Assembling tool for flap type end enclosure

A melon-shaped and head-sealing technology, which is applied to the field of assembly tools for large melon-shaped heads, can solve the problems of gap adjustment, difficulty in assembly tasks, huge weight and shape, etc., and achieves easy production and improved assembly. Effect on quality and efficiency, simple and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

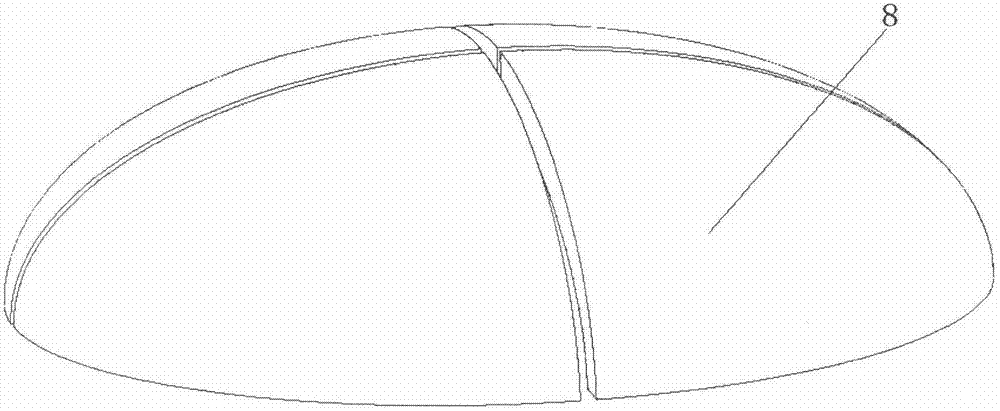

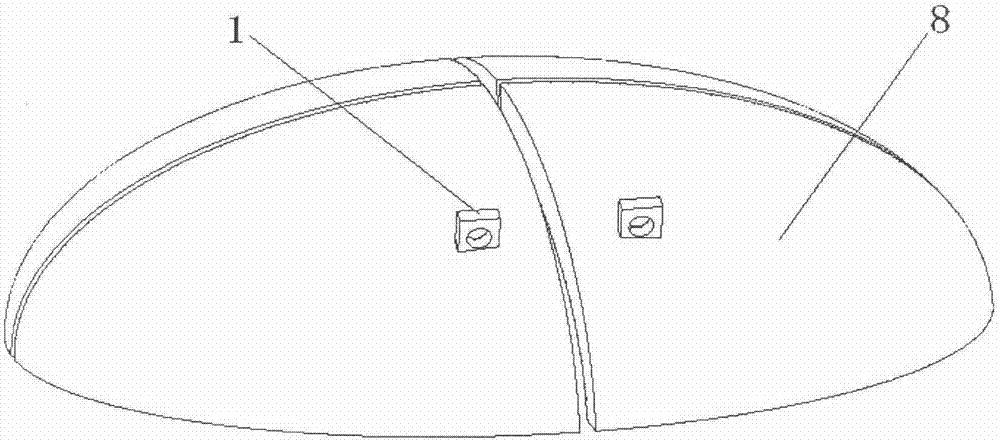

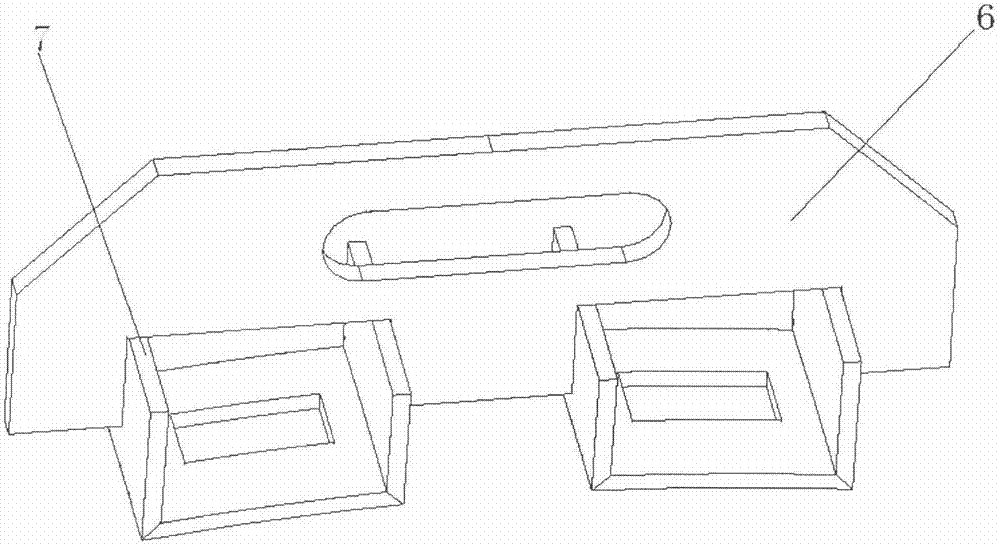

[0018] figure 1 is a schematic diagram of the structure of the melon petal head to be assembled and adjusted; figure 2 It is a schematic diagram of the positioning plate structure, the positioning plate 1 is square, with a circular hole in the center, and is fixed on both sides of the melon petal by symmetrical welding; image 3 It is a schematic diagram of the gantry structure. The gantry 2 is an assembly, which is welded by the gantry plate 6 and the channel steel 7. The gantry plate 6 has long holes in the horizontal direction, which is easy to hold, and the lower part is symmetrically slotted, which is convenient for adjustment. Positioning adopts a welded structure with channel steel 7 with a rectangular hole at the bottom, which can increase the force contact area on the side of the gantry panel 1, reduce the thickness and quality of the gantry panel 1, and ensure rigidity and light operation; Figure 4 It is a schematic diagram of the fixing structure of melon petals,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com