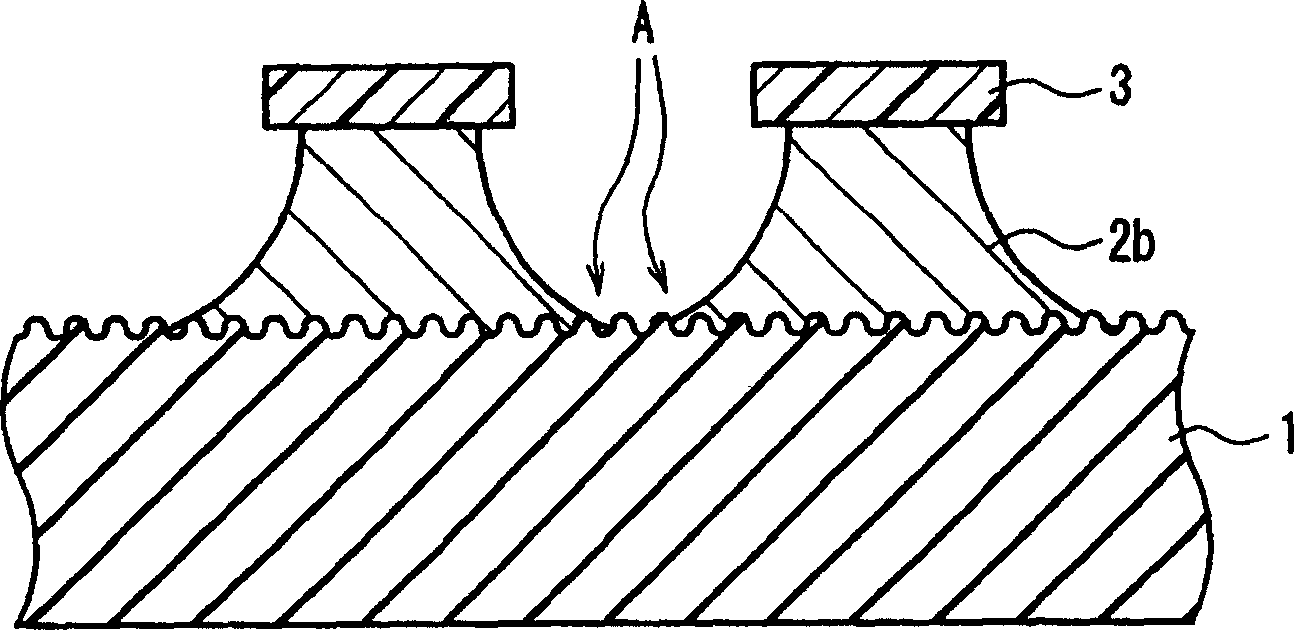

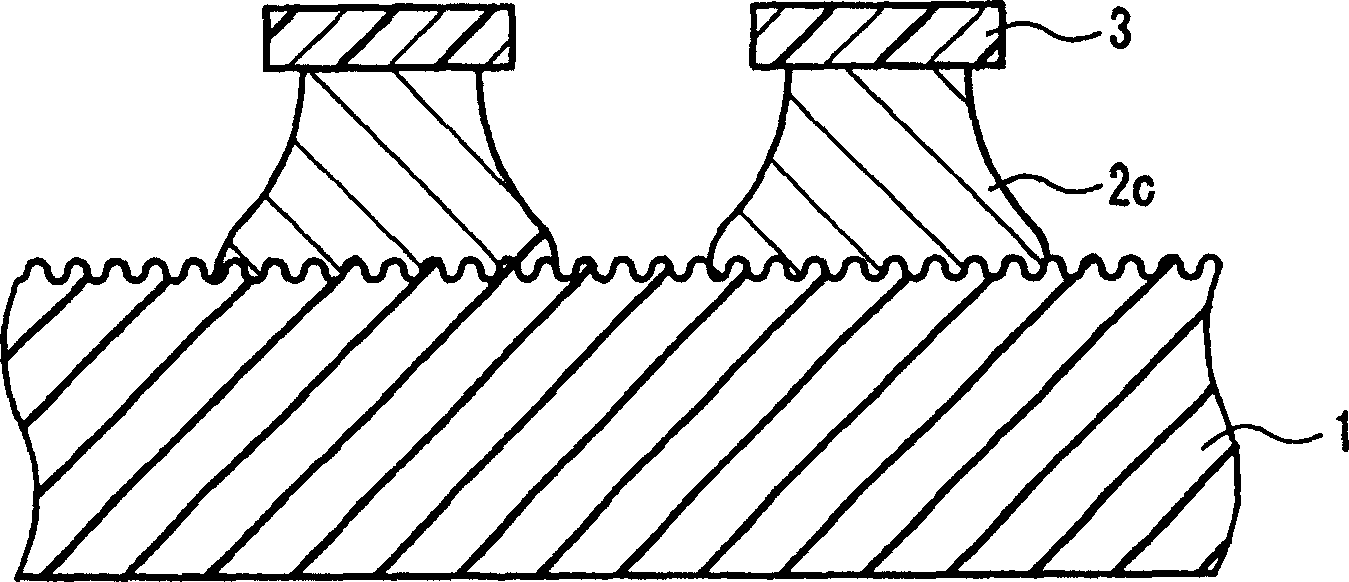

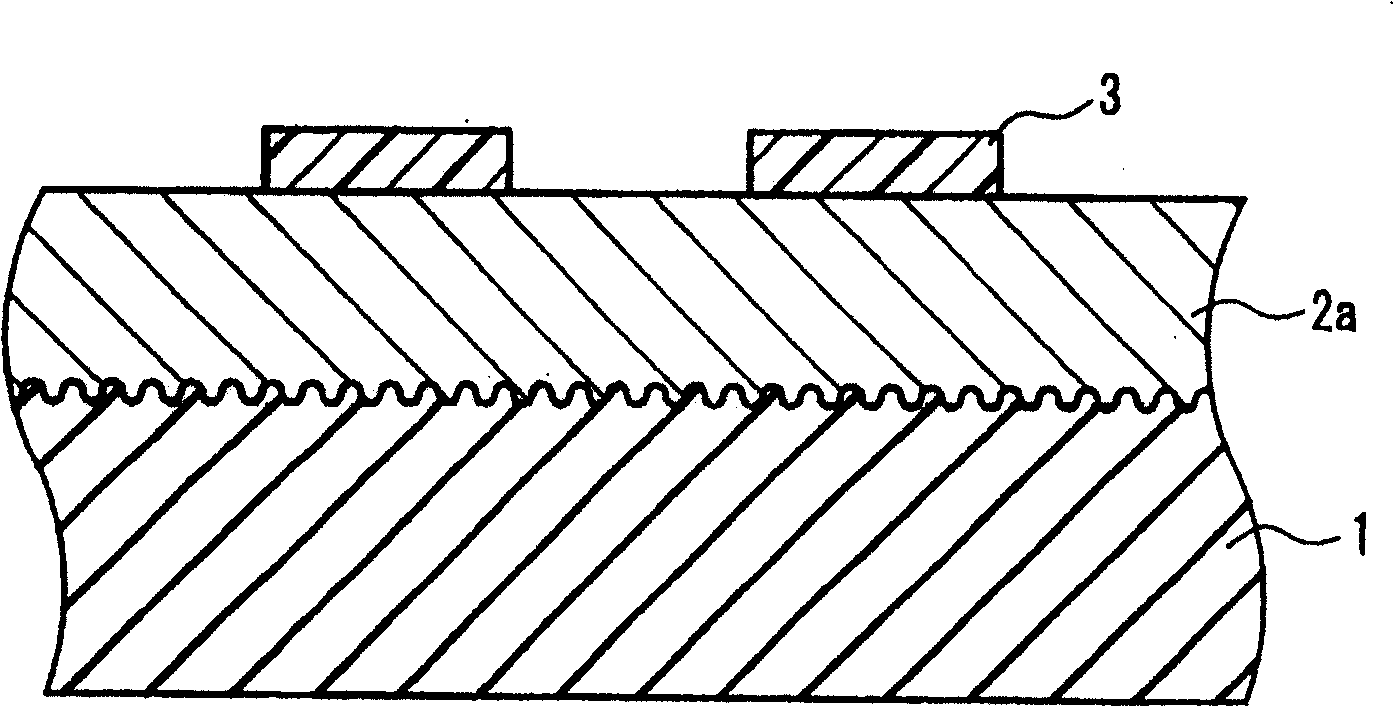

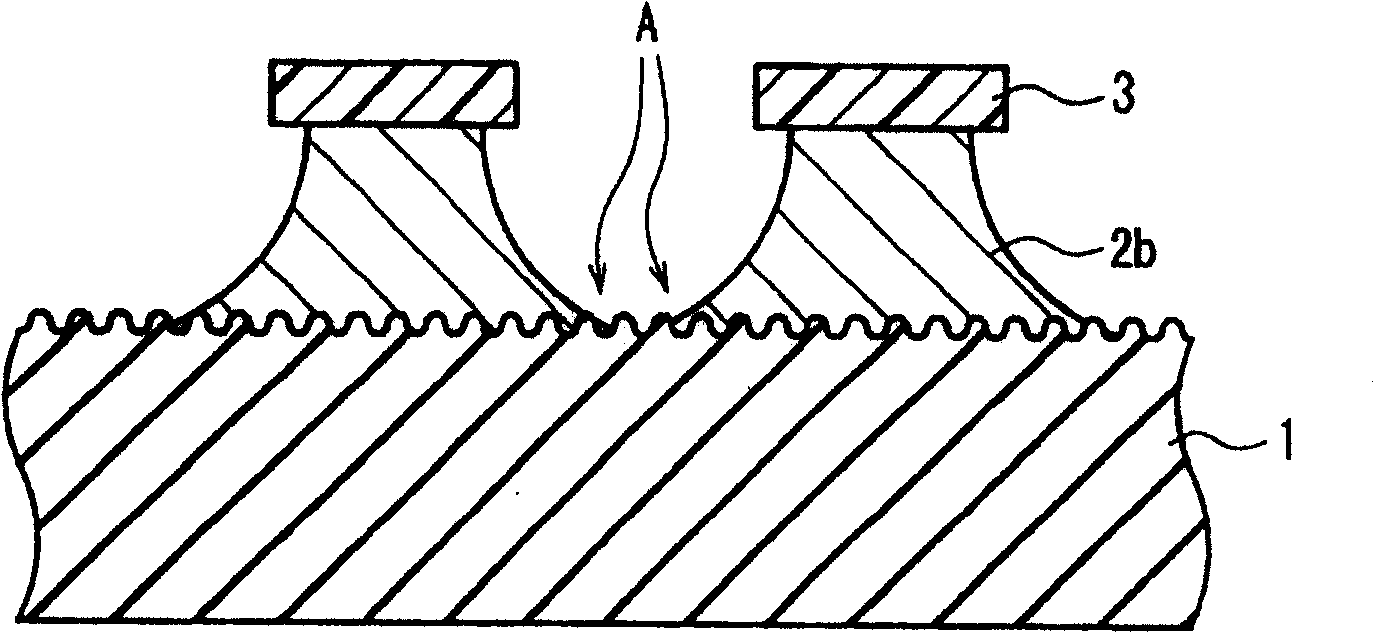

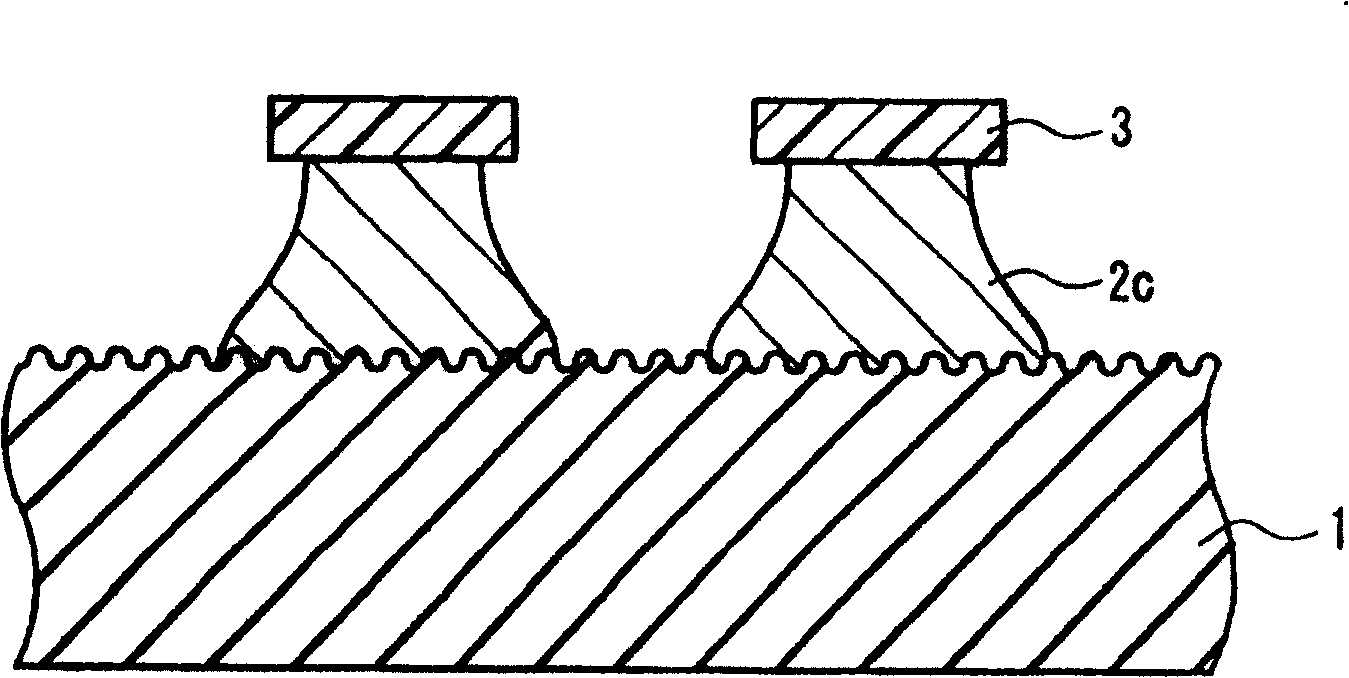

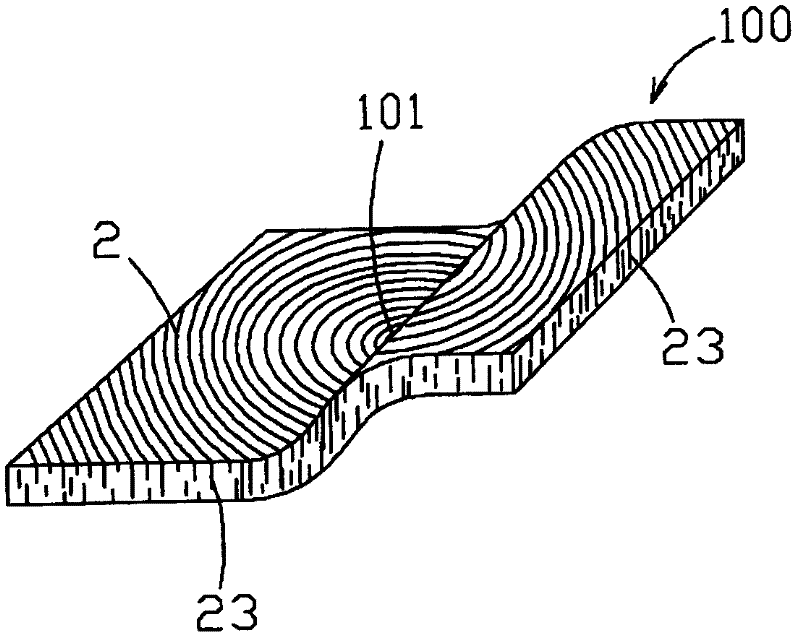

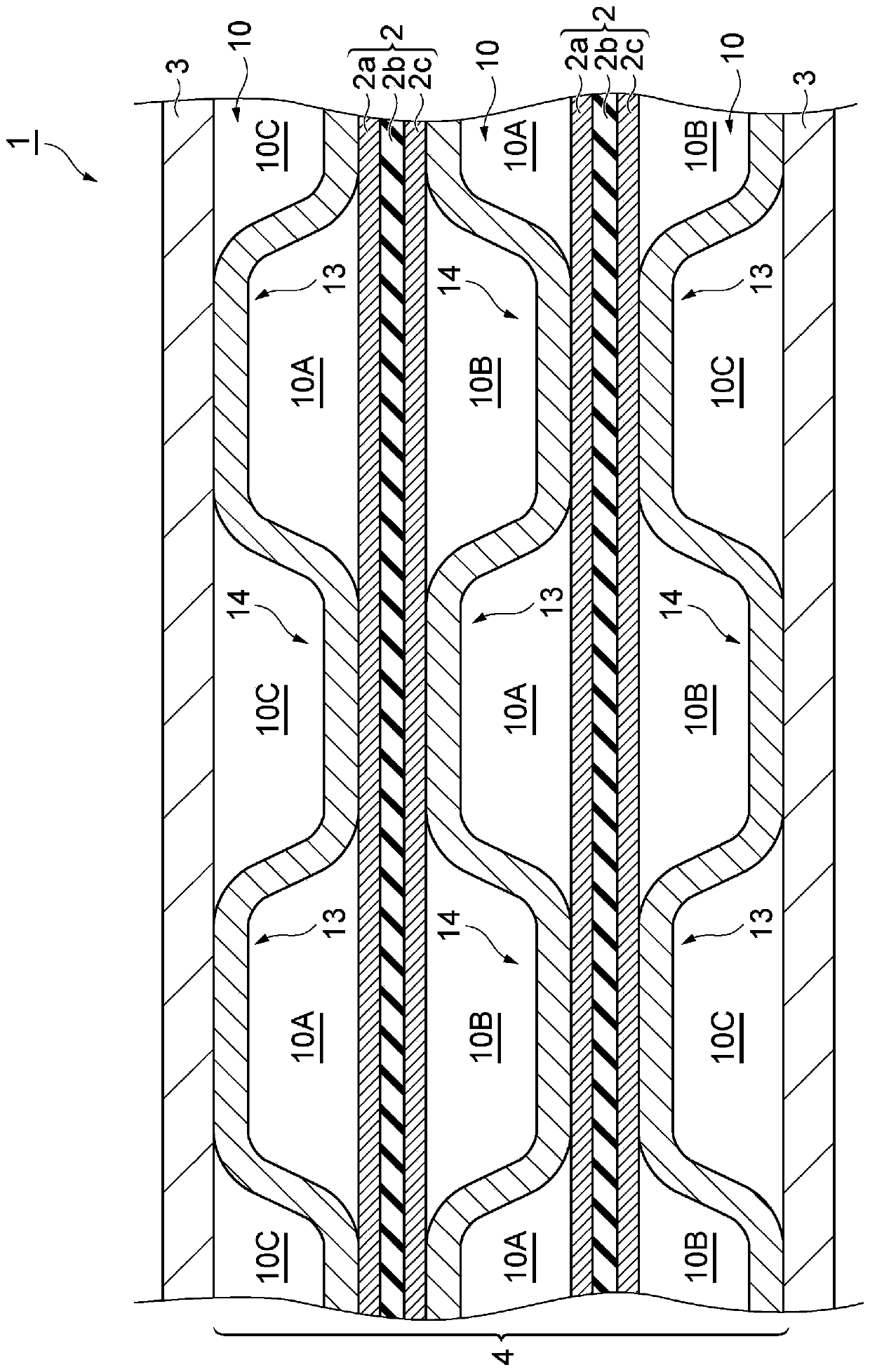

Etching solution of copper or copper alloy and method for producing electronic substrate using the solution

InactiveCN1570212AInhibition of thinningLess side etchingConductive material chemical/electrolytical removalOrganic acidEtching

The present invention provides an etching liquid for copper or a copper alloy capable of producing an electronic substrate in which side etches are reduced, the narrowing of the upper part of copper wiring is suppressed, and short circuits are not generated, and to provide a method for producing an electronic substrate using the same. In the method for producing an electronic substrate, a copper layer (2a) formed on an electrically insulated base material (1) is etched so as to be a prescribed shape to form copper wiring (2c). After the main etching, copper (A) to be removed remaining in the cuff part of copper wiring (2b) is removed with an aqueous solution comprising (a) an oxidizer for copper by 1 to 50 g / L, (b) at least one kind of acid selected from the group consisting of hydrochloric acid by 1 to 400g / L and organic acid by 1 to 200 g / L, and (c) at least one kind of polymer selected from the group consisting of polyalkylene glycol and a copolymer of polyamine and polyalkylene glycol by 0.01 to 50 g / L.

Owner:MEC CO LTD

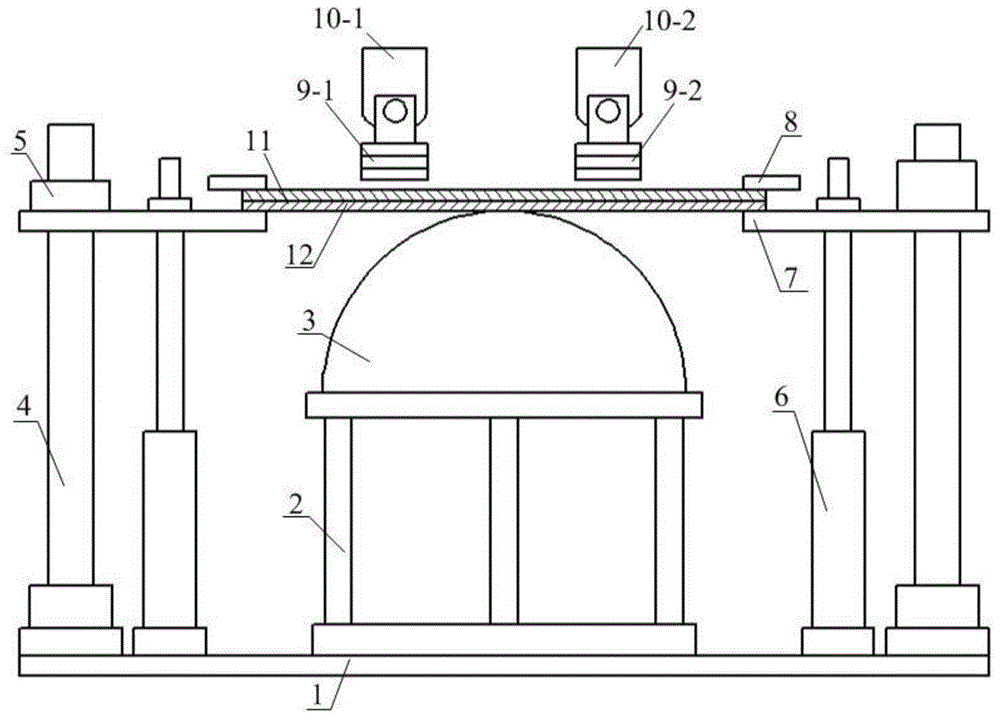

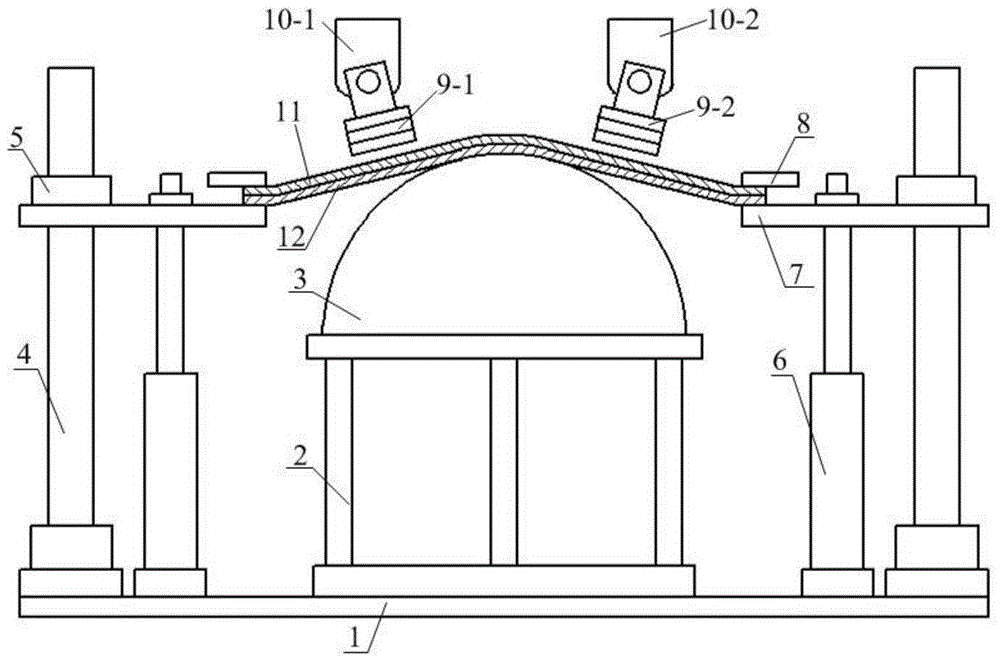

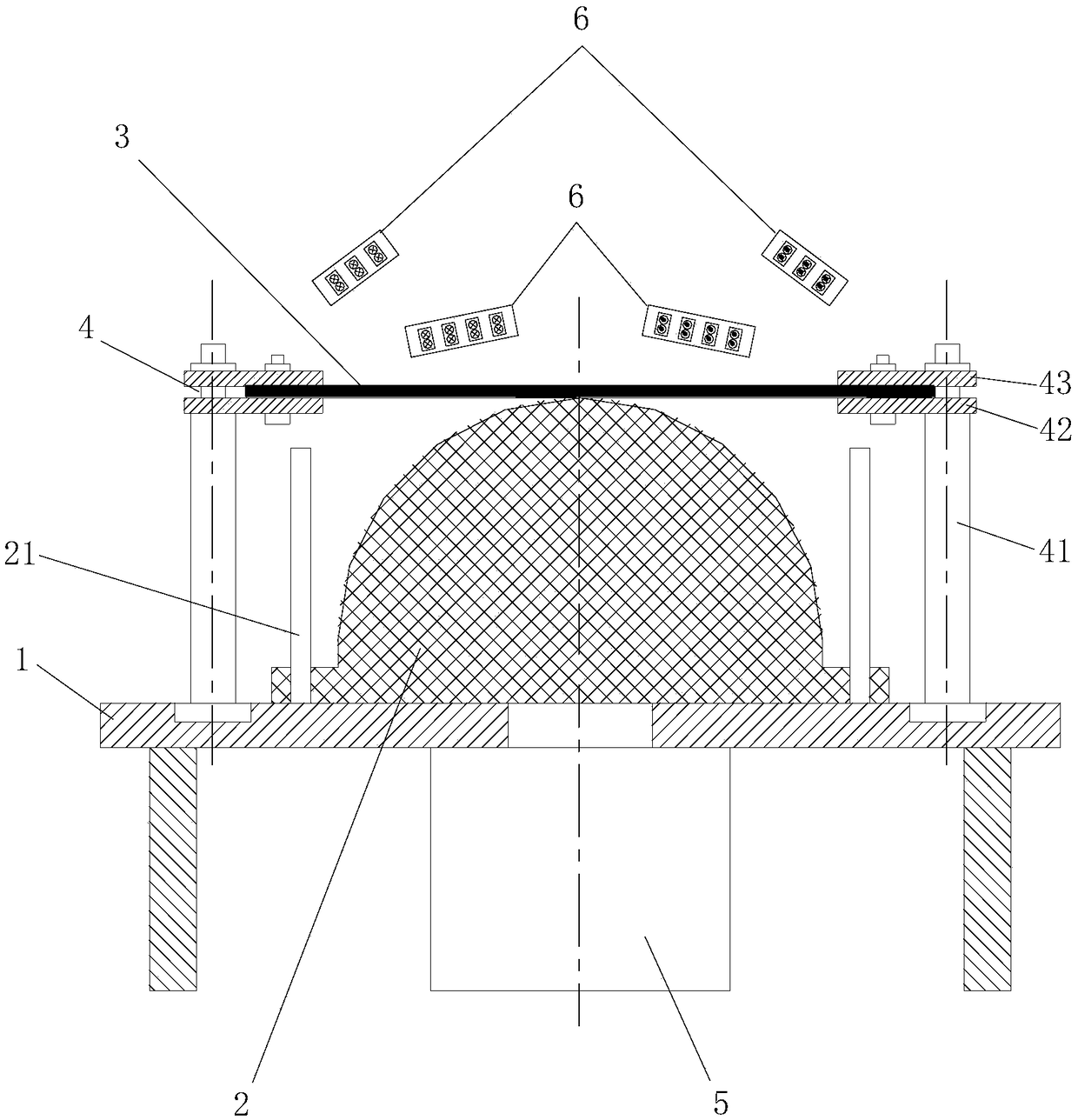

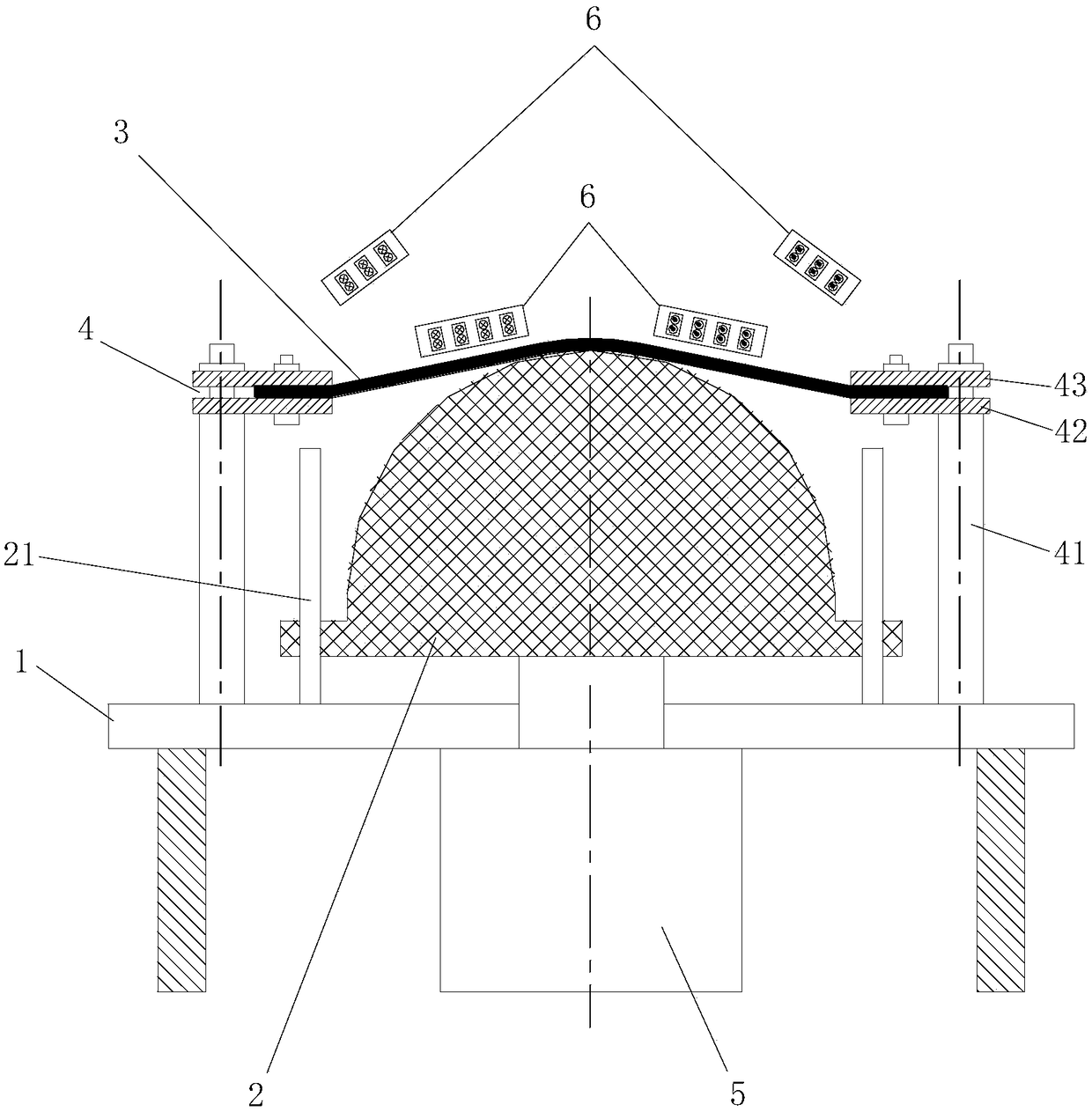

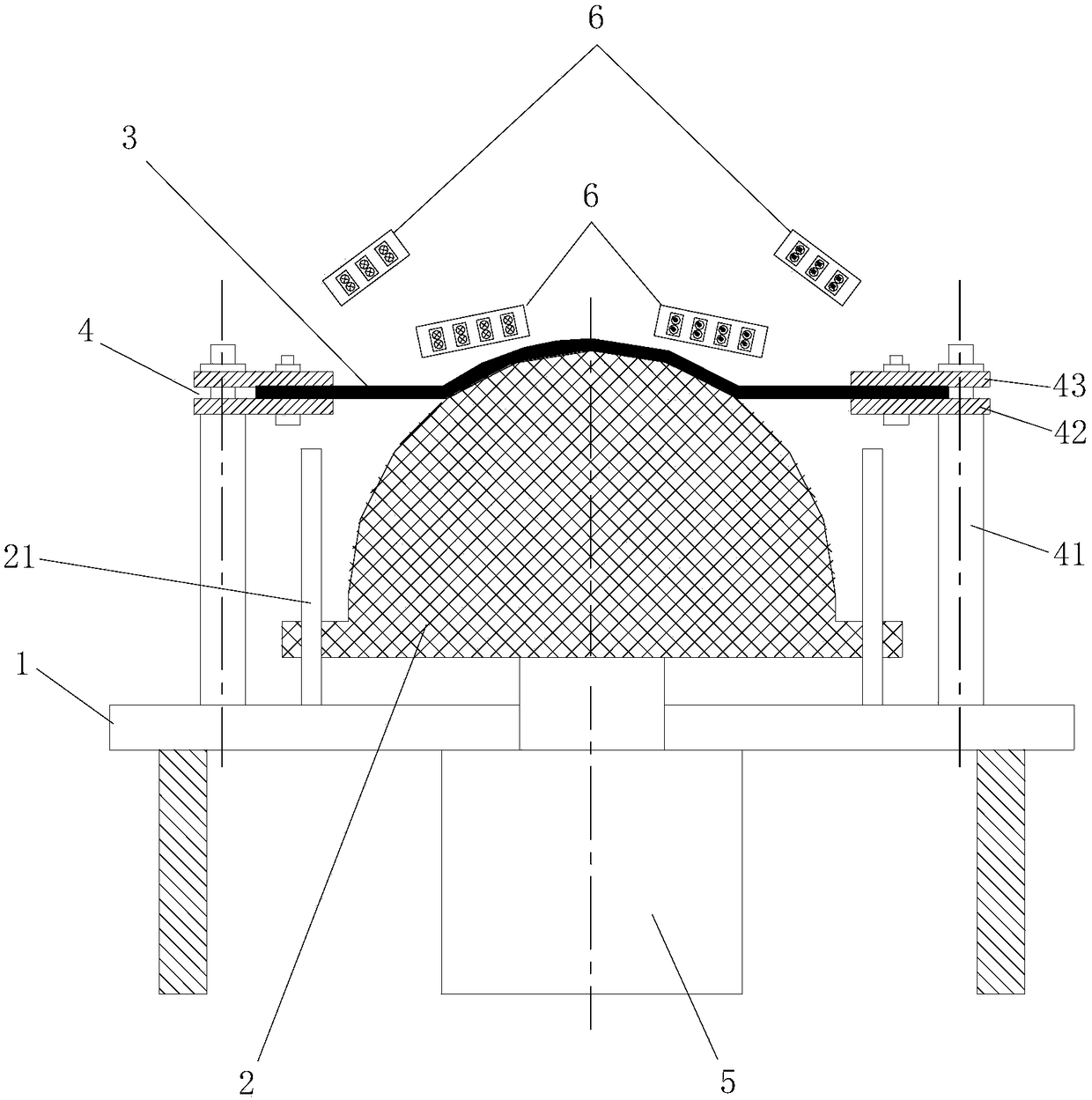

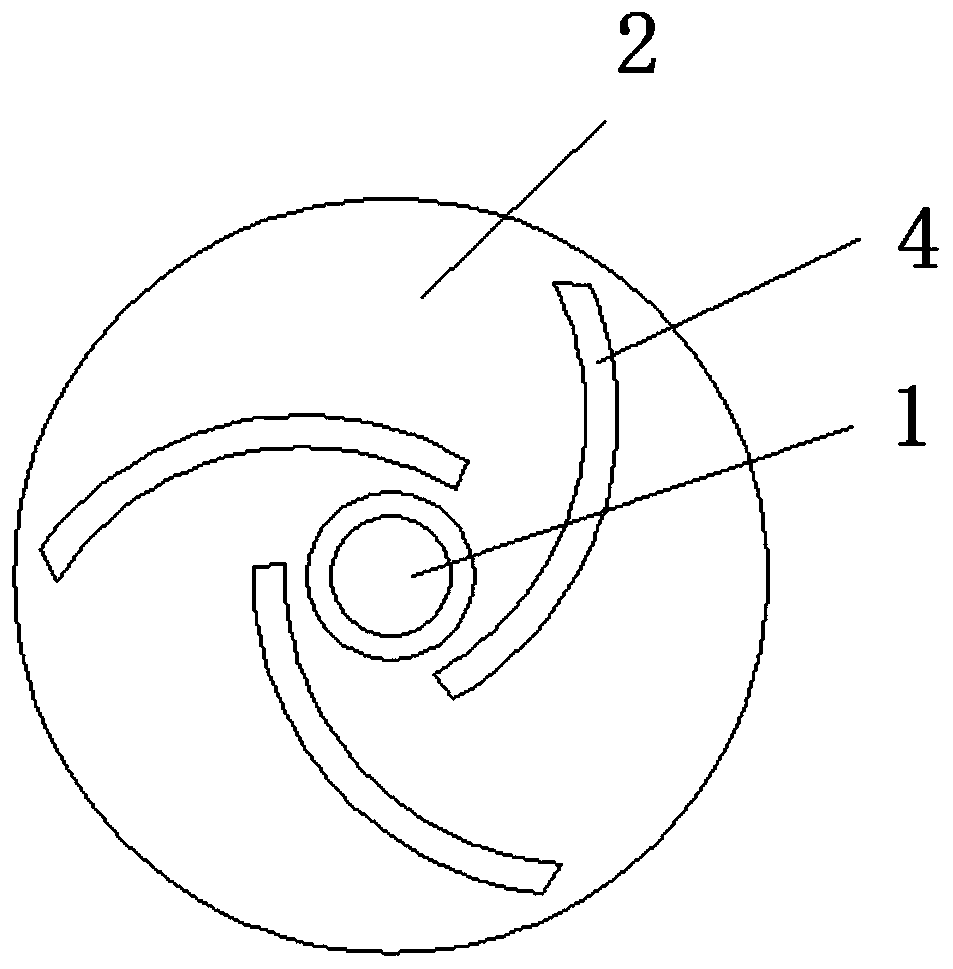

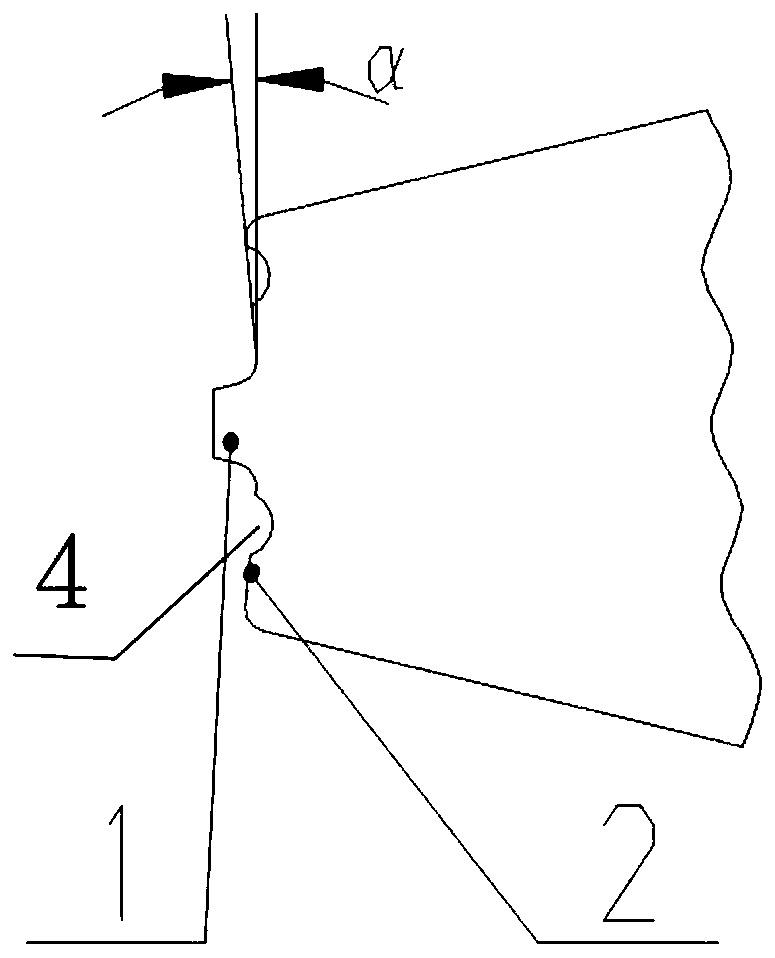

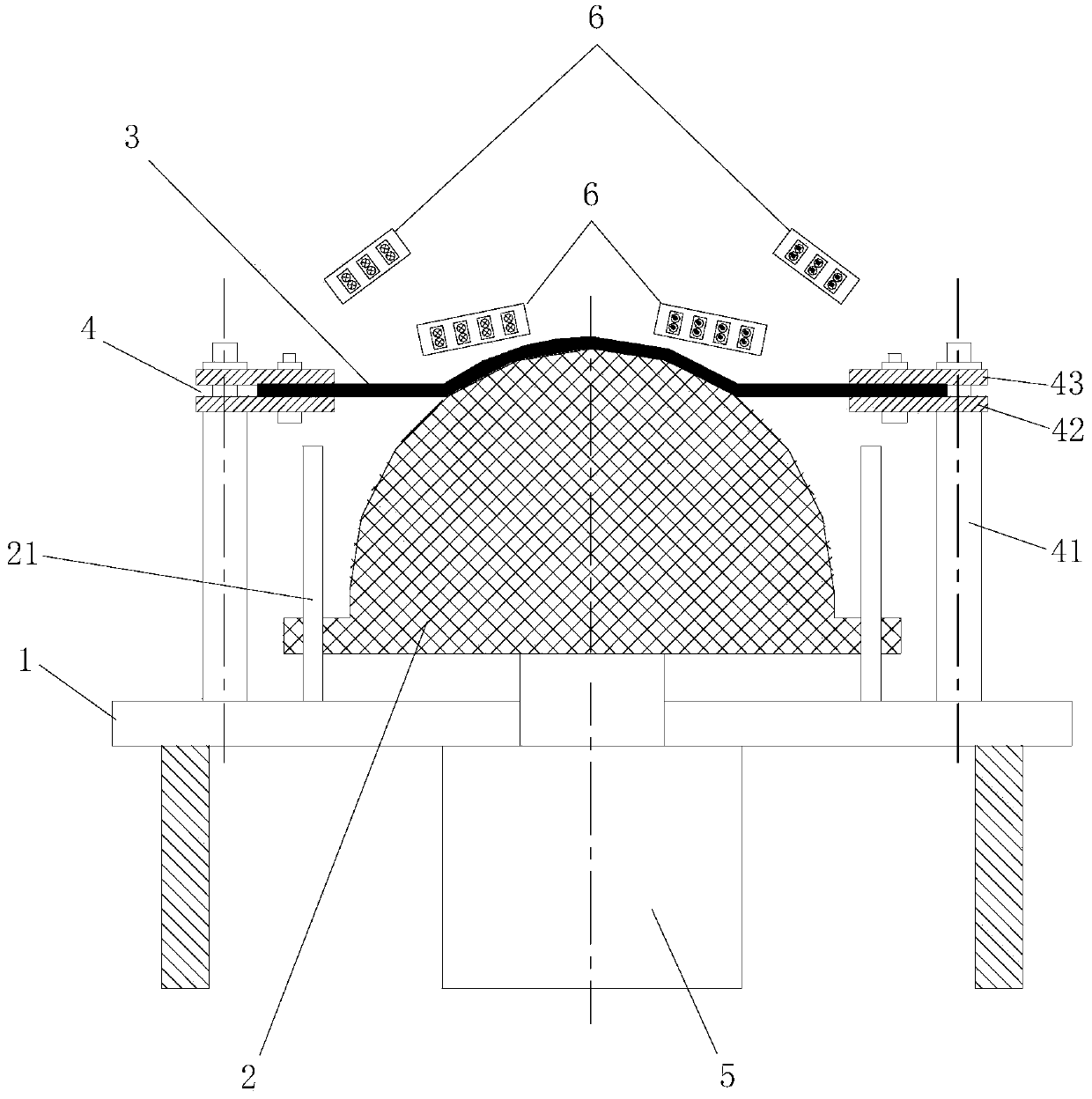

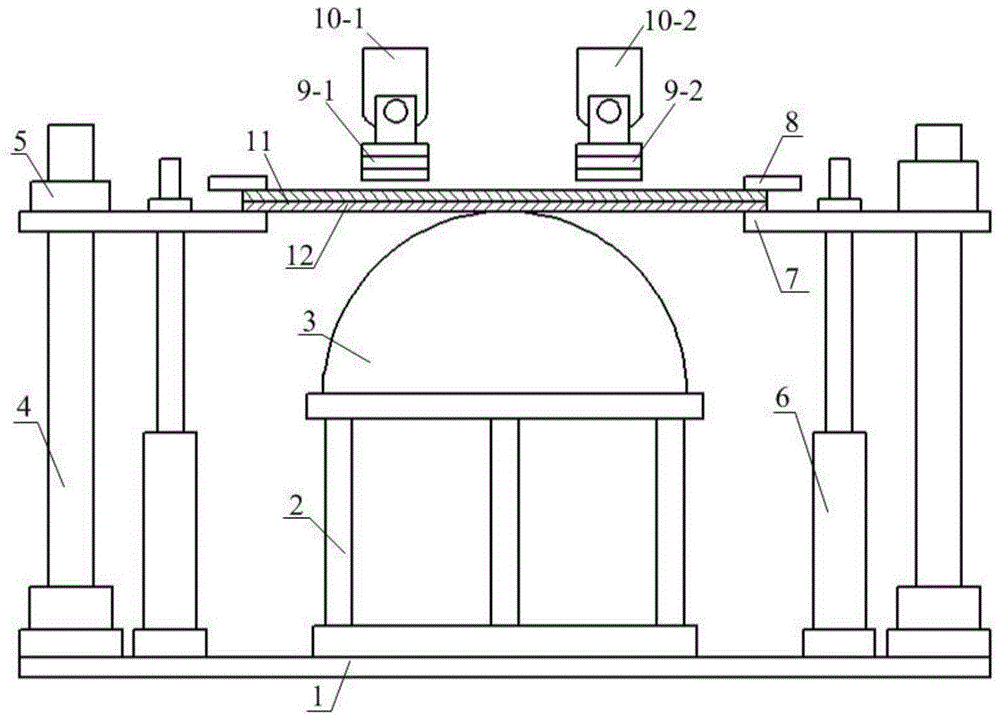

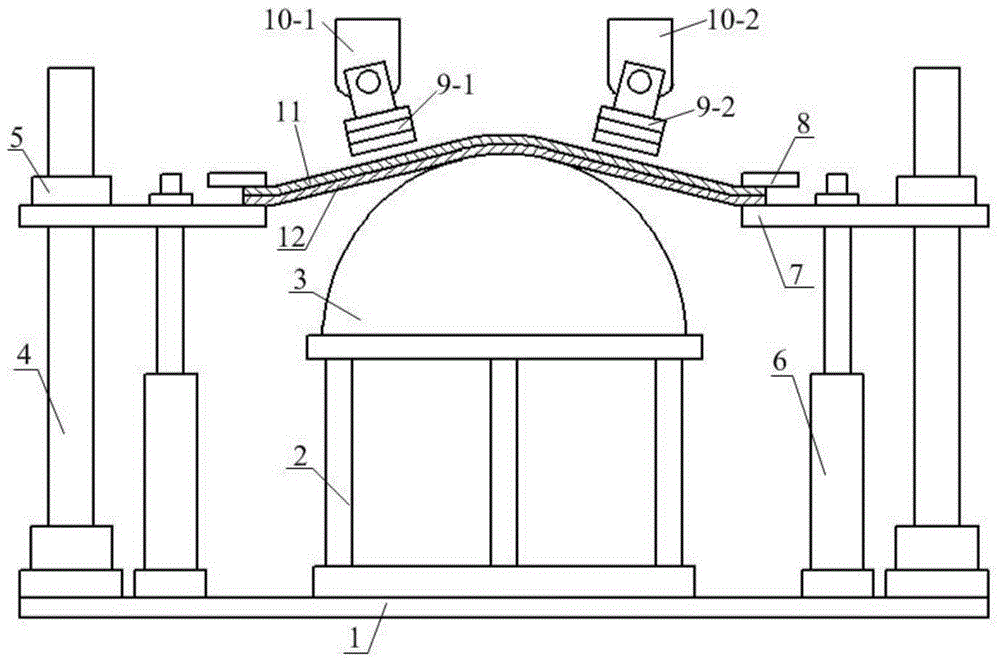

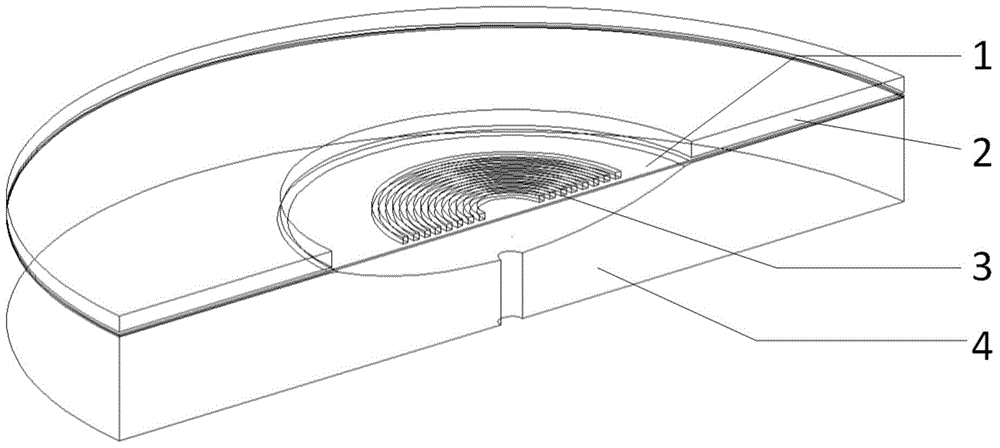

Workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and workpiece electromagnetic incremental forming method

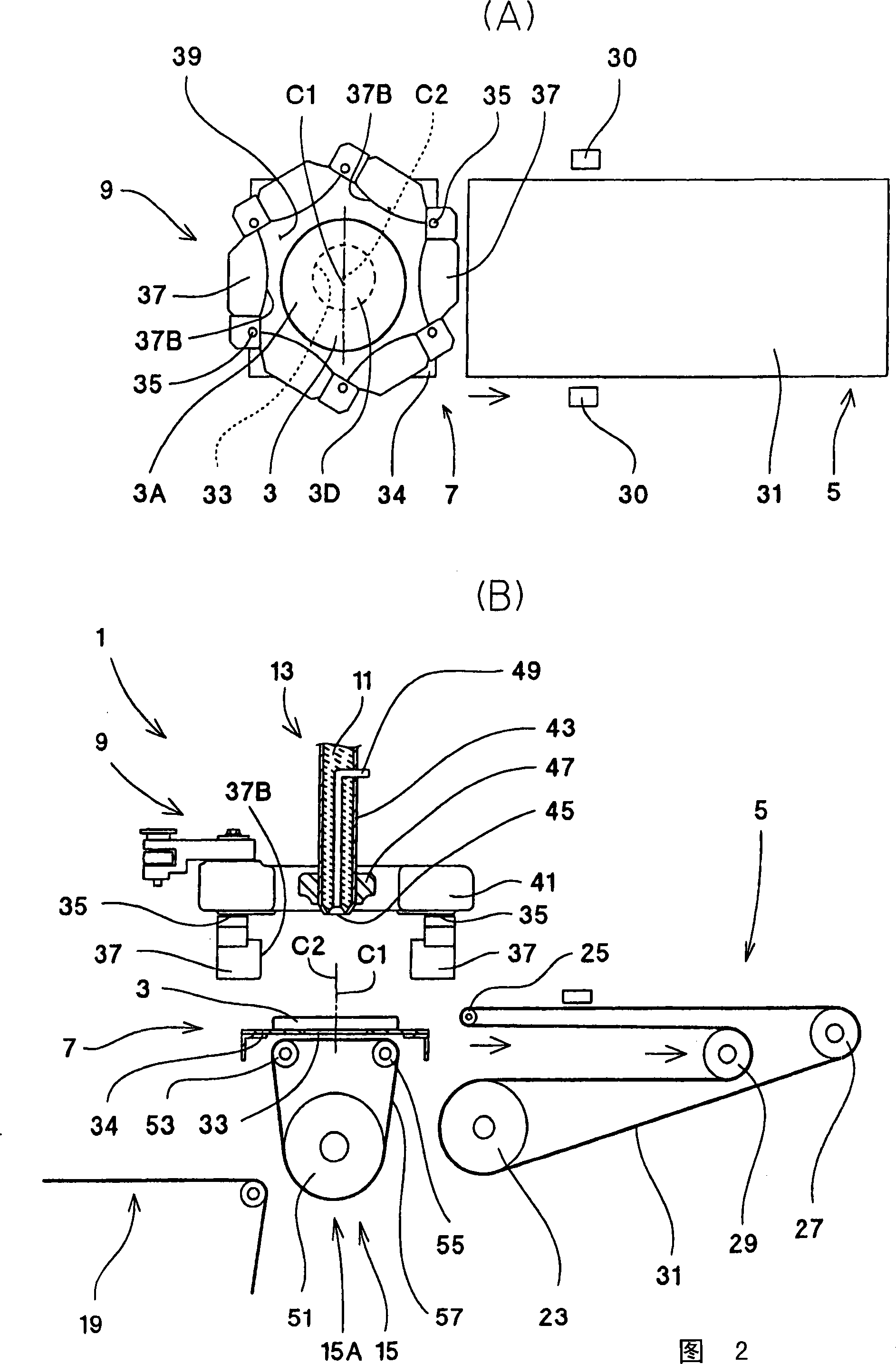

ActiveCN108856444AGuaranteed forming qualityIncrease forming heightEngineeringElectromagnetic forming

The invention discloses a workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and further discloses a workpiece electromagnetic incremental forming method. The workpiece electromagnetic incremental forming device comprises a supporting frame, a mould, a plate, plate clamping assemblies for fixedly clamping the plate, and a driving piece for driving the mould to move so as to conduct stretch forming on the plate, and further comprises the multiple profile-followed arrangement coils. The plate clamping assemblies are arranged on the supporting frame; the plate is fixedly clamped between the plate clamping assemblies; the driving piece is connected with the mould; the profile-followed arrangement coils are arranged on the periphery of the surface of the plate subjected to stretch forming by the mould in a surrounding mode; and all the profile-followed arrangement coils are arranged on layers of different heights above the plate correspondingly. The workpiece electromagnetic incremental forming method comprises the steps of plate fixing, stretch forming of the plate, electromagnetic forming through the profile-followed arrangement coils and the like, and the plate and the mould are attached by repeatedly executing plate stretch forming and electromagnetic forming. The workpiece electromagnetic incremental forming device and methodhave the advantages of being high in forming precision, good in forming quality, high in efficiency, high in utilization rate of discharge energy, low in equipment energy demand and the like.

Owner:CENT SOUTH UNIV

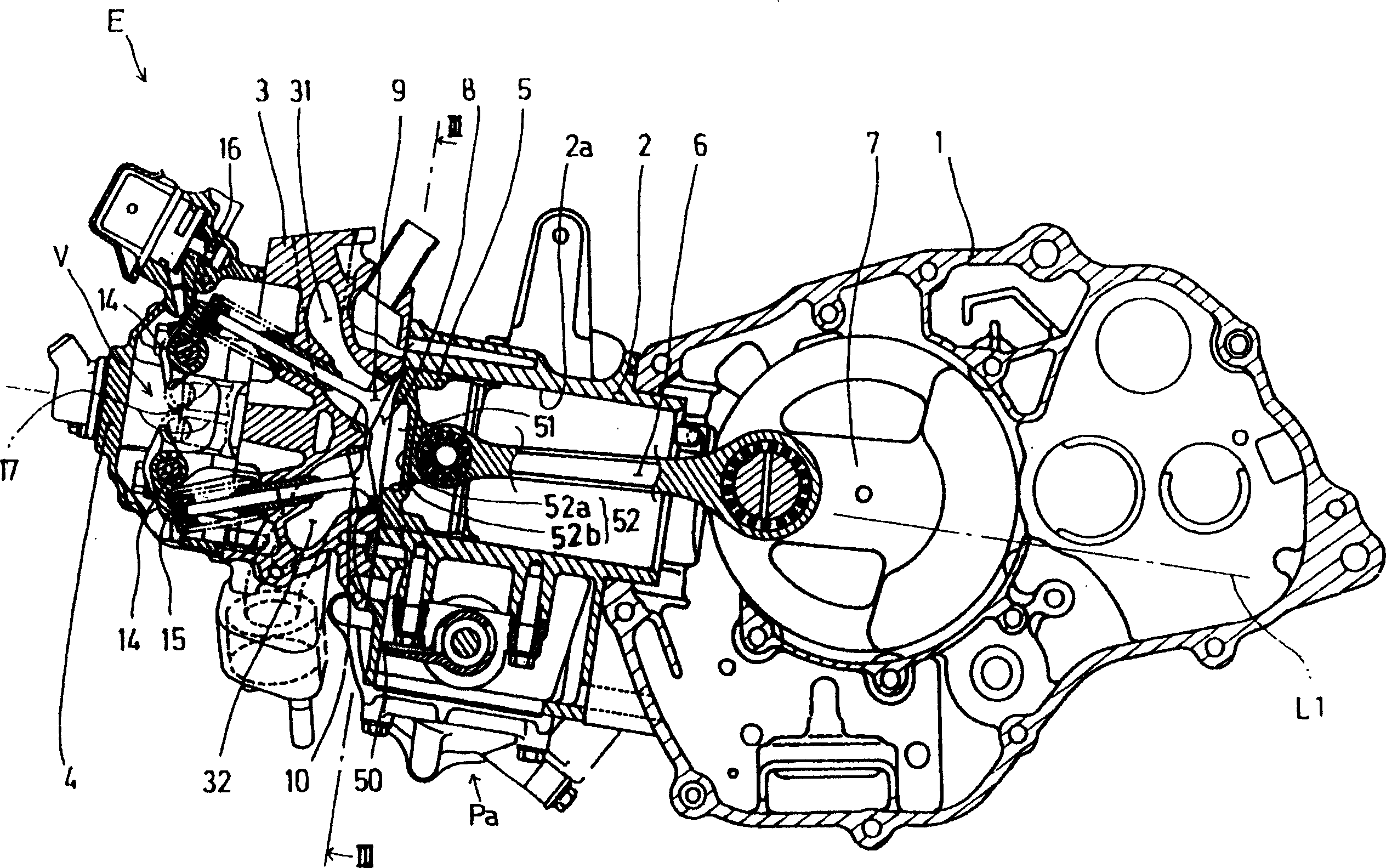

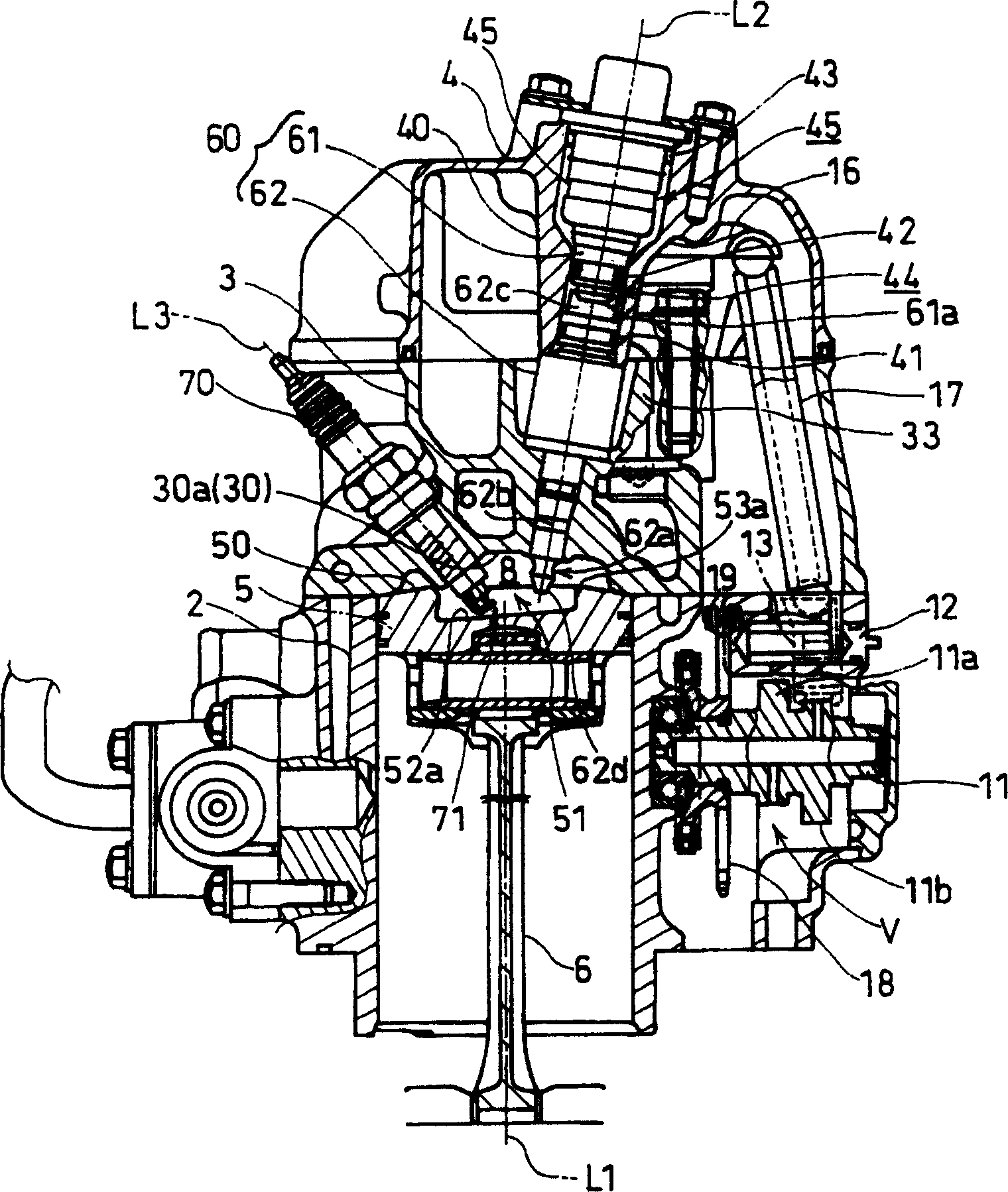

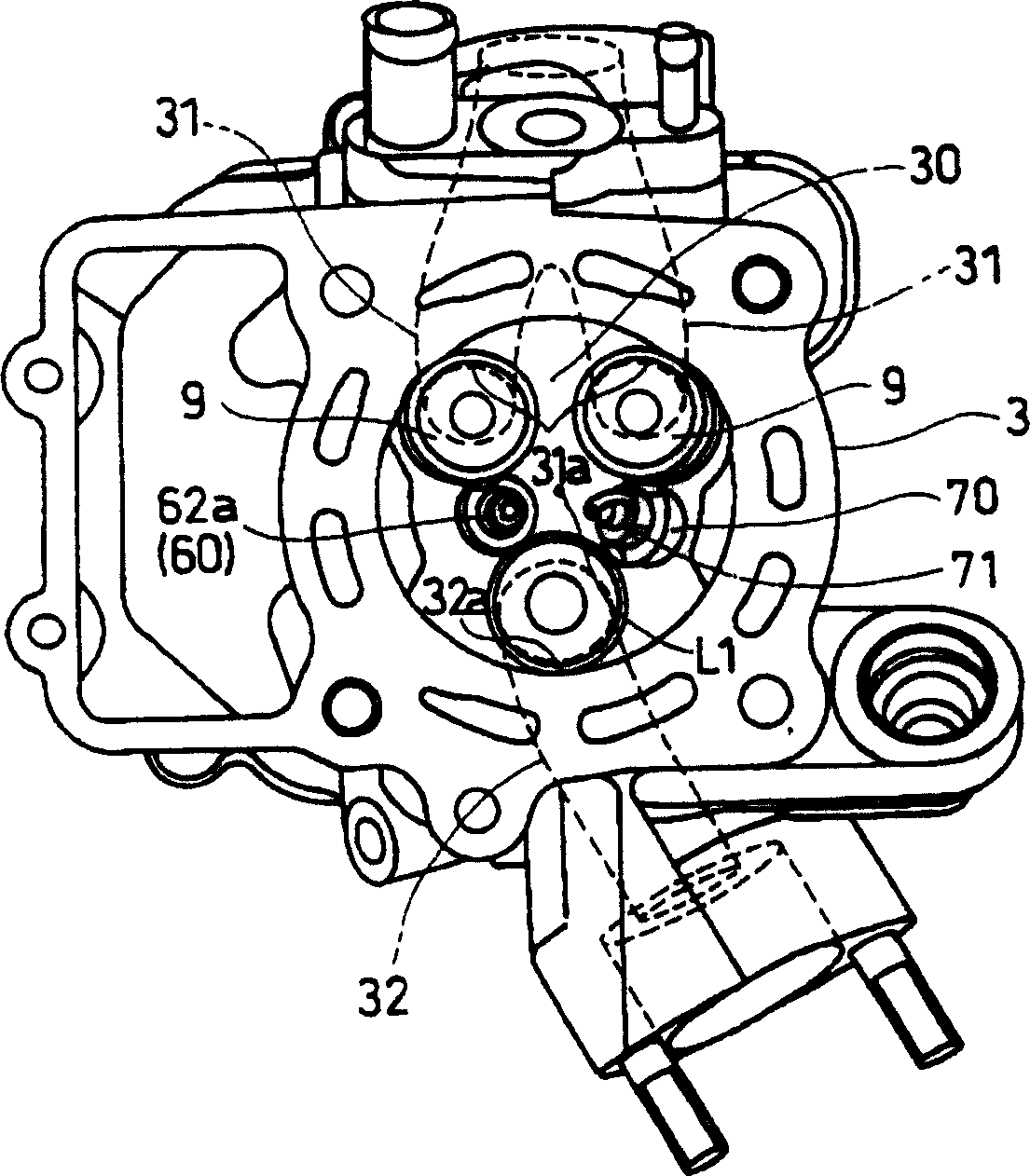

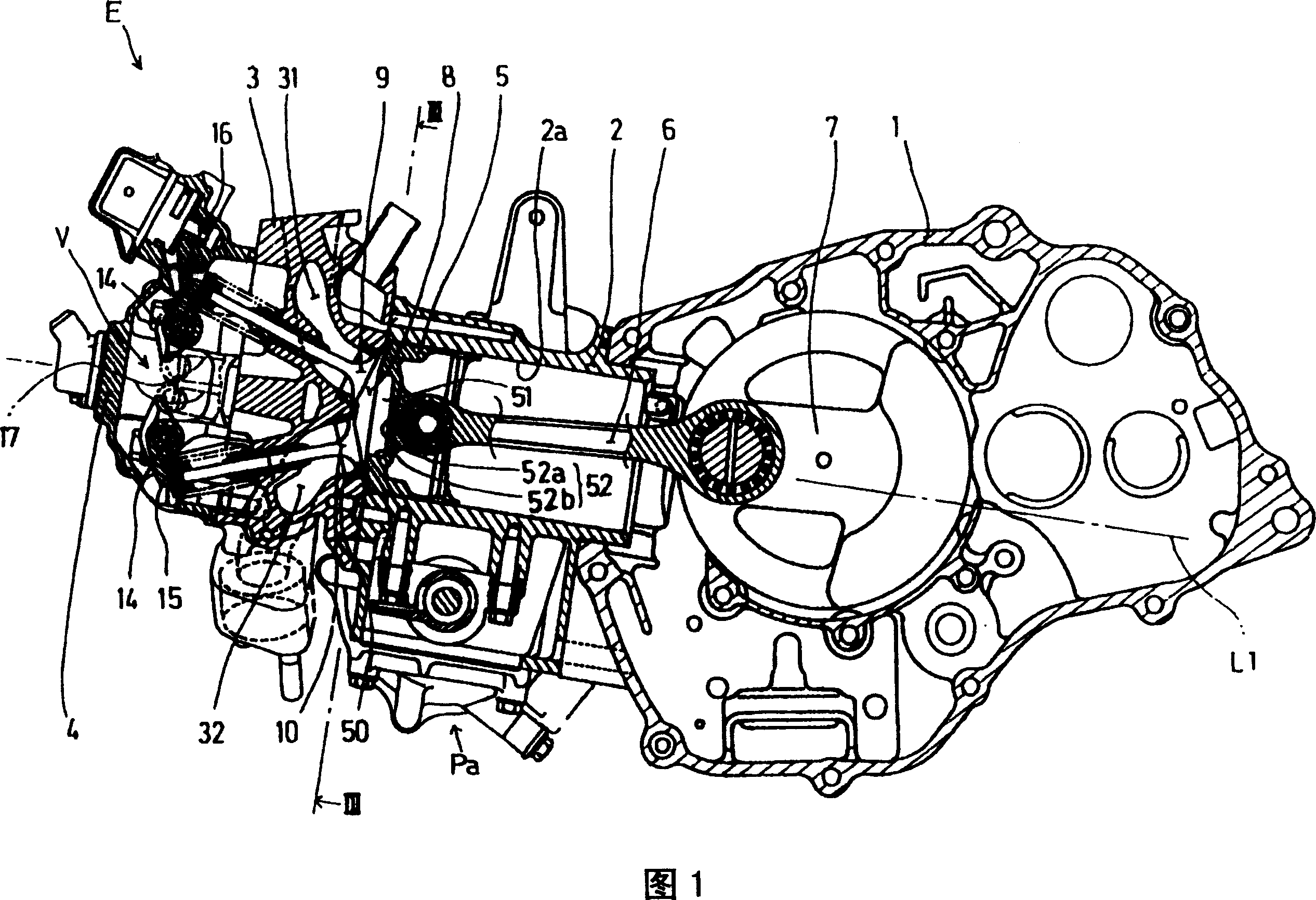

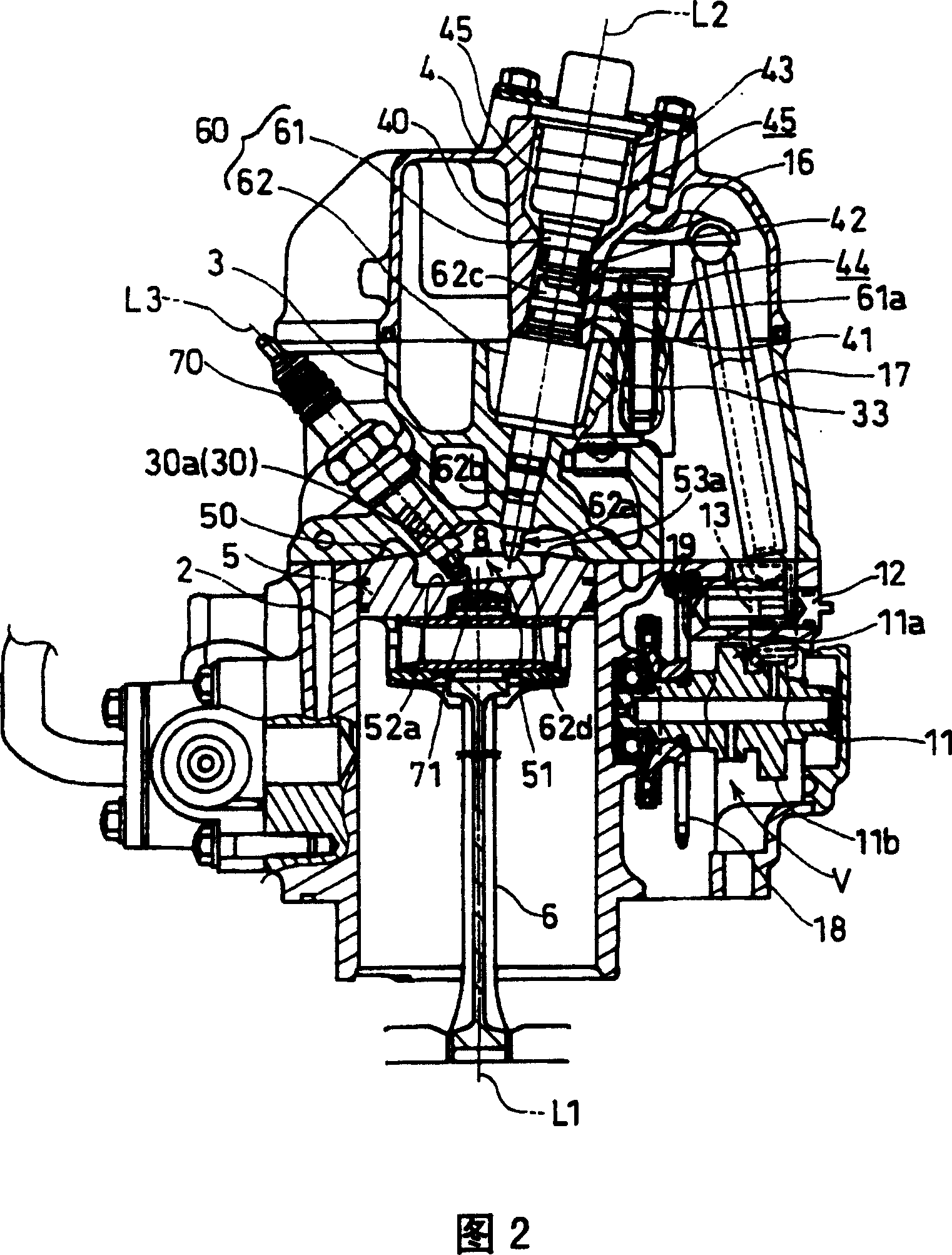

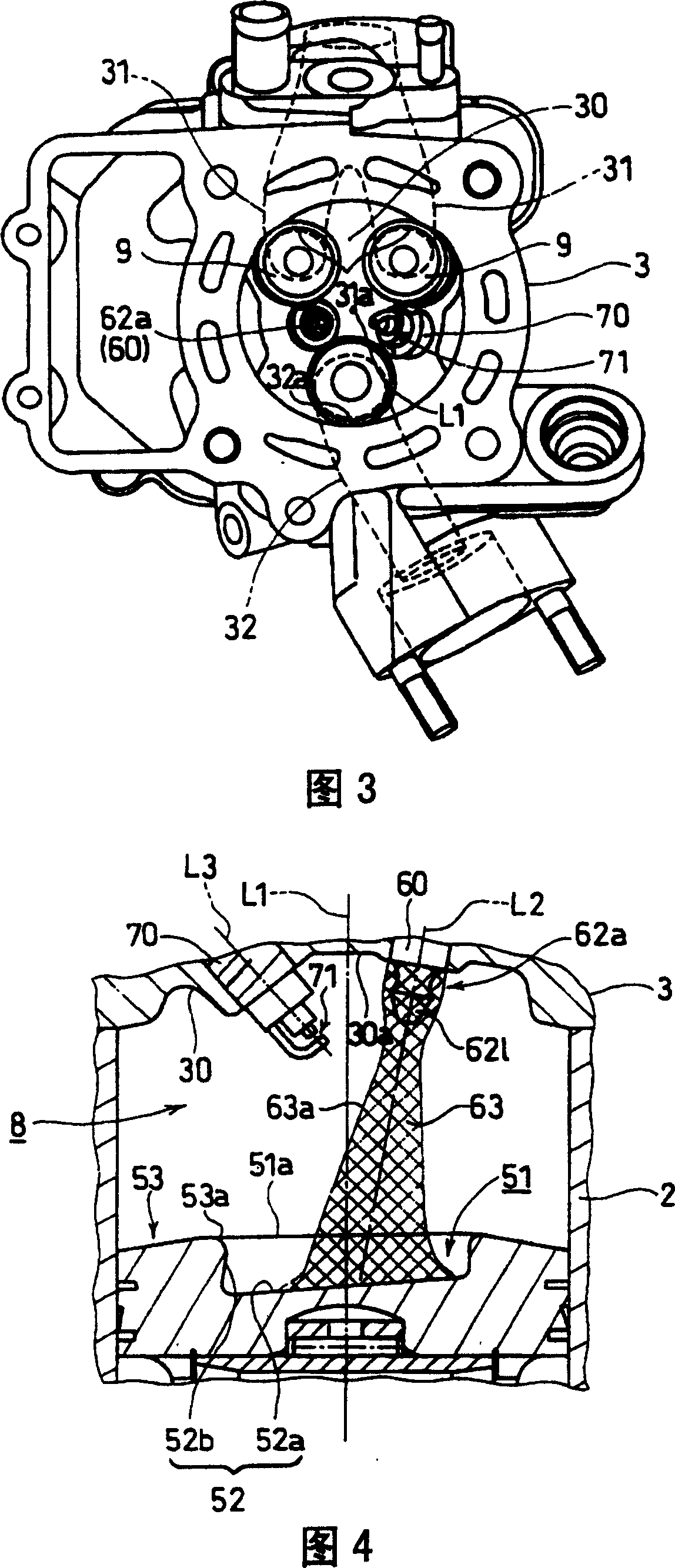

In cylinder fuel oil jet type IC engine

InactiveCN1590729AReliable ignitionImprove ignition performanceInternal combustion piston enginesHigh pressure gas fuel injectionCombustion chamberExhaust valve

PROBLEM TO BE SOLVED: To provide a cylinder injection internal combustion engine with excellent ignitability for improving combustion efficiency and improving fuel consumption without enlarging a cavity, by separating a tip firing part of an ignition plug from a jet flow of a fuel injection valve and bringing the tip firing part close to a center axis of the cavity. ŽSOLUTION: In the cylinder injection internal combustion engine, a combustion chamber 8 is formed between a piston 5 in which the cavity 51 is formed in a top surface thereof and a cylinder head 3, and a lower wall surface of the cylinder head 3 is a ceiling surface of the combustion chamber 8. A plurality of intake and exhaust valves, the fuel injection valve 60, an ignition plug 70 are disposed to face the combustion chamber 8. The ignition plug 70 is inserted from a side surface of the cylinder head 3 toward the combustion chamber 8, and the tip firing part 71 thereof is inclined with respect to the cylinder axis L1 and approximated to the center axis L1. The fuel injection valve 60 is inserted from an upper surface of the cylinder head 3 toward the combustion chamber 8 and inclined on a side approximately opposite to the ignition plug 70 with respect to the cylinder axis L1, and a tip nozzle 62a thereof is separated in an inclination direction from the center axis L1 of the cavity 51. Ž

Owner:HONDA MOTOR CO LTD +1

Aclinal stirring friction welding method for AZ31 magnesium alloy sheet and stirring head

PendingCN109877443AAvoid Organizational DefectsReduce complexityNon-electric welding apparatusRound tableFriction stir welding

The invention relates to an aclinal stirring friction welding method for an AZ31 magnesium alloy sheet and a stirring head; the method comprises the following steps of: firstly, mechanically polishinga butt jiont face to be welded of the AZ31 magnesium alloy, cleaning by acetone, absolute ethanol and deionized water successively, and then fixing the AZ31 magnesium alloy on the base plate of a stirring friction welding machine after being quickly dried; conducing a single pass aclinal stirring friction welding treatment to the butt joint face to be welded of the AZ31 magnesium alloy by the aclinal stirring friction welding stirring head, wherein the stirring head comprises a cylindrical clamping part, a round table shaft shoulder and round table stirring needle; the stirring head shaft shoulder is concave design, and three spiral grooves are uniformly distributed on the surface of the round table. The welding method and stirring head provided by the invention solve the problem that themechanical property of the welding joint is reduced due to the thinned weld seam when the magnesium alloy sheet is welded by the inclined stirring friction and the problem that the traditional welding method is easy to form pores, cracks and deformations in a weld zone. The welding joint obtained by the invention has beautiful appearance, and the maximum tensile strength of the joint can reach 97.8% of a base metal.

Owner:YULIN UNIV

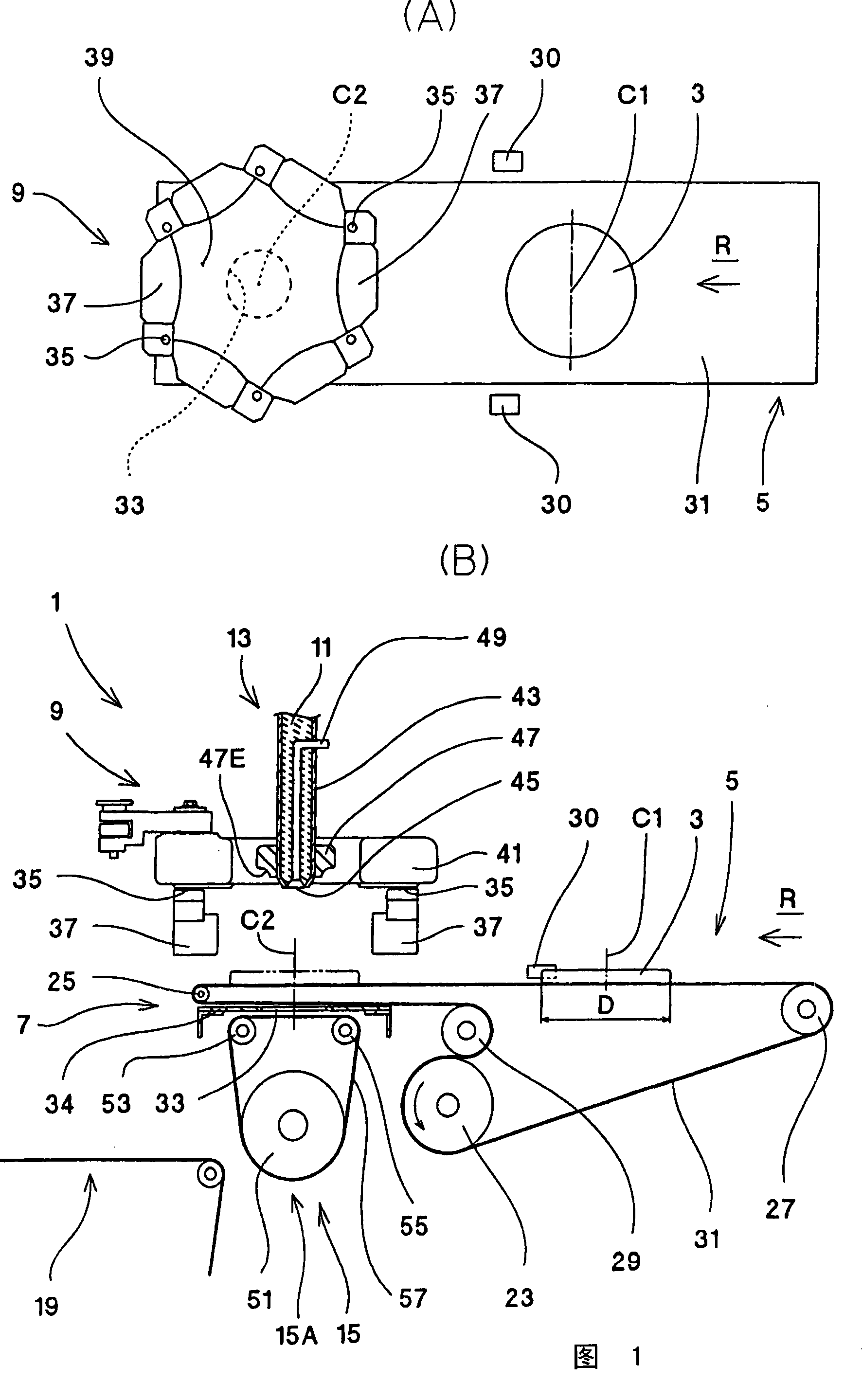

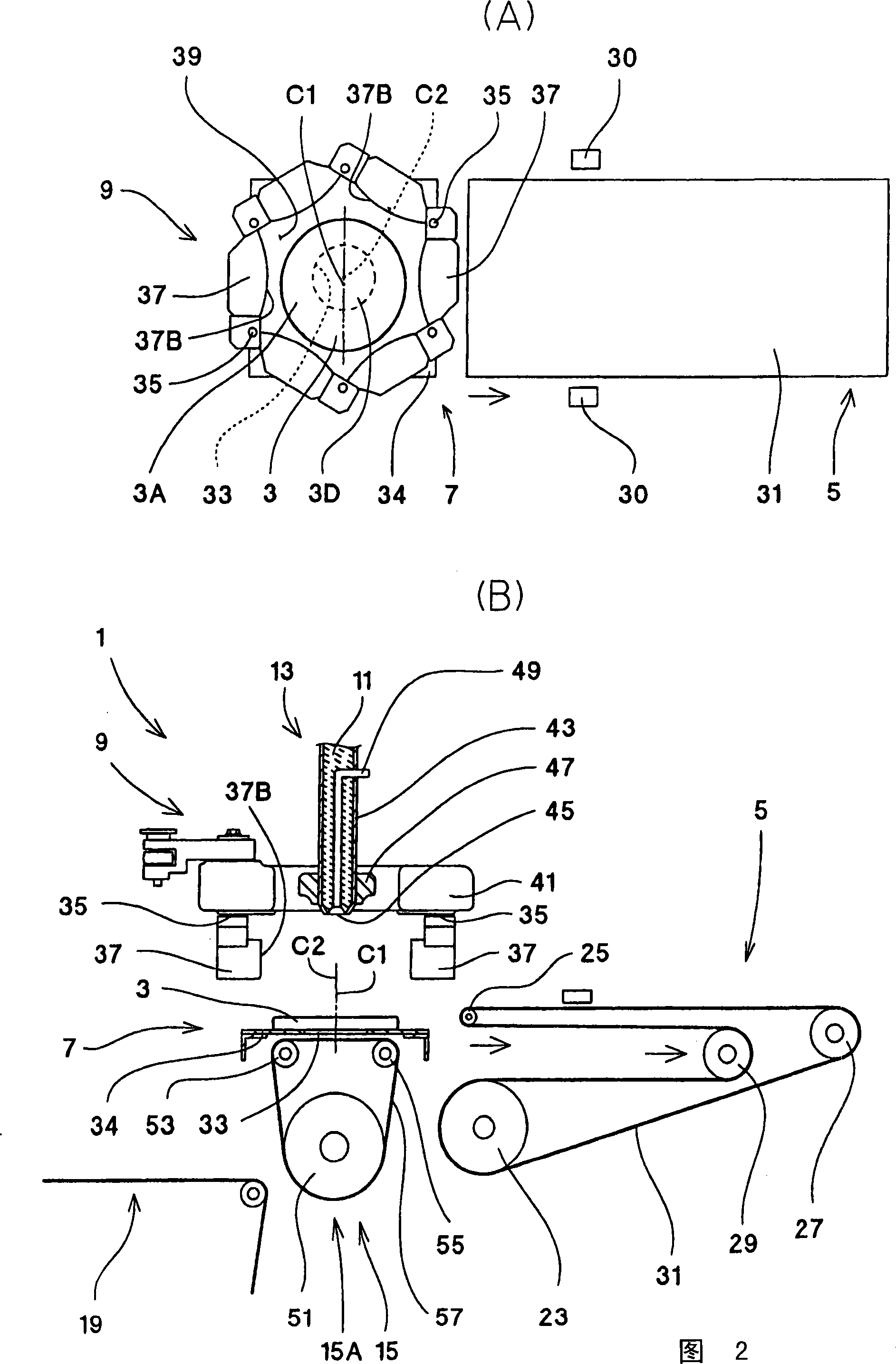

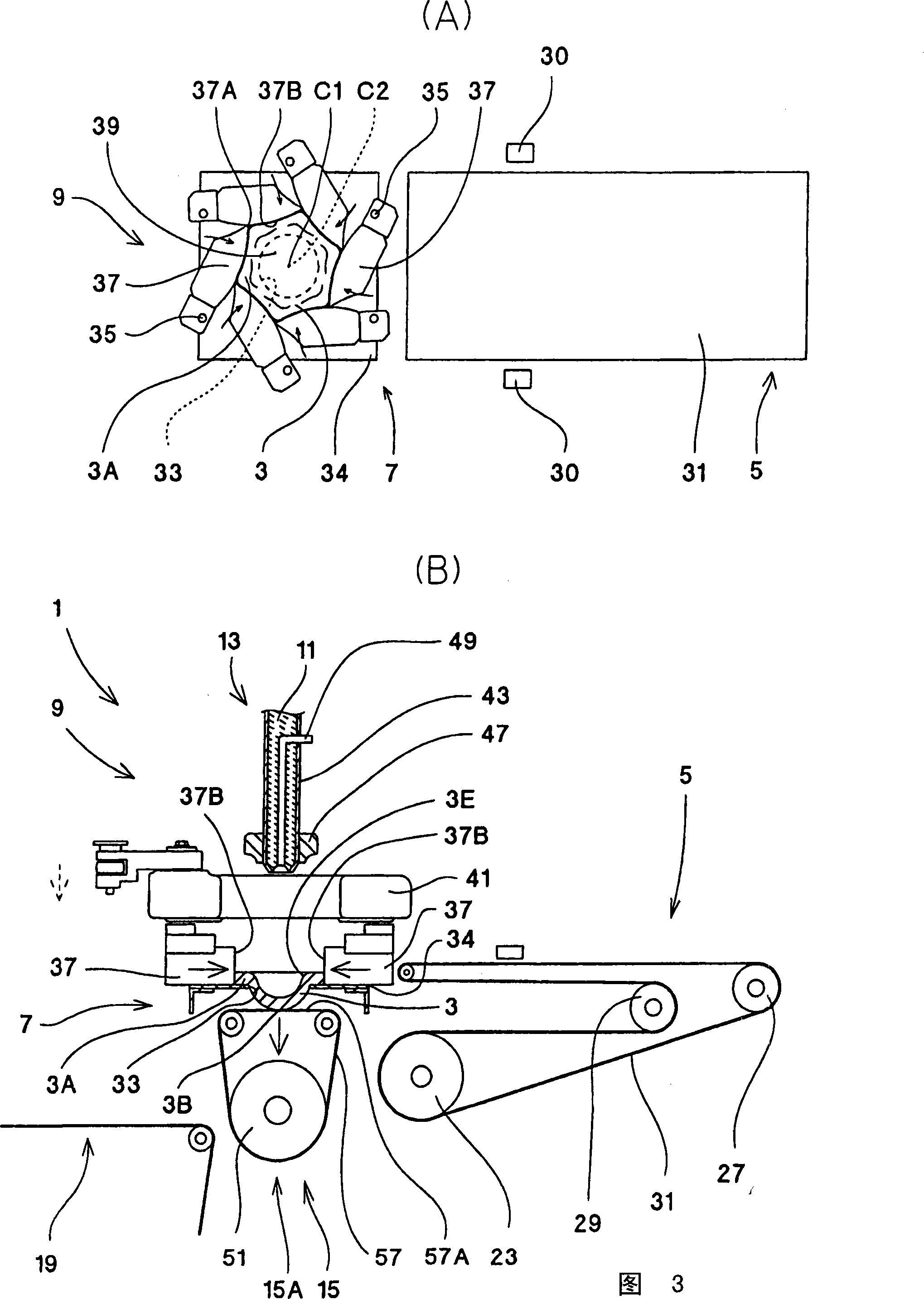

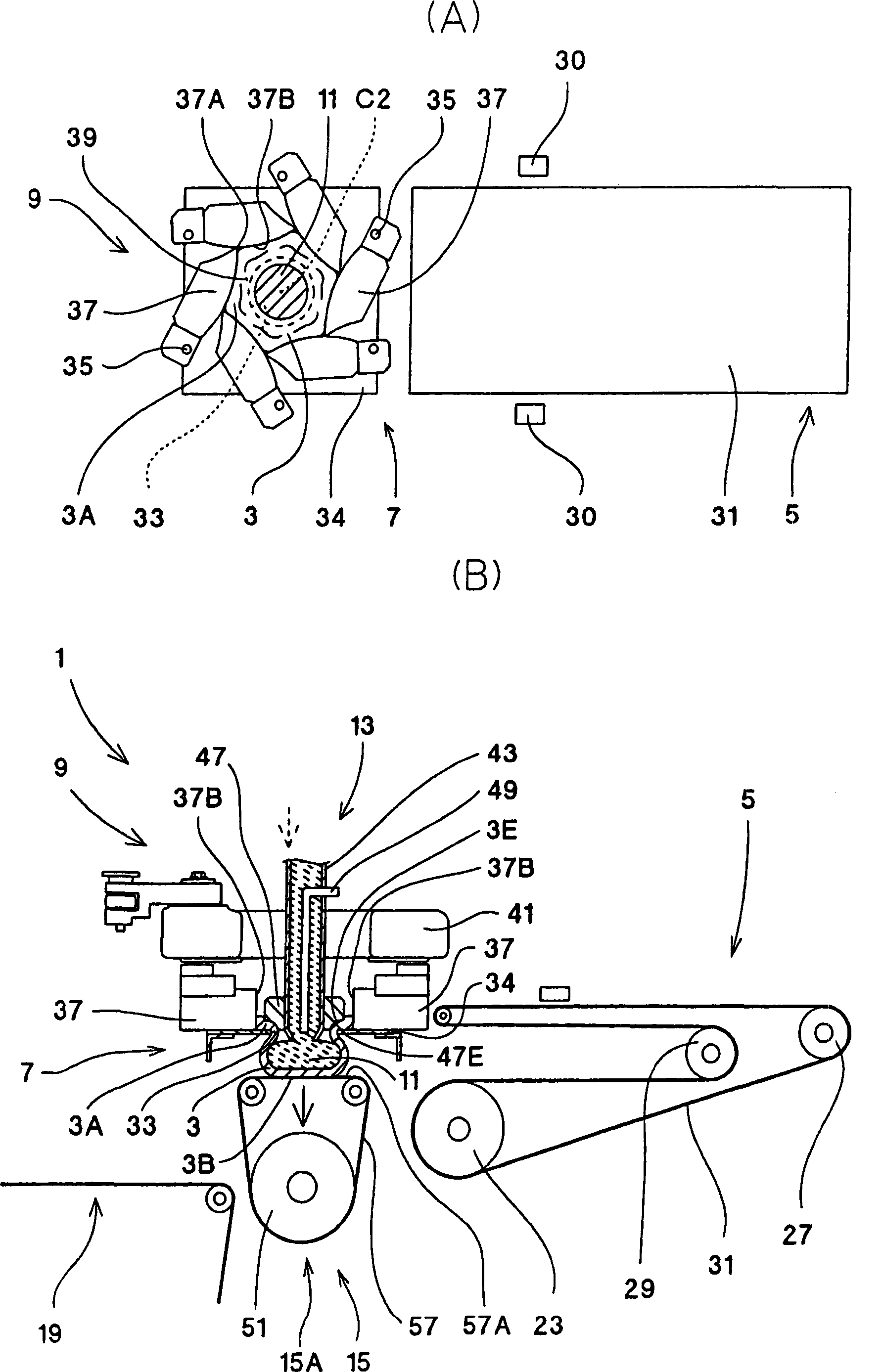

Food manufacturing device

The present invention relates to an apparatus for preparing the following foods (production) continuously, the foods is made by packaging inner material composed of foods such as stuffing or fruit jam etc. by tegmen material composed of foods blank such as bread etc. A blank pressing component is formed integratedly on the peripheral of a nozzle component for extruding inner material, the peripheral part of the tegmen material locating on the upper surface of a carrying component with hatch is clipped between the blank pressing component and the carrying component, and the upper opening of the bowl-shaped tegmen material is closed by the nozzle component and the blank pressing component, so as to prevent the inner material from leaking from the upper opening by maintaining the clipping state when ejecting the inner material into the inner of the tegmen material, and to prevent inner material from leaking to manufacture no good production when sealing the peripheral of the tegmen material. In addition, due to prevent inner material from polluting food manufacture device, it is able to prepare foods continuously without stop the running of the device.

Owner:RHEON AUTOMATIC MASCH CO LTD

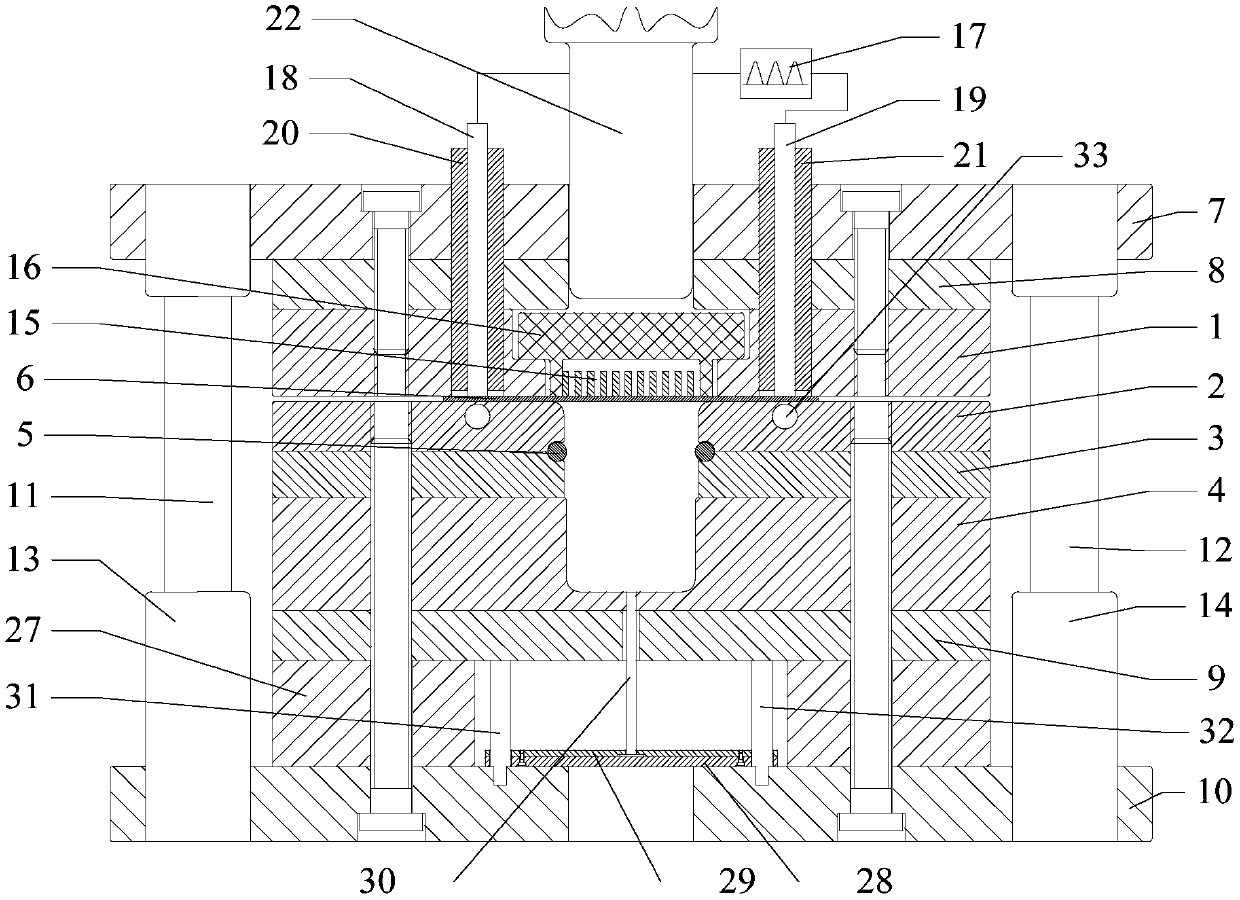

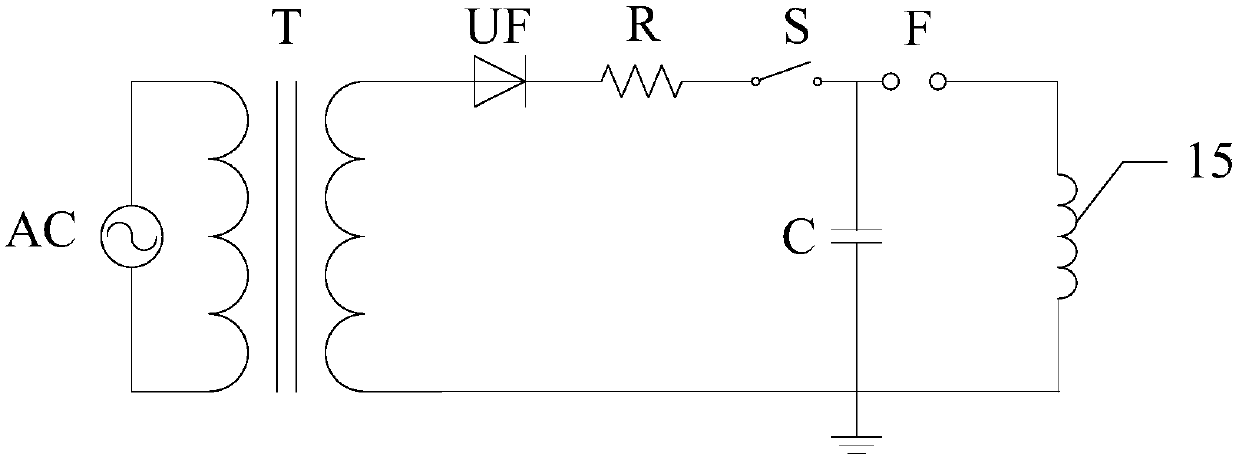

Aluminum alloy battery box composite forming device

ActiveCN109590405AImprove plasticityAvoid the problem of self-strength reductionShaping toolsHollow articlesAutomotive batteryElectric-vehicle battery

The invention provides an aluminum alloy battery box composite forming device, belongs to the field of metal material processing and forming, and solves the problem that an existing electric vehicle battery box forming process easily leads to poor quality of the formed part. The forming device lies in that a supporting plate, a preforming concave die and a pressing plate are stacked on a forming concave die sequentially from bottom to top; a first through cavity, a preforming through cavity, a second through cavity and a forming cavity form a vertically communicating cavity; a to-be-formed aluminum alloy sheet is clamped between the pressing plate and the preforming concave die; an electromagnetic pulse preforming unit is used for preforming the aluminum alloy sheet in the performing through cavity; an electroplastic element makes the preformed aluminum alloy sheet generate an electroplastic effect; a stamping forming unit is used for secondary forming of the aluminum alloy sheet withelectroplastic effect in the forming cavity; and an electromagnetic pulse rectifying unit is used for performing electromagnetic pulse forming on a fillet region of the reformed aluminum alloy sheet,so that the fillet region of the aluminum alloy sheet is further adhered to the fillet region of the forming cavity.

Owner:XIANGTAN UNIV

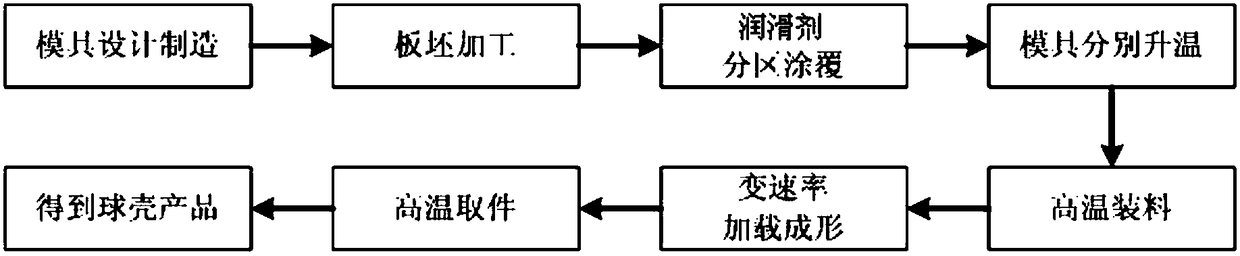

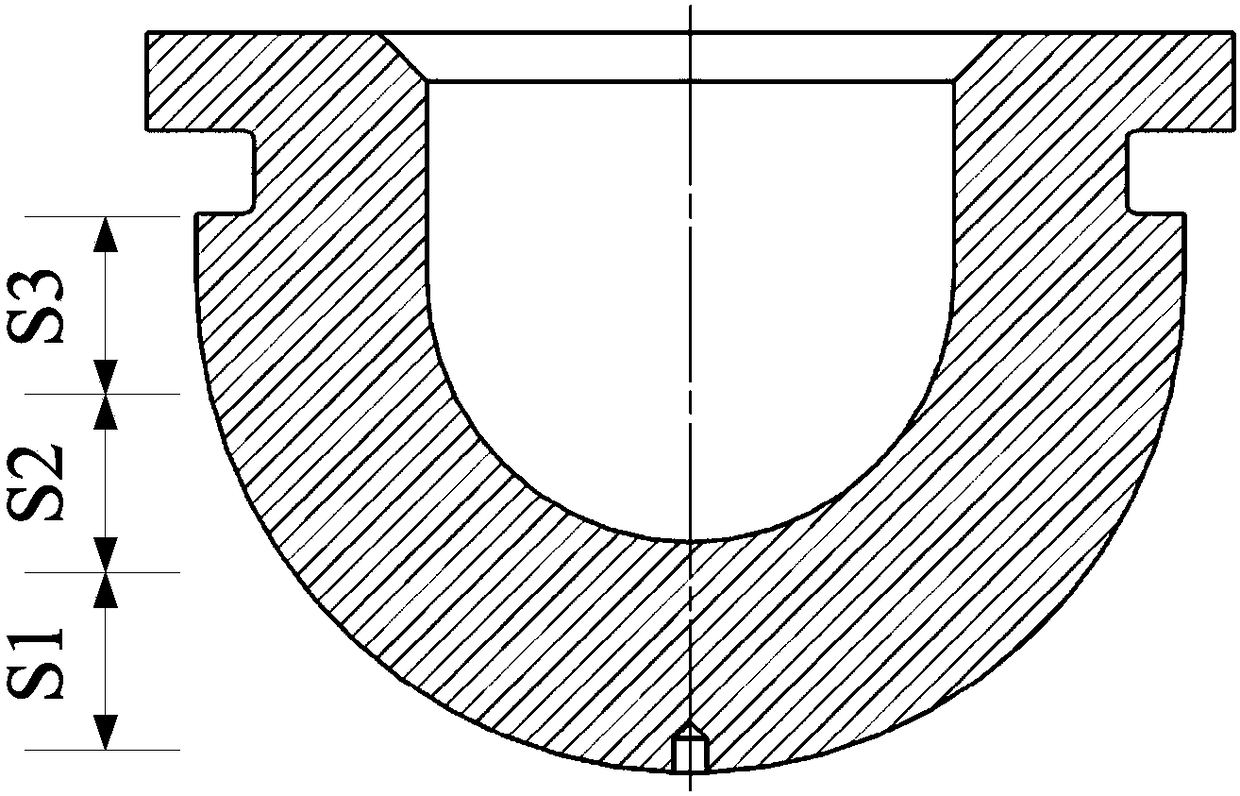

Wall thickness homogenization method adopting isothermal stamping for titanium alloy thick-wall spherical shell

ActiveCN108145000ADimensionally stableReduced loss of mechanical propertiesShaping toolsHollow articlesReduction rateTitanium

The invention discloses a wall thickness homogenization method adopting isothermal stamping for a titanium alloy thick-wall spherical shell. Through divisional design on friction coefficients of a male die and a to-be-formed plate, the male die and pull rings are heated separately so that a temperature gradient is formed, the wall thickness homogenization of the titanium alloy thick-wall sphericalshell is ensured, the spherical bottom reduction rate is reduced from 50% in conventional forming to below 15%, the overall wall thickness fluctuation of a housing does not exceeds 30% of the wall thickness of a blank and the size is stable. Since the reduction of the spherical bottom is inhibited effectively, the extent of damage of the mechanical property at the spherical bottom is reduced substantially, the overall mechanical property of the titanium alloy thick-wall spherical shell is better, the titanium alloy thick-wall spherical shell is particularly applicable to development and production of a TA7 low-temperature titanium alloy gas cylinder product for a carrier rocket, and is also applicable to the development and production of titanium alloys in other fields and other trademarks and the like products, and the wall thickness homogenization method is very practical.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

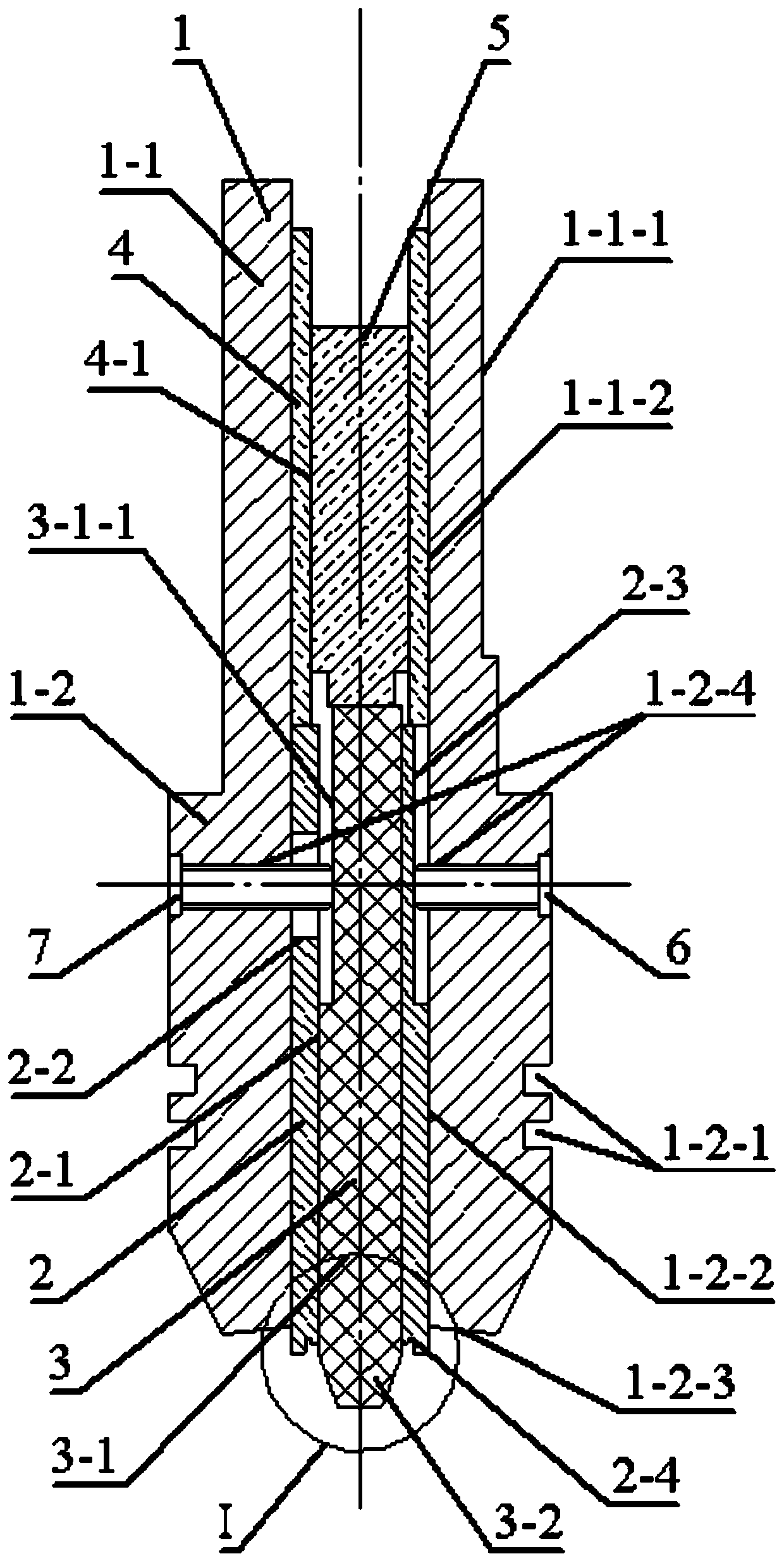

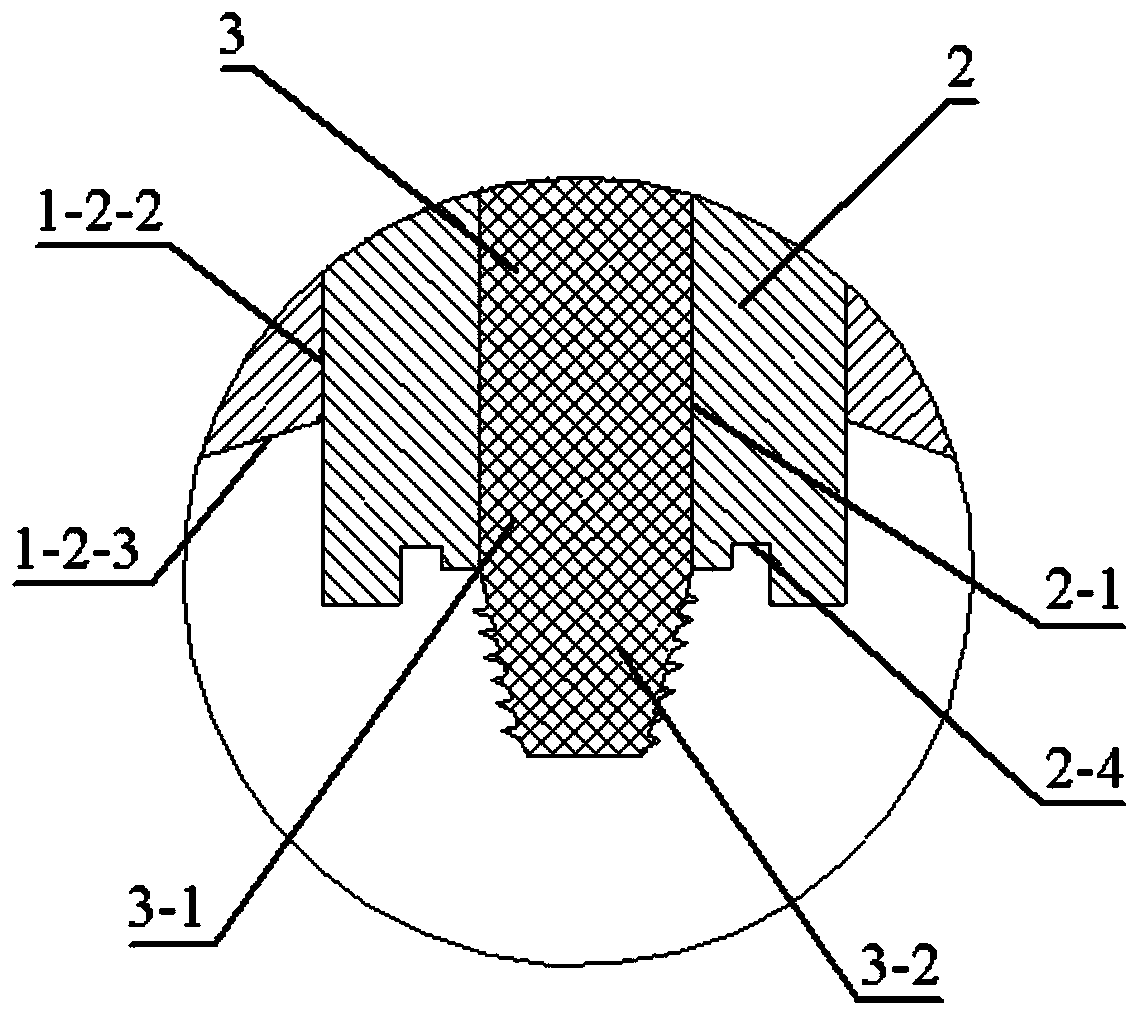

One-time welding synchronous two-time reshaping thinning-free friction stir welding tool and welding method.

ActiveCN110773861ALow heat inputImprove mechanical propertiesNon-electric welding apparatusFriction weldingStructural engineering

The invention provides a one-time welding synchronous two-time reshaping thinning-free friction stir welding tool and a welding method. The welding tool comprises a welding tool clamping body, an inner side shaft shoulder, a stirring body, a shaft shoulder adjusting bolt, a needle length adjusting bolt, a shaft shoulder fastening bolt and a stirring body fastening bolt, wherein the welding tool clamping body comprises a clamping handle and an outer side shaft shoulder which are integrally formed and coaxially arranged; a first threaded through hole is formed in the axis of the clamping handle;the shaft shoulder adjusting bolt is arranged in the first threaded through hole; and a second threaded through hole is formed in the axis of the shaft shoulder adjusting bolt. According to the one-time welding synchronous two-time reshaping thinning-free friction stir welding tool and the welding method, the pressing-in amount of the inner side shaft shoulder and the pressing-in amount of a stirring needle are adjusted through the two adjusting bolts correspondingly, forming of the interior of a welding seam can be guaranteed in the welding process, the zero pressing-in amount is kept between the outer side shaft shoulder and the surface of a base material to be welded, the inner concave face of the outer side shaft shoulder can contain materials which are extruded by the inner side shaft shoulder and the stirring needle to overflow, the materials are rotationally rolled and reshaped, and the stirring friction welding seam free of flash and thinning is formed.

Owner:HARBIN INST OF TECH

Etching solution of copper or copper alloy and method for producing electronic substrate using the solution

InactiveCN100436645CInhibition of thinningLess side etchingConductive material chemical/electrolytical removalOrganic acidEtching

The present invention provides an etching liquid for copper or a copper alloy capable of producing an electronic substrate in which side etches are reduced, the narrowing of the upper part of copper wiring is suppressed, and short circuits are not generated, and to provide a method for producing an electronic substrate using the same. In the method for producing an electronic substrate, a copper layer (2a) formed on an electrically insulated base material (1) is etched so as to be a prescribed shape to form copper wiring (2c). After the main etching, copper (A) to be removed remaining in the cuff part of copper wiring (2b) is removed with an aqueous solution comprising (a) an oxidizer for copper by 1 to 50 g / L, (b) at least one kind of acid selected from the group consisting of hydrochloric acid by 1 to 400g / L and organic acid by 1 to 200 g / L, and (c) at least one kind of polymer selected from the group consisting of polyalkylene glycol and a copolymer of polyamine and polyalkylene glycol by 0.01 to 50 g / L.

Owner:MEC CO LTD

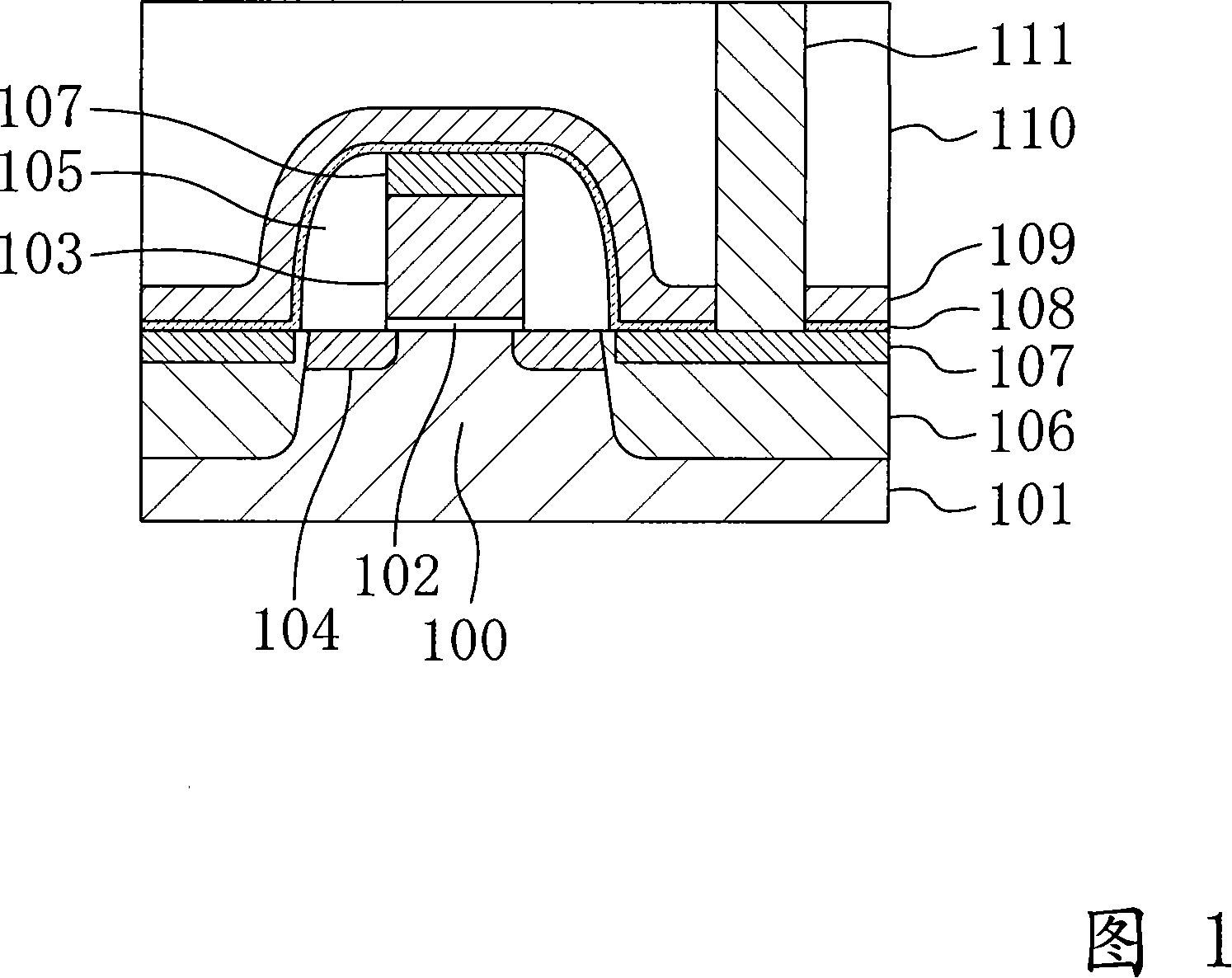

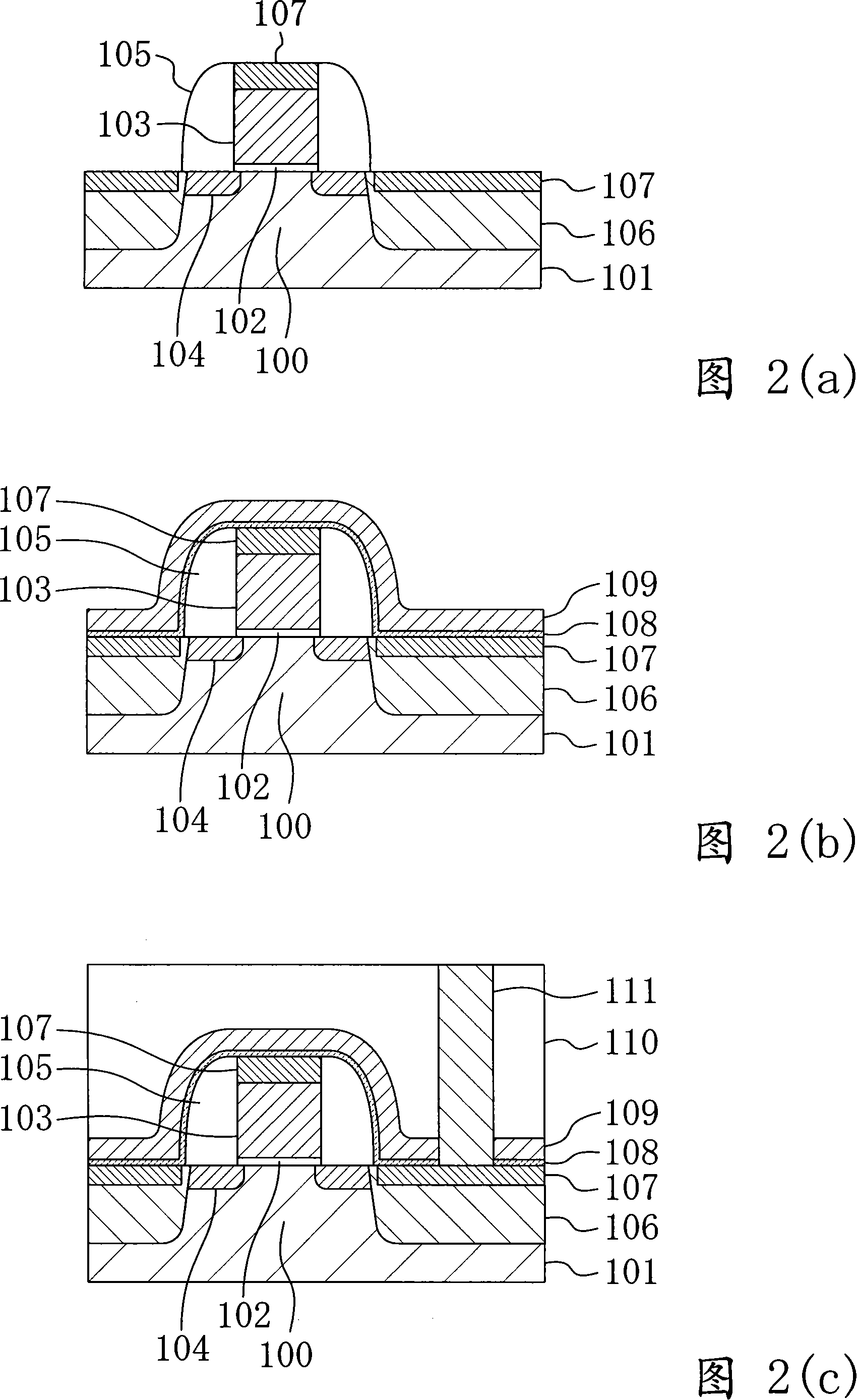

Semiconductor device and method for fabricating the same

InactiveCN101236988AEliminate low-level dependenciesEasy to driveTransistorSemiconductor/solid-state device manufacturingAtomic layer depositionPlasma chemistry

The invention discloses a semiconductor device and method for fabricating the same. The semiconductor device has a structure that can eliminate dependency of coating film bottom. The semiconductor device in an active region (100) has a gate insulating film (102), a gate electrode (103), a sidewall (105), a source drain region (106) and a silicide region (107). The semiconductor device also has an underlying insulating film (108) formed over the active region (100) using atomic layer deposition so as to cover the gate electrode (103), the sidewall (105) and the silicide region (107); and a contact liner film (109) formed on the underlying insulating film using plasma CVD and made of a stress insulating film for applying a tensile or compressive stress in a gate length direction in a channel region.

Owner:PANASONIC CORP

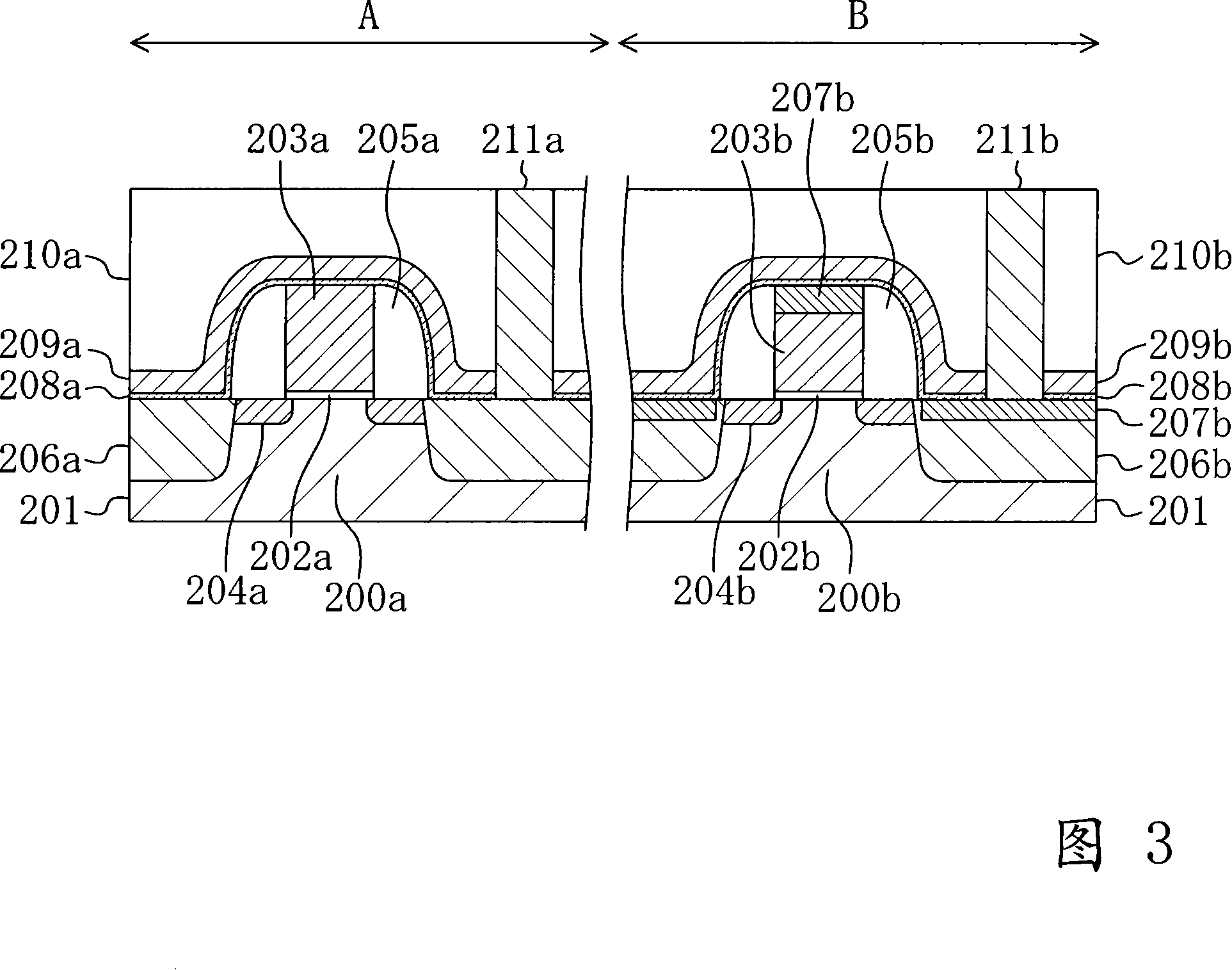

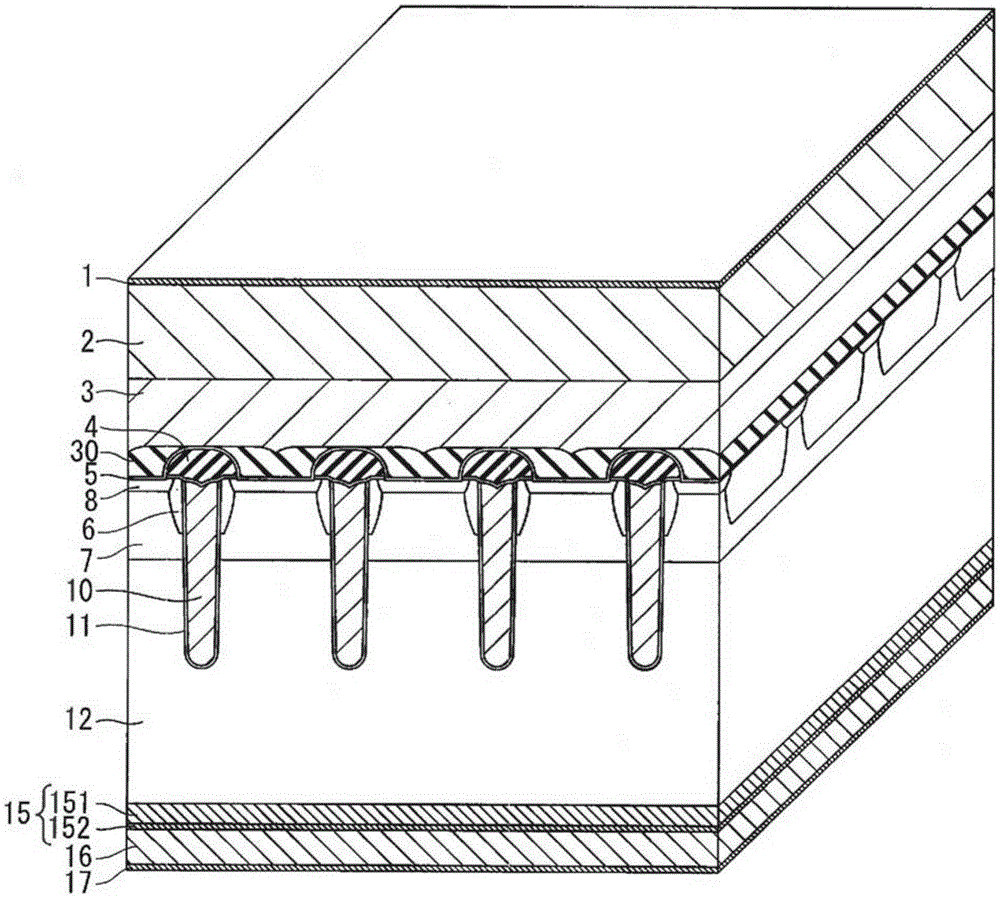

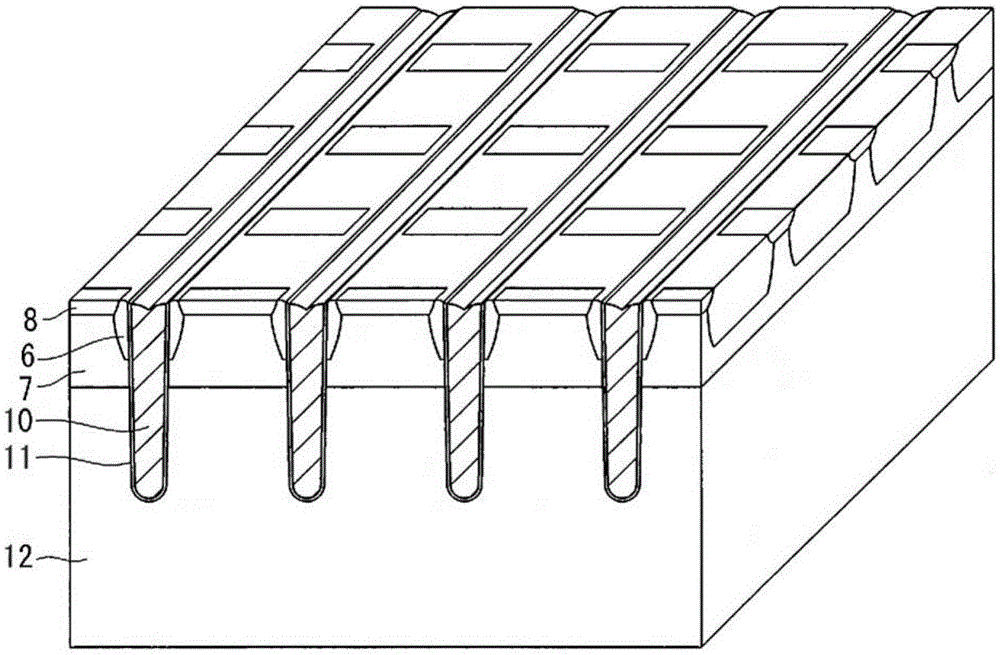

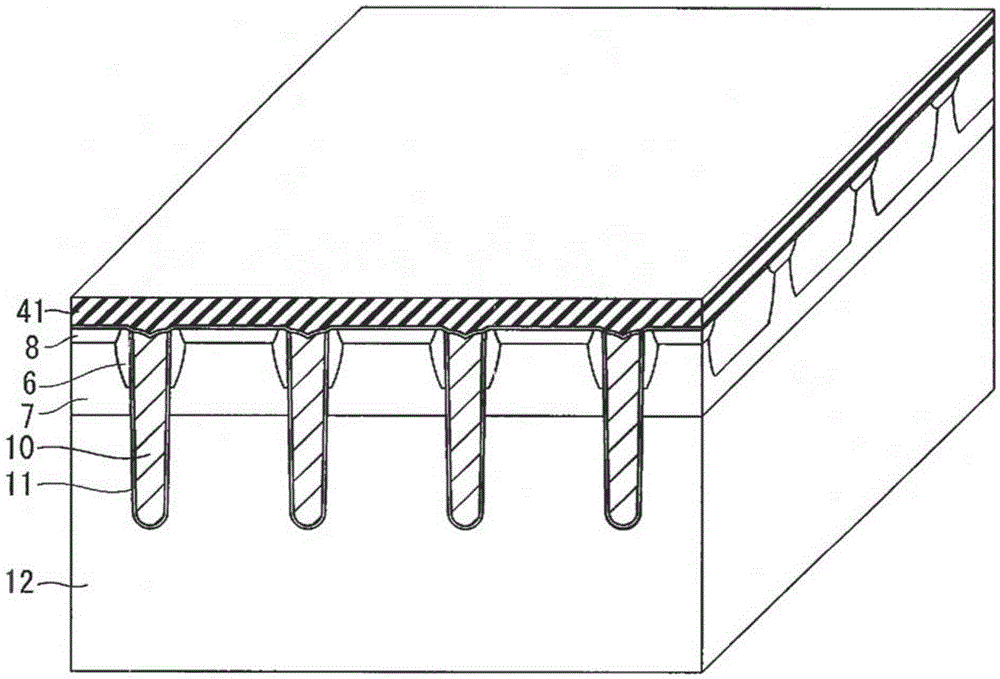

Semiconductor device and method for manufacturing the same

InactiveCN105720103AInhibition of "thinningUniform film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingBand shapeTrench gate

A semiconductor device includes: a semiconductor substrate; a plurality of trench gate electrodes that have a stripe shape in plan view and are located in parallel with each other at an interval; a gate insulating film located on surfaces of the trench gate electrodes; a first impurity layer located in an upper layer portion of the semiconductor substrate; a second impurity layer that is selectively located in a surface of the first impurity layer and is in contact with the gate insulating film; an interlayer insulating film that is located so as to cover upper portions of the trench gate electrodes and an upper portion of the second impurity layer, projects on the semiconductor substrate, and has a stripe shape in plan view; and a planarized buried film of metal that is buried in portions between projecting portions of the interlayer insulating film on the semiconductor substrate.

Owner:MITSUBISHI ELECTRIC CORP

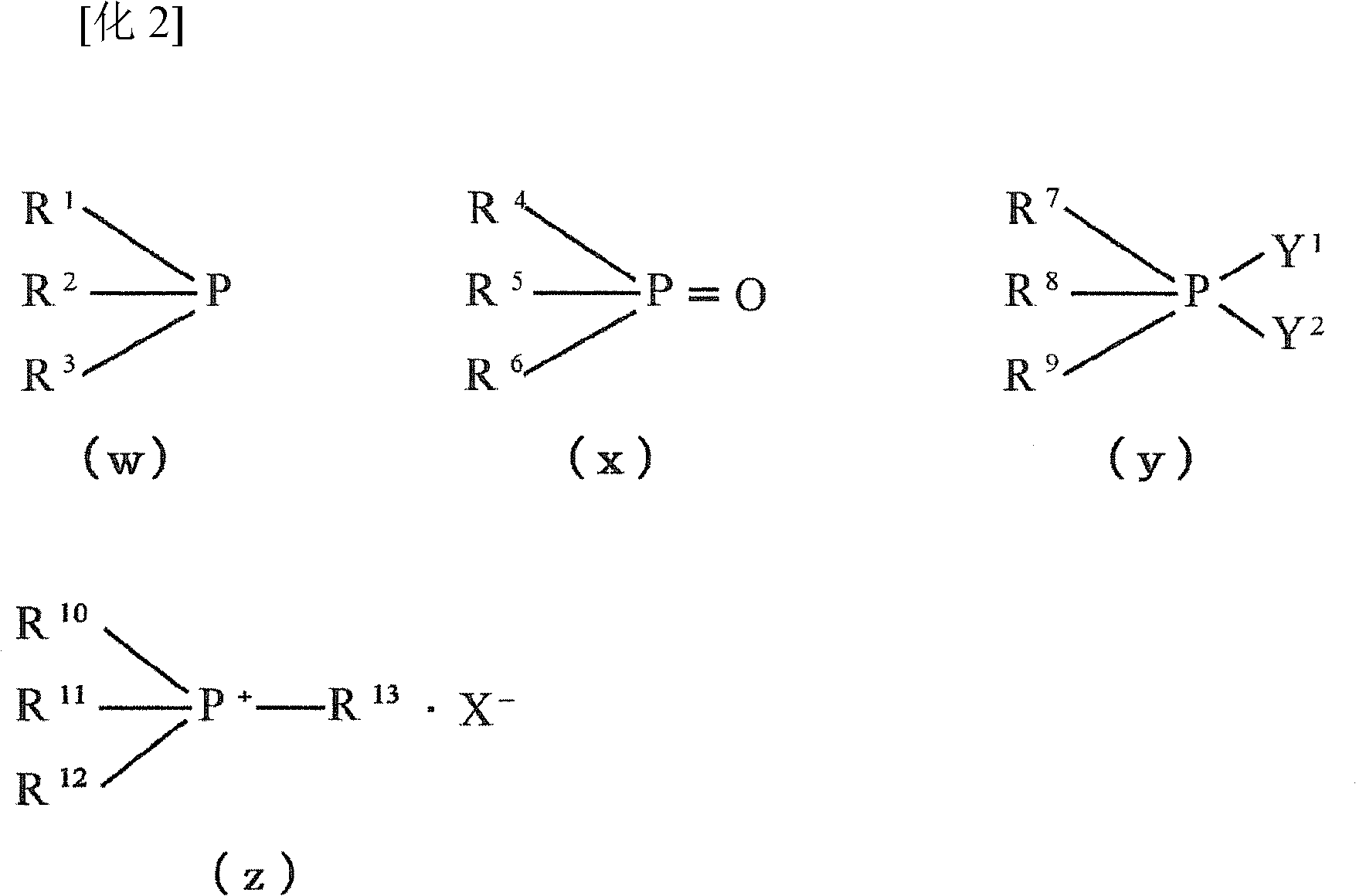

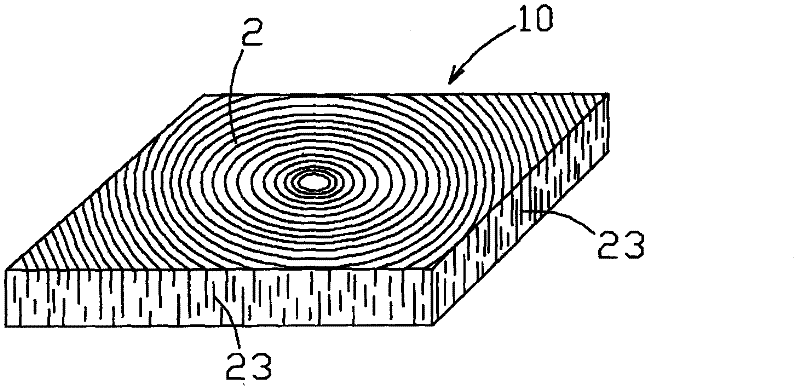

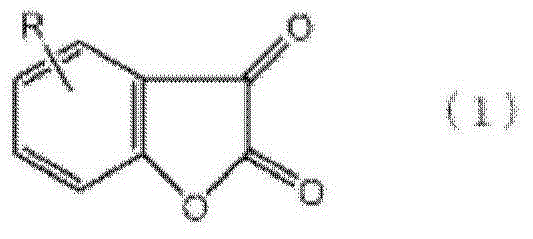

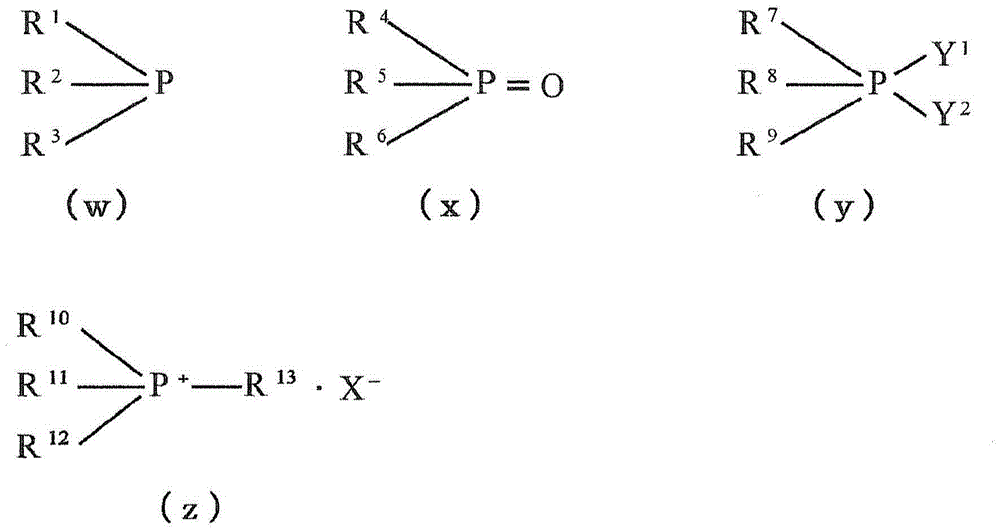

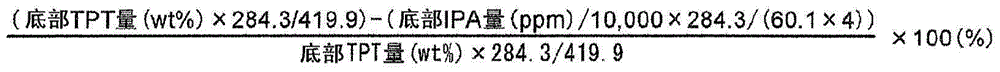

Process for production of diaryl oxalate

ActiveCN102712564AImprove conversion rateSimple processOrganic compound preparationPreparation by ester-hydroxy reactionOxalateAryl

Disclosed is a process for producing a diaryl oxalate, which involves a step of carrying out the transesterification reaction of a dialkyl oxalate or / and an alkylaryl oxalate with an aryl alcohol in the presence of a tetra(aryloxy)titanium that serves as a catalyst. The process is characterized in that the tetra(aryloxy)titanium is supplied to a reaction system to be used for the transesterification reaction in the form of a solution of the tetra(aryloxy)titanium in an aryl alcohol, wherein the solution is produced by reacting an tetraalkoxytitanium with an excess amount of the aryl alcohol and removing an alkyl alcohol that is produced as a byproduct.

Owner:UBE IND LTD

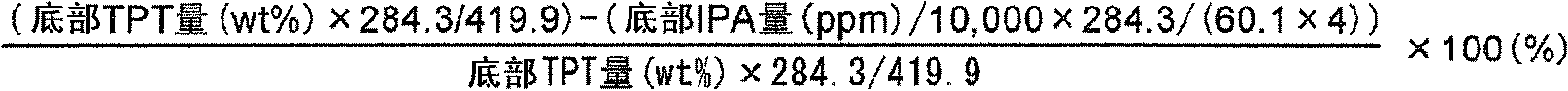

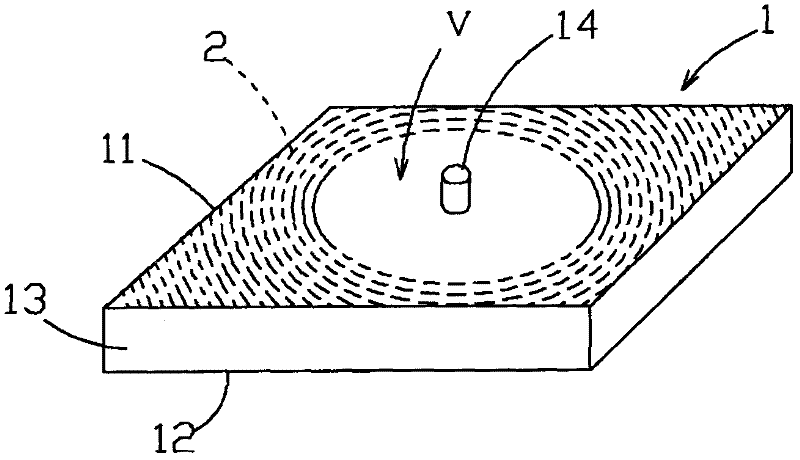

Fibrous structural article and manufacturing method thereof

ActiveCN102330288ANo elastic recoveryEasy to useSuperstructure subunitsNon-woven fabricsPolymer scienceFiber structure

The present fibrous structural article is a material in a plate-like shape and having multiple fibers adhered to one another, and fibers are oriented from one surface side toward the other surface side of the fibrous structural article, and the fibers are arranged in an annual ring centering on a virtual axis. The present production method of a fibrous structural article comprises a fiber supplying process for blowing and supplying first short fibers and second short fibers, into a forming mold in a hollow box shape and having a first bottom wall, sidewalls and second bottom wall, from a fiber supplying port formed through the first bottom wall, and a melting process for melting at least part of the second short fibers.

Owner:TOYOTA BOSHOKU KK

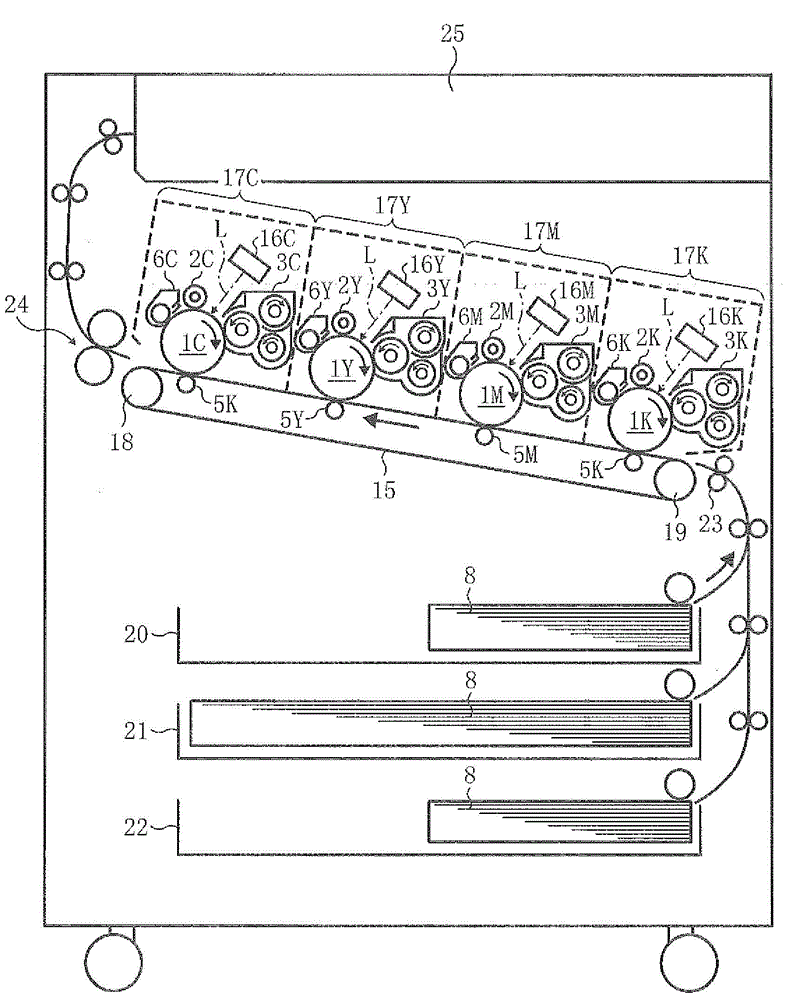

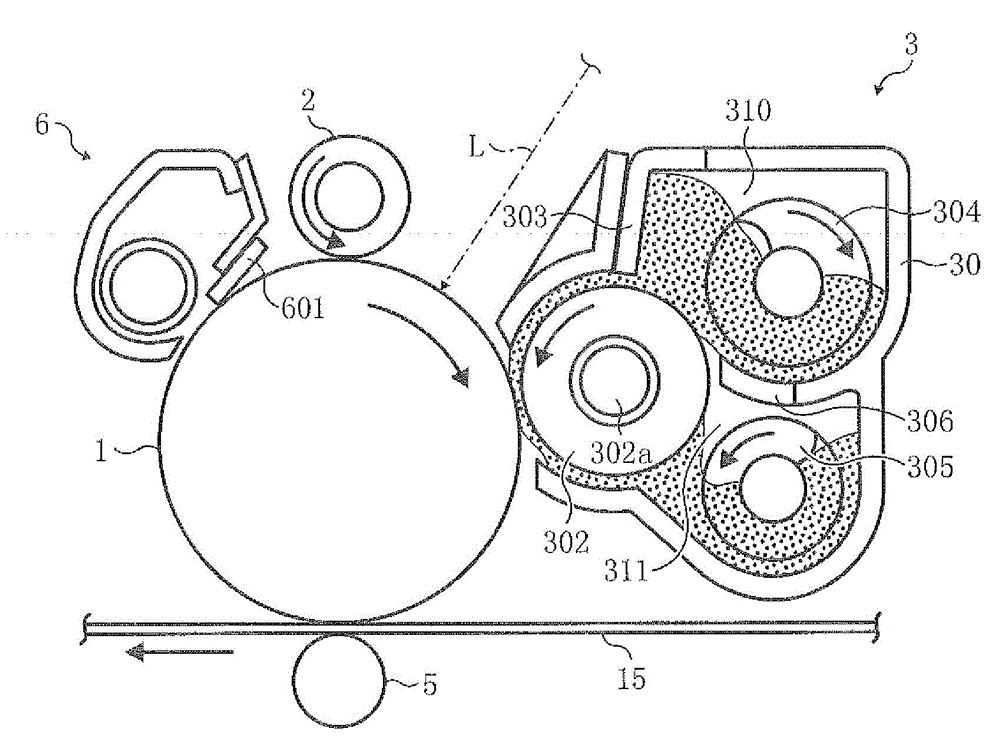

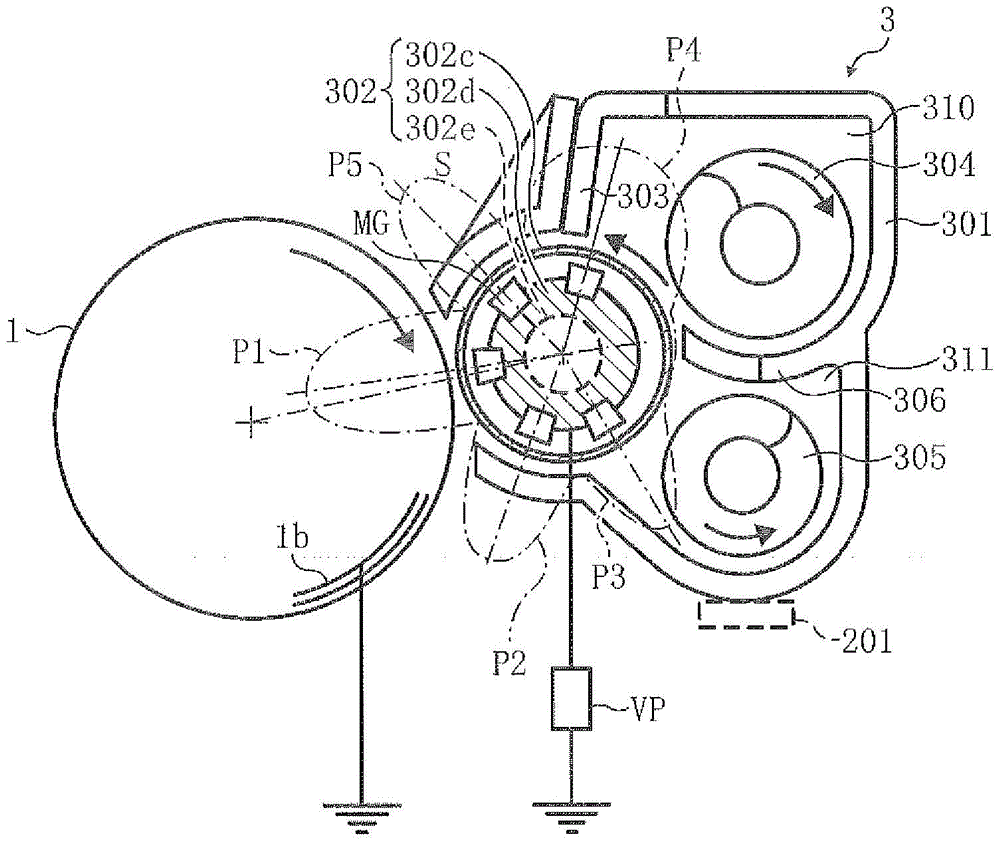

Image forming device

InactiveCN104035297ASuppression of image density unevennessReduced imaging performanceElectrographic process apparatusVoltageLatent image

The present invention provides an image forming device which is capable of inhibiting image concentration dis-uniformity on one hand, and preventing a line dust and a line from diming on the other hand when printing images with high image area rate. The image forming device comprises a toner concentration sensor (390) for the concentration of the toner in a detection recycling agent accommodation chamber (311), and an engine control portion which adjusts a write light intensity of an electro-static latent image of a photoreceptor according to an output difference deltaVt of an output voltage of the toner concentration sensor (390) when two screw rod components (304, 305) are driven by a normal rotation speed and an output voltage of the toner concentration sensor (390) when the two screw rod components (304, 305) are driven by speed lower than the normal rotation speed.

Owner:RICOH KK

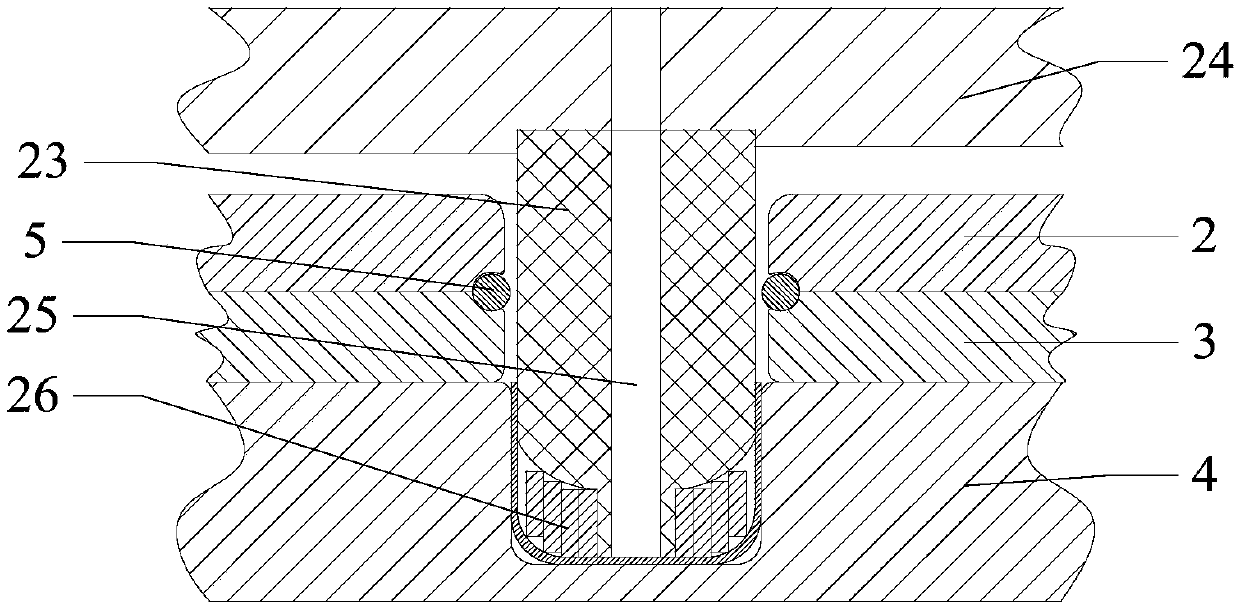

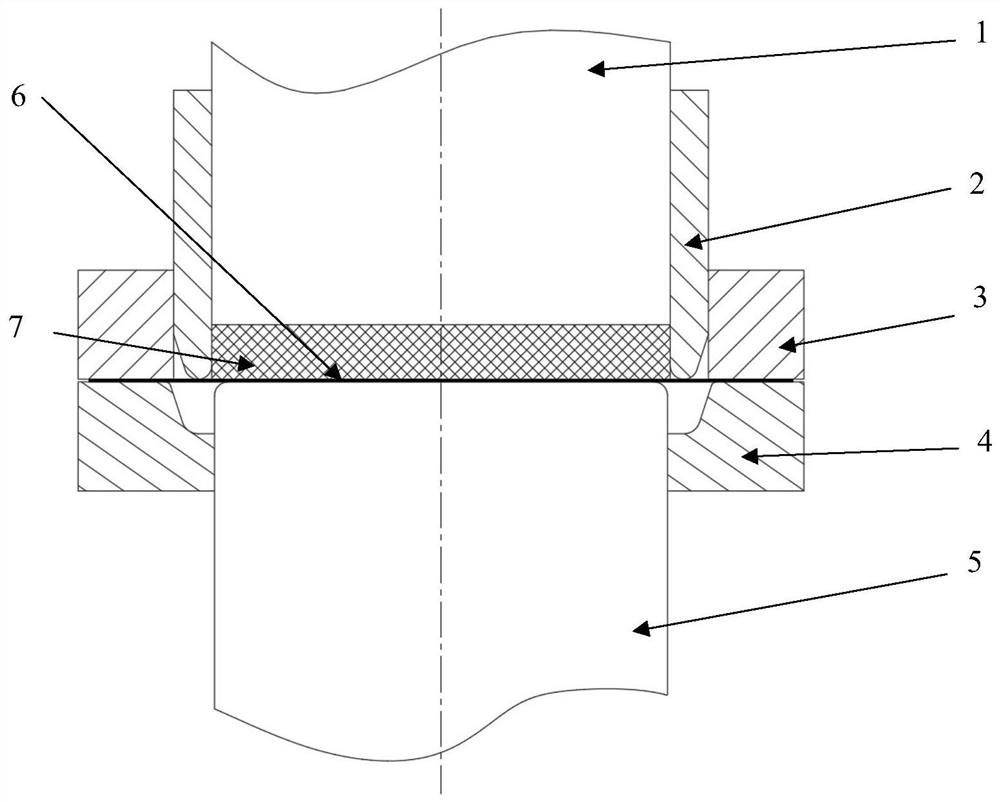

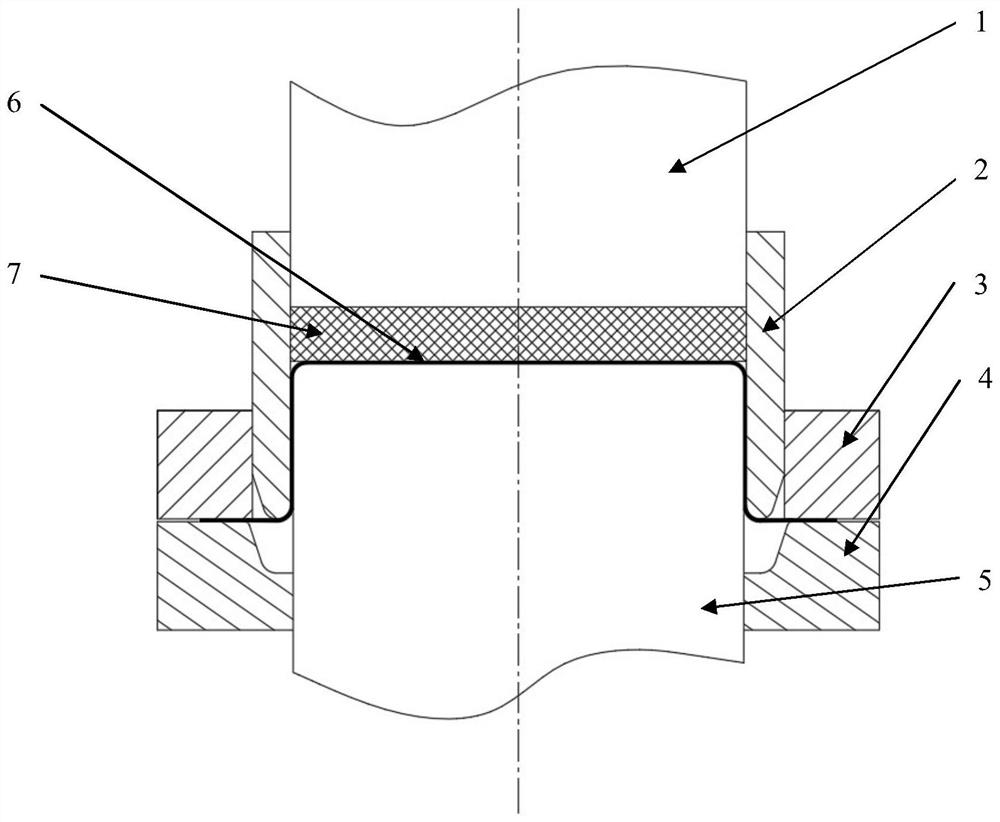

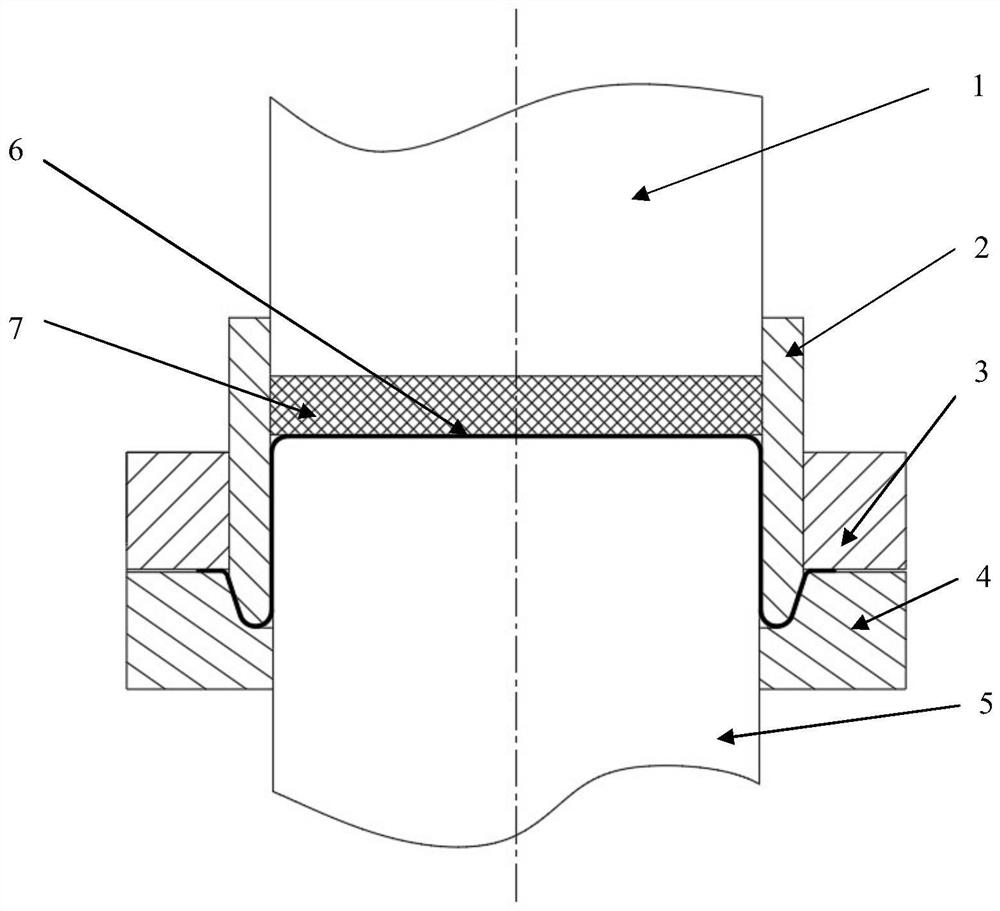

Die and method for front and back deep drawing of double-layer cylindrical parts

The invention discloses a front and back drawing forming die and method of a double-layer cylindrical part. The lower end of the mold has a punch and a die, the die has a deep drawing groove, the upper end of the die has a back pressure punch and a convex ring, and the convex ring is covered with a blank holder. When forming positive and negative deep drawing, the plate is placed on the mold. At the beginning, the upper end of the punch is flush with the bottom end of the blank holder, and the plate is placed between the punch and the convex ring. The convex ring is stationary, and the bottom punch moves upward. The drawn sheet flows into the convex ring, and the sheet gradually covers the punch under the action of the back pressure of the back pressure punch, the downward pressure of the convex ring and the upward pressure of the punch. When the punch rises to the specified stroke, it begins to fall. When the convex ring goes down to draw the sheet, under the pressure of each part in the mold, the thickness of the sheet covering the punch part remains basically unchanged, while the sheet below the blank holder continues to be fed until the sheet is attached to the die, and the forming is terminated . The invention saves molds, shortens the processing procedure of workpieces and improves production efficiency.

Owner:YANSHAN UNIV

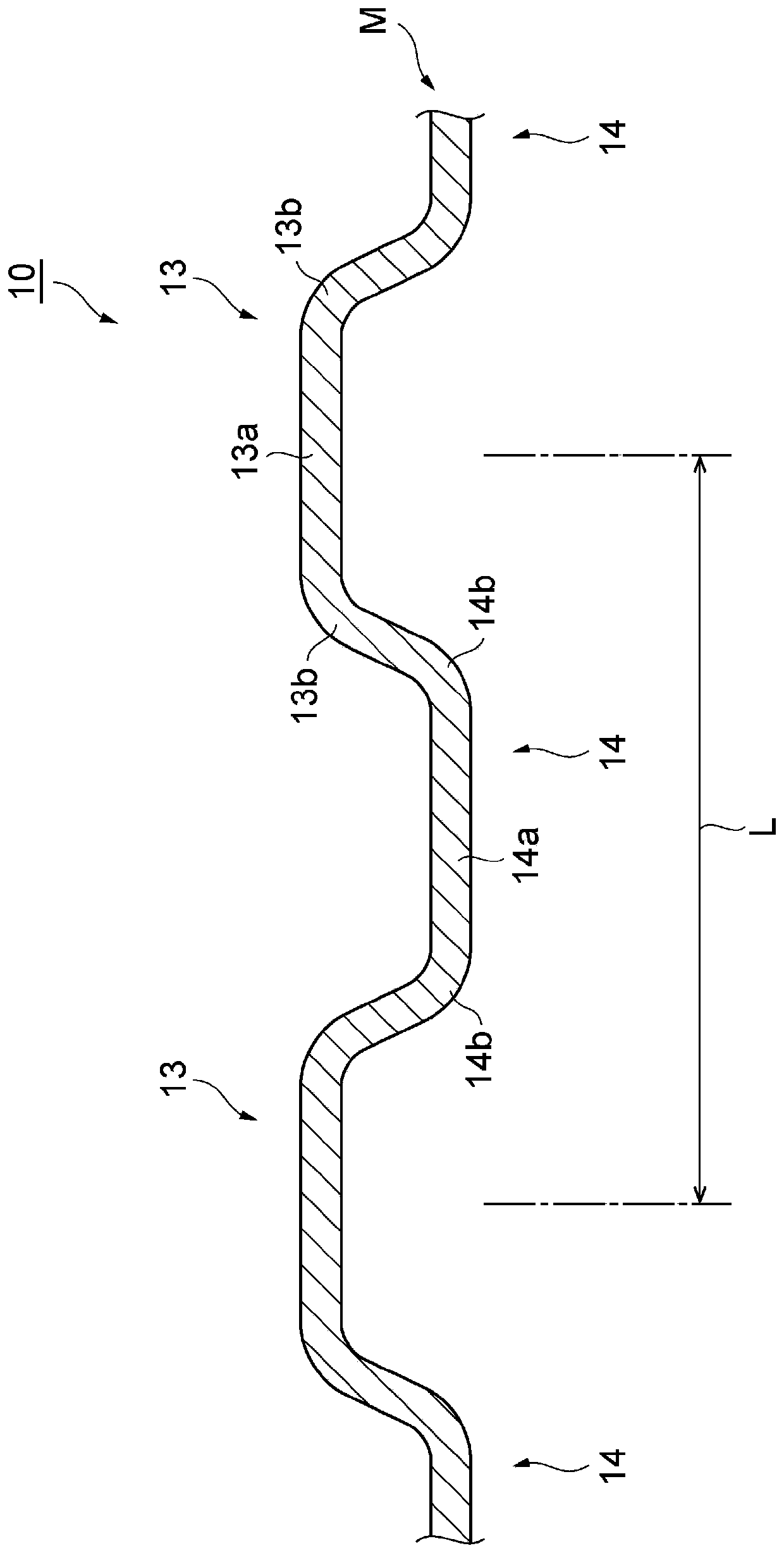

Manufacturing method of metal forming body

InactiveCN110125249AInhibition of thinningFully flat areaShaping toolsFinal product manufactureMetal formingMetal mold

The purpose of the present invention is to provide a method for manufacturing a metal molded body, which can suppress thinning of the corner portion, ensure a sufficient flat region, and flatten the ceiling wall. The method for manufacturing a metal molded body is characterized by comprising the following steps of: stretching and molding a flat metal plate so that temporary concave parts and temporary convex parts are alternately arranged to form a temporary molded body: a step in which the temporary concave portion and the temporary convex portion each include a top wall having a concave portion recessed inward; and a step of pressing the temporary formed body and pressing the recessed portions outward to form a formed body in which recessed portions and protruding portions are alternately arranged, the top wall of which is flat.

Owner:MITSUI HIGH TEC INC

Processing method of resistance copper foil material for mobile phone vibration motor PCB

InactiveCN113079628AInhibition of thinningStable plating resistancePrinted circuit aspectsConductive material chemical/electrolytical removalEngineeringCopper foil

The invention relates to the technical field of electronic materials, in particular to a processing method of a resistance copper foil material for a mobile phone vibration motor PCB. The method comprises the following steps: providing a resistor copper foil plate, and carrying out cutting treatment, pressing treatment, drilling treatment, electroplating treatment, outer layer film drying, outer layer etching treatment, etching, film drying, differential etching treatment, ink printing, gold plating and lead etching to obtain the resistor. According to the processing method, the resistor copper foil material is adopted to replace a traditional carbon resistor printing ink printing technology, the prepared resistor copper foil material enables the electroplating resistance value of the PCB to be more stable, the precision is higher, and the product yield can be improved; the method is simple and easy to control, high in production efficiency, stable in product quality and beneficial to industrial production.

Owner:东莞市科佳电路有限公司

A workpiece electromagnetic progressive forming device and method provided with coils arranged along the shape

ActiveCN108856444BGuaranteed forming qualityIncrease forming heightEngineeringElectromagnetic forming

Owner:CENT SOUTH UNIV

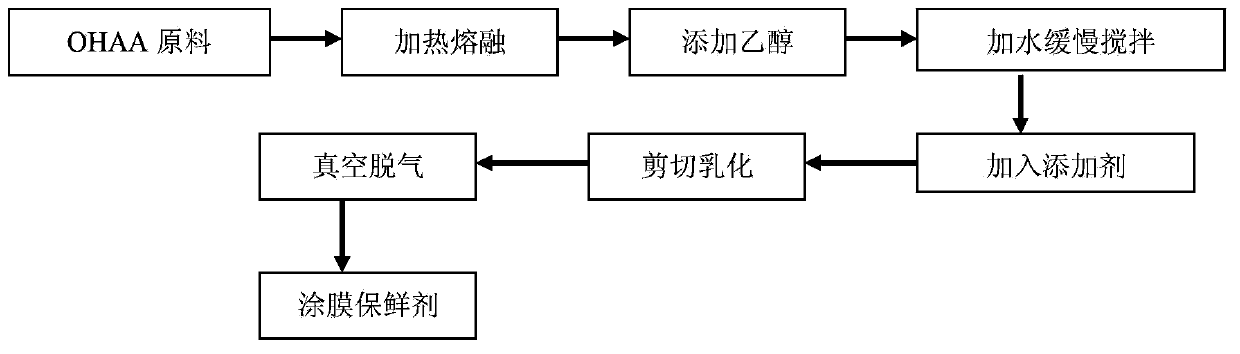

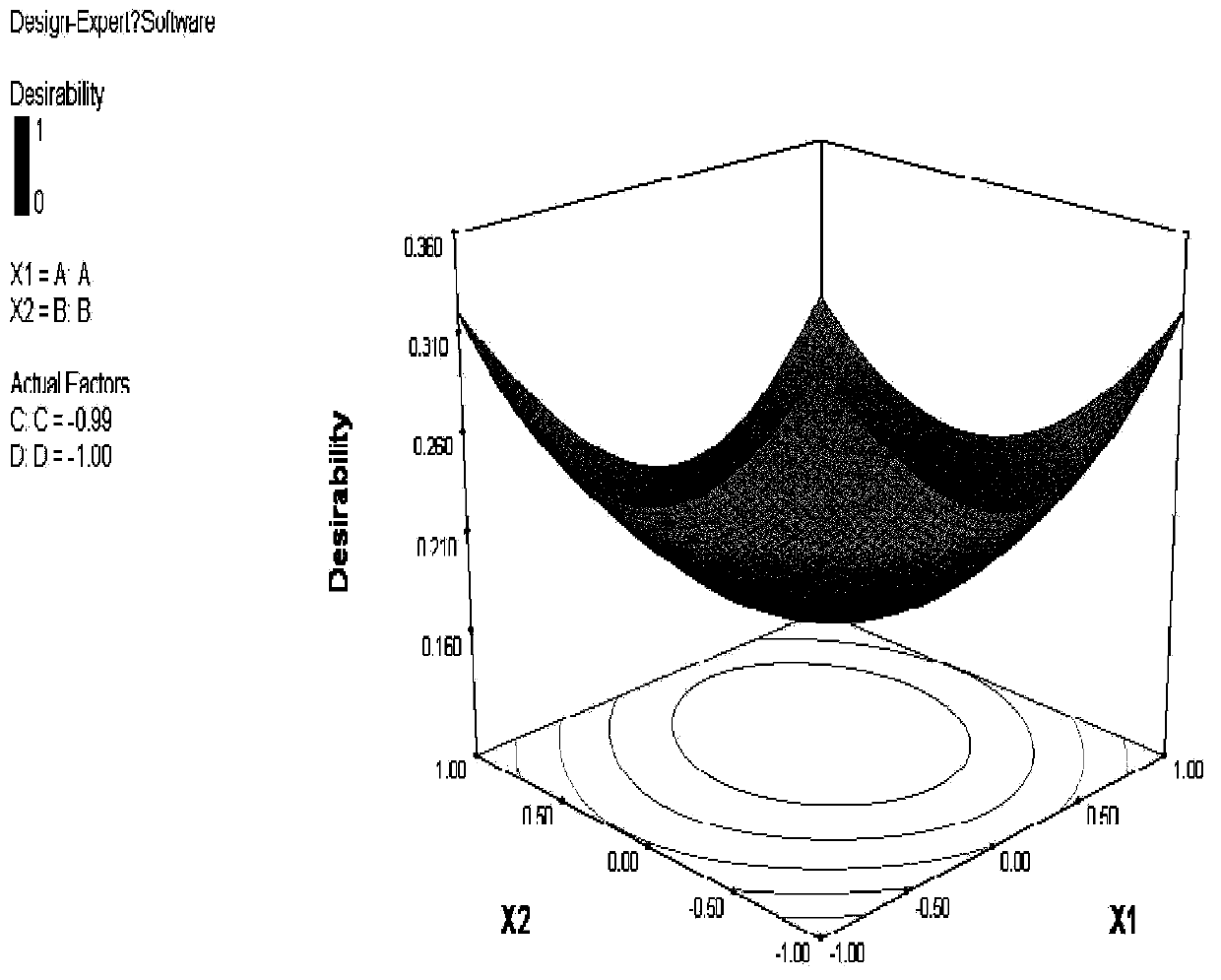

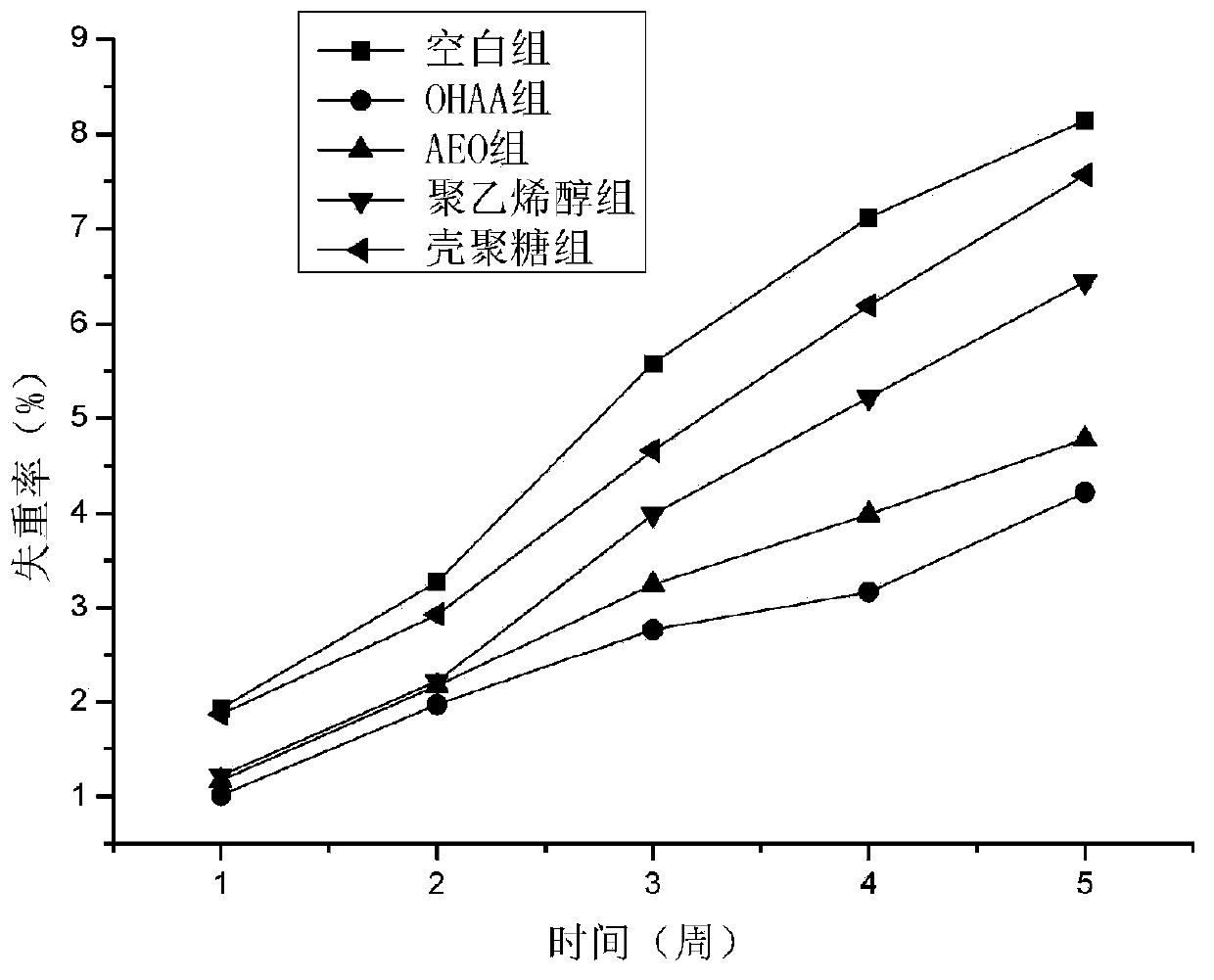

Egg coating preservative with oxyethlene higher aliphatic alcohol

ActiveCN102894068BGood effectFilm-formingEggs preservation by coatingAdditive ingredientGas composition

Owner:HUAZHONG AGRI UNIV

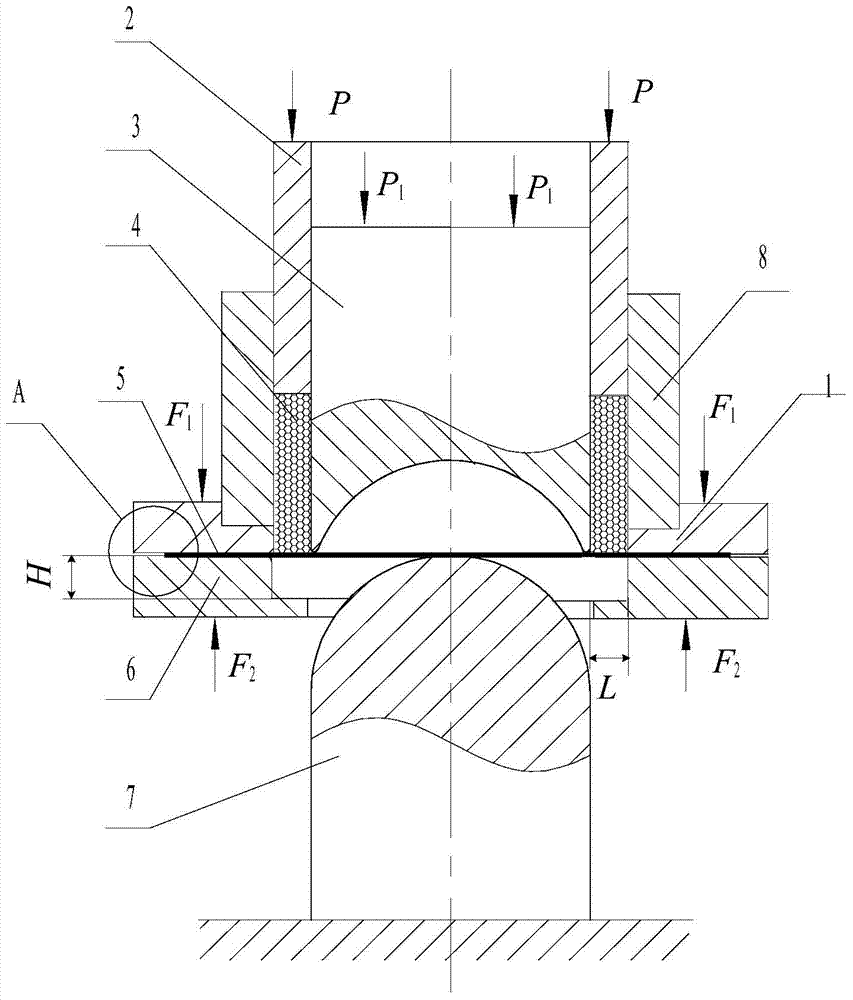

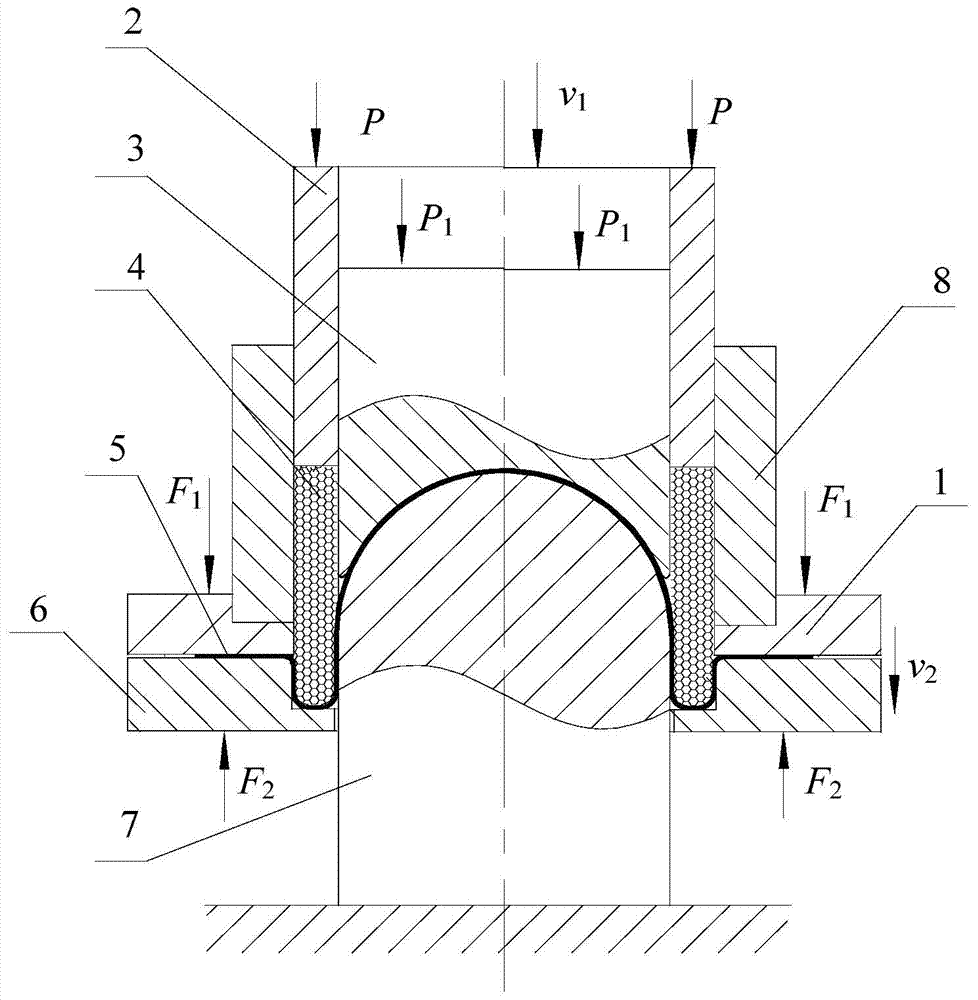

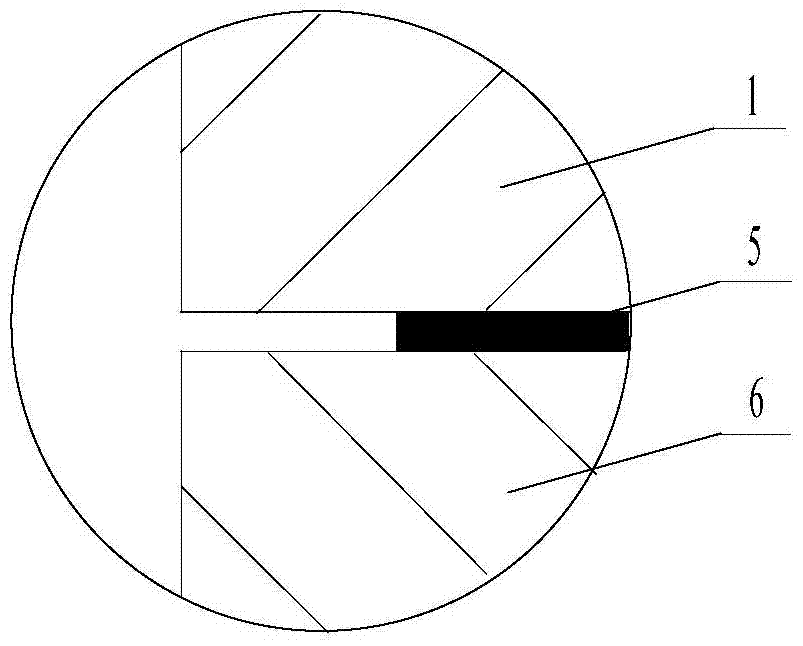

A method for front and back deep drawing of metal sheet soft mold

The invention discloses a forward-backward drawing and forming method for a metal plate soft mould. A lower drawing ring is arranged on the outer surface of a male mould of a mould device in a sleeving mode; a drawing slot is formed in the lower drawing ring; an upper drawing ring is arranged on the upper surface of the lower drawing ring; a charging barrel is arranged on the upper drawing ring; a force-reducing column is arranged in the charging barrel; a pressure head is arranged between the force-reducing column and the charging barrel; and the lower end of the force-reducing column is a concave surface which corresponds to the male mould. The forming method is mainly characterized in that the upper and the lower drawing rings are oppositely pressed by external force; a solid particle medium is put into a ring-shaped cavity, the pressure head descends at a speed of v1, and the particle medium is compressed to carry out forward drawing deformation on the plate; meanwhile, under the action of back pressure P1, the force-reducing column is always in a contact state with the plate, the pressure head continuously descends, and the upper and the lower drawing rings float along with the pressing of the pressure head, wherein a flotation speed is smaller than a pressing speed of the pressure head. According to the invention, by combining solid particle medium soft mould forming and backward drawing into one set of mould, the invention provides the forward-backward drawing and forming method for the metal plate soft mould which is simple in structure, is energy-saving and environmentally-friendly, and is formed once.

Owner:YANSHAN UNIV

Food manufacturing device

The present invention relates to an apparatus for preparing the following foods (production) continuously, the foods is made by packaging inner material composed of foods such as stuffing or fruit jam etc. by tegmen material composed of foods blank such as bread etc. A blank pressing component is formed integratedly on the peripheral of a nozzle component for extruding inner material, the peripheral part of the tegmen material locating on the upper surface of a carrying component with hatch is clipped between the blank pressing component and the carrying component, and the upper opening of the bowl-shaped tegmen material is closed by the nozzle component and the blank pressing component, so as to prevent the inner material from leaking from the upper opening by maintaining the clipping state when ejecting the inner material into the inner of the tegmen material, and to prevent inner material from leaking to manufacture no good production when sealing the peripheral of the tegmen material. In addition, due to prevent inner material from polluting food manufacture device, it is able to prepare foods continuously without stop the running of the device.

Owner:RHEON AUTOMATIC MASCH CO LTD

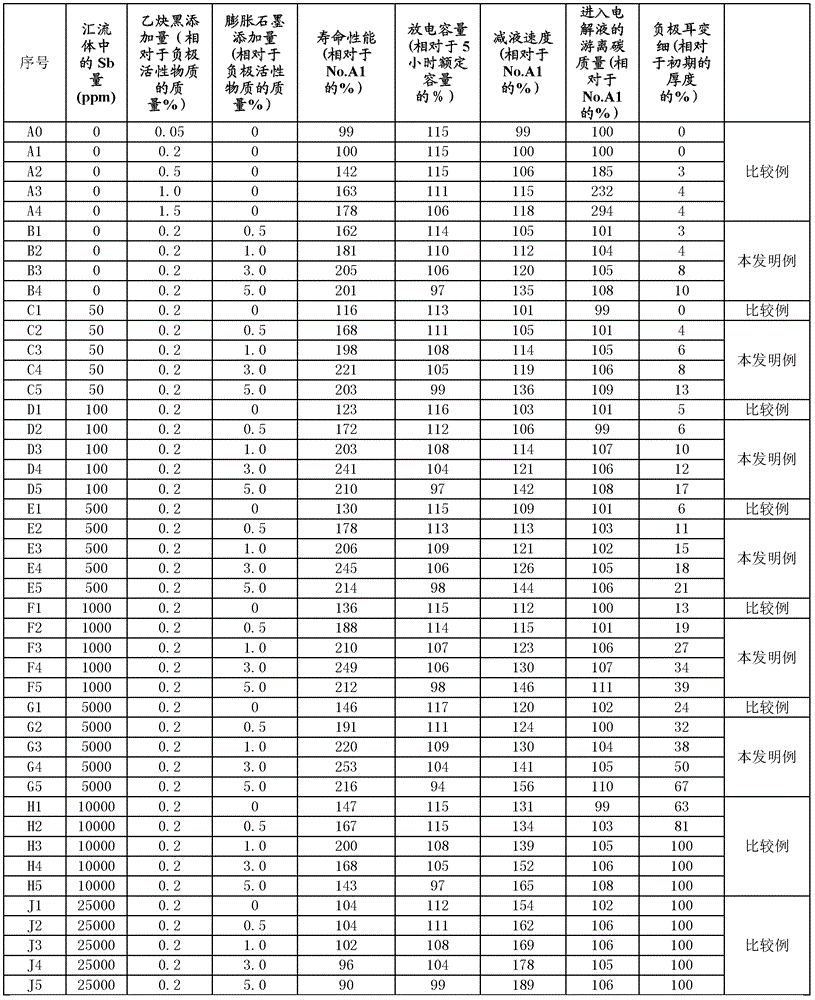

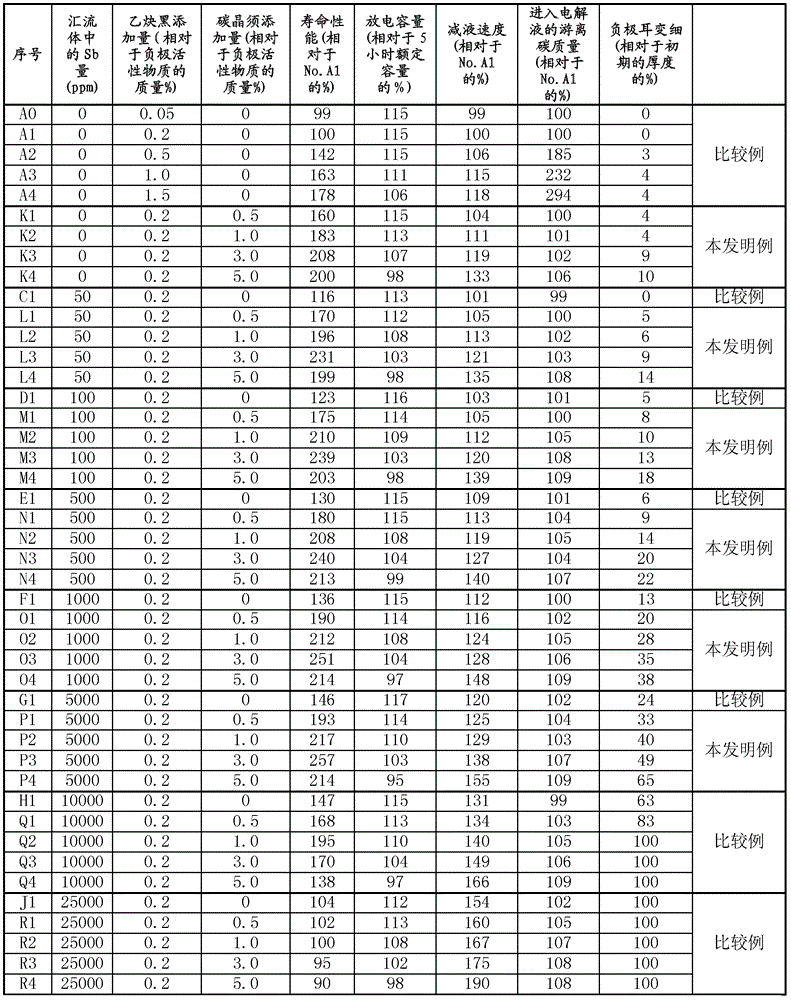

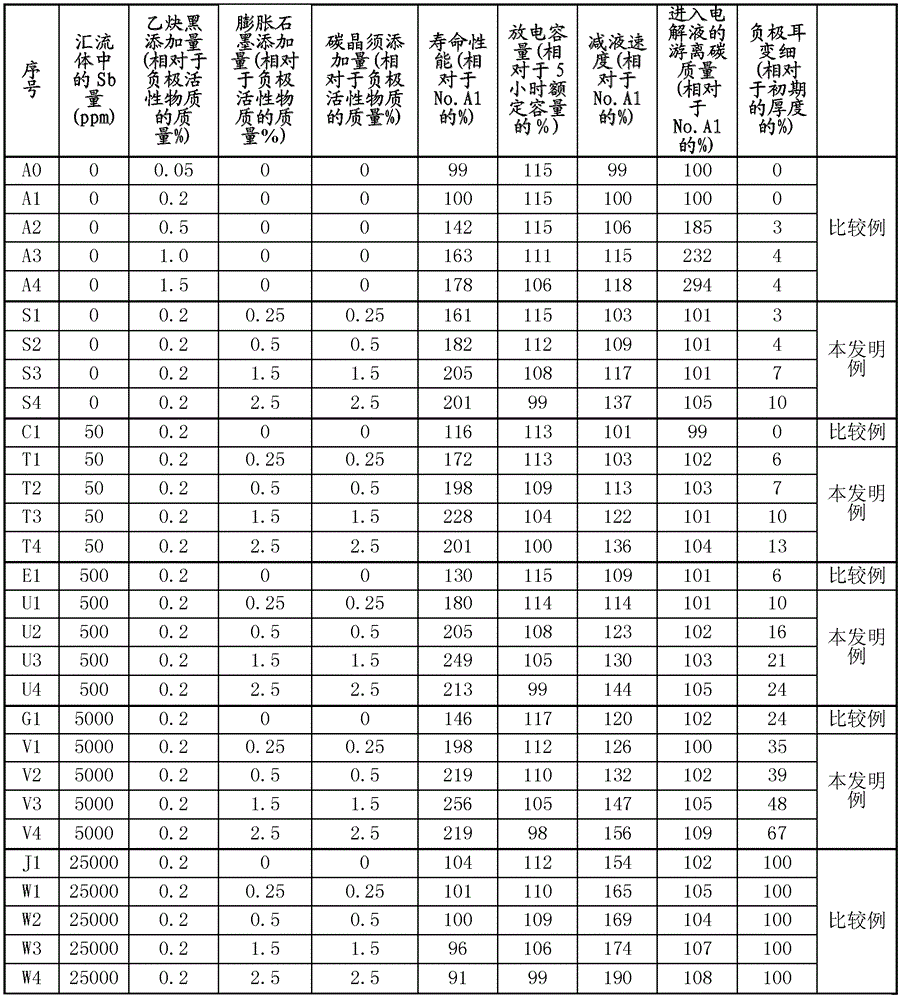

Lead acid storage battery

ActiveCN102484286BImprove life performanceHypostatic inhibitionLead-acid accumulatorsElectrode carriers/collectorsAlloyGraphite

Provided is a lead acid storage battery wherein the life time performance is significantly improved, reduction of liquid is suppressed, corrosion of the negative electrode ear is suppressed, and the amount of free carbon in the electrolytic solution is small. In the lead acid storage battery, positive and negative electrode grids are comprised of a Pb-Ca-Sn alloy which does not substantially contain Sb, positive and negative electrode straps are comprised of a lead alloy containing 5,000 mass ppm or less of Sb (including cases of substantially 0 mass ppm), and the negative electrode active material is doped with carbon that uses expanded graphite and / or whisker-like carbon in a part thereof. The total additive amount of the expanded graphite and / or the whisker-like carbon is preferably 0.5-3.0 mass% with respect to the mass of the negative electrode active material.

Owner:GS YUASA INT LTD

In cylinder fuel oil jet type IC engine

InactiveCN1316153CReliable ignitionImprove ignition performanceInternal combustion piston enginesHigh pressure gas fuel injectionCombustion chamberExhaust valve

PROBLEM TO BE SOLVED: To provide a cylinder injection internal combustion engine with excellent ignitability for improving combustion efficiency and improving fuel consumption without enlarging a cavity, by separating a tip firing part of an ignition plug from a jet flow of a fuel injection valve and bringing the tip firing part close to a center axis of the cavity. ŽSOLUTION: In the cylinder injection internal combustion engine, a combustion chamber 8 is formed between a piston 5 in which the cavity 51 is formed in a top surface thereof and a cylinder head 3, and a lower wall surface of the cylinder head 3 is a ceiling surface of the combustion chamber 8. A plurality of intake and exhaust valves, the fuel injection valve 60, an ignition plug 70 are disposed to face the combustion chamber 8. The ignition plug 70 is inserted from a side surface of the cylinder head 3 toward the combustion chamber 8, and the tip firing part 71 thereof is inclined with respect to the cylinder axis L1 and approximated to the center axis L1. The fuel injection valve 60 is inserted from an upper surface of the cylinder head 3 toward the combustion chamber 8 and inclined on a side approximately opposite to the ignition plug 70 with respect to the cylinder axis L1, and a tip nozzle 62a thereof is separated in an inclination direction from the center axis L1 of the cavity 51. Ž

Owner:HONDA MOTOR CO LTD +1

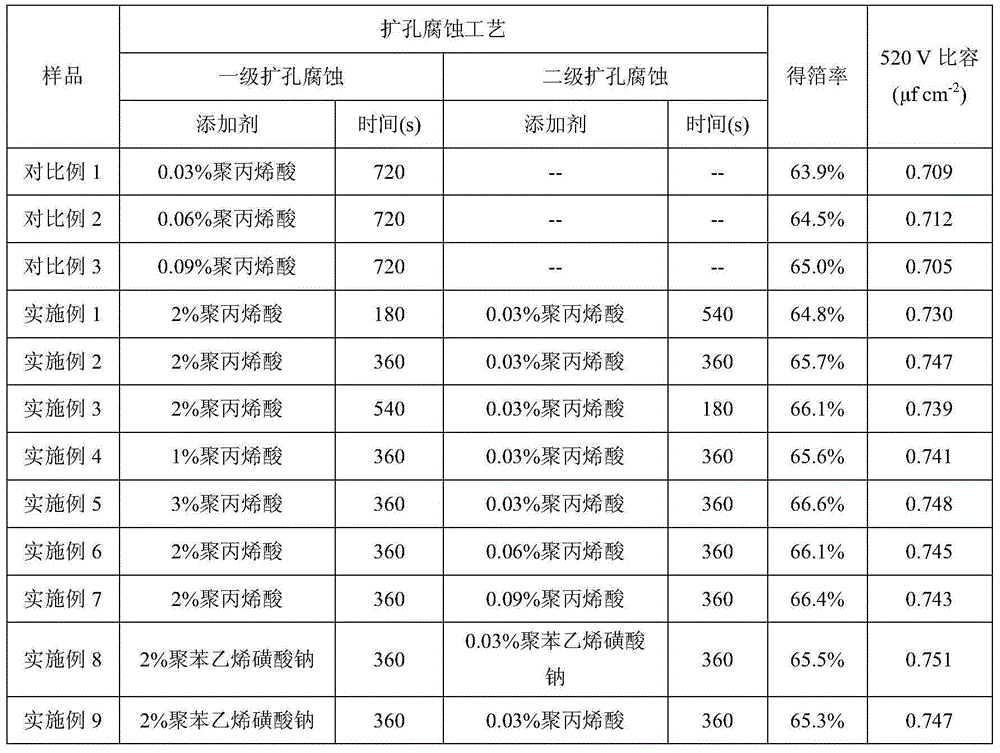

Method for Two-Stage Hole Reaming Corrosion of Medium and High Voltage Electronic Aluminum Foil

ActiveCN103280329BIncreased foil yieldHigh specific capacitanceElectrolytic capacitorsMetal surface removal provisionThinningCapacitance

The invention relates to a method for reaming and corroding a high-medium-voltage electronic aluminum foil in two levels. The method comprises the following steps that a conical tunnel hole with a large opening and small interior is formed the high-medium-voltage electronic aluminum foil after being pretreated and perforated, the two-level reaming corrosion is adopted, the primary reaming corrosion is anode reaming corrosion which is carried out in a corrosive solution with 0.1 to 5 percent by weight of macromolecular corrosion inhibitor, and the secondary reaming corrosion is the anode reaming corrosion which is carried out in a corrosive solution with 0.01 to 0.1 percent by weight of macromolecular corrosion inhibitor. By adopting the method, the tunnel holes with high consistency in aperture can be obtained, not only can the specific capacitance of the aluminum foil be remarkably improved, but also the corrosion thinning of the aluminum foil can be efficiently inhibited, and the yield and the bending performance of the aluminum foil can be improved.

Owner:新疆广投桂东电子科技有限公司

The manufacture method of diaryl oxalate

ActiveCN102712564BImprove conversion rateSimple processPreparation by ester-hydroxy reactionOrganic compound preparationOxalateAryl

Disclosed is a process for preparing a diaryl oxalate which comprises the step of transesterifying a dialkyl oxalate or / and an alkylaryl oxalate with an aryl alcohol in the presence of a tetra(aryloxy)titanium as a catalyst, wherein the tetra(aryloxy)titanium is fed into a reaction system of the transesterification as an aryl alcohol solution of the tetra(aryloxy)titanium which is prepared by reacting a tetraalkoxy titanium and an excess amount of the aryl alcohol and removing a by-producing alkyl alcohol.

Owner:UBE IND LTD

High-performance bird-egg coating preservative

InactiveCN105746681APrevent intrusionInhibition of thinningEggs preservationPreservativeEthylene oxide

The present invention relates to the technical field of fine chemicals, and in particular relates to a high-performance bird-egg coating preservative. The high-performance bird-egg coating preservative comprises, by weight, 4-8 parts of ethanol, 1-2 parts of oxyethlene higher aliphatic alcohol, 0.5-1 part of Span 80, 0.5-1 part of glycerol, 1-3 parts of beeswax and 30-50 parts of water. Object of the present invention is to provide a safe and practical high-performance bird-egg coating preservative having a wide application range.

Owner:王叶苗

Stretch and electromagnetic compound incremental forming method and device for large thin-walled parts

The invention discloses a stretch-forming and electromagnetic combining incremental forming method and device of a large thin-wall part. The method comprises the steps that a driving plate is arranged above a plate to be deformed, the driving plate and the plate to be deformed are clamped by a pressing plate and a supporting plate, and a lifting oil cylinder drives the supporting plate to move, so that the driving plate and the plate to be deformed are stretch-bent and tightened preliminarily, and the stretch-forming process is achieved; the position of an electromagnetic coil is adjusted, the electromagnetic coil is made to exactly face the driving plate to be deformed to discharge electricity, the coil rotates on the surface of the driving plate for a circle around the axis of a male die, and the plate to be deformed is attached to the male die at the same height; then, the oil cylinder descends again to stretch-bend the plate, the coil discharges electricity to deform the plate to be deformed again, the plate to be deformed is attached to the male die, and the alternate forming process of stretch-forming, discharging, re-stretch-forming and re-discharging of the plate is achieved in the same way till deformation of the plate is finished. The flowing evenness of materials can be improved, the thinning ratio of the plate can be reduced, and flexible processing and precise plastic manufacturing of large plates hard to deform can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

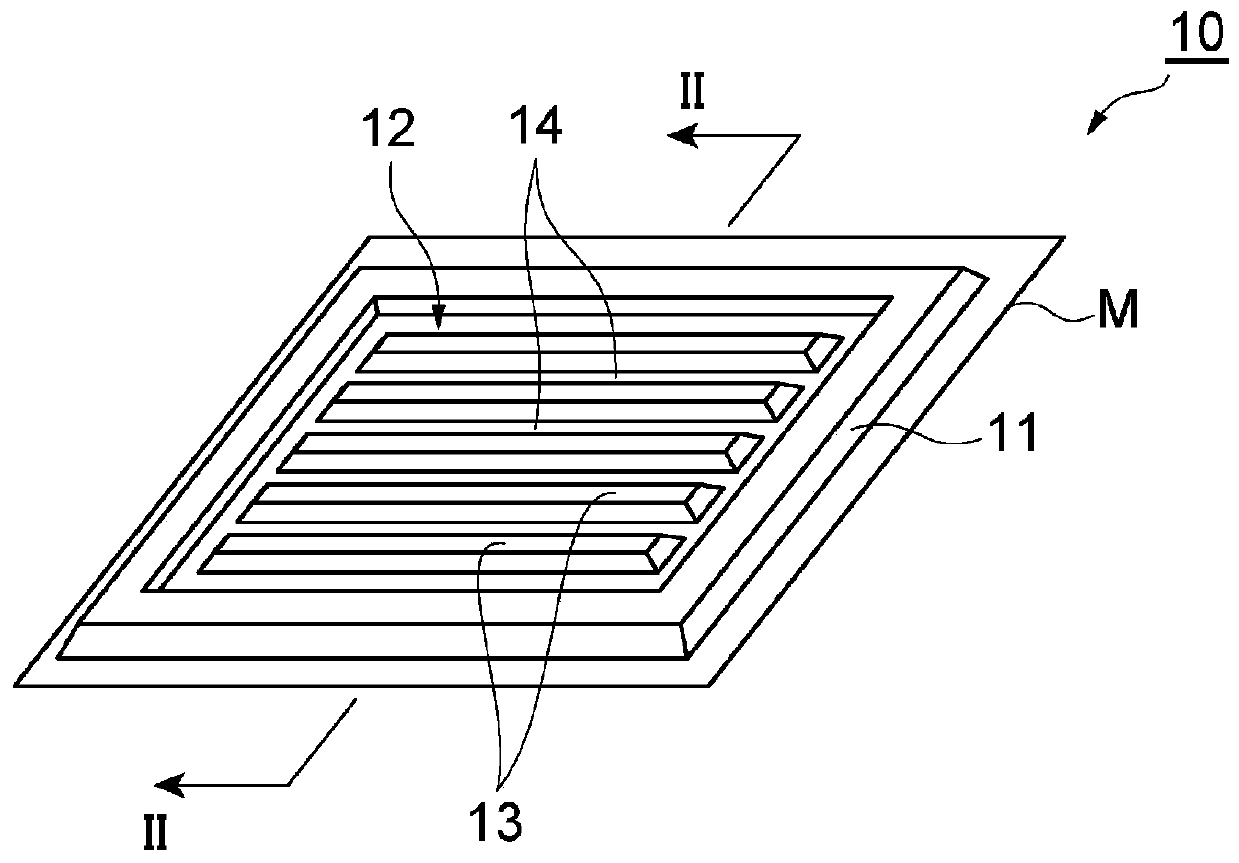

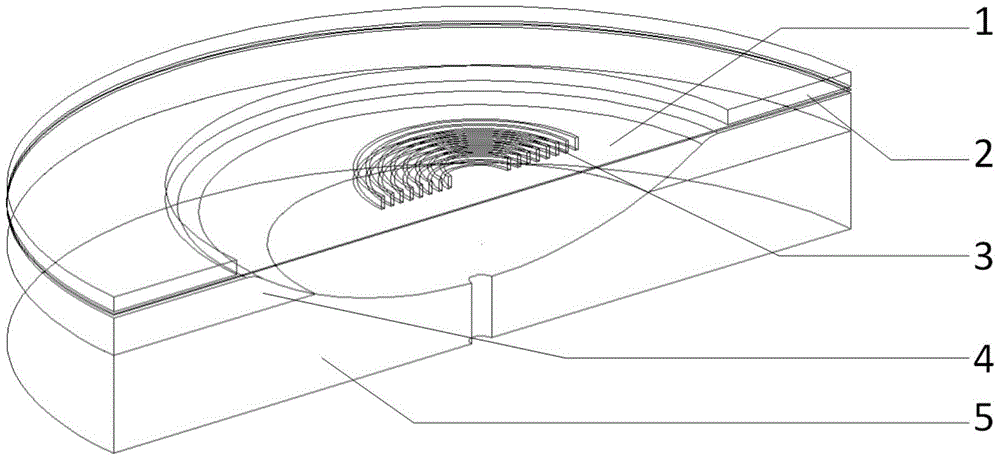

A Layer Controlled Electromagnetic Progressive Forming Method

The invention discloses an electromagnetic incremental forming method. The electromagnetic incremental forming method adopts a hierarchical manner to realize layer-by-layer forming from the bottom up; only a local position is formed during each forming, so that a die fittingness range is expanded continually till the forming of a whole workpiece is completed; then shaping is realized to improve the forming quality of a sheet; finally, a housing part which is uniform in thickness distribution and good in surface quality is obtained. Shaping can be realized through an orthotic coil or the orthotic coil and a magnet collector. According to the method, after hierarchical forming, the fluidity of sheets is improved, and a local thinning phenomenon is prevented; meanwhile, a sheet waving phenomenon, which is caused by instability wrinkling, in an electromagnetic incremental forming process can be prevented, so that the electromagnetic incremental forming precision is improved; as the fluidity of the sheets is improved after hierarchical forming and the local thinning phenomenon is prevented, the forming of housing parts with uniform wall thickness is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com