Lead acid storage battery

A lead-acid battery, quality technology, applied in the direction of lead-acid battery, lead-acid battery electrode, battery electrode, etc., to achieve the effect of suppressing the thinning of the negative electrode ear, improving the life performance, and suppressing the liquid reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

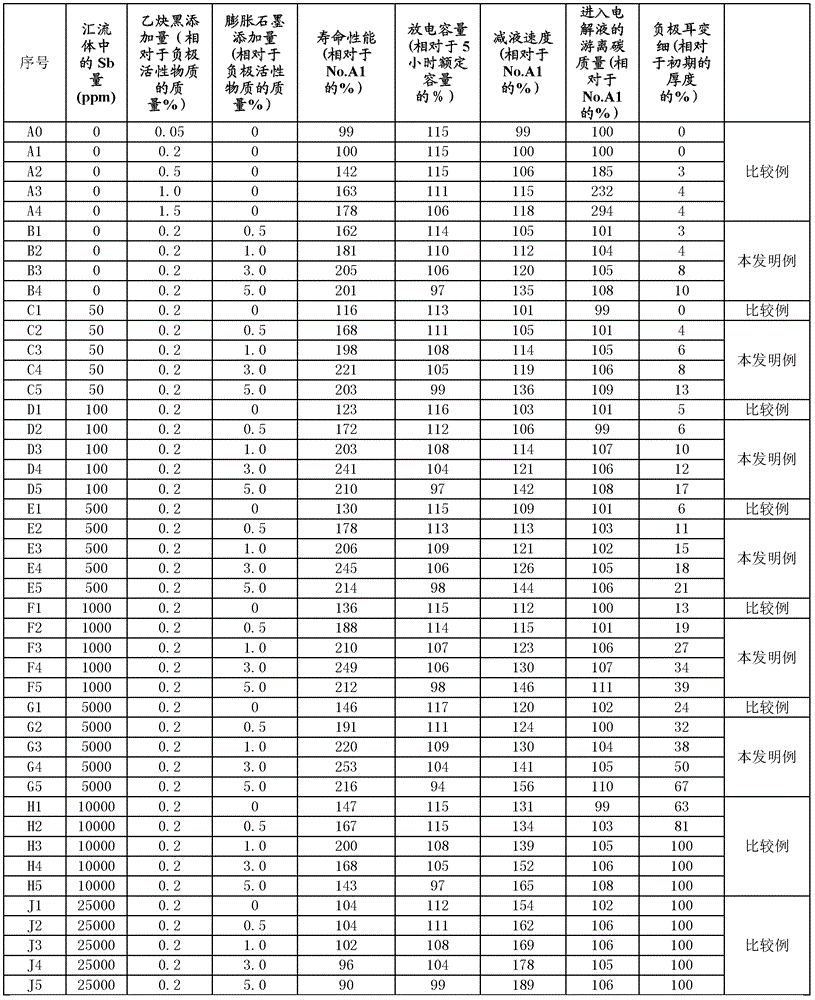

Embodiment 1

[0053] Negative plate of embodiment 1

[0054] When making the negative electrode plate, in the negative electrode active material paste, relative to the mass of the negative electrode active material (lead powder), 0%, 0.5% by mass, 1.0% by mass, and 0.2% by mass of acetylene black with a particle diameter of about 40nm are added together. Mass %, 3.0 mass %, and 5.0 mass % of expanded graphite having a particle diameter of about 20 μm.

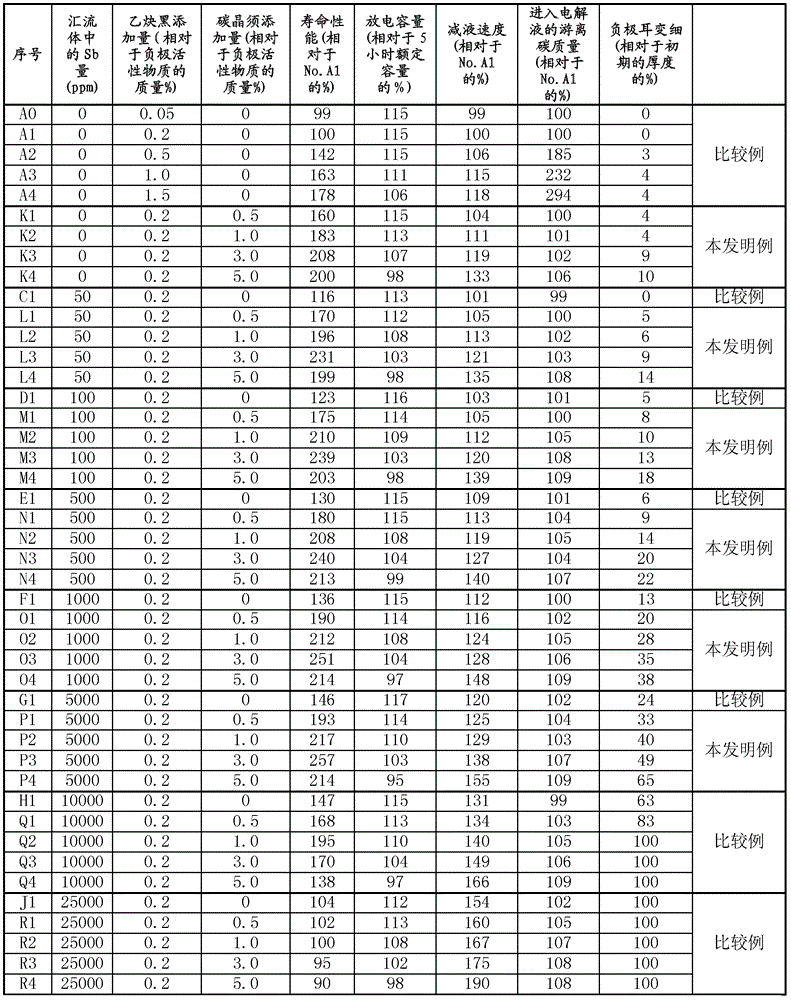

Embodiment 2

[0055] The negative plate of embodiment 2

[0056] When making the negative electrode plate, in the negative electrode active material paste, relative to the mass of the negative electrode active material (lead powder), 0%, 0.5% by mass, 1.0% by mass, and 0.2% by mass of acetylene black with a particle diameter of about 40nm are added together. % by mass, 3.0% by mass, and 5.0% by mass of carbon whiskers having a diameter of about 150 nm and a length of about 20 μm.

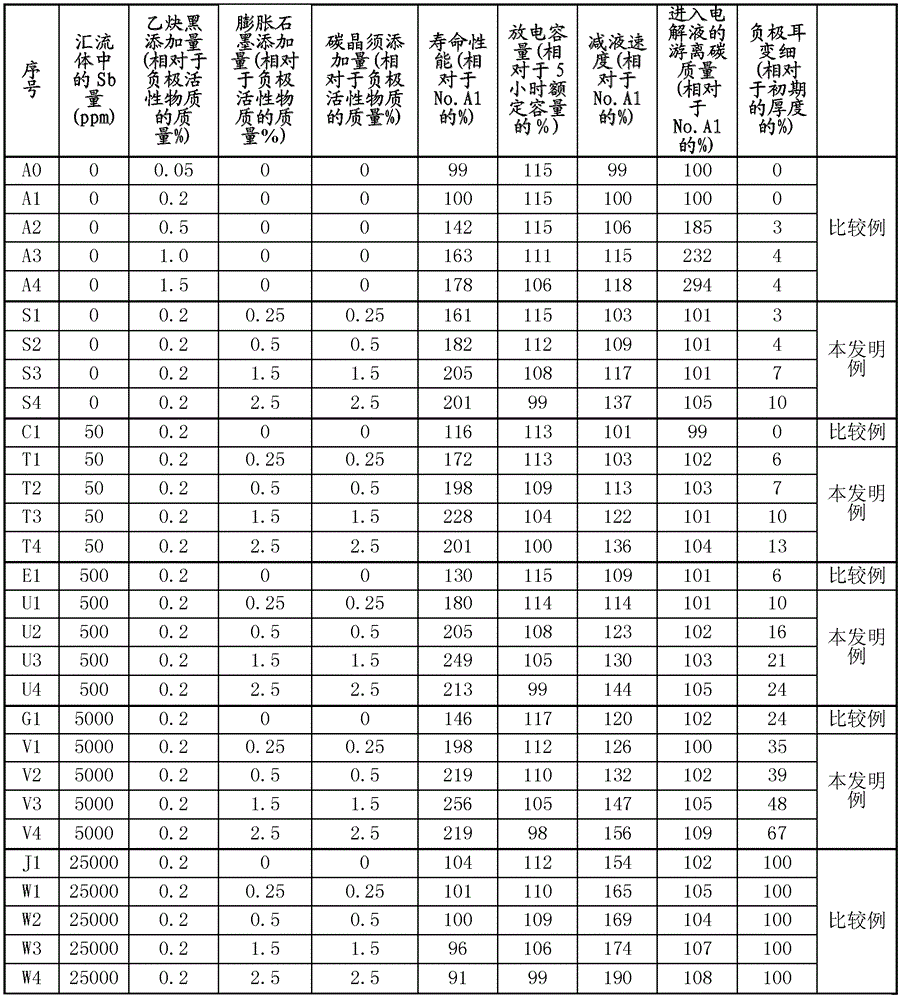

Embodiment 3

[0057] The negative plate of embodiment 3

[0058] When making the negative electrode plate, in the negative electrode active material paste, relative to the mass of the negative electrode active material (lead powder), together with 0.2% by mass of acetylene black with a particle diameter of about 40nm, add a particle diameter of about 20 μm in equal amounts. 0%, 0.5% by mass, 1.0% by mass, 3.0% by mass, and 5.0% by mass of expanded graphite and carbon whiskers with a diameter of about 150 nm and a length of about 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com