Water-proof method for seepagetunnel with super burial depth

A technology for diversion tunnels and waterstops, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., to ensure the quality of tunnel formation, the compactness, and the stability of the tunnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions and technical effects of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

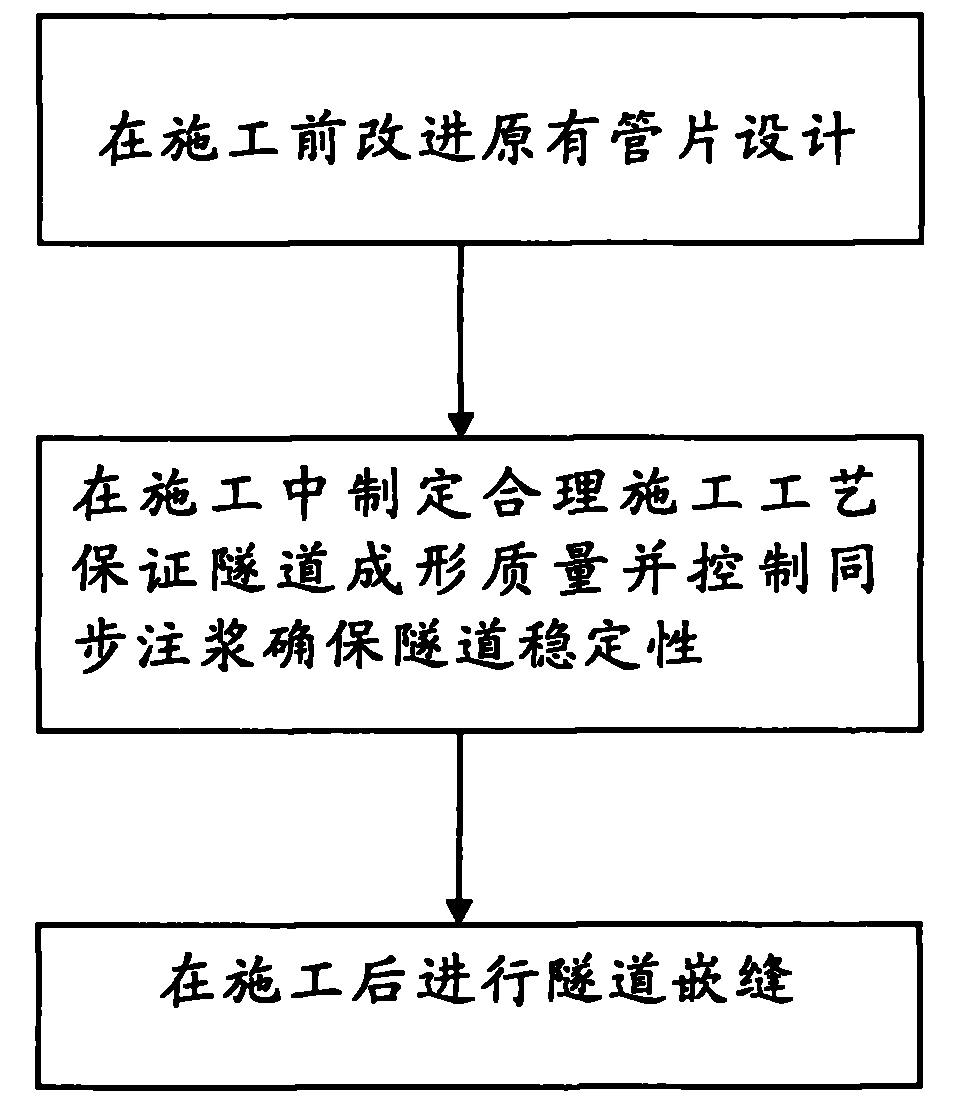

[0020] Such as figure 1 As shown, the super-buried deep water diversion tunnel waterproofing method of the present invention mainly includes improving the original segment design before construction; formulating a reasonable construction process during construction to ensure the quality of tunnel formation and controlling synchronous grouting to ensure tunnel stability; and after construction. Carry out steps such as tunnel caulking to meet the waterproof requirements of ultra-deep diversion tunnels.

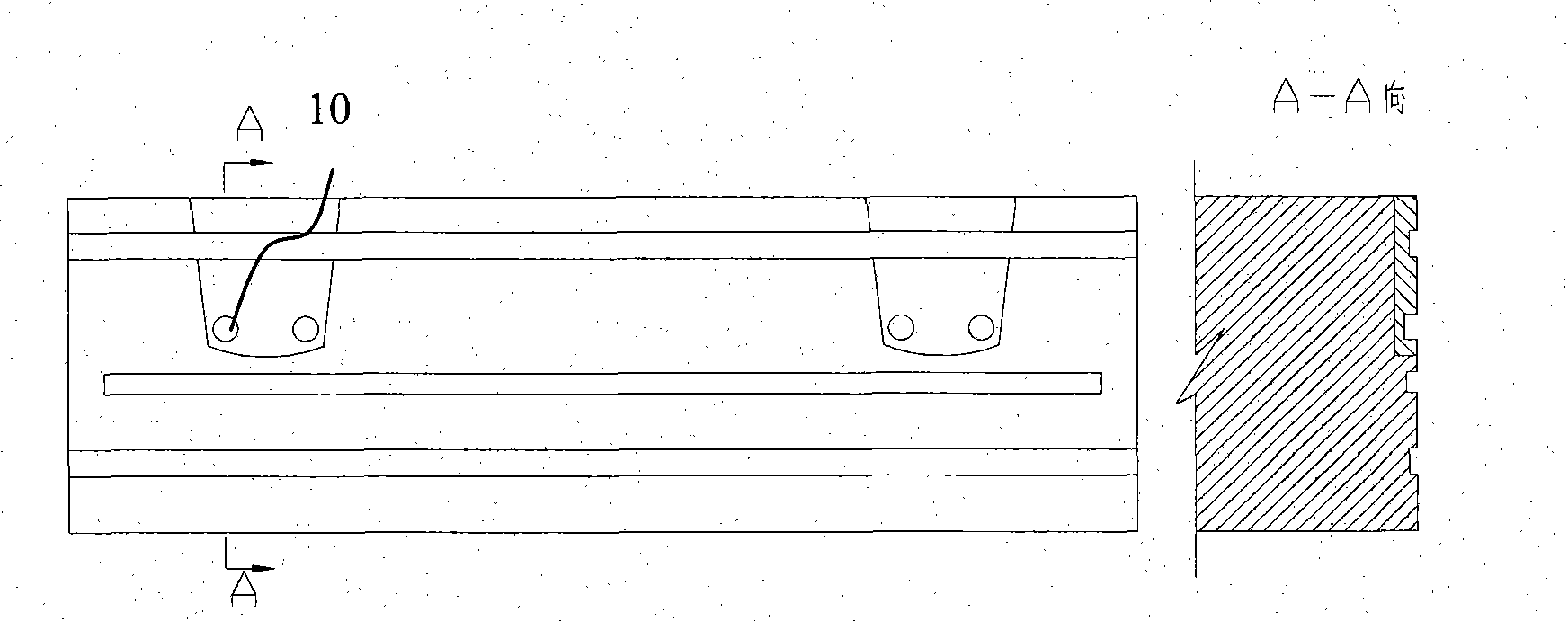

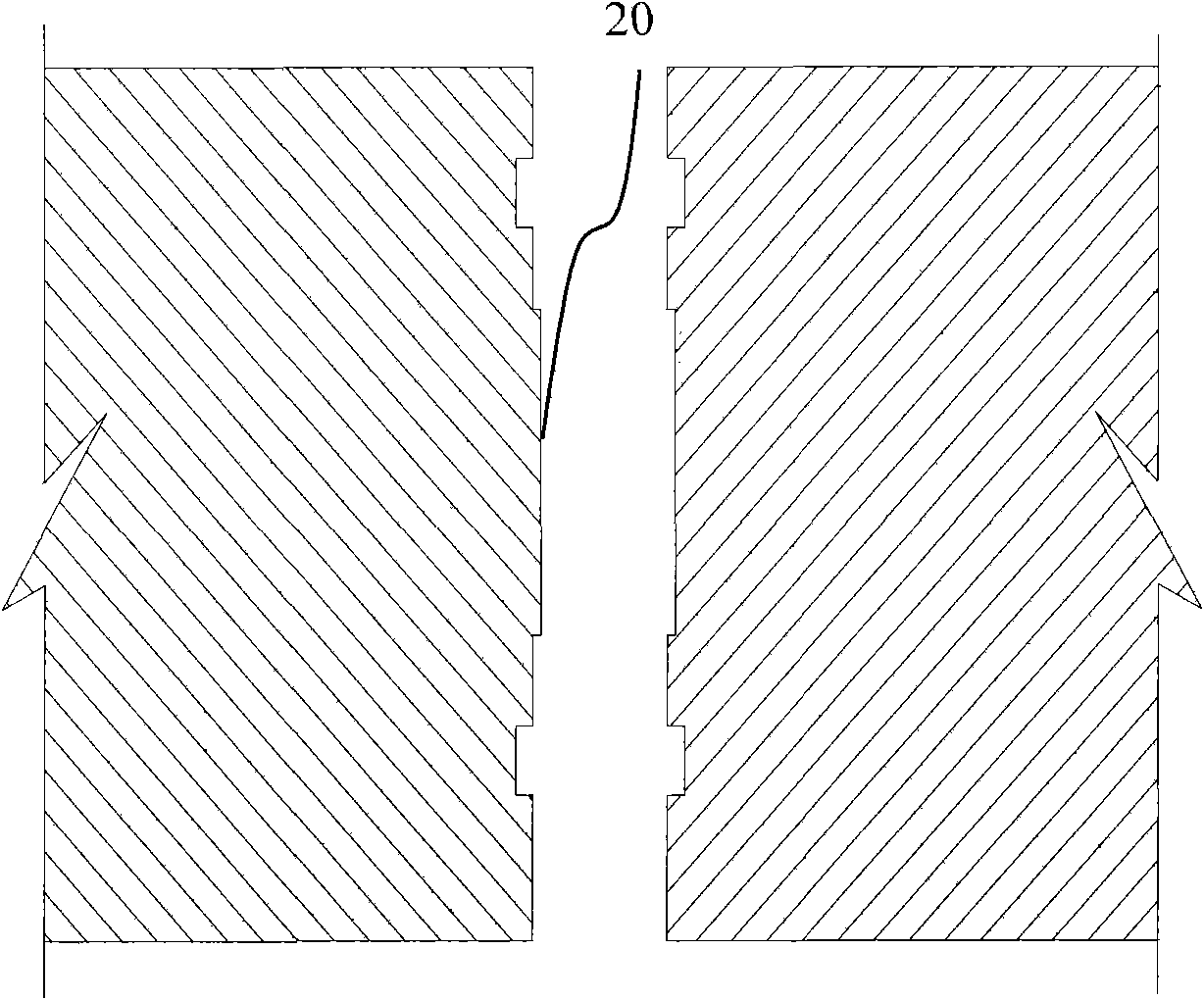

[0021] Figure 2 to Figure 5 It shows the improvement of the original segment design before the construction of the super-buried deep water diversion tunnel waterproofing method of the present invention.

[0022] Such as figure 2 As shown, the waterproof method of the ultra-deep diversion tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com