Wall thickness homogenization method adopting isothermal stamping for titanium alloy thick-wall spherical shell

An isothermal stamping and titanium alloy technology, applied in the field of plastic processing, to achieve reasonable distribution, controllable machining allowance, and good overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

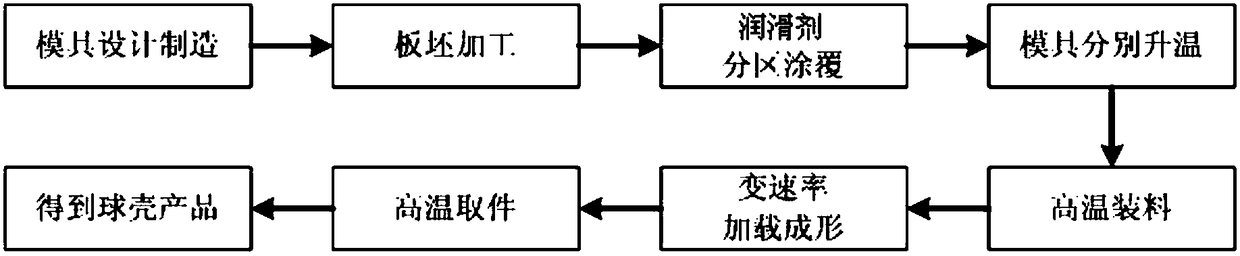

[0045] In this embodiment, the TA7 titanium alloy plate conforming to GJB2505A-2008 is used. The wall thickness of the target TA7 hemispherical product is required to be 20-25 mm, the wall thickness of the plate to be formed is 25 mm, and the diameter is 940 mm.

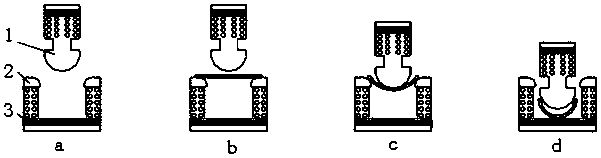

[0046] (1) Mold design and manufacture: the mold includes a punch 1, a pull ring 2 and a support seat 3, such as figure 1 As shown, the punch, pull ring and support seat are made of high temperature resistant cast steel Ni7N, the punch design is hemispherical, the support seat is a hollow structure, and the pull ring is circular, placed on the top of the support seat;

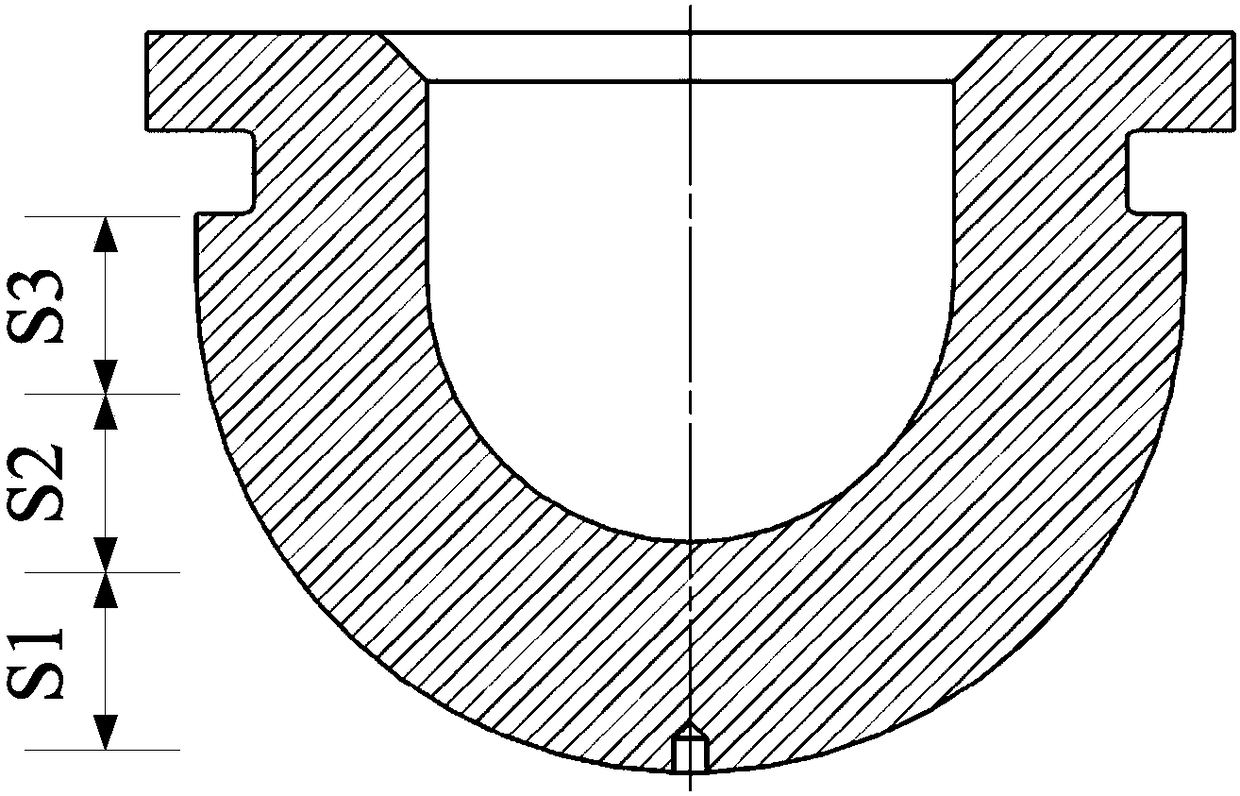

[0047] (2) Carry out roughness partition processing on the surface of the punch: the partition method is as follows image 3 As shown, from the bottom of the punch ball to the maximum diameter of the hemisphere, it is evenly divided into three areas S1, S2 and S3 along the height direction. The S1 area is sandblasted with dry sand with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com