Aluminum alloy battery box composite forming device

A composite forming and battery box technology, applied in forming tools, metal processing equipment, other household appliances, etc., can solve problems such as poor quality of formed parts, achieve good plasticity, uniform configuration, and avoid the effect of reducing its own strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

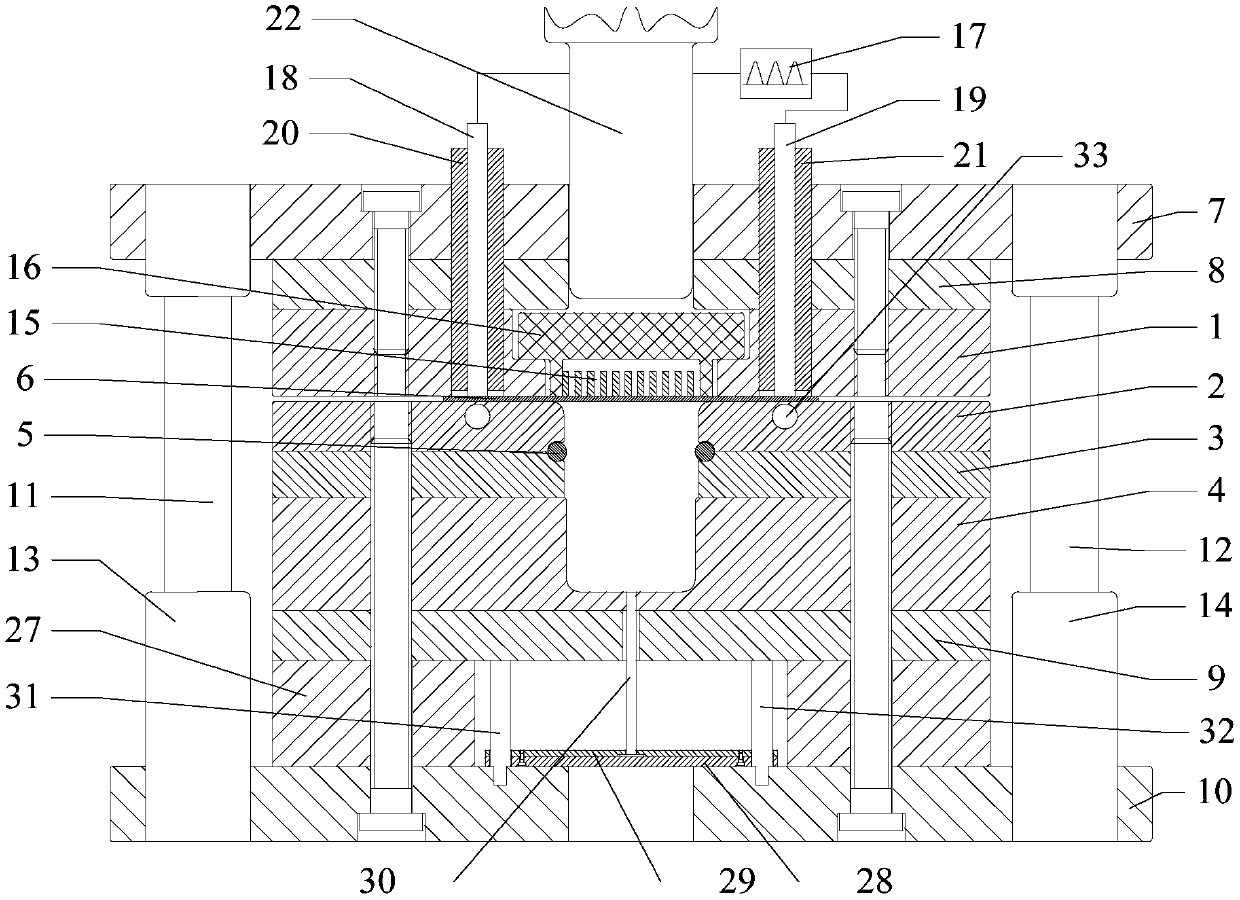

[0075] Embodiment: combine below Figure 1 to Figure 19 This embodiment will be described in detail.

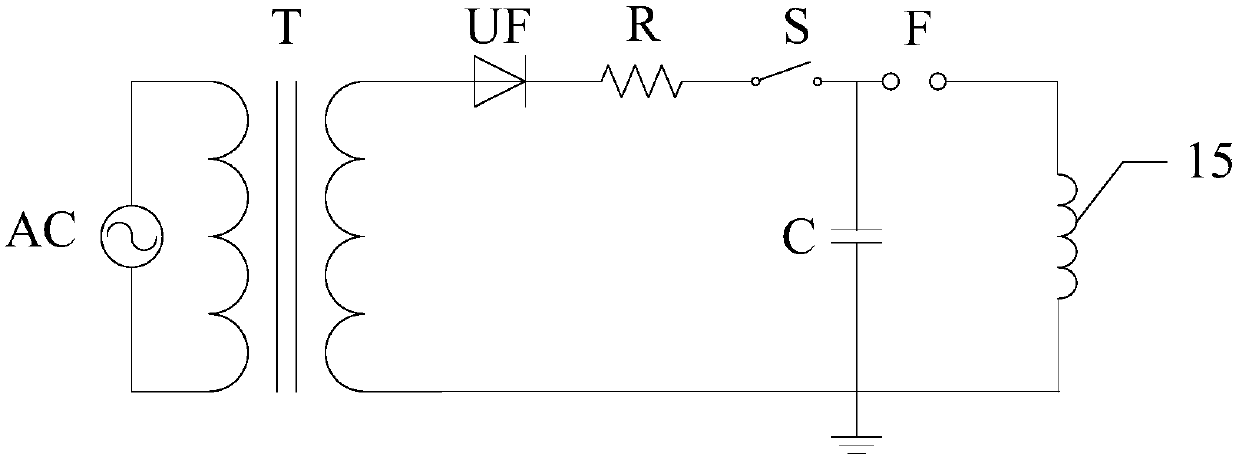

[0076] The aluminum alloy battery box compound forming device described in this embodiment includes a combined mold unit, an electromagnetic pulse preforming unit, an electroplastic unit, a stamping forming unit, and an electromagnetic pulse orthopedic unit;

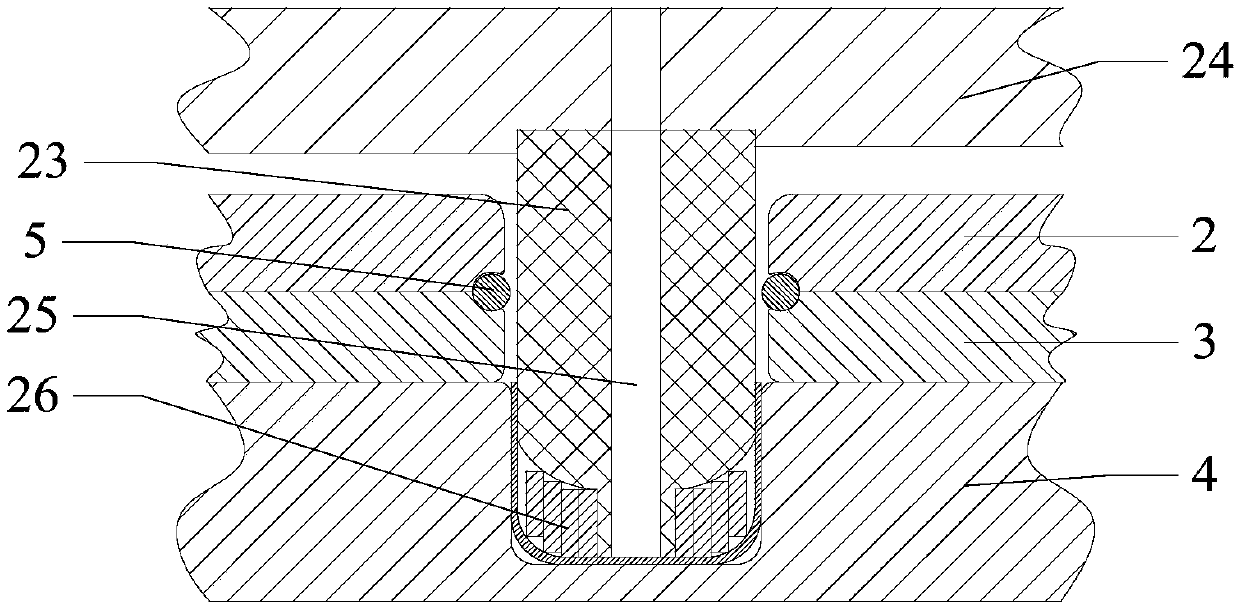

[0077] The combined mold unit comprises a binder plate 1, a preforming die 2, a supporting plate 3 and a forming die 4, and a first through cavity is provided in the binder plate 1 from its top surface to the bottom surface, and the preforming die 2, a pre-formed through cavity is provided from its top surface to its bottom surface, a second through cavity is provided in the supporting plate 3, from its top surface to its bottom surface, and a forming cavity is recessed on the top surface of the forming die 4;

[0078] The supporting plate 3, the preforming die 2 and the binder plate 1 are stacked on the forming die 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com