A casing for anchor rods passing through underground continuous walls

An underground diaphragm wall and casing technology, which is applied in the direction of sheet pile walls, excavation, construction, etc., can solve the problems of basement water leakage, wall damage, and existing engineering safety, so as to save manpower and material resources, foundation pit engineering and The effect of underground structure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention pre-buries the casing inside the underground continuous wall to facilitate construction and meet the requirements of the underground continuous wall for stress and basement waterproofing. In conjunction with the accompanying drawings, the specific description is as follows:

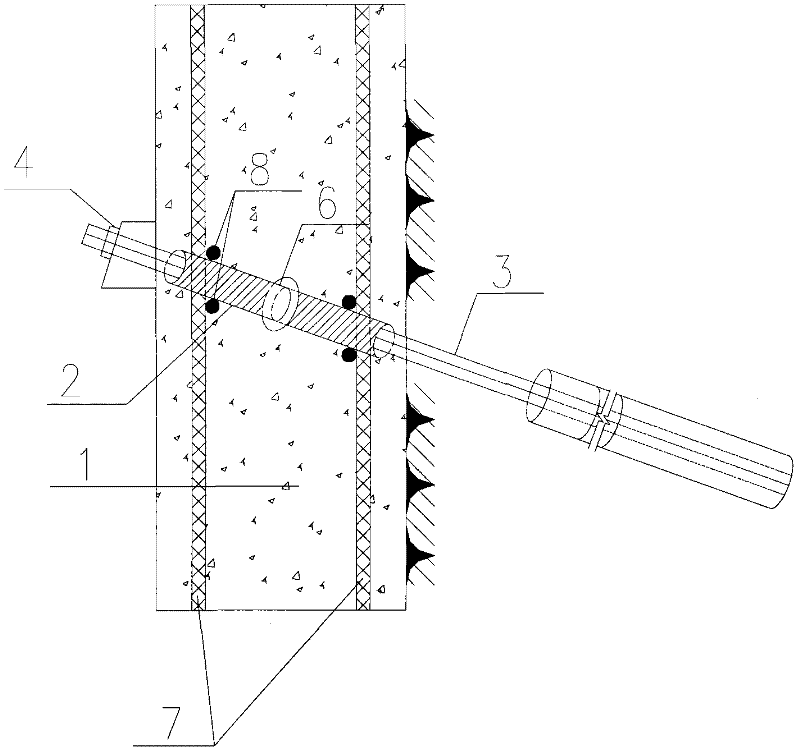

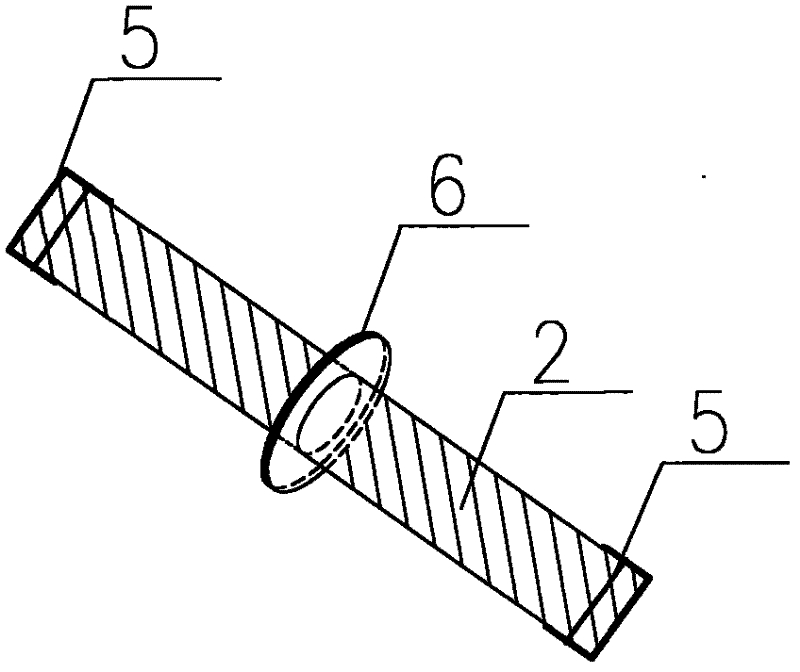

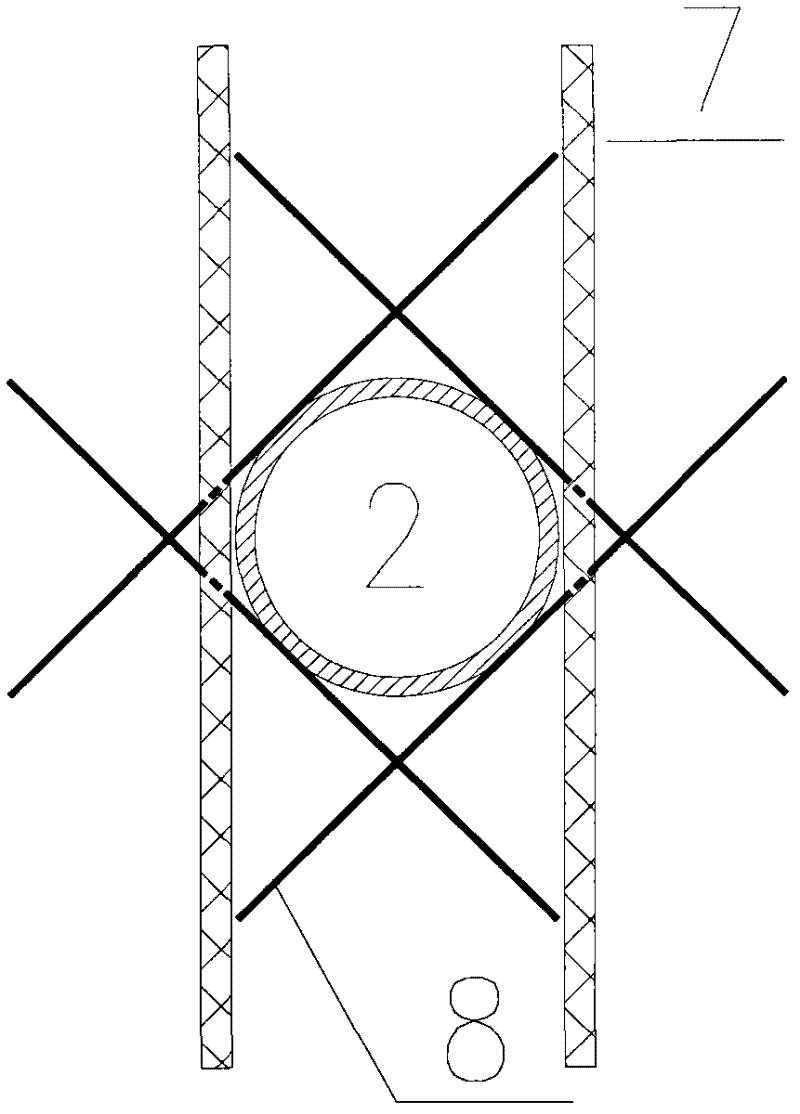

[0012] Such as figure 1 As shown, by pre-embedding the casing 2 in the underground diaphragm wall 1, when the post anchor rod 3 is constructed, it can directly pass through the underground diaphragm wall 1, avoiding drilling holes on the underground diaphragm wall 1, and finally fix the anchor rod 3 on anchor 4. Such as figure 2 As shown, before the casing 2 is fixed to the steel cage of the underground diaphragm wall 1, the water stop plate 6 can be welded to the casing 2. The thickness and width of the water stop plate 6 should be based on the geographical environment of the foundation pit project. Comprehensively determined. Before the casing 2 is fixed on the reinforcement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com