Die and method for front and back deep drawing of double-layer cylindrical parts

A technology of forming dies and double-layer cylinders, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of one-time stamping and forming of positive and negative deep drawing structures, easy cracking of plates, and high processing costs, so as to avoid wrinkling , reduce residual stress, improve the effect of forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

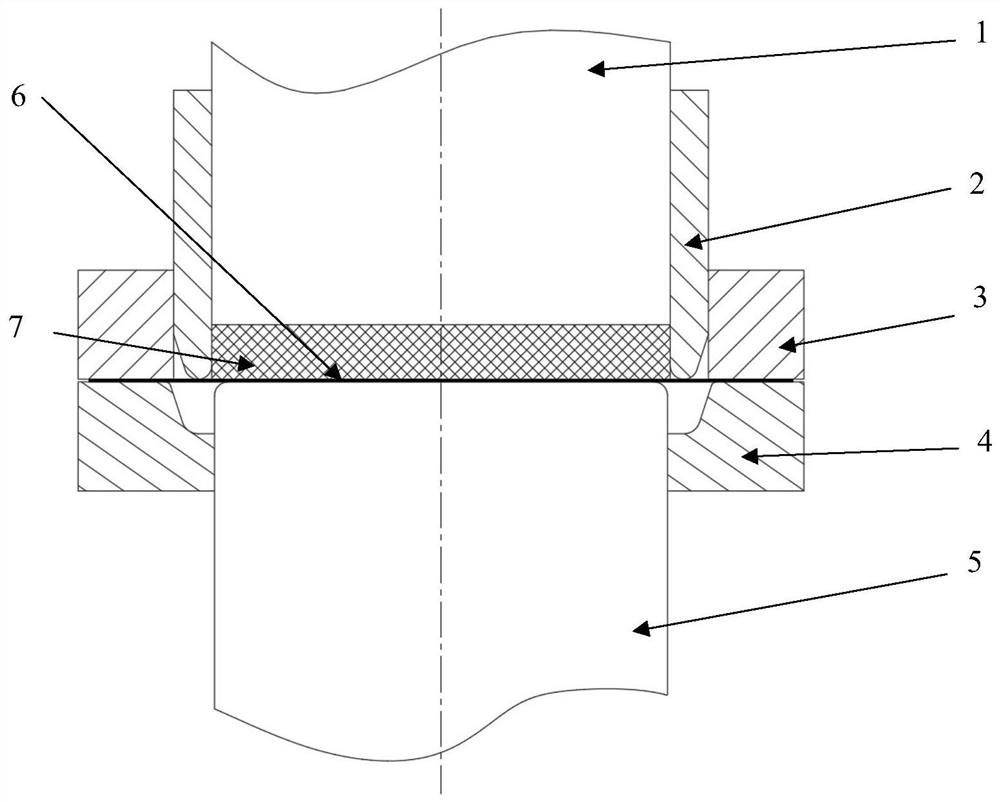

[0050] see figure 1 , which shows a schematic cross-sectional front view of the double-layer tubular part before processing the front and back drawing dies in Embodiment 1 of the present invention. The mold includes a second part and a first part which are arranged up and down oppositely and matched with each other, the first part is located below the second part, and the plate 6 for making the double-layer tubular part is located in the middle of the first part and the second part;

[0051] The first part is the lower end of the mold, including: a cylindrical punch 5 and a die 4 fixed on the forming equipment or mold fixture. Punch 5 is cylindrical, and the shape of its upper end is conical shape, and its diameter is identical with the inner diameter of the double-layer cylindrical part to be made. The die 4 is an annular part with a first central through hole, the diameter of the first central through hole is greater than or equal to the outer diameter of the punch 5 , and ...

Embodiment 2

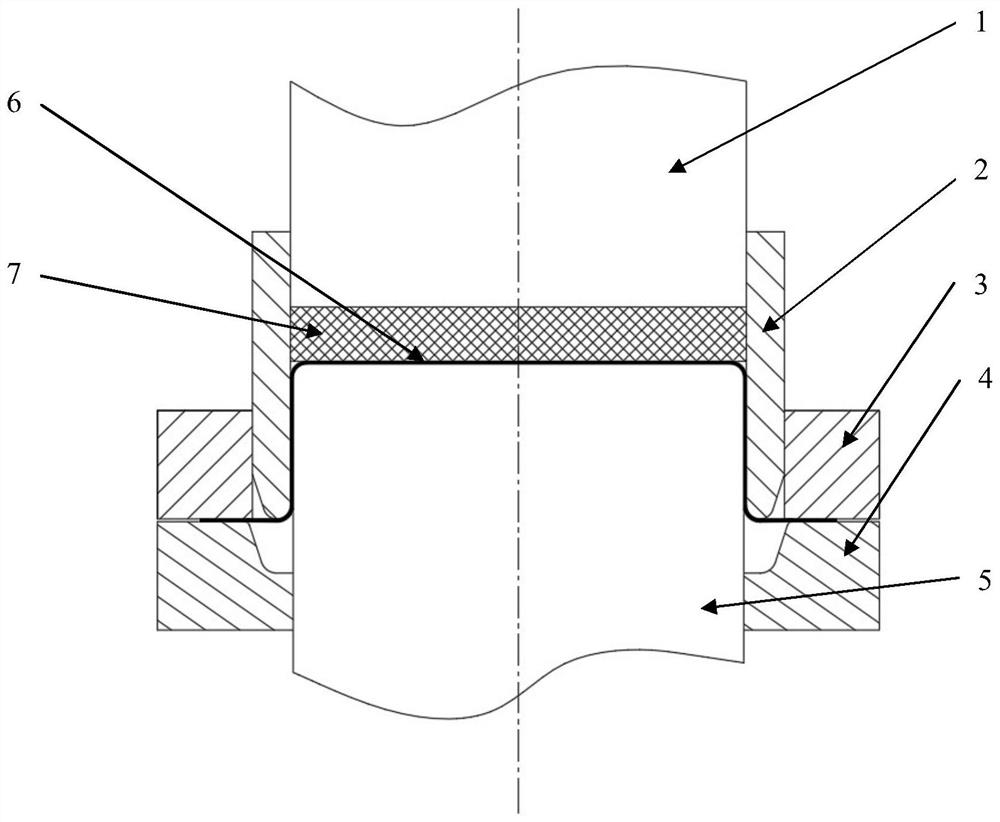

[0060] see Figure 5 , which shows a schematic cross-sectional front view of the double-layer tubular part before processing the front and back drawing dies in Embodiment 2 of the present invention. The mold includes a second part and a first part which are arranged up and down oppositely and matched with each other, the first part is located below the second part, and the plate 6 for making the double-layer tubular part is located in the middle of the first part and the second part;

[0061] The first part is the lower end of the mold, including: a cylindrical punch 5 and a die 4 fixed on the forming equipment or mold fixture. The punch 5 is cylindrical, the shape of its upper end is conical, and there is a spherical bulge in the middle of the truncated end face. The specific size of the spherical bulge is related to the parts to be processed. The inner diameter of parts is the same, and the die 4 is an annular part with a first central through hole, the diameter of the firs...

Embodiment 3

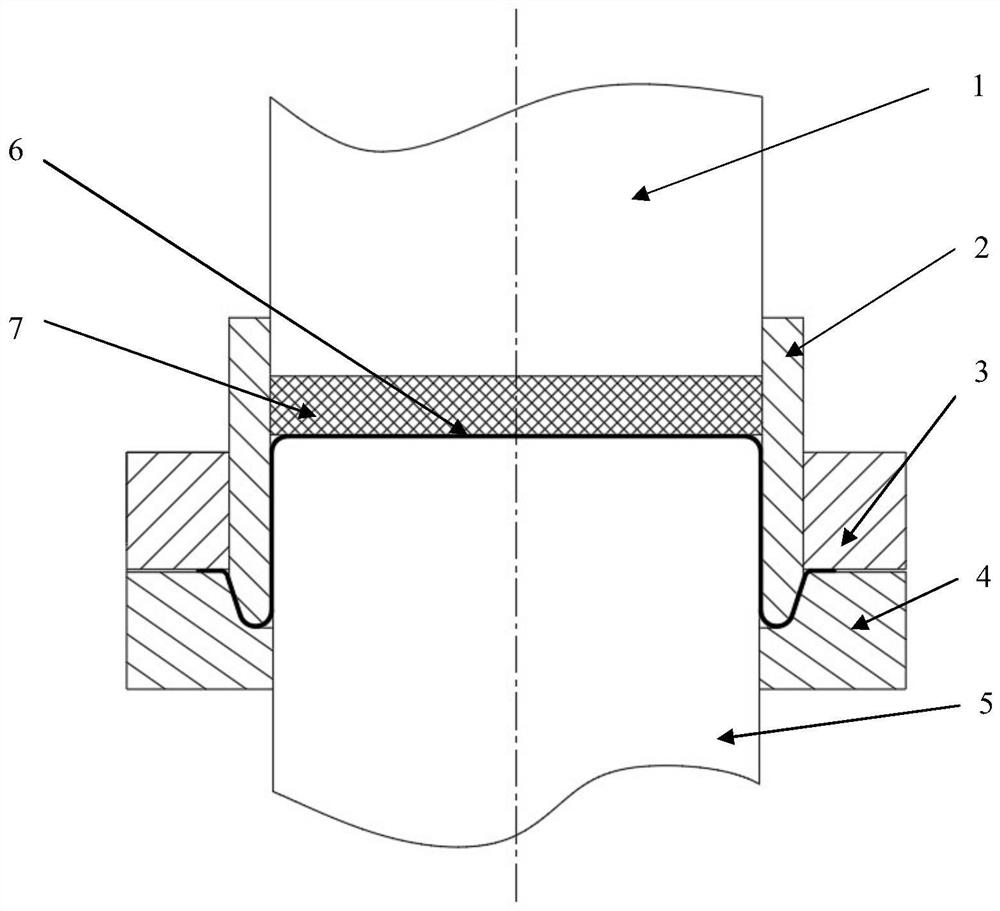

[0069] see Figure 8 , which shows a schematic cross-sectional front view of the double-layer tubular part before processing the front and back drawing dies in Embodiment 3 of the present invention. The mold includes a second part and a first part which are arranged up and down oppositely and matched with each other, the first part is located below the second part, and the plate 6 for making the double-layer tubular part is located in the middle of the first part and the second part;

[0070] The first part is the lower end of the mold, including: a cylindrical punch 5 and a die 4 fixed on the forming equipment or mold fixture. The punch 5 is cylindrical, and its upper end is in the shape of a truncated cone. There is a truncated cone-shaped protrusion in the middle of the truncated cone-shaped end surface. The specific size of the truncated cone-shaped protrusion is related to the parts to be processed. The inner diameter of the shaped parts is the same. The die 4 is an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com