Method for Two-Stage Hole Reaming Corrosion of Medium and High Voltage Electronic Aluminum Foil

An electronic aluminum foil, medium and high voltage technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of decreased specific capacitance, small increase in specific volume of aluminum foil, and insignificant effect of suppressing thinning, so as to improve mechanical strength and obtain foil rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

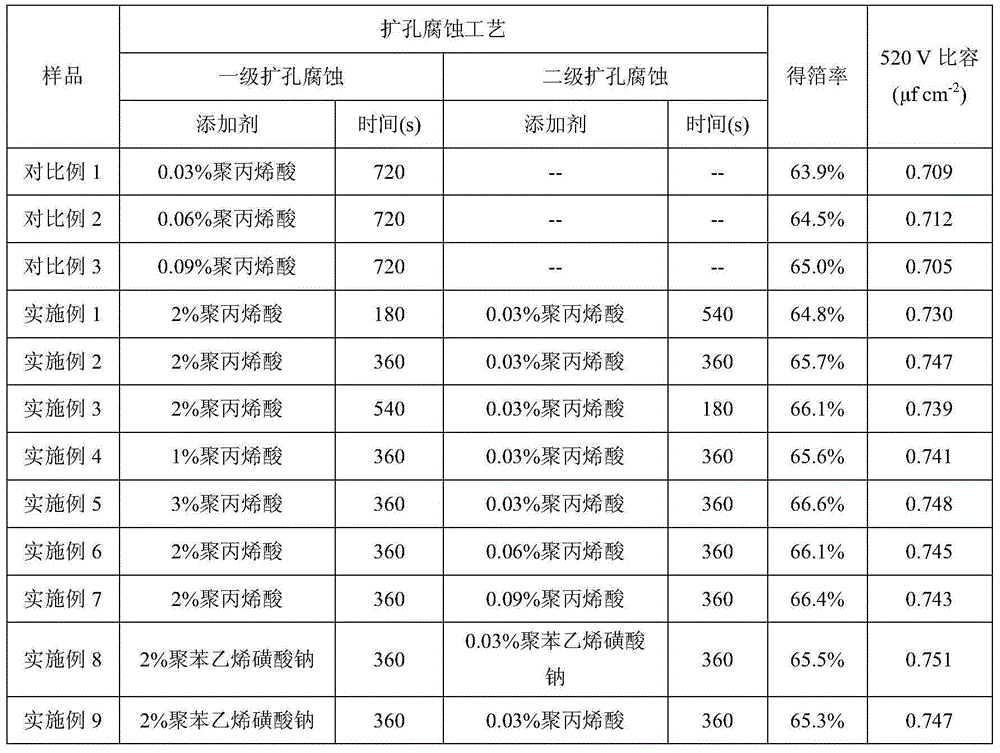

no. 1 example

[0026] The first example of the method for two-stage pore expansion corrosion of medium and high voltage electronic aluminum foil described in the present invention comprises the following steps: carrying out the same pretreatment and pore corrosion on the aluminum light foil as in the comparative example, and then putting the pore foil into the temperature 70°C, in a mixed solution containing 3% nitric acid and 2% polyacrylic acid by mass percentage, the applied current density is 100mAcm -2 The direct current was used for the first-stage hole expansion corrosion for 180s, and then it was placed in a mixed solution containing 3% nitric acid and 0.03% polyacrylic acid in a temperature of 70°C, and the applied current density was 100mAcm -2 The direct current is used for second-stage hole expansion corrosion for 540s, and finally the same post-treatment and 520V chemical formation treatment as in the comparative example are carried out.

no. 2 example

[0028] The second example of the method for two-stage hole expansion corrosion of medium and high voltage electronic aluminum foil according to the present invention includes the following steps: carrying out the same pretreatment and hole corrosion on the aluminum light foil as in the comparative example, and then putting the hole foil into the temperature 70°C, in a mixed solution containing 3% nitric acid and 2% polyacrylic acid by mass percentage, the applied current density is 100mAcm -2 The DC current was used for the first-stage hole expansion corrosion for 360s, and then it was placed in a mixed solution containing 3% nitric acid and 0.03% polyacrylic acid at a temperature of 70°C, and the applied current density was 100mAcm -2 The direct current is used for second-stage hole expansion corrosion for 360s, and finally the same post-treatment and 520V chemical formation treatment as in the comparative example are carried out.

no. 3 example

[0030] The third example of the method for two-stage hole expansion corrosion of medium and high voltage electronic aluminum foil according to the present invention includes the following steps: carrying out the same pretreatment and hole corrosion on the aluminum light foil as in the comparative example, and then putting the hole foil into the temperature 70°C, in a mixed solution containing 3% nitric acid and 2% polyacrylic acid by mass percentage, the applied current density is 100mAcm -2 The direct current was used for the first-level hole expansion corrosion for 540s, and then it was placed in a mixed solution containing 3% nitric acid and 0.03% polyacrylic acid at a temperature of 70°C, and the applied current density was 100mAcm -2The direct current is used for the second-stage hole expansion corrosion for 180s, and finally the same post-treatment and 520V chemical formation treatment as in the comparative example are carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com