Workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and workpiece electromagnetic incremental forming method

A progressive forming and coil technology, which is applied in the field of sheet metal forming, can solve the problems that the difficult oil cylinder has the same displacement, cannot guarantee the sheet metal forming accuracy, and the sheet metal deformation uniformity is poor, so as to improve the forming accuracy and improve the utilization of discharge energy Uniformity in rate and forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

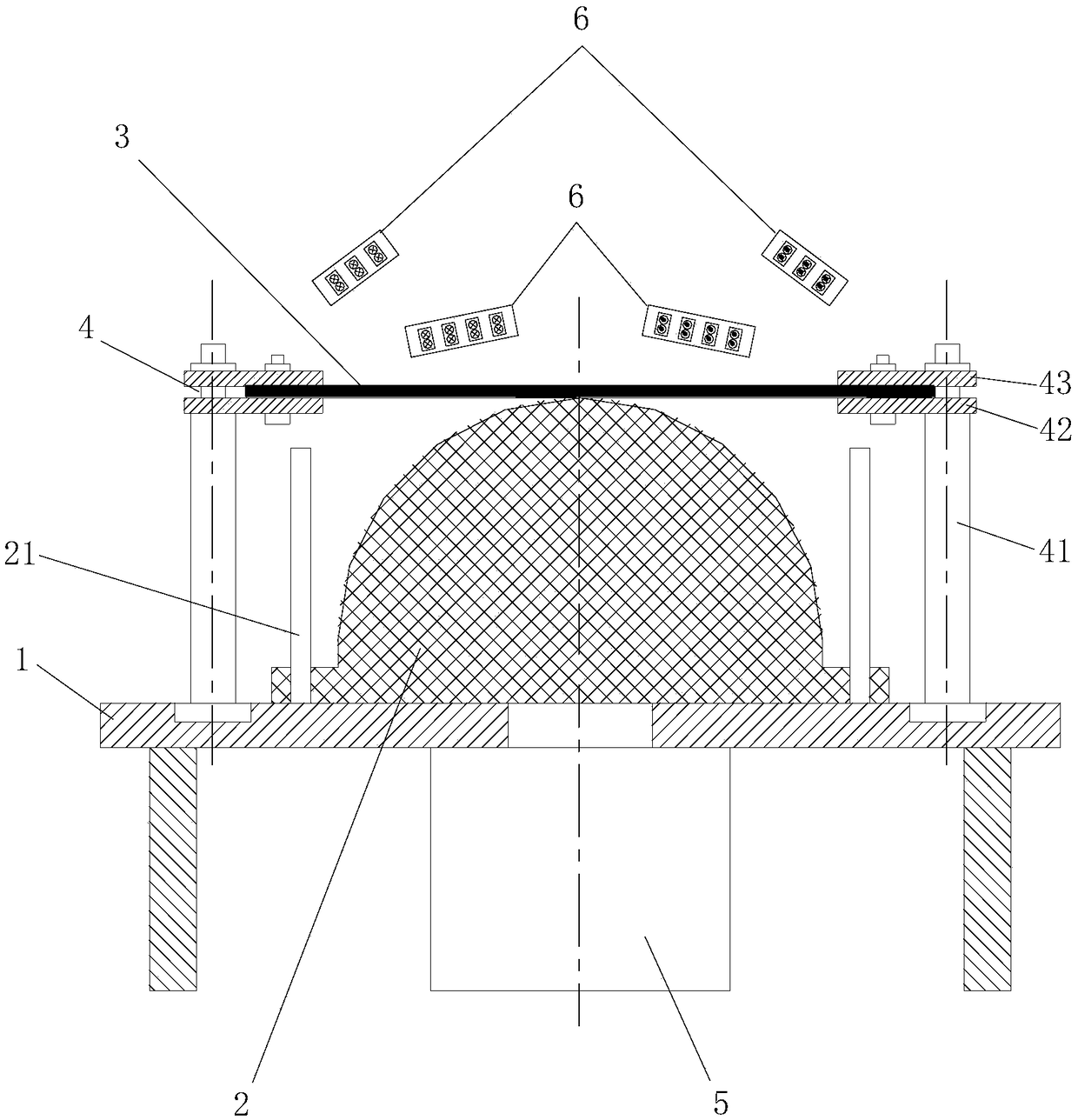

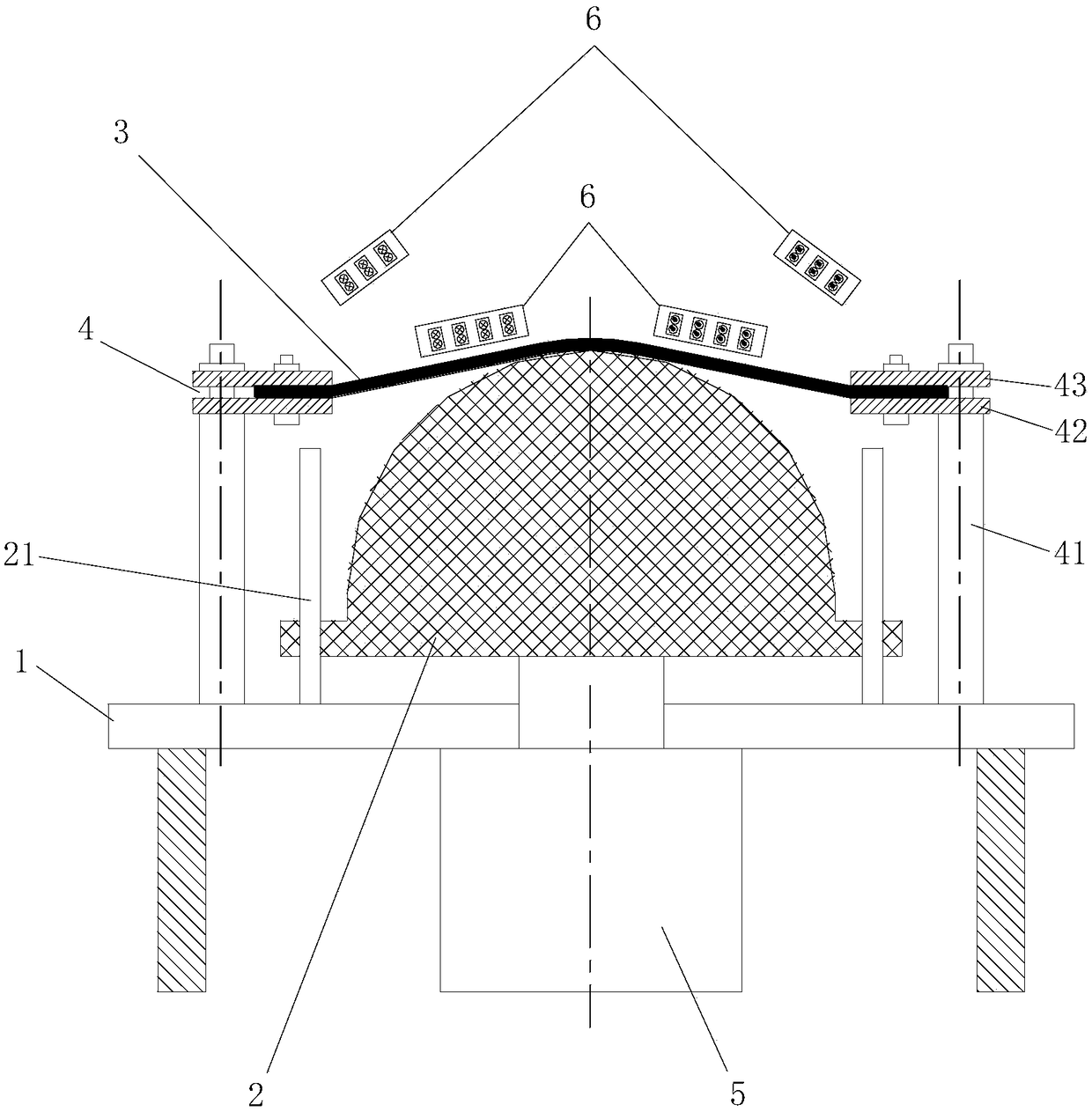

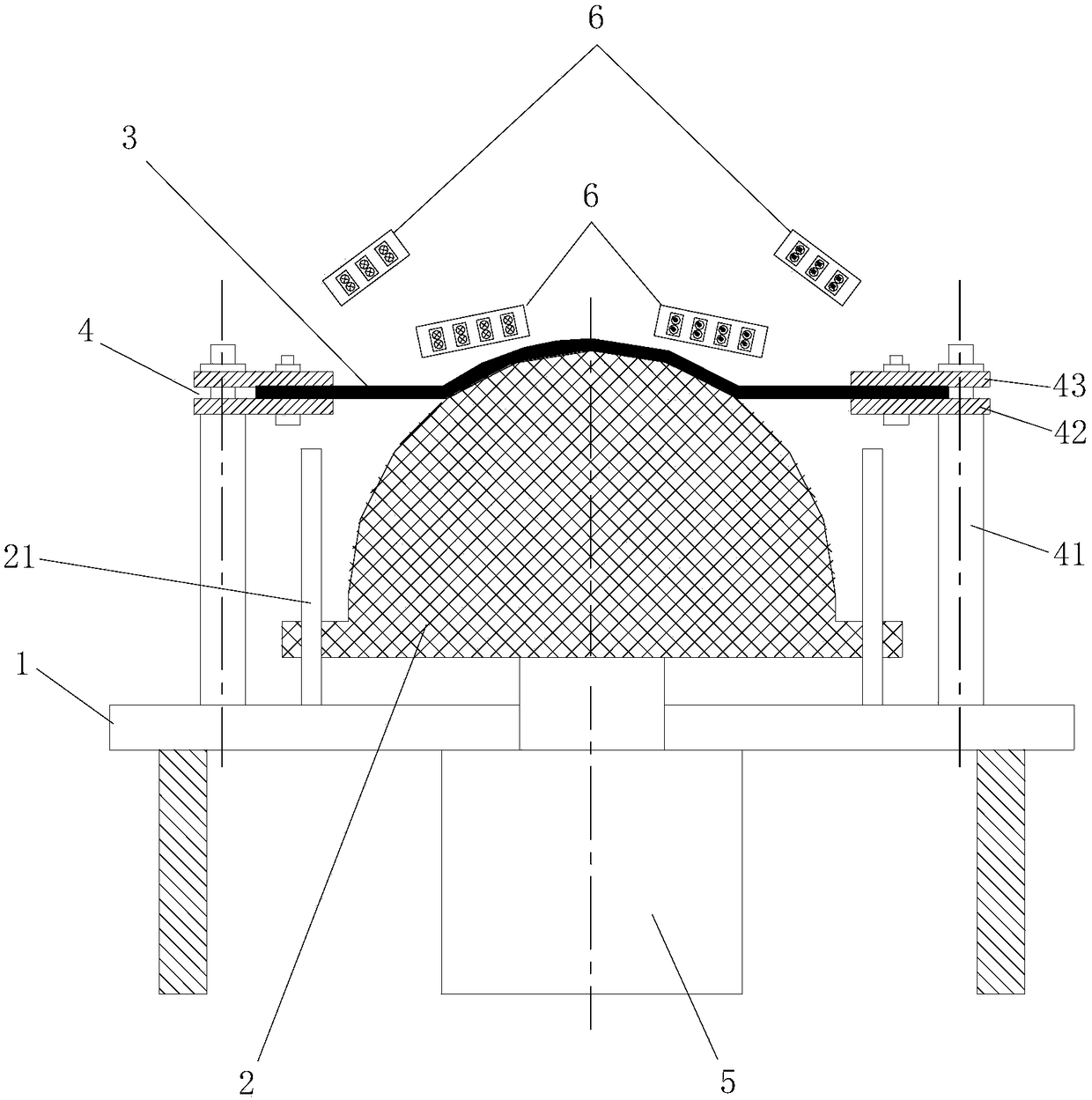

[0039] Such as Figure 1 to Figure 6 As shown, the workpiece electromagnetic progressive forming device provided with conformal coils in this embodiment includes a support frame 1, a mold 2, a sheet material 3, a splint assembly 4 for fixing and clamping the sheet material 3, and a clamping plate assembly 4 for driving the mold 2 The drive member 5 that moves to pull the sheet material 3, the splint assembly 4 is arranged on the support frame 1, the sheet material 3 is fixedly clamped between the splint assembly 4, the drive member 5 is connected with the mold 2, and includes a plurality of surrounding The conformal arrangement coils 6 arranged around the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com