Egg coating preservative with oxyethlene higher aliphatic alcohol

A coating film preservative and high-grade fatty alcohol technology, which can be used in egg preservation, food preservation, egg preservation with a protective layer, etc., can solve the problems of unsatisfactory product sensory, low safety, poor moisture resistance, etc., and achieve good Fresh-keeping effect, simple coating process, good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The formula research of OHAA poultry egg coating preservative

[0023] 1 Test method

[0024] 1.1 Determination of the amount of ethanol added

[0025] Absolute ethanol has good comprehensive properties, not only beneficial to the dissolution of OHAA, reducing viscosity, speeding up the film forming speed, shortening the film forming time, but also reducing the interaction between OHAA molecules and water molecules due to the interaction between ethanol molecules and water molecules. The bonding between molecules is promoted, and the film-forming performance is improved. The amount of absolute ethanol added needs to be controlled at an appropriate ratio in order to achieve a better defoaming effect. In the experiment, weigh a certain amount of OHAA, add ethanol according to the ratio of OHAA: absolute ethanol = 1:1~8 (weight ratio), stir evenly after adding, and observe the influence of ethanol on the dissolution effect of OHAA.

[0026] 1.2 Determinati...

Embodiment 2

[0065] A coating preservative for poultry eggs, consisting of the following ingredients in parts by weight:

[0066]

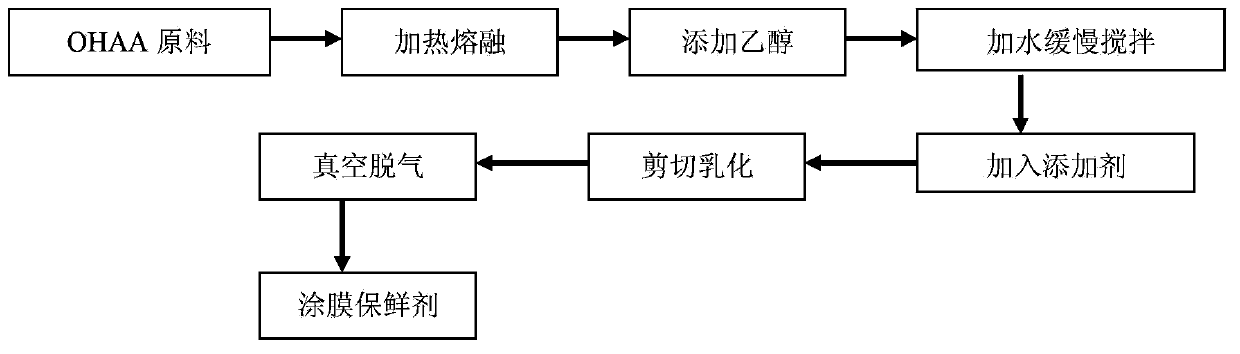

[0067] The preparation method is: as figure 1 As shown, first heat and melt the ethylene oxide higher fatty alcohol, add absolute ethanol after cooling, stir slowly until fully dissolved, then add water, Tween 80, glycerin, palm oil, stir evenly, and finally remove it under vacuum gas, packaging.

[0068] Continue to carry out applied research to the poultry egg coating preservative of the present embodiment, the results are as follows:

[0069] 1 Test method

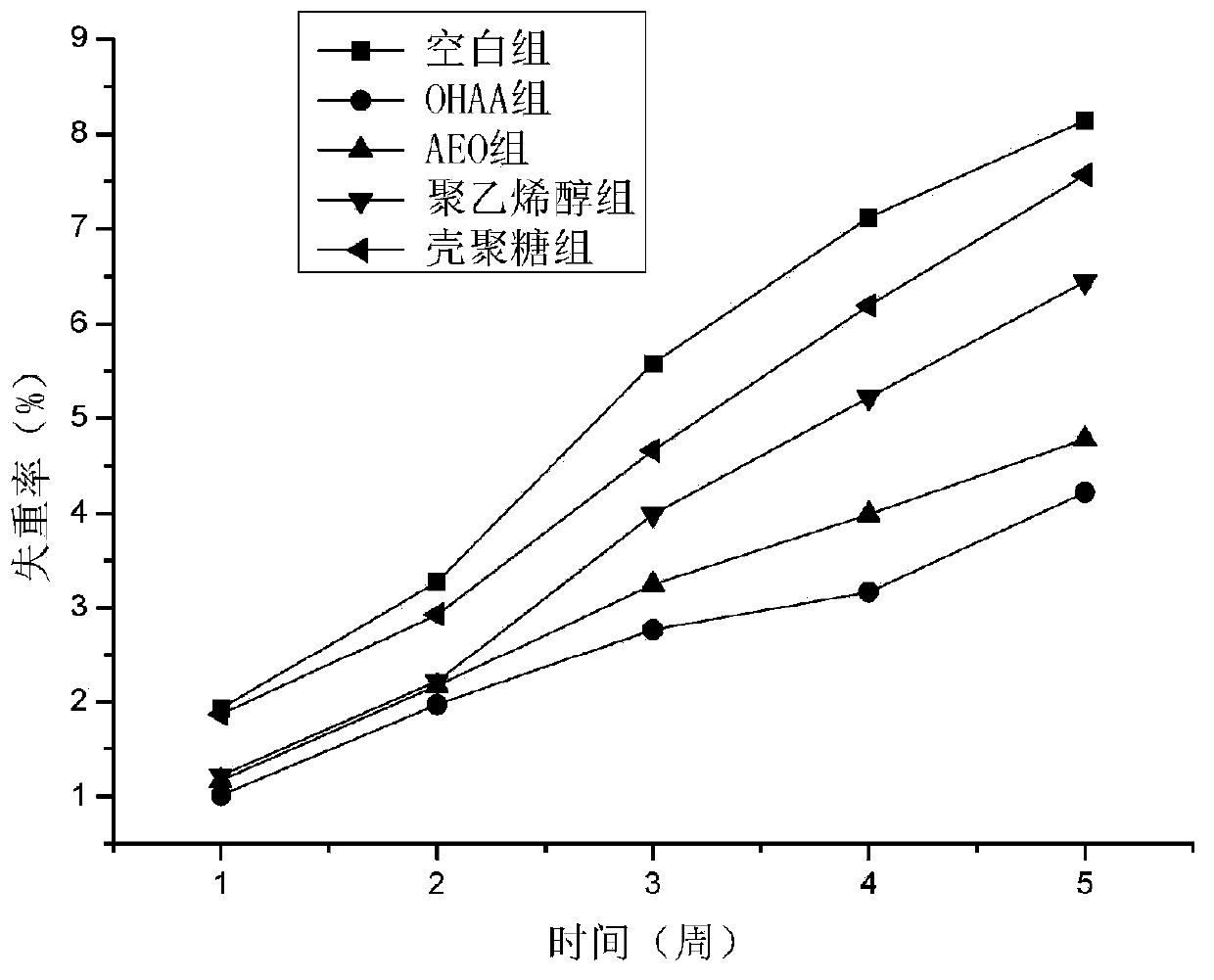

[0070] Chitosan poultry egg coating preservative, fatty alcohol polyoxyethylene ether (AEO) poultry egg coating preservative and polyvinyl alcohol poultry egg coating preservative were selected as controls to compare the fresh-keeping effect of OHAA poultry egg coating preservative Make an evaluation.

[0071] 1.1 Preparation method

[0072] Chitosan poultry egg coating preservative, AEO poultry...

Embodiment 3

[0114] A coating preservative for poultry eggs, consisting of the following ingredients in parts by weight:

[0115]

[0116] The preparation method is: first, heat the higher fatty alcohol of ethylene oxide to 55°C to melt it, then slowly add absolute ethanol at a speed of 150 rpm, and after the higher fatty alcohol of ethylene oxide is fully dissolved, then slowly Add water, stir evenly, then add Tween 80, glycerin, palm oil, and nisin in sequence, shear and emulsify the above mixture at a speed of 3000 rpm, vacuum degas the homogeneous liquid, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com