Semiconductor device and method for manufacturing the same

A manufacturing method and semiconductor technology, which can be used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as uneven film thickness of the base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

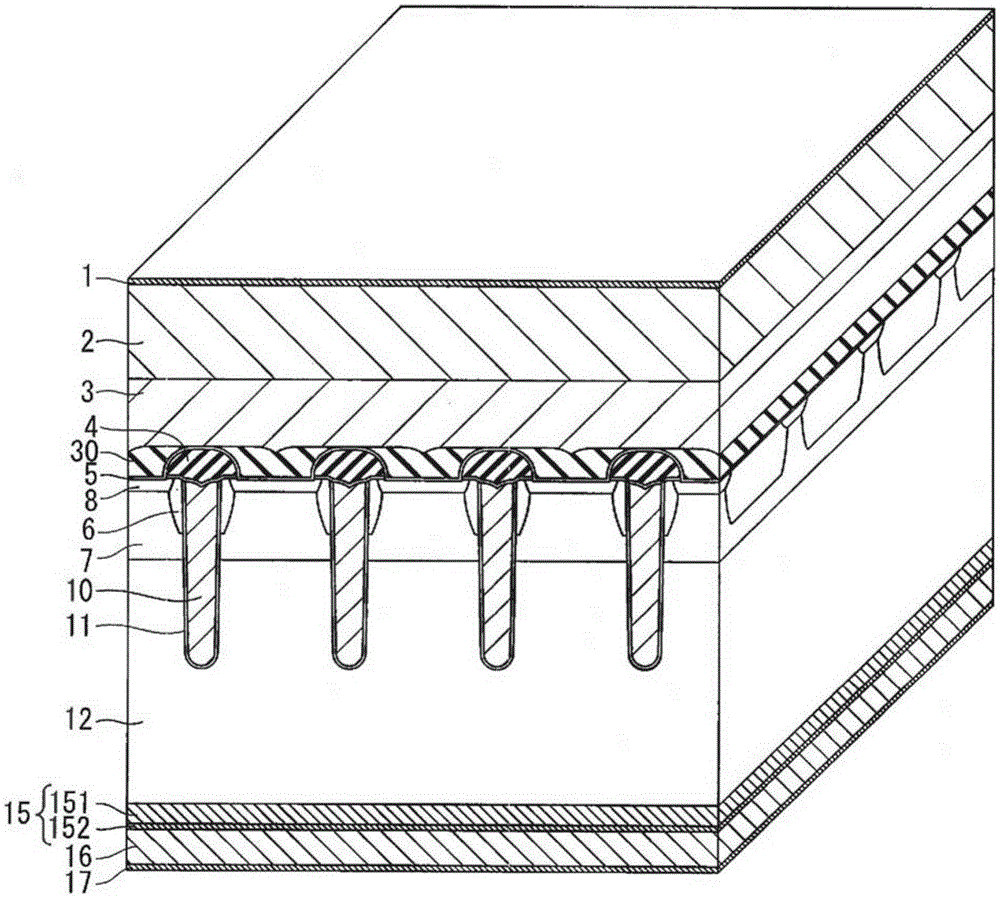

[0031]

[0032] Before describing the embodiments according to the present invention, problems in forming lead-out electrodes in a general vertical power device will be described.

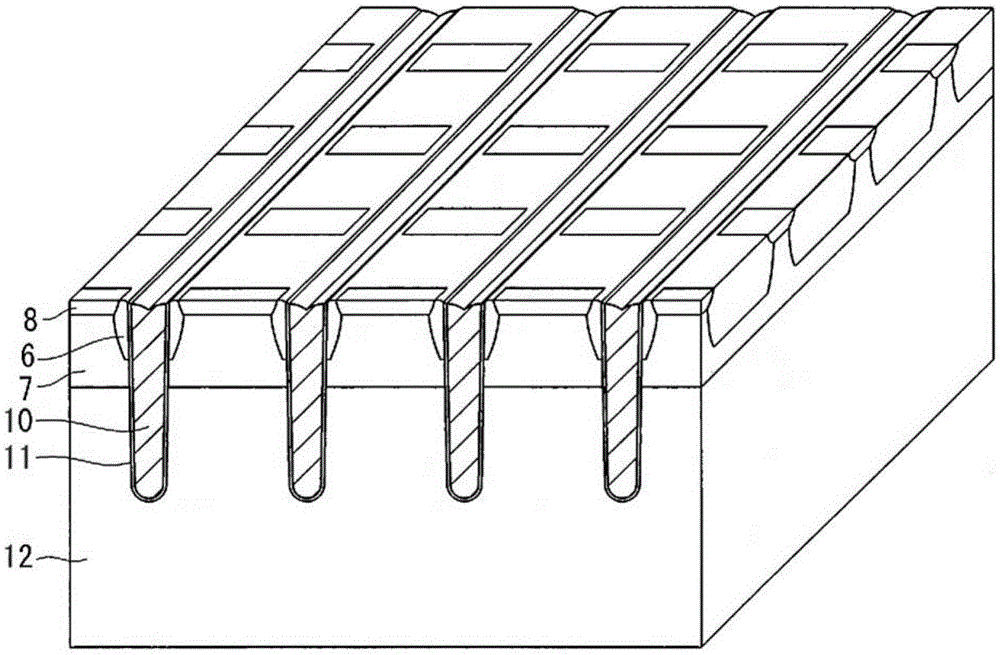

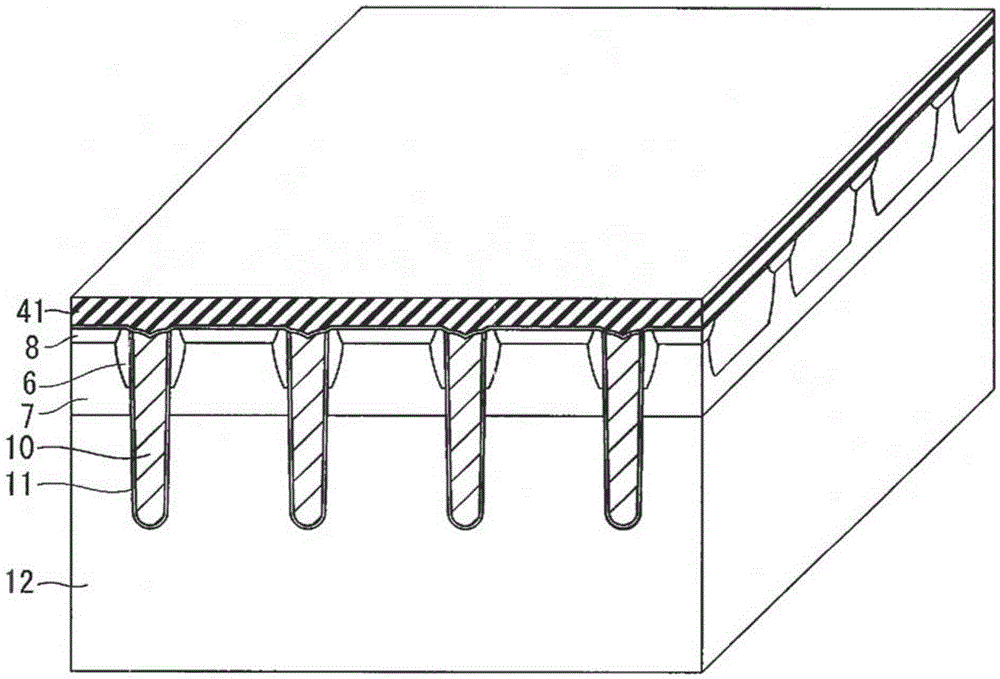

[0033] Figure 12 It is a cross-sectional view showing a partial structure of a trench gate type MOS transistor. In addition, this MOS transistor will be described as an N-channel type MOS transistor. Such as Figure 12 As shown, a P-type impurity layer 7 (body region) is provided on one main surface (upper main surface) side of an N-type semiconductor substrate 12, and a P-type impurity layer 8 (body region) is selectively provided in the surface of the impurity layer 7 ( contact area). Further, a plurality of trench gate electrodes 10 are provided so as to penetrate the impurity layer 8 and the impurity layer 7 and reach into the semiconductor substrate 12 .

[0034] The surface of trench gate electrode 10 is covered with gate oxide film 11 (gate insulating film), and N-type impurity layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com