Catalyst for use in preparation of hydrogen peroxide by anthraquinone method and preparation method thereof

A technology of hydrogen peroxide and catalyst, which is applied in the field of palladium-loaded catalyst for the production of hydrogen peroxide by anthraquinone method and its preparation field, which can solve the problems of large particle size of catalyst active components, loss of metal active components, decline of catalyst activity, etc., and achieve Effects of improving electronic properties and geometric properties, increasing catalyst life, and increasing reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

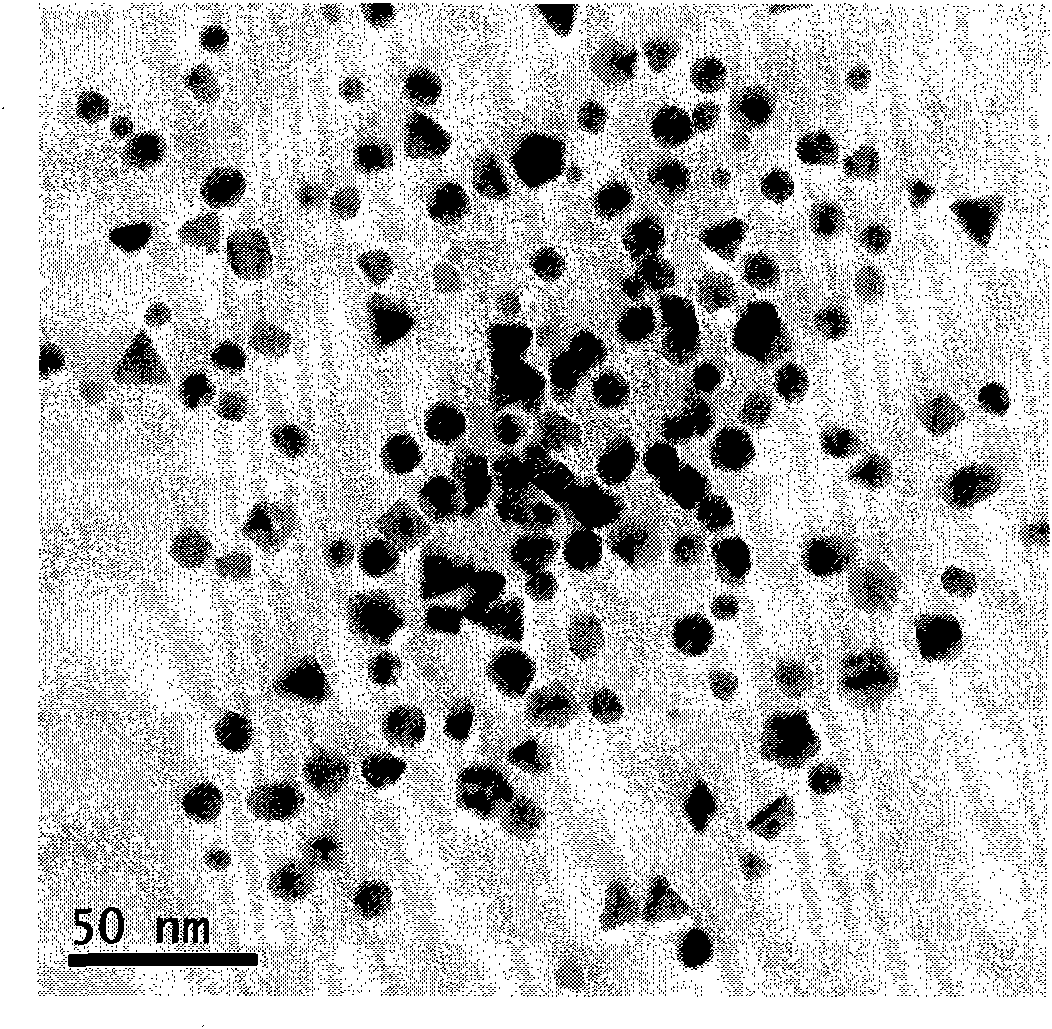

[0026] Pipette 12.0mL concentration to be the Pd(Ac) of 0.0178mol / L 2 The solution was placed in a 250mL three-necked flask, and 80mL of aqueous ethanol (V 乙醇 :V 水 =1) For dilution, add 0.36 g of stabilizer PVP according to the molar ratio PVP:Pd=15:1 (PVP is calculated as monomer). Heating to 85° C. in a water bath, and refluxing for 2-3 hours under magnetic stirring to obtain a brown palladium sol, and adjusting the pH of the palladium colloid solution to 7 with ammonia water (5%) for later use. (the palladium nanoparticle average particle size that this method prepares is 10nm, the electron micrograph of gained palladium nanoparticle sees figure 1 .

[0027] After mixing 2.0 g of pseudo-boehmite and 20 mL of deionized water, heat to 85° C. under stirring to form pseudo-boehmite slurry.

[0028] According to the proportions of different mass ratios in Table 1, the metal palladium sol was added dropwise to the pseudo-boehmite slurry according to the formula ratio under st...

Embodiment 2

[0034] The preparation of metal palladium sol is the same as in the examples.

[0035] After mixing 2.0 g of pseudo-boehmite and 20 mL of deionized water, heat to 85° C. under stirring to form pseudo-boehmite slurry. Under stirring, metal palladium sol and lanthanum nitrate solution with a concentration of 9.2mmol / L were mixed and added dropwise to the pseudo-boehmite slurry (see the table below for the ratio of palladium, lanthanum oxide, and pseudo-boehmite), and the stirring reaction 4 Hour. Remove the solvent by rotary evaporation, dry the solid at 120°C, grind it, and bake it at 450°C for 4 hours to obtain a series of Pt-La / γ-Al 2 o 3 Catalyst, and carry out ICP elemental analysis to a series of catalysts, analyze the mass percentage content of palladium and dilanthanum trioxide in the catalyst.

[0036] m (palladium): m (lanthanum nitrate): m (pseudoboehmite)

[0037] Get 0.5g gained catalyst (Pd content 0.7%, La 2 o 3 content 1.5%), after mixing with 1g t...

Embodiment 3

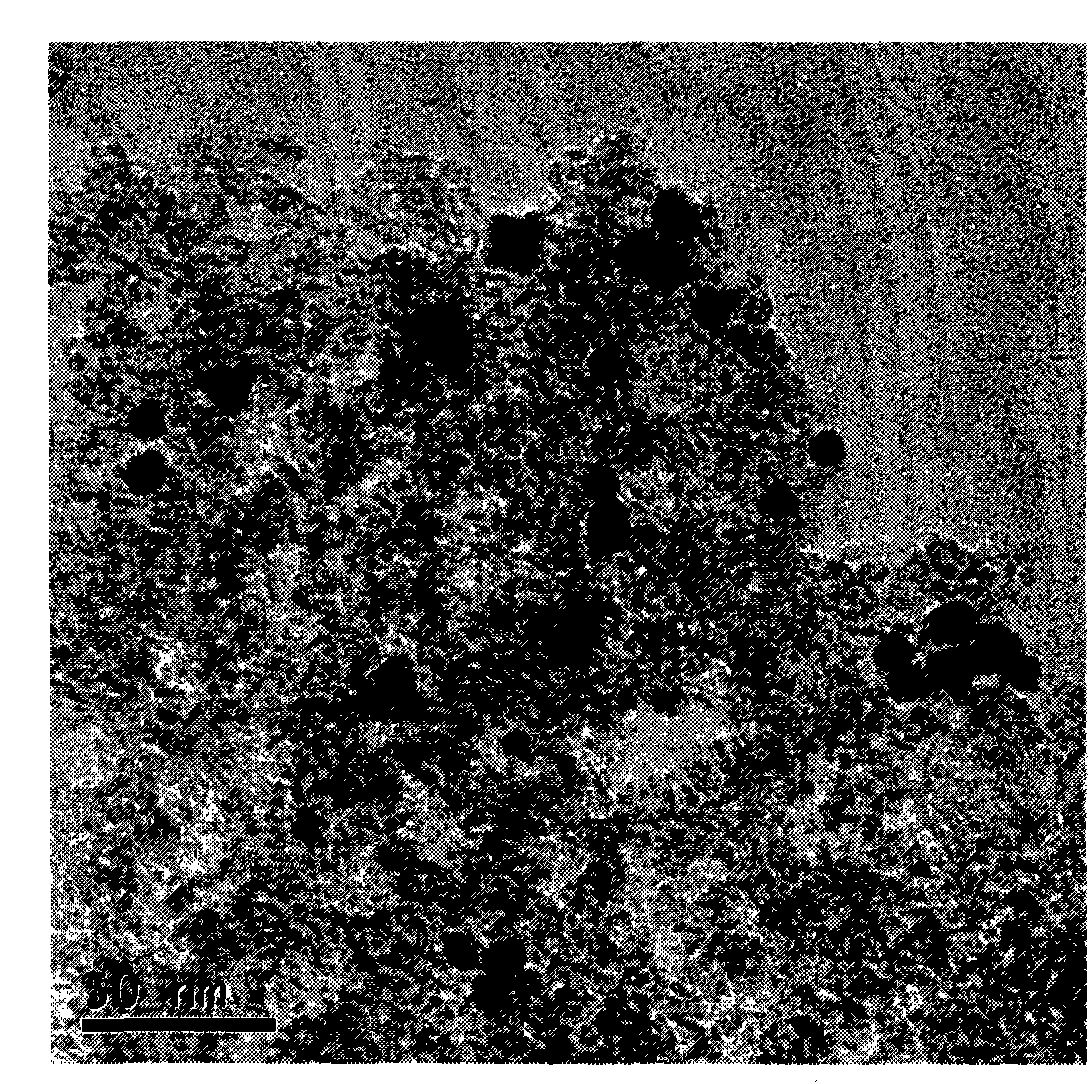

[0039] The PVP in Example 1 was replaced with PVA, and the metal palladium sol was prepared according to the molar ratio PVA:Pd=30:1 (PVA is calculated as monomer), and the preparation method was as in Example 1. The palladium nanoparticles prepared by the method have an average diameter of 8nm. Use ammonia water (5%) to adjust the pH of the palladium colloid solution to 7 before use.

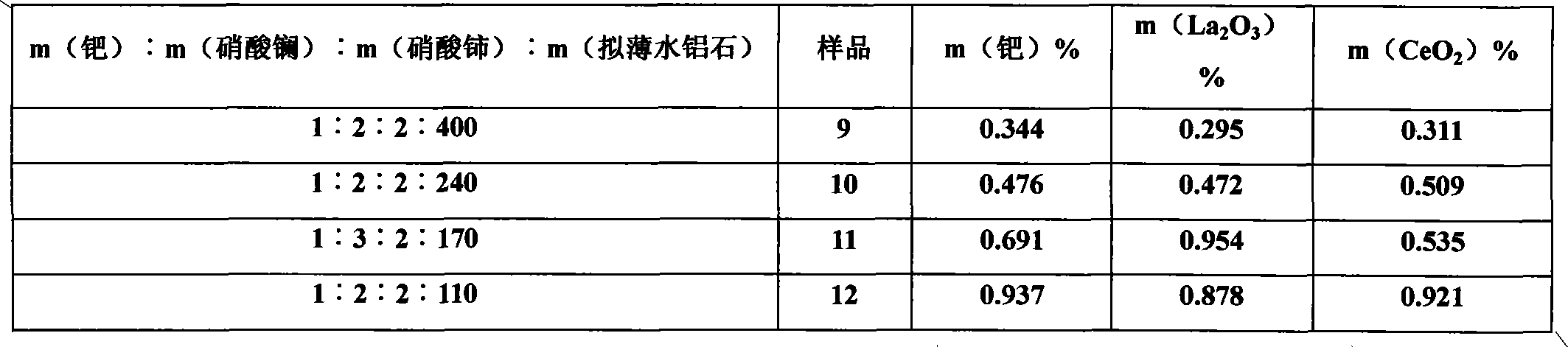

[0040] After mixing 2.0 g of pseudo-boehmite and 20 mL of deionized water, heat to 85° C. under stirring to form pseudo-boehmite slurry. Under stirring, metal palladium sol was mixed with lanthanum nitrate and cerium nitrate solutions with a concentration of 9.2mmol / L, and then added dropwise to the pseudo-boehmite slurry (see below for the ratio of palladium, rare earth metal oxides, and pseudo-boehmite) Table), stirred reaction 4 hours. Remove the solvent by rotary evaporation, dry the solid at 120°C, grind it, and bake it at 450°C for 4 hours to obtain a series of Pt-LaCe / γ-Al 2 o 3 Cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com