Carton correction pressing and pasting device

A technology of pressing and sticking cartons, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., and can solve problems such as uneven stacking, troublesome normal operation, troublesome stacking and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

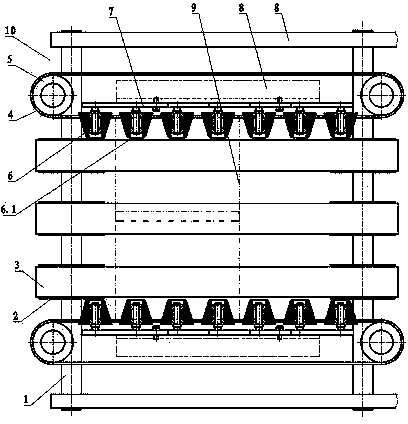

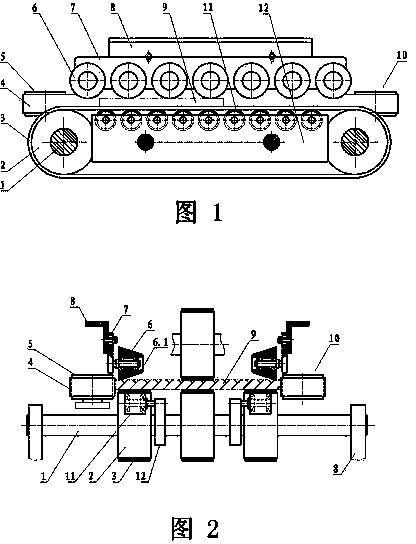

[0014] exist figure 1 , figure 2 and image 3 In the shown carton correction and pressing device, two rotatable and movable paper transport shafts 1 are arranged in parallel on the frame 8, and the paper transport wheel 2 is fixedly connected to the paper transport shaft 1. On the paper transport wheel 2 Wrapping the paper belt 3, a paper jogging device 10 is installed on the outer frame 8 of the paper belt 3, and the paper transport wheel 2 and the corresponding paper belt 3 and the paper jogging device 10 are two sets. The set of paper transport wheels 2 and the corresponding paper transport belts 3 and paper aligning devices 10 are symmetrically arranged, and a row of idler rollers 11 are arranged on the back of each paper transport belt 3. On the one hand, the application of the idler 11 has played a role in supporting the belt surface of the paper belt 3, and on the other hand, the idler 11 can produce a corresponding rotation under the twitch of the paper belt 3, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com