Etching solution of copper or copper alloy and method for producing electronic substrate using the solution

A technology for etching solutions and electronic substrates, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, and can solve problems such as smaller grounding areas and poor installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

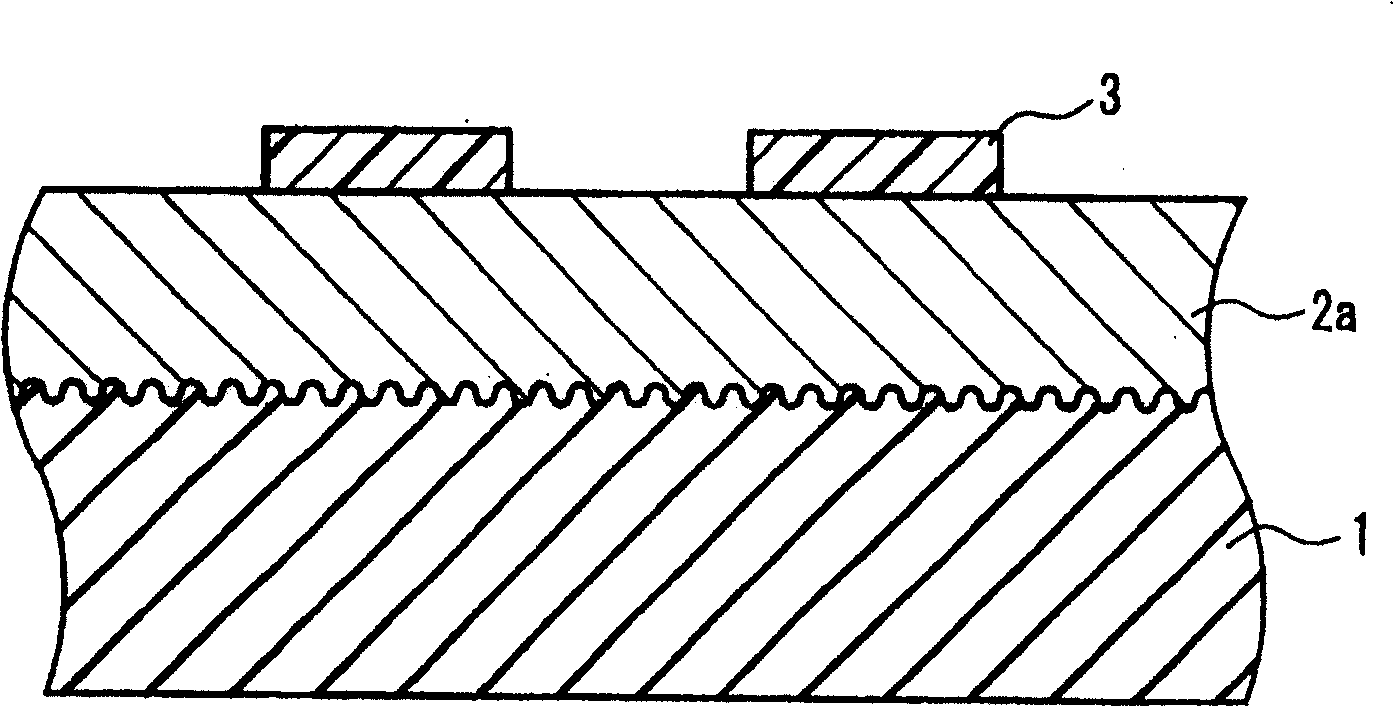

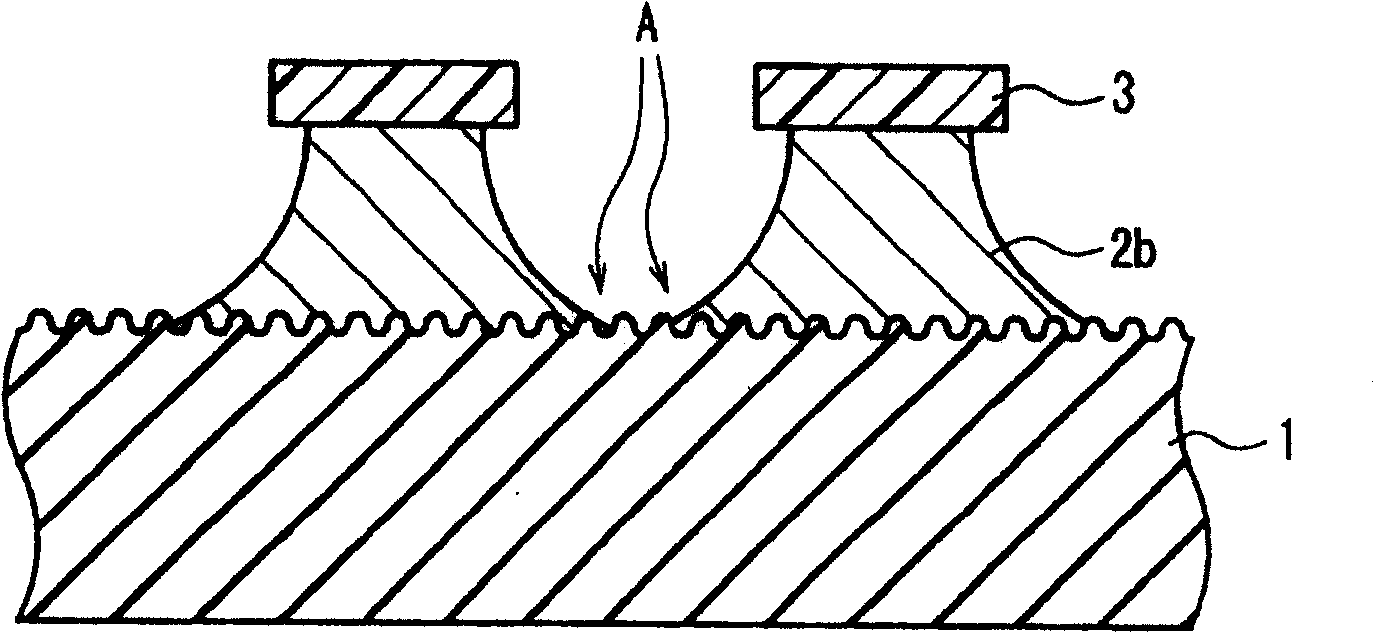

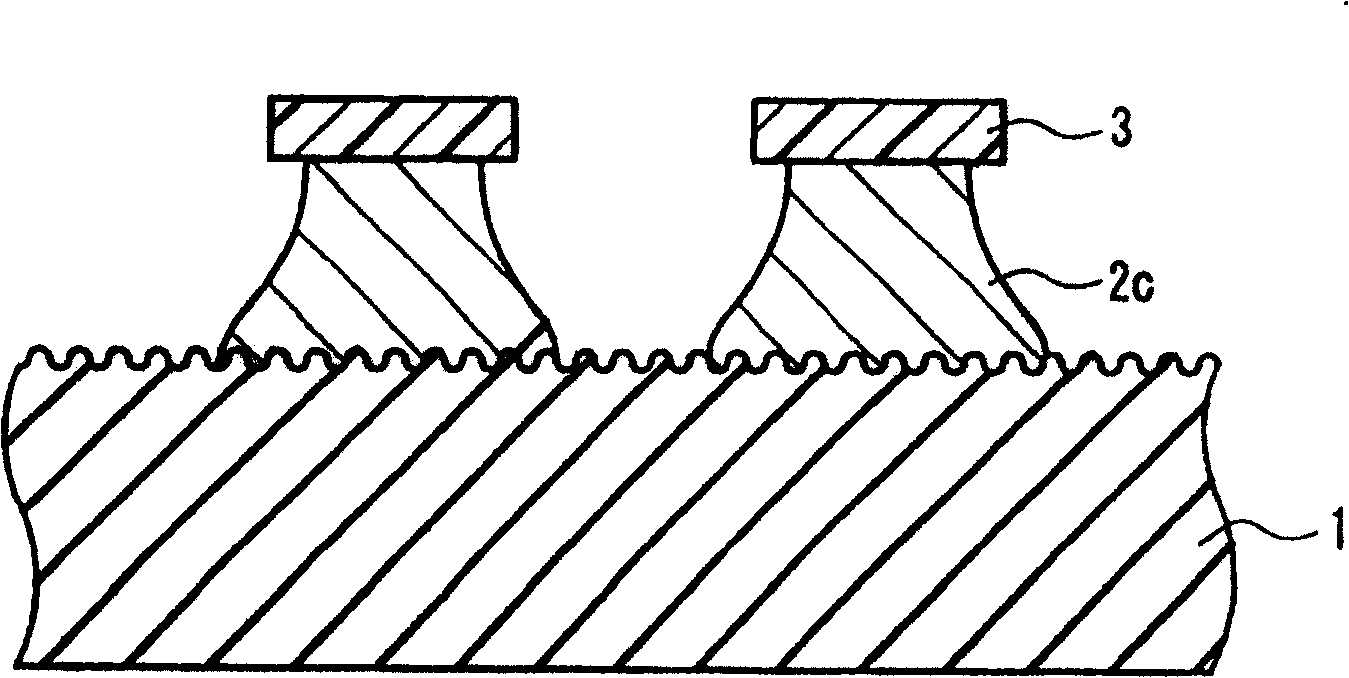

[0020] The etching solution of the present invention will be described.

[0021] (a) Oxidizing agent for copper

[0022] As an oxidizing agent of copper, copper ion and iron ion are mentioned, for example. In the case of copper ions, copper (II) chloride, copper (II) bromide, copper (II) hydroxide, etc. are added to generate copper ions in the solution. In the case of iron ions, with iron (III) chloride, iron (III) bromide, iron (III) iodide, iron (III) sulfate, iron (III) nitrate, iron (III) acetate, etc. produced iron ions. From the viewpoint of removing the copper remaining at the bottom of the copper wiring, the concentration of the oxidizing agent is preferably 1 g / liter; from the viewpoint of not generating copper remaining at the bottom of the copper wiring, it is preferably 50 g / liter or less, particularly preferably 45 g / L or less. In the case of copper ions, it is more preferably 3 to 40 g / liter, and in the case of iron ions, it is more preferably 5 to 30 g / liter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com