Fibrous structural article and manufacturing method thereof

A manufacturing method and structure technology, applied in the direction of upper structure, upper structure sub-assembly, non-woven fabric, etc., can solve the problems of unstable shape, inconvenient use, easy elongation, etc., and achieve easy operation, easy use, and restraint The effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

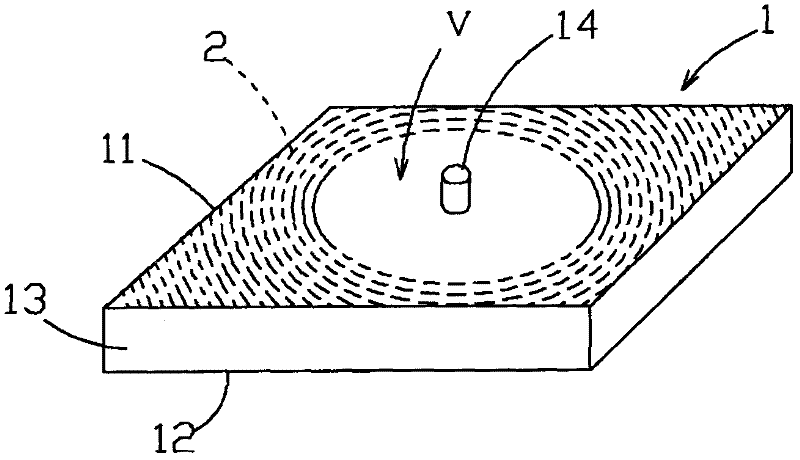

Embodiment 1

[0085] Use 40% by mass of polyethylene terephthalate fibers (manufactured by Nippon Koan (Gaoan) Co., Ltd., trade name "SD 150", average fineness: 3.3 dtex, average fiber length: 10mm) as the first short fiber , using 40% by mass of core-sheath type heat-fusible short fibers (manufactured by Japan Toray (Toray) Co., Ltd., trade name "T9611", average fineness: 2.2 dtex, average fiber length: 10mm) as the second short fiber , and use 20% by mass of granular polyurethane foam (use the crushed block of soft polyurethane foam. Density: 0.015 ~ 0.030g / cm 3 , maximum size: 15mm), wherein, the material of the core of the core-sheath heat-fusible short fiber is polyethylene terephthalate (melting point: 260°C), and the core-sheath heat-fusible short fiber The material of the sheath portion of the fiber is a fiber of copolymer polyester (melting point: 110° C.).

[0086] Dry-mix the above-mentioned first and second short fibers and granular polyurethane foam, and pour the mixture into ...

Embodiment 2

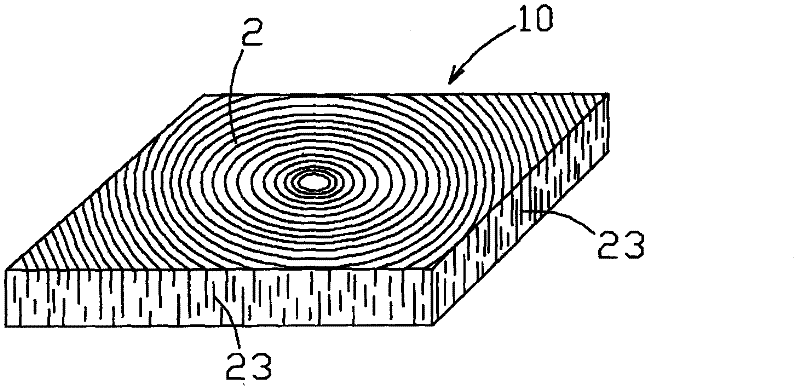

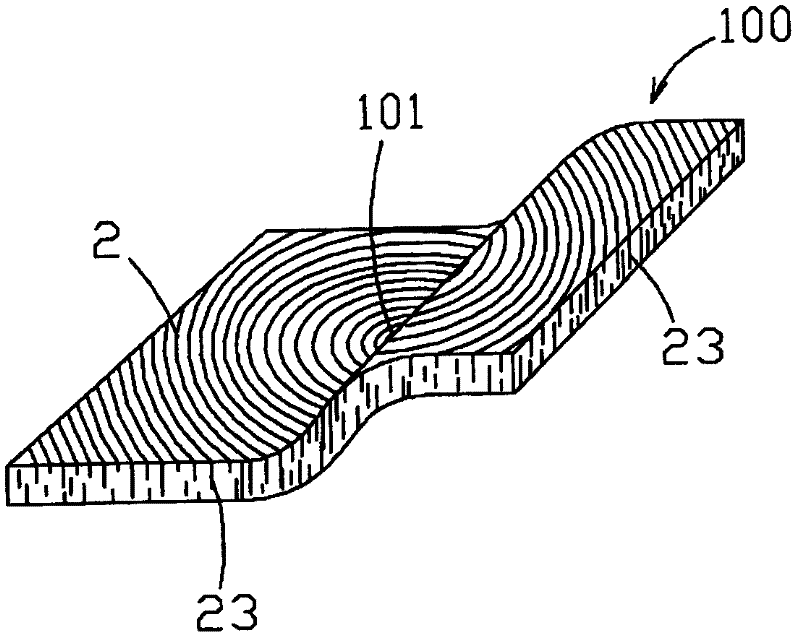

[0089] The mixture of dry blending 20% by mass of the first short fiber, 20% by mass of the second short fiber, and 60% by mass of the granular polyurethane foam is formed into a mold surface having a shape along the shape of the preformed body 10a. The mold, fed by pneumatic conveying at a constant speed of 50g / sec, is formed as Figure 13 A preform 10 having four preforms 10a is shown. Thereafter, using the preform 10 formed with the four preforms 10a, heat treatment was carried out in the same manner as in Example 1 to produce Figure 14 As shown, there is formed a fiber structure molded body 100b of four fiber molded parts 100a (in addition, in order to avoid complexity, in Figure 14 The annual ring-shaped dotted lines are omitted).

[0090] As described above, especially when the final shape of the fibrous structure is more complicated, the preformed part 10b having a shape corresponding to the final shape may be formed in advance to manufacture the molded body 100b ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com