Aluminum alloy hub powerful spinning machining molding method and demolding mechanism

An aluminum alloy wheel hub and powerful spinning technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult demoulding, complex parameters, etc., to ensure the forming quality, strong versatility, and simple demoulding principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

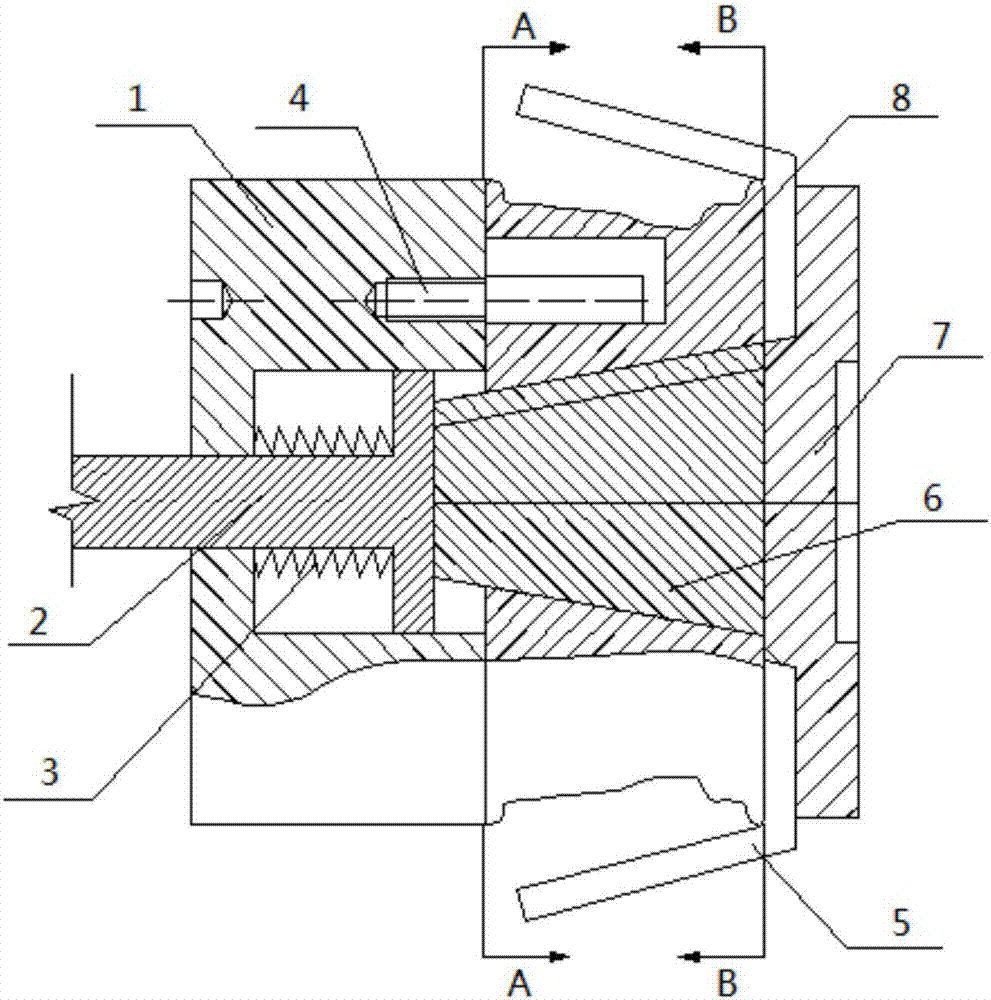

[0037] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

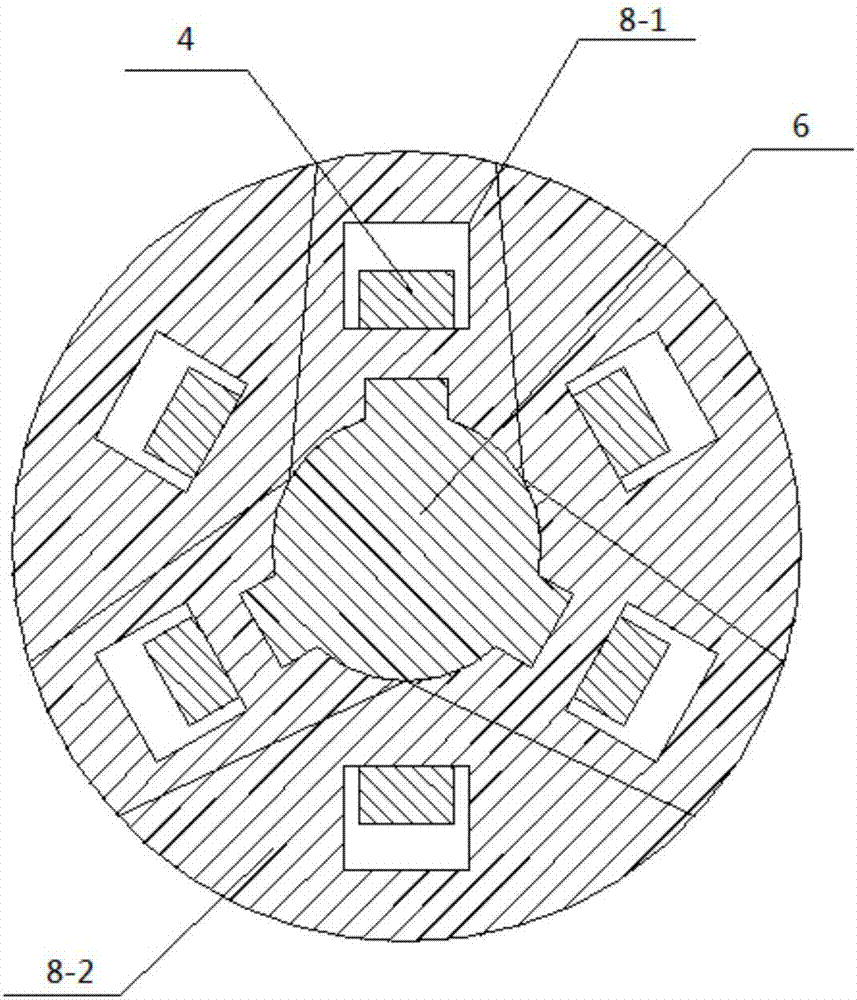

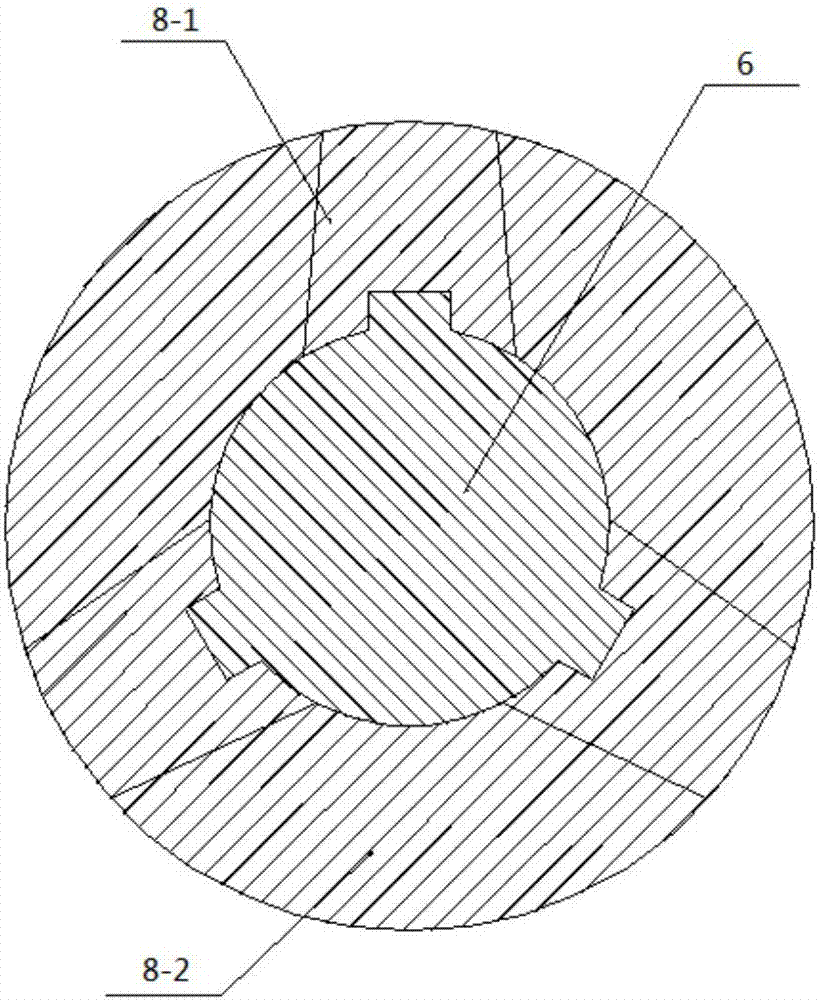

[0038] like Figure 1 to Figure 9 As shown, a powerful spinning demoulding mechanism for an aluminum alloy wheel includes a mandrel structure. The mandrel structure includes an inner core film 6 and an outer mandrel sleeved outside the inner core film 6. Locked and fixed confinement block 4 with the outer mandrel moving radially under force, and a position-limiting telescopic mechanism for pushing the structure of the mandrel to move and driving the outer mandrel away from the confinement block.

[0039] The limit telescopic mechanism includes a limit rod 2 and a spring 3 located in the guide cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com