Patents

Literature

45results about How to "Improved thickness distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

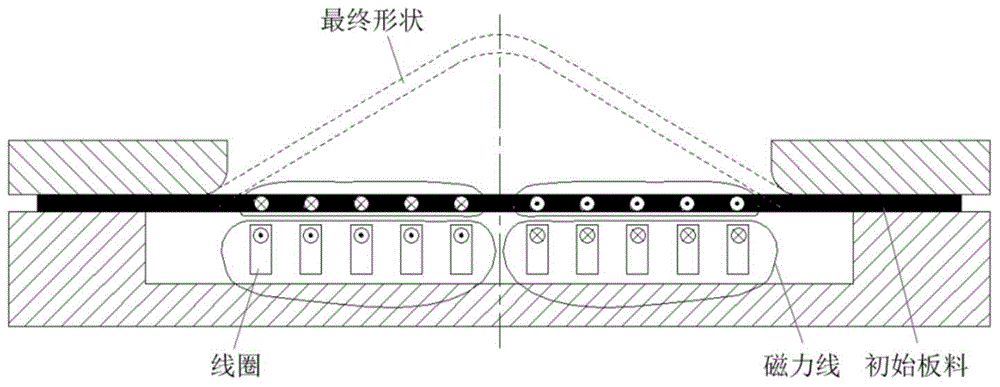

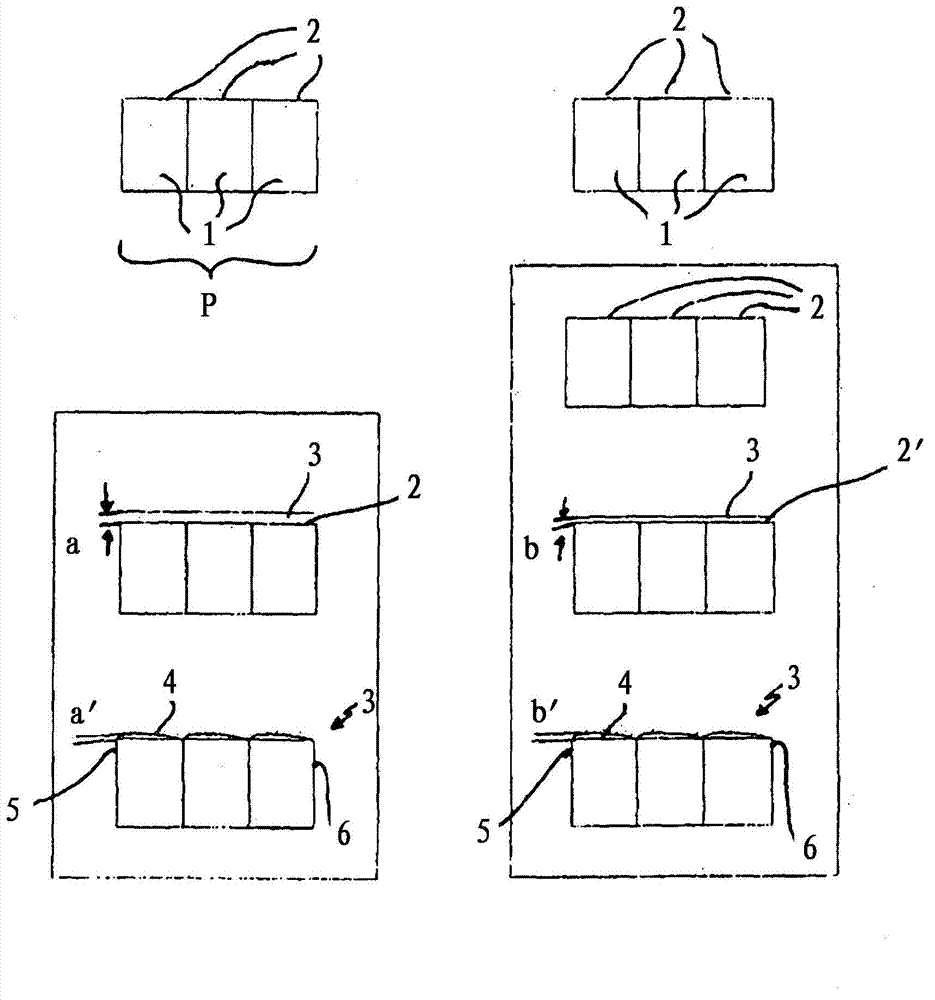

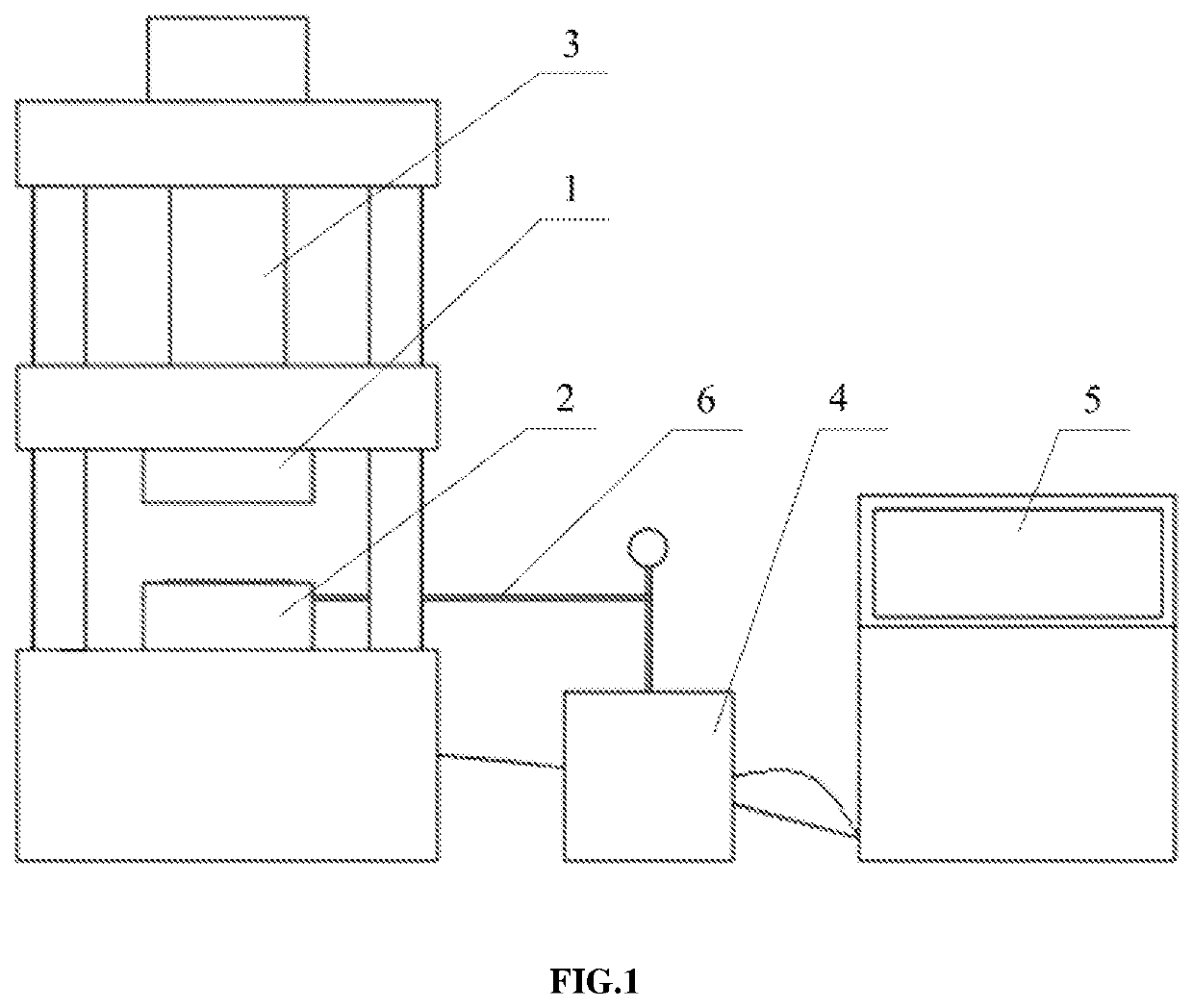

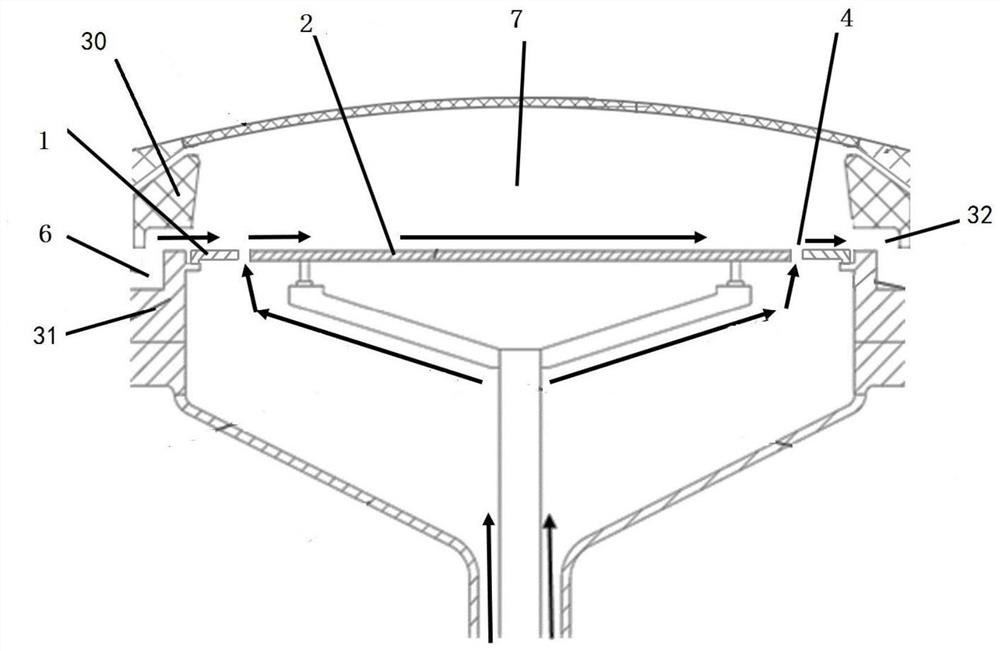

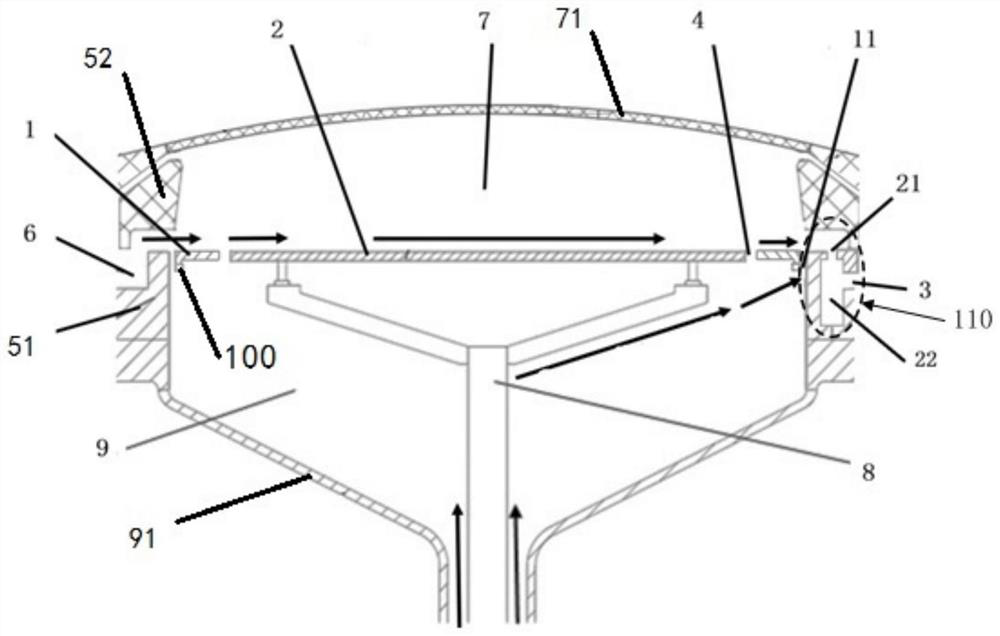

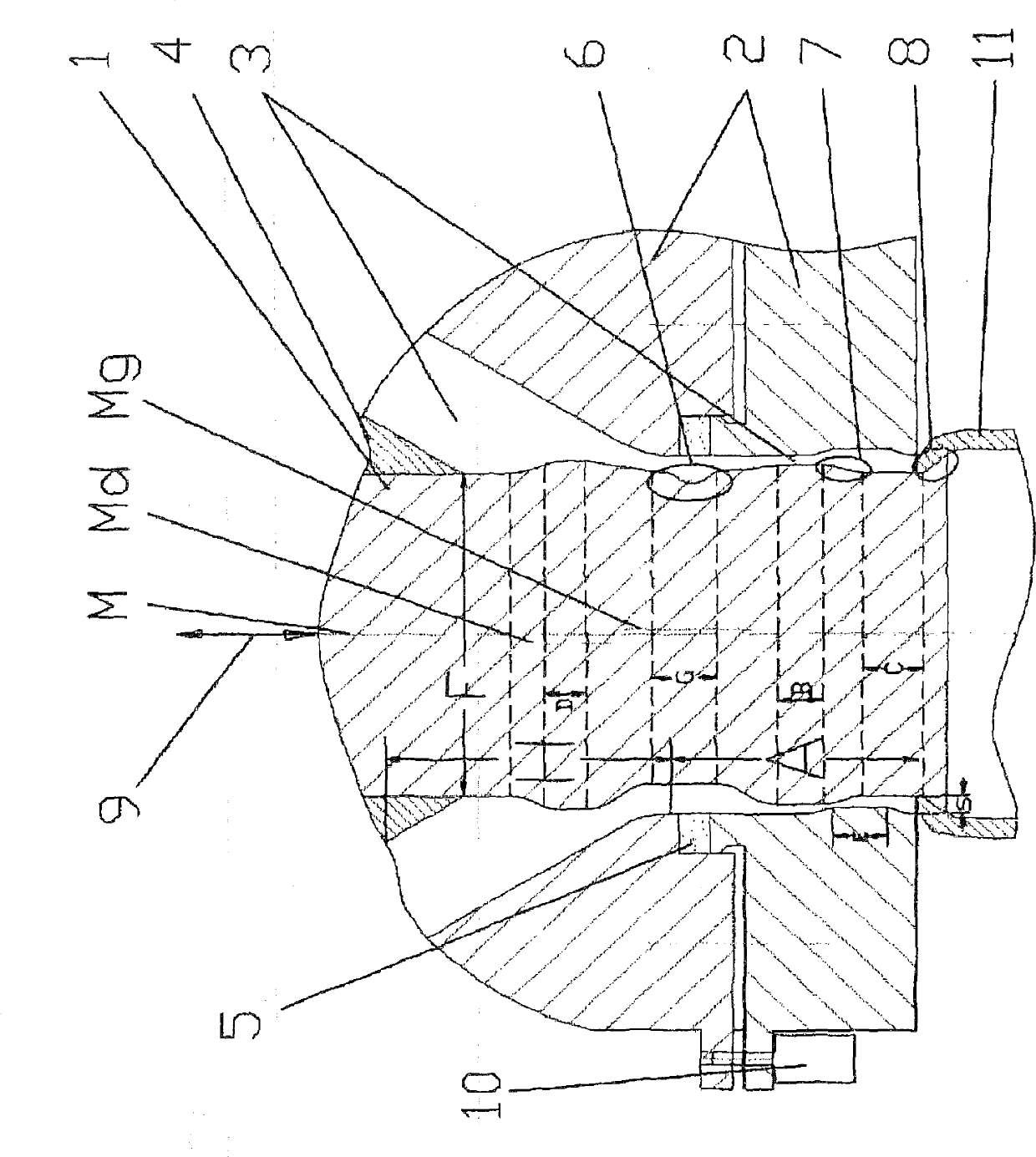

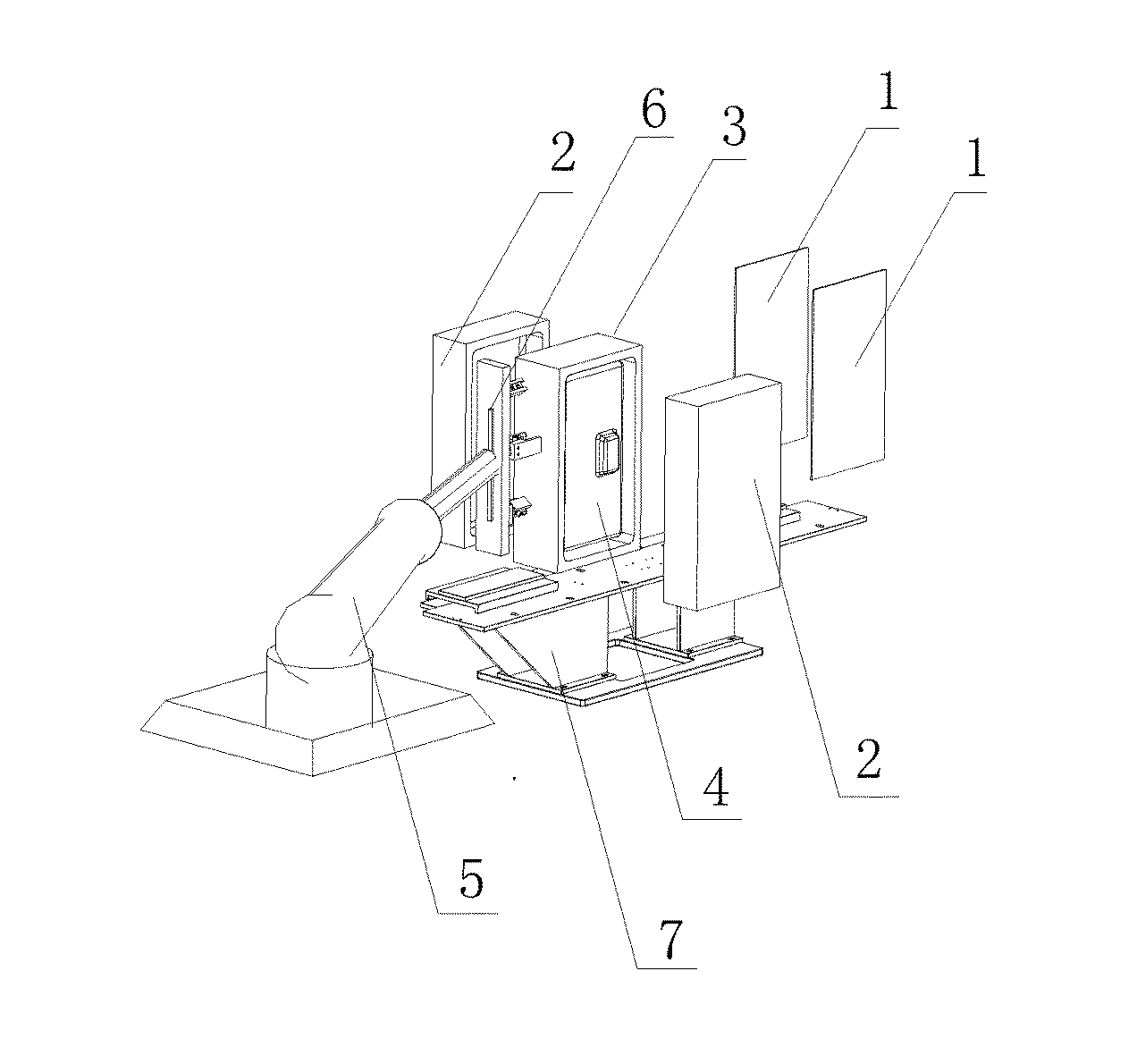

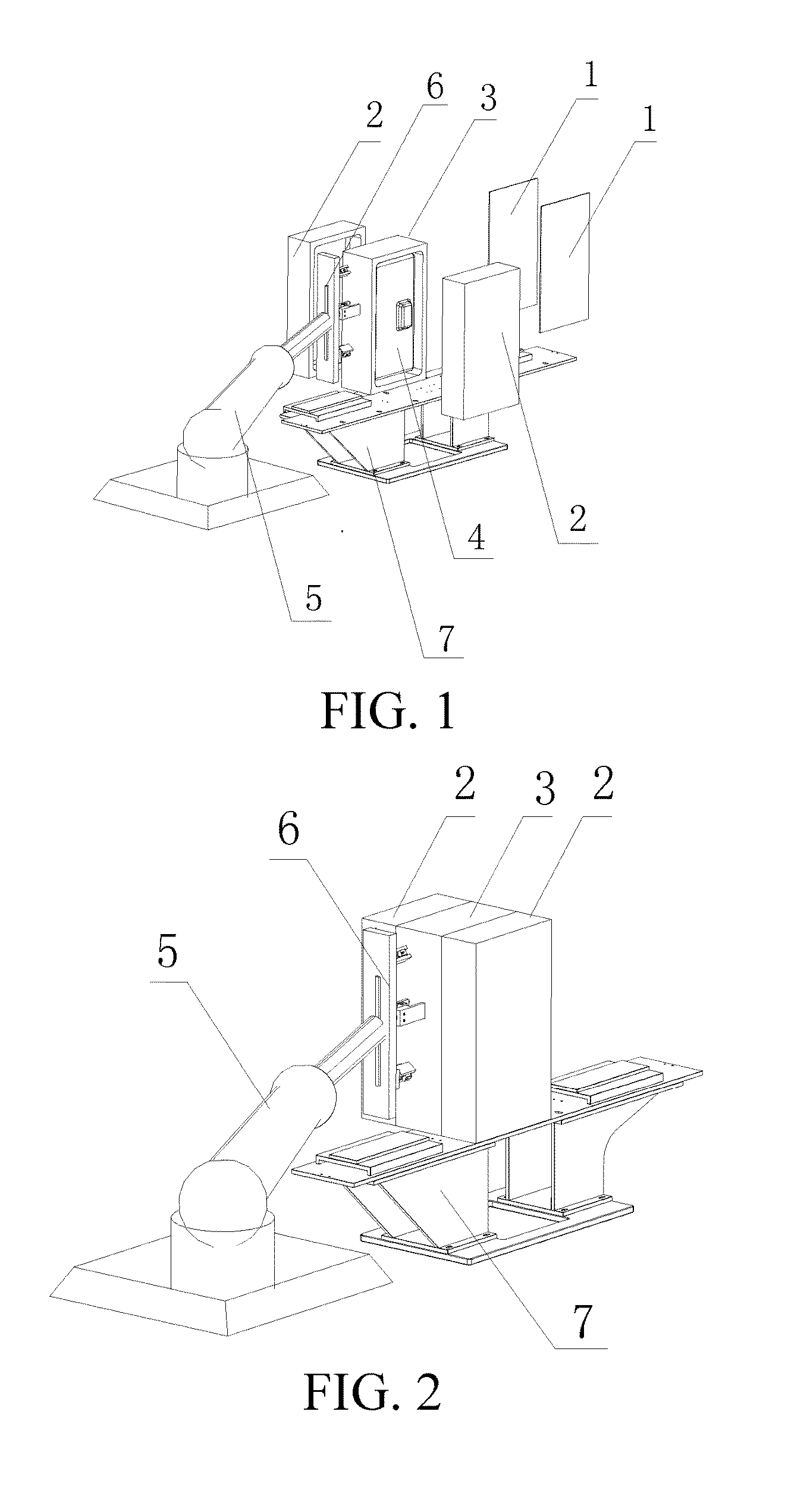

Stretch-forming and electromagnetic combining incremental forming method and device of large thin-wall part

The invention discloses a stretch-forming and electromagnetic combining incremental forming method and device of a large thin-wall part. The method comprises the steps that a driving plate is arranged above a plate to be deformed, the driving plate and the plate to be deformed are clamped by a pressing plate and a supporting plate, and a lifting oil cylinder drives the supporting plate to move, so that the driving plate and the plate to be deformed are stretch-bent and tightened preliminarily, and the stretch-forming process is achieved; the position of an electromagnetic coil is adjusted, the electromagnetic coil is made to exactly face the driving plate to be deformed to discharge electricity, the coil rotates on the surface of the driving plate for a circle around the axis of a male die, and the plate to be deformed is attached to the male die at the same height; then, the oil cylinder descends again to stretch-bend the plate, the coil discharges electricity to deform the plate to be deformed again, the plate to be deformed is attached to the male die, and the alternate forming process of stretch-forming, discharging, re-stretch-forming and re-discharging of the plate is achieved in the same way till deformation of the plate is finished. The flowing evenness of materials can be improved, the thinning ratio of the plate can be reduced, and flexible processing and precise plastic manufacturing of large plates hard to deform can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

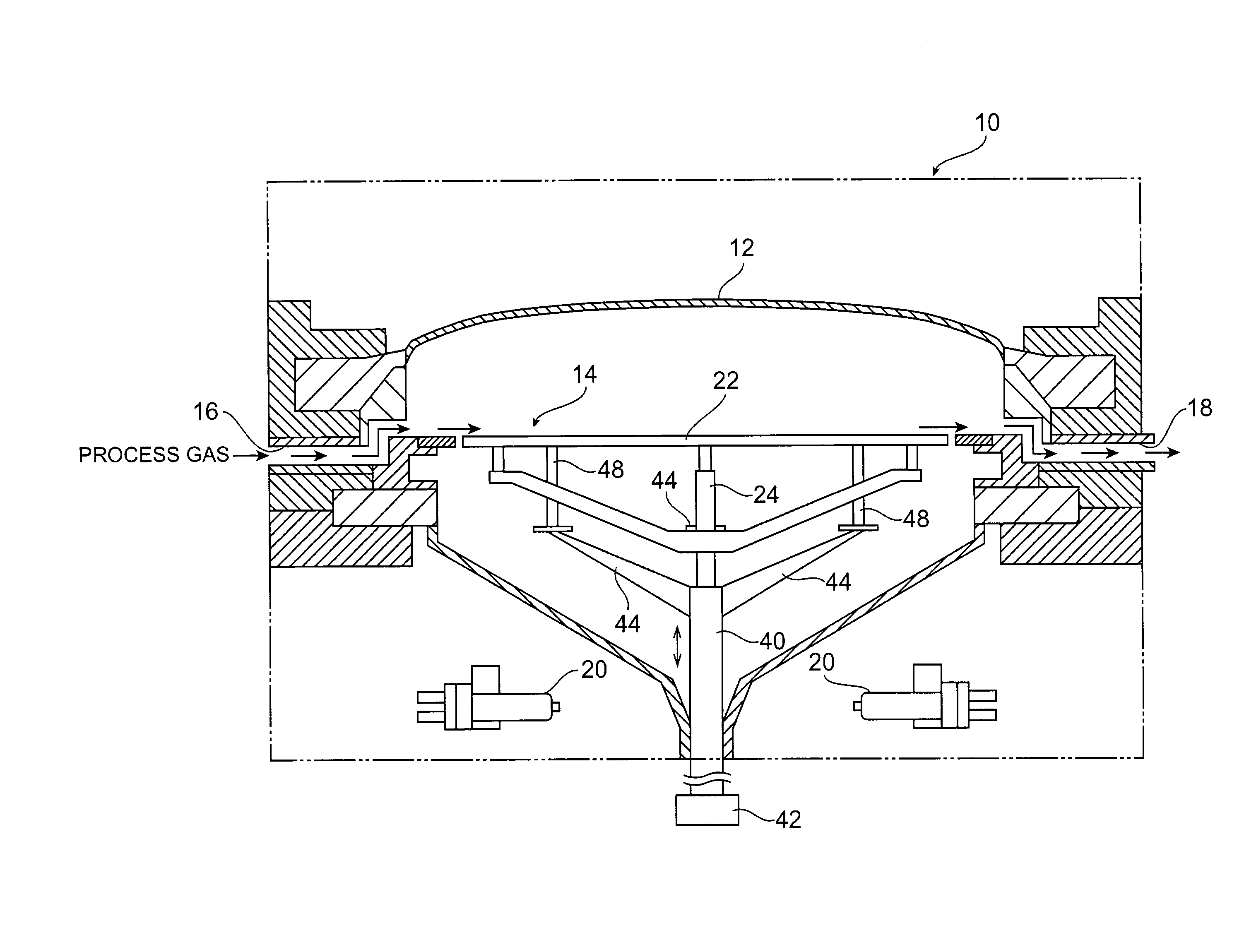

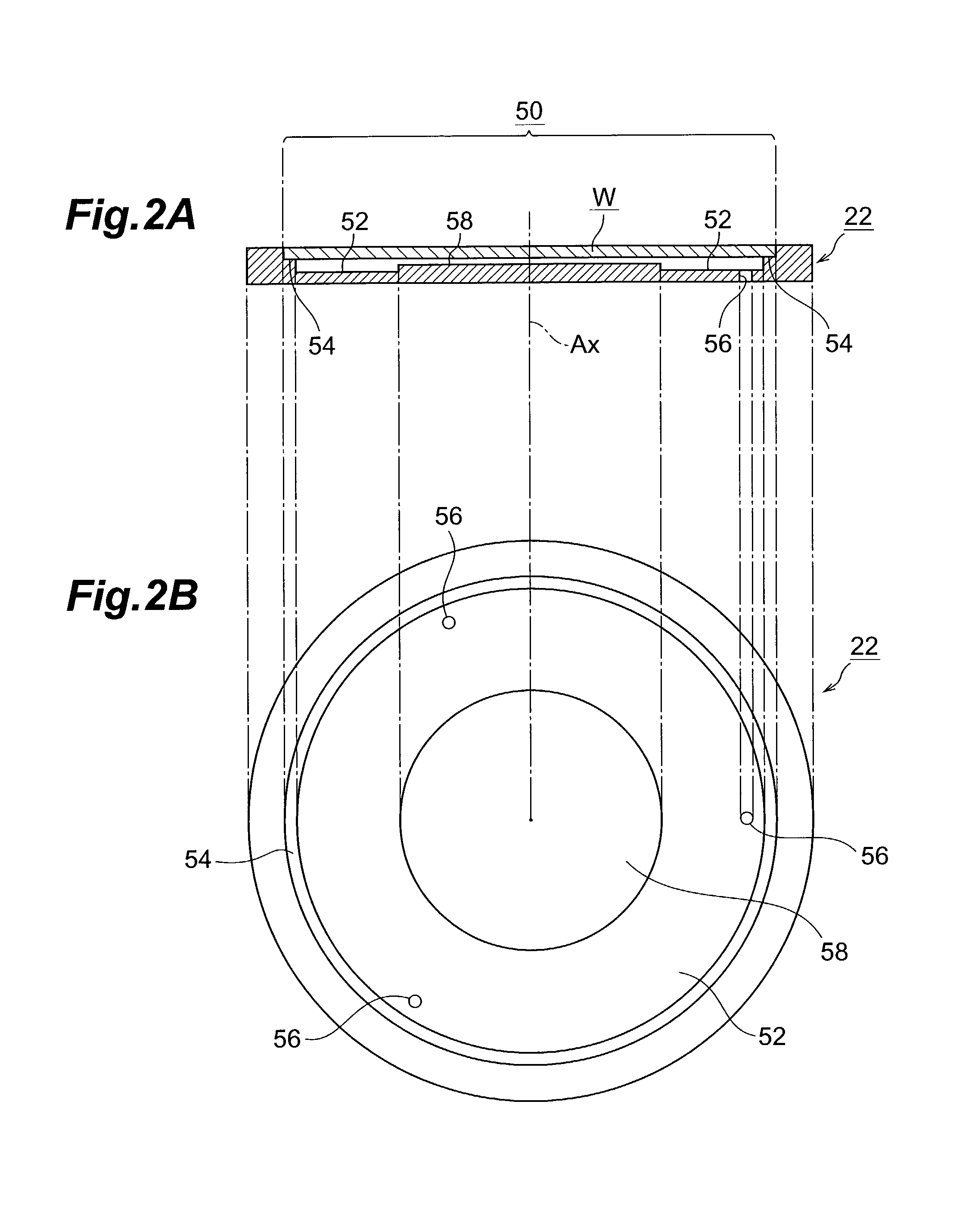

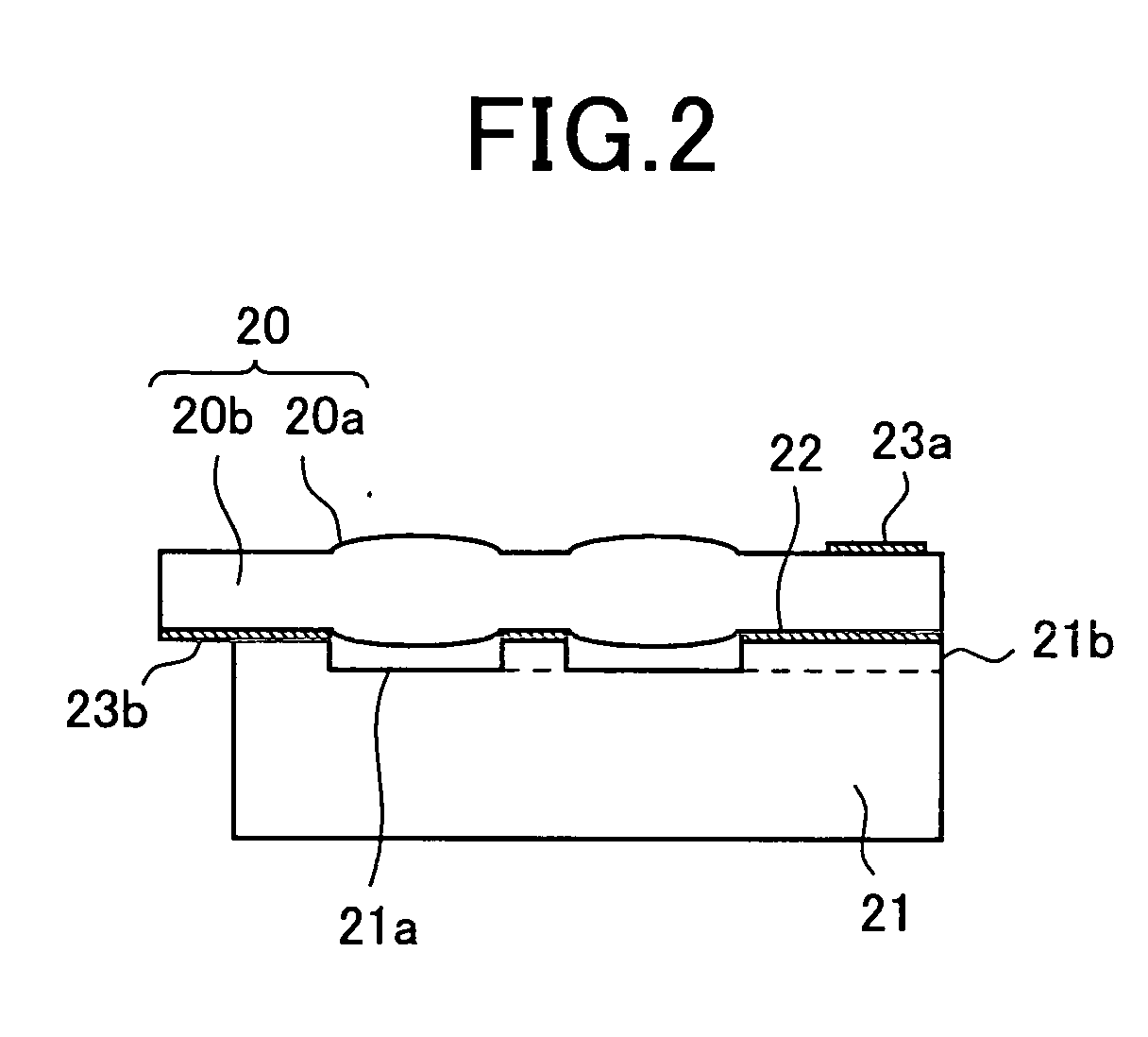

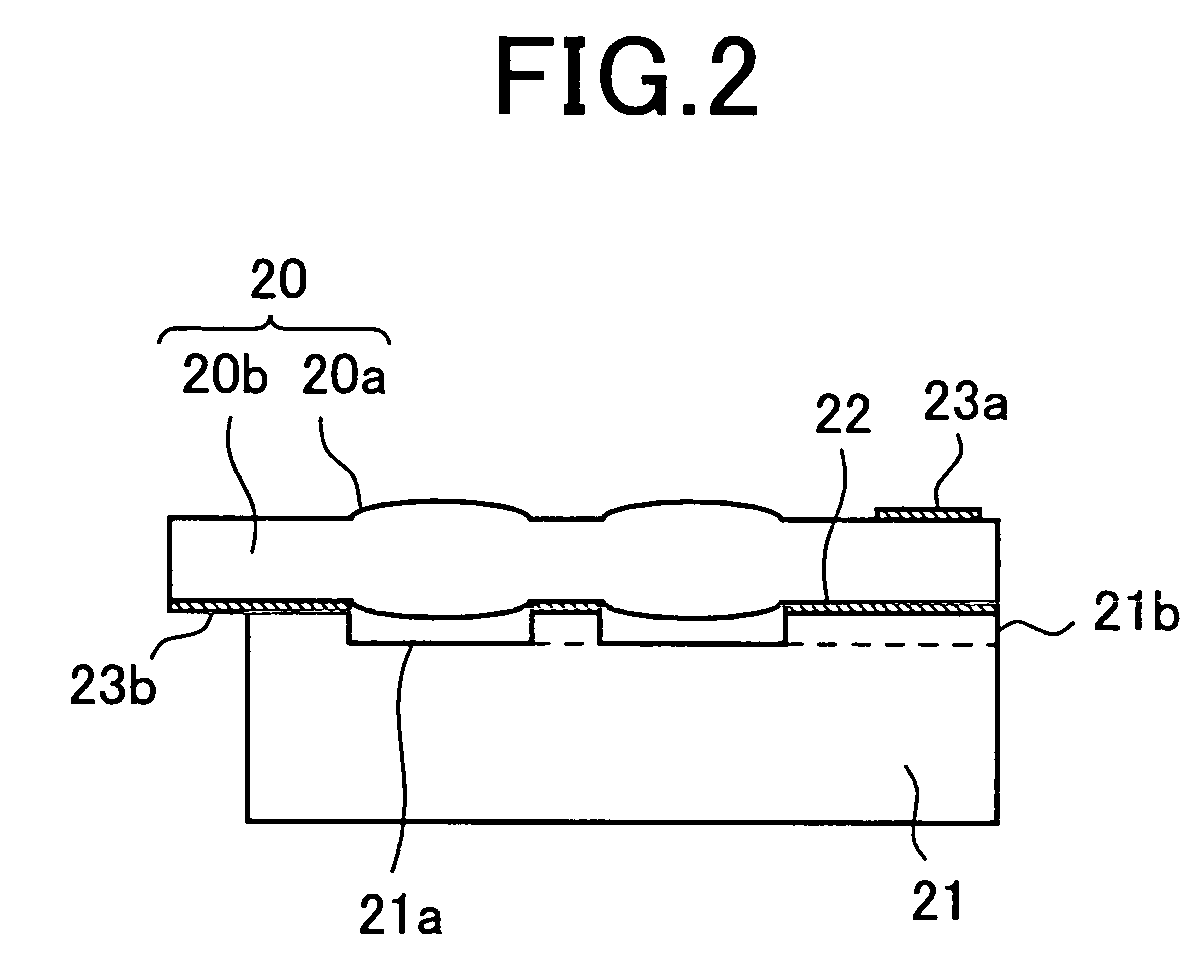

Semiconductor-manufacturing apparatus

ActiveUS7393417B1Reduce the impactUniform film thickness distributionVacuum evaporation coatingSemiconductor/solid-state device manufacturingSusceptorManufactured apparatus

On a wafer holding area 50 on the upper surface of a susceptor 22, a wafer W is supported by a wafer support 54 such that a gap with a predetermined distance is formed between the wafer W and a wafer heating surface 52. A projection 58 that decreases the distance of the gap with respect to the wafer W is formed on the wafer heating surface 52. At this time, the heating condition for the wafer W by the susceptor 22 is adjusted by means of the distances of the gaps at the respective portions of the wafer holding area 50. Thus, the uniformity of the planar temperature distribution of the wafer W and that of the thickness distribution of the formed film can be improved.

Owner:APPLIED MATERIALS INC

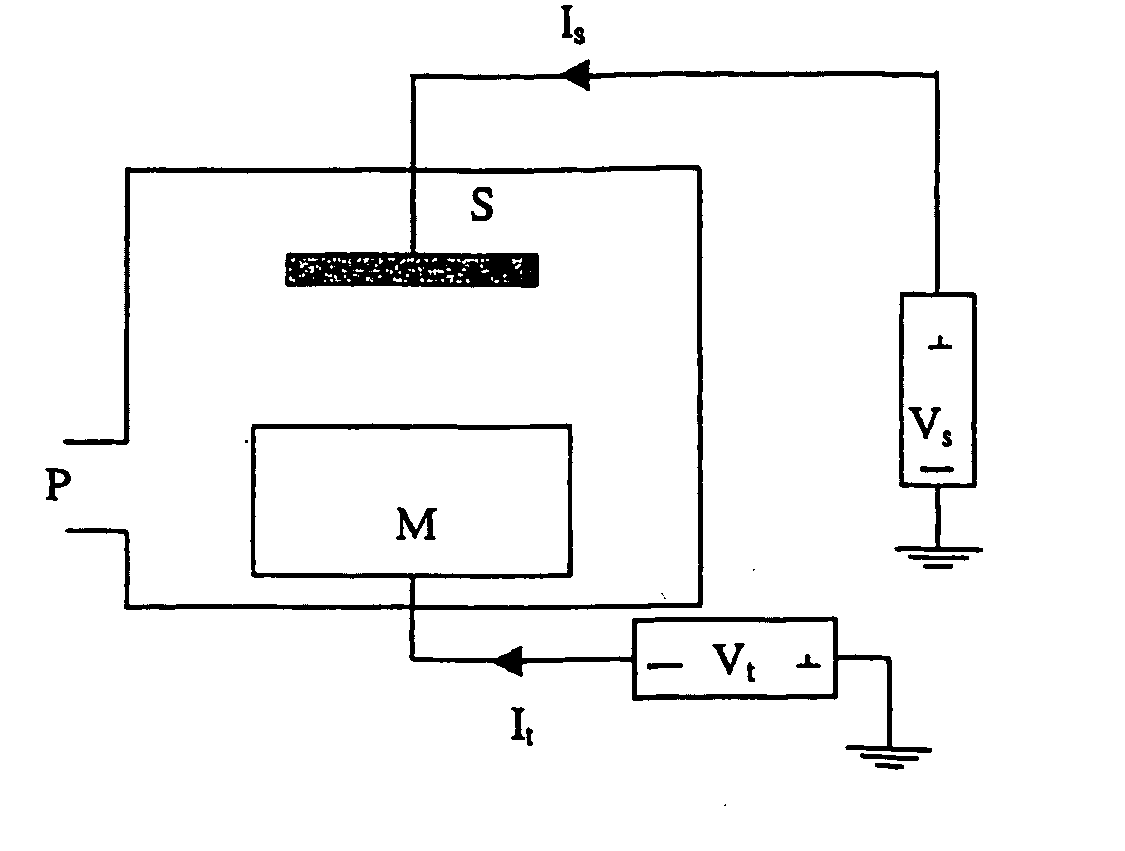

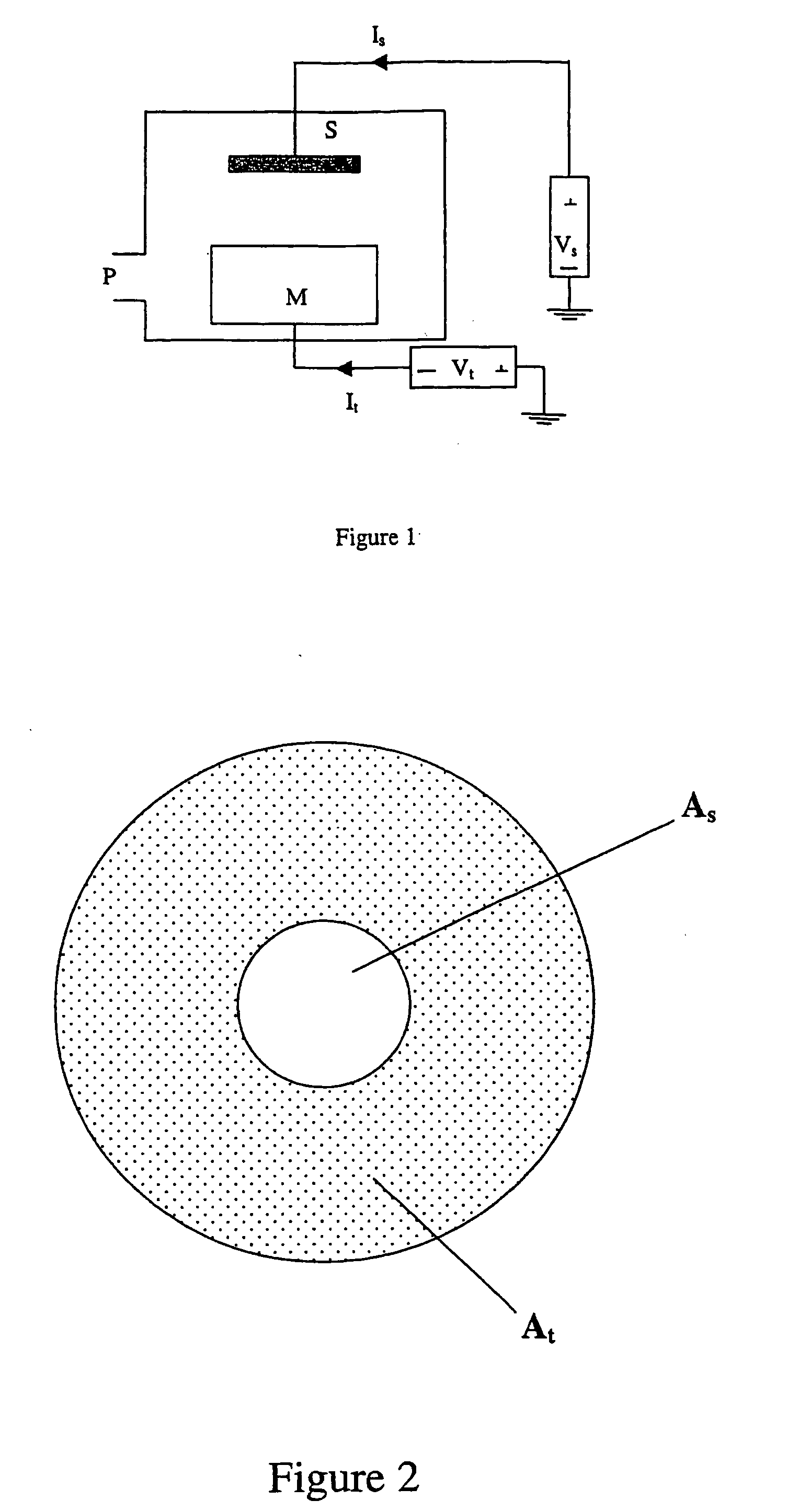

Method of coating a cutting tool

InactiveUS20050145479A1Reduce residual stressImproved thickness distributionVacuum evaporation coatingSputtering coatingTarget surfaceSputtering

A method of depositing a nitride-based wear resistant layer on a cutting tool for machining by chip removal using reactive magnetron sputtering has a deposition rate, td, higher than 2 nm / s, a positive bias voltage, Vs, (with respect to ground potential) between +1 V and +60 V applied to the substrate, a substrate current density, Is / As, larger than 10 mA / cm2, a target surface area, At, larger than 0.7 times the substrate surface area, As, and a distance between the target surface and the substrate surface, dt, less than (At)0.5.

Owner:SECO TOOLS AB

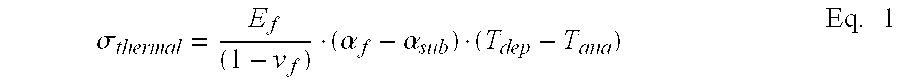

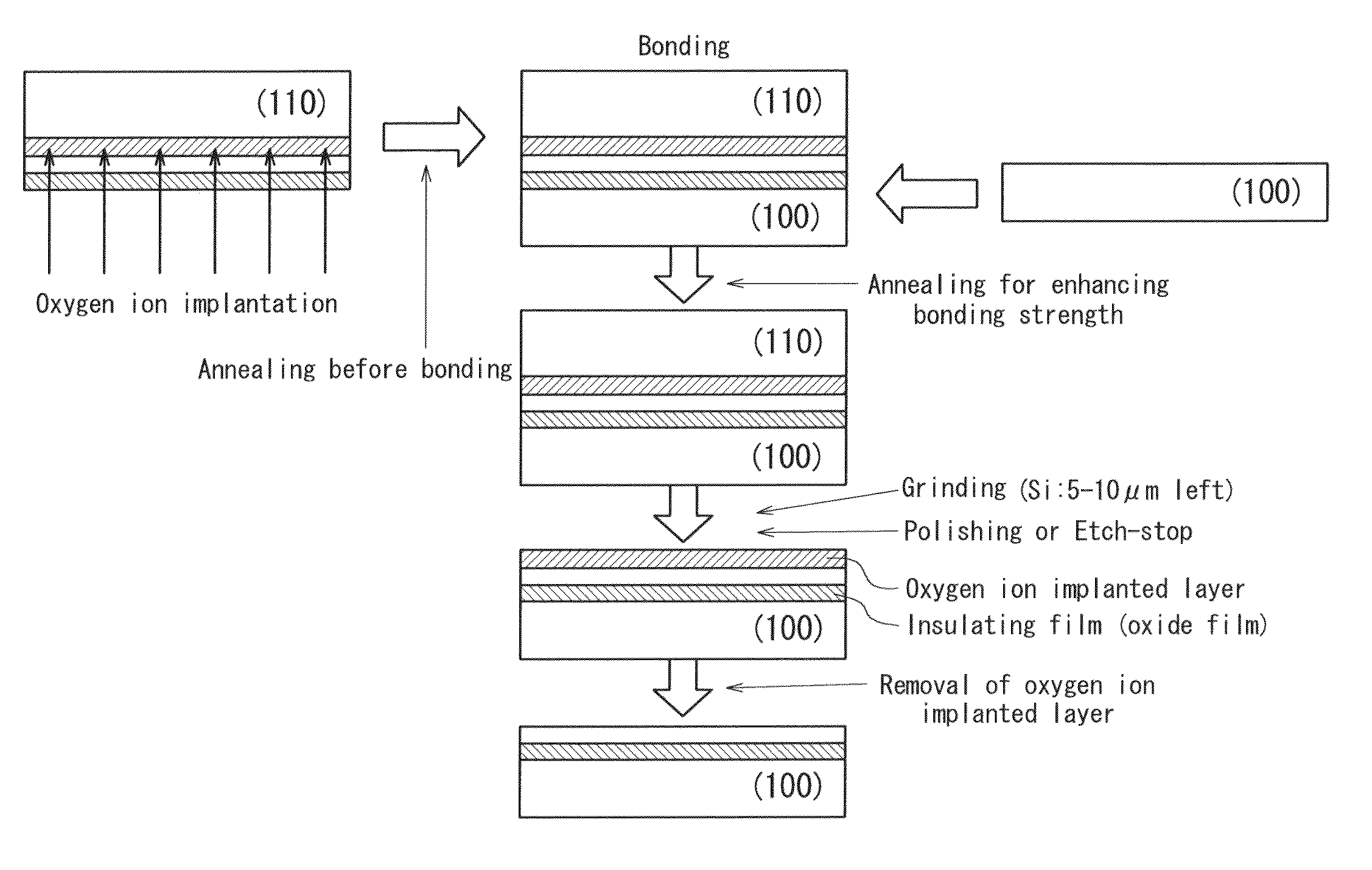

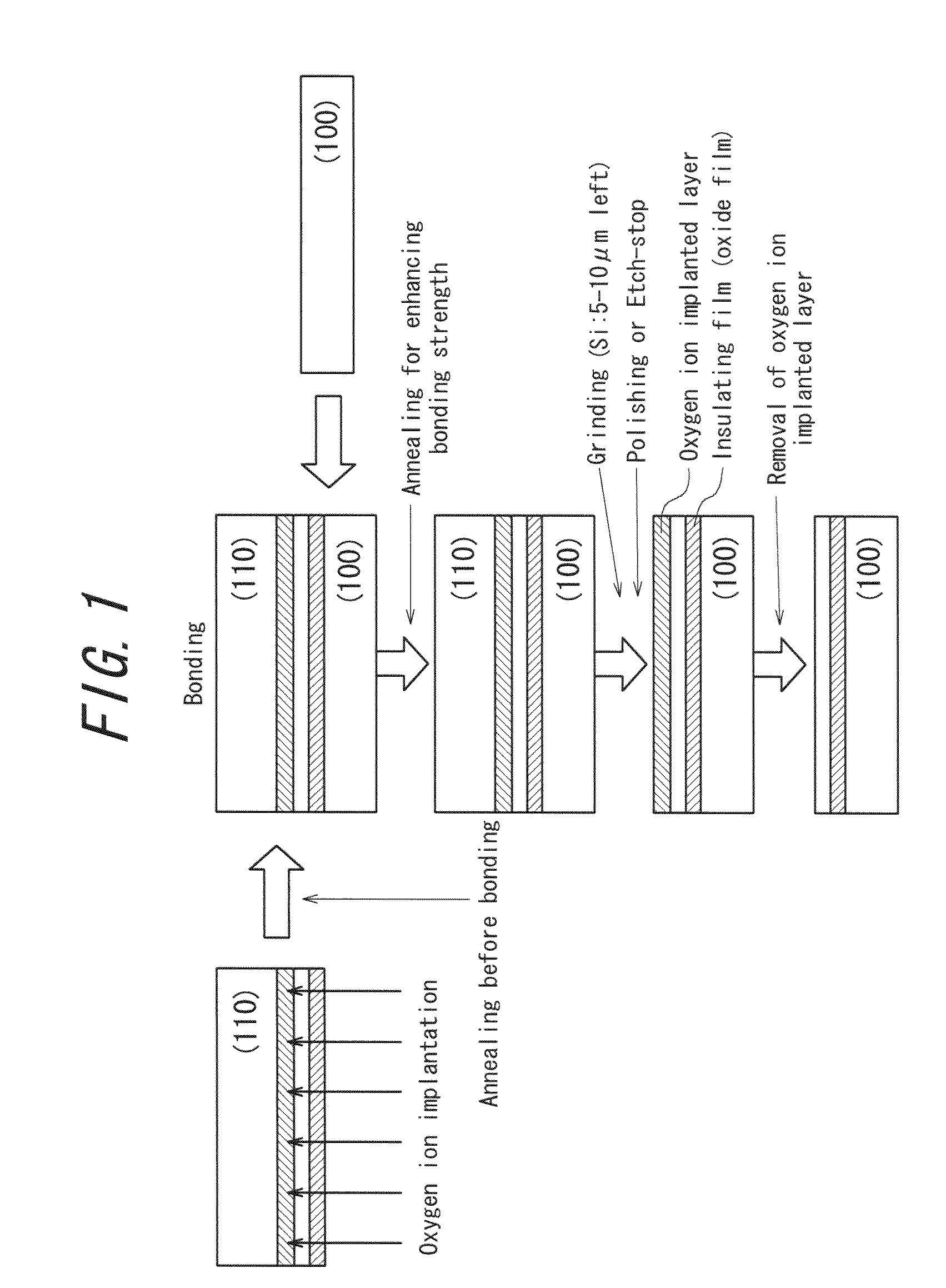

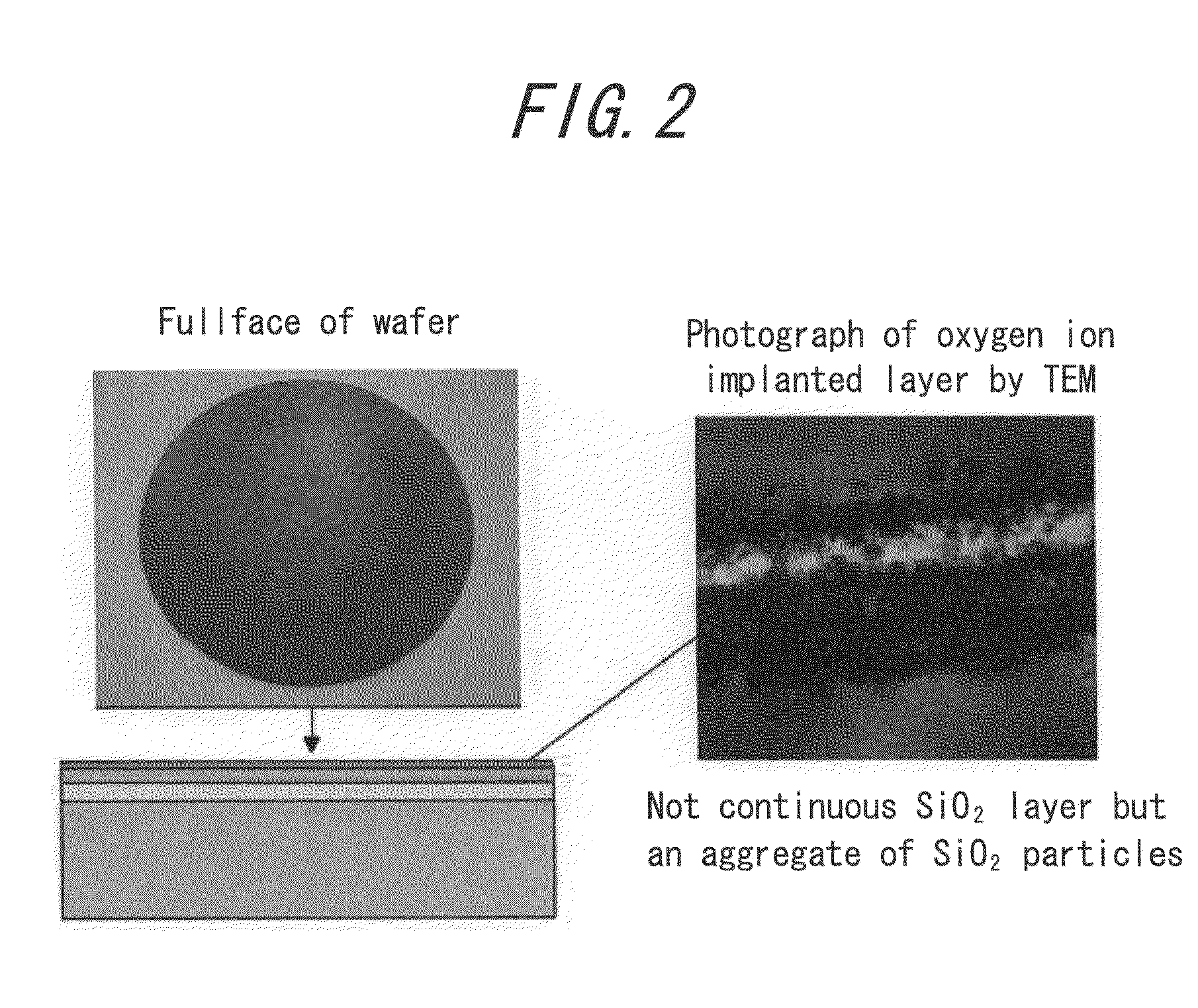

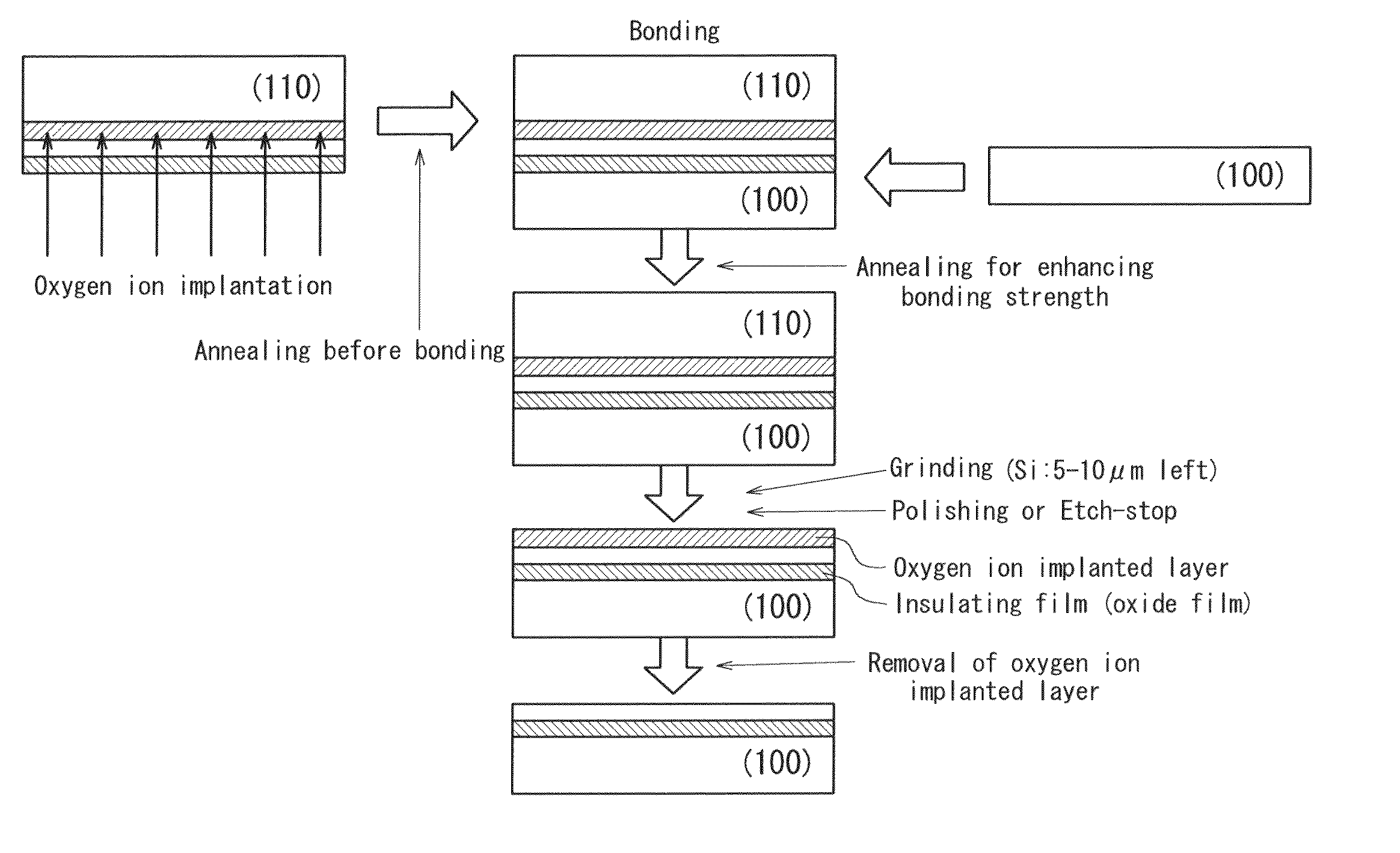

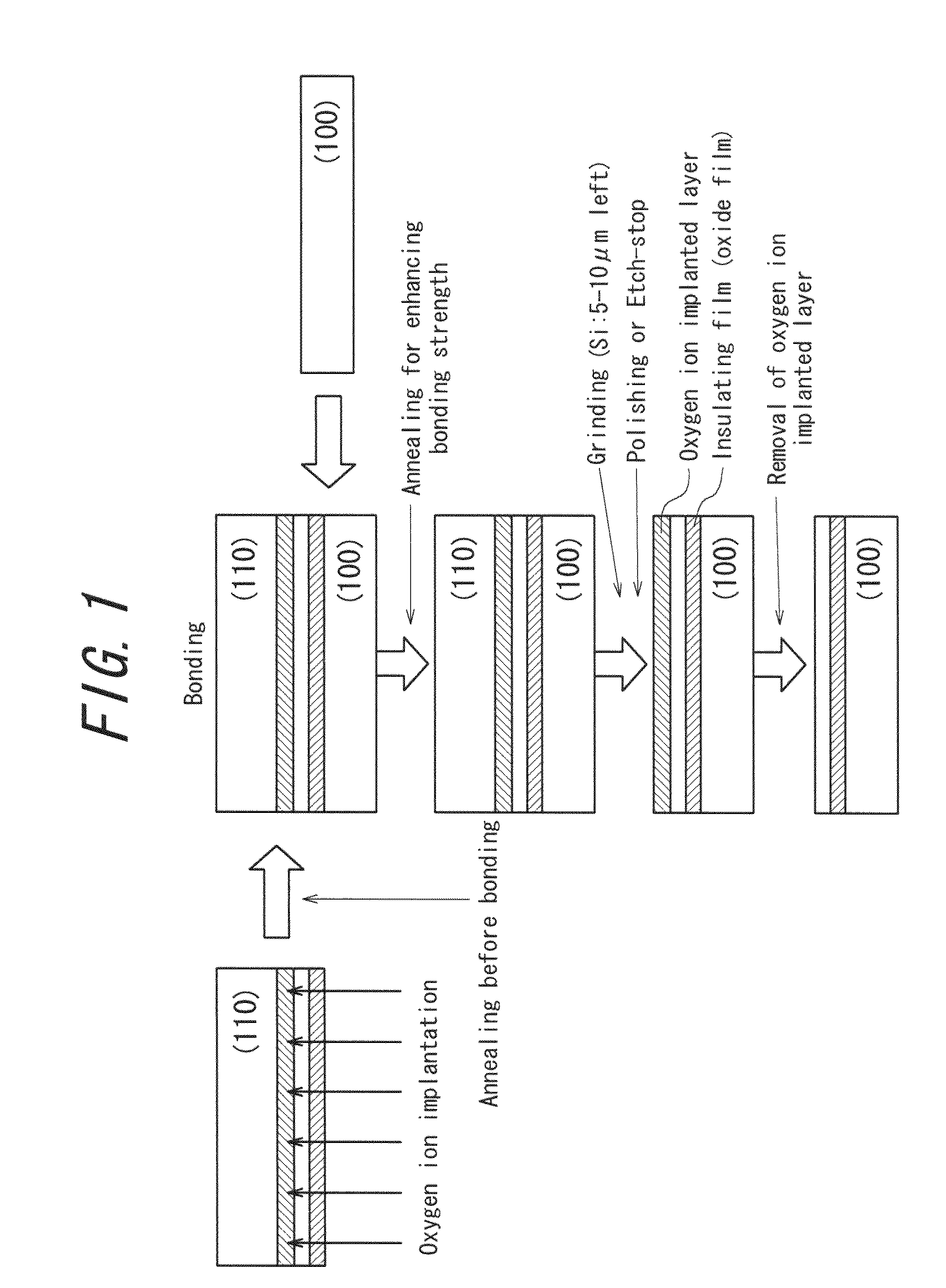

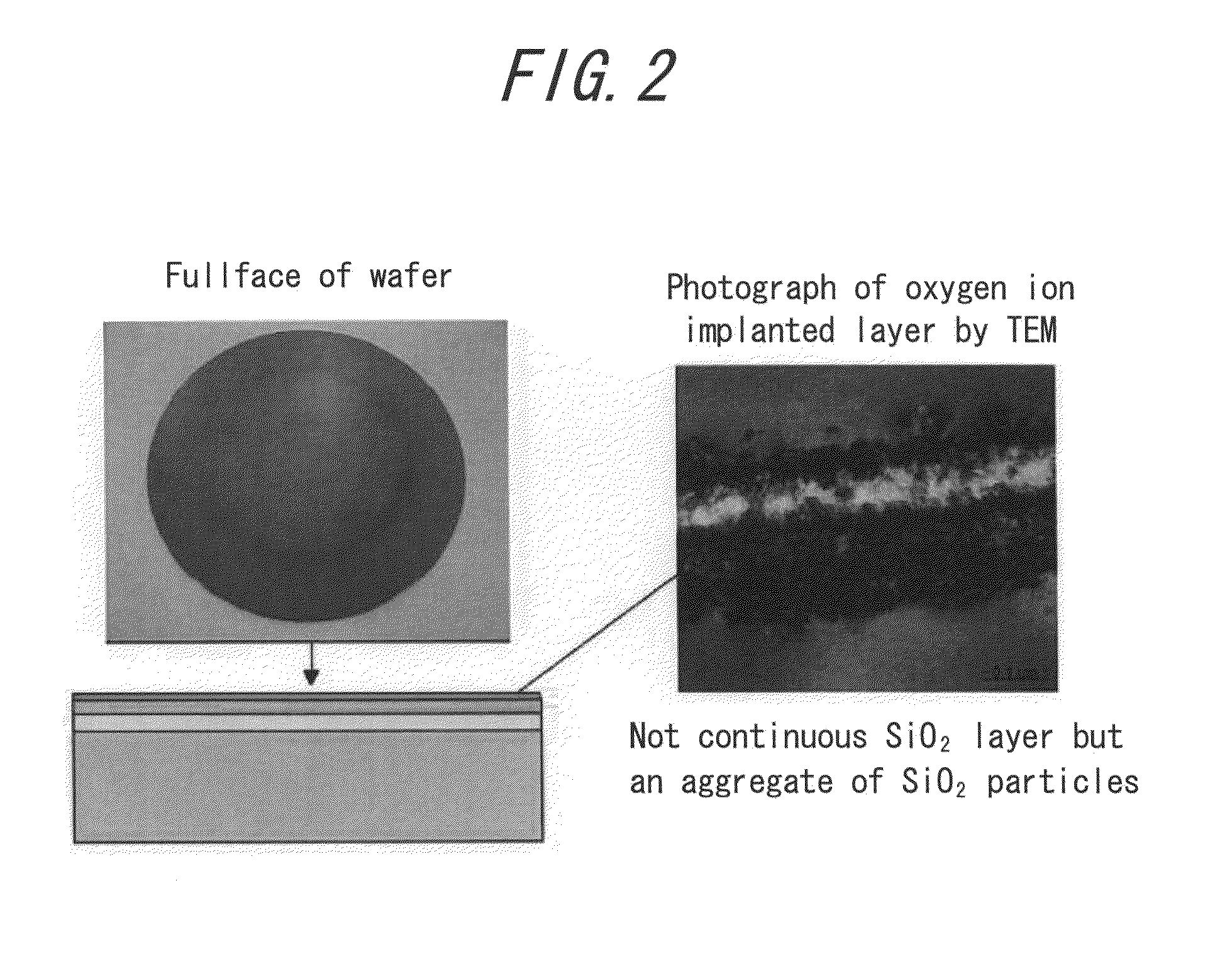

Method for producing bonded wafer

ActiveUS20090258475A1High bonding strengthSimple heat treatment processSemiconductor/solid-state device manufacturingOxygen ionsPhysical chemistry

Even if an oxygen ion implanted layer in a wafer for active layer is not a completely continuous SiO2 layer but a layer mixed partially with Si or SiOx, it is removed by here is provided a method for producing a bonded wafer in which it is possible to remove an oxygen ion implanted layer effectively as it is by repetitive treatment with an oxidizing solution and HF solution at a step of removing the oxygen ion implanted layer in a bonded wafer.

Owner:SUMCO CORP

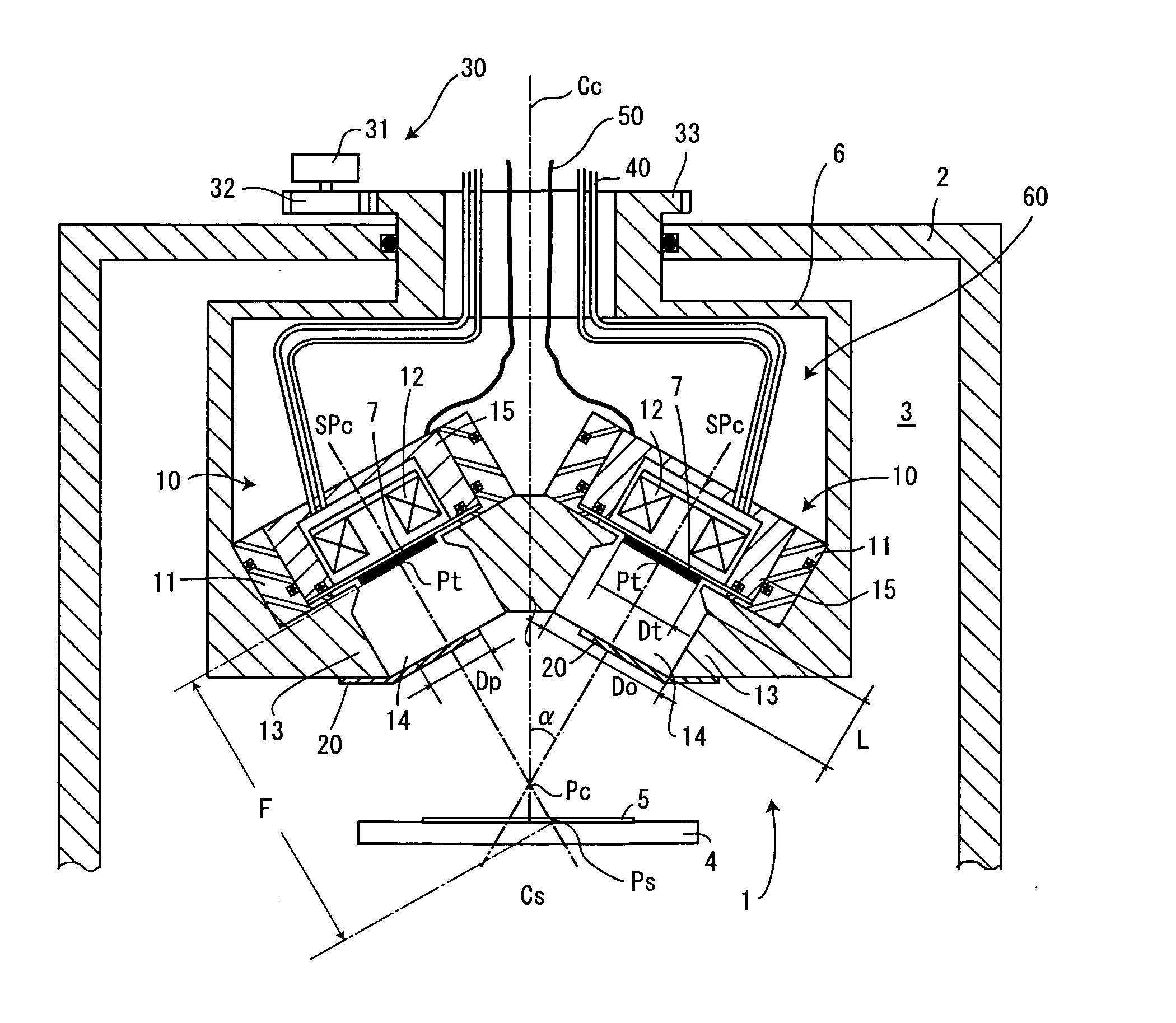

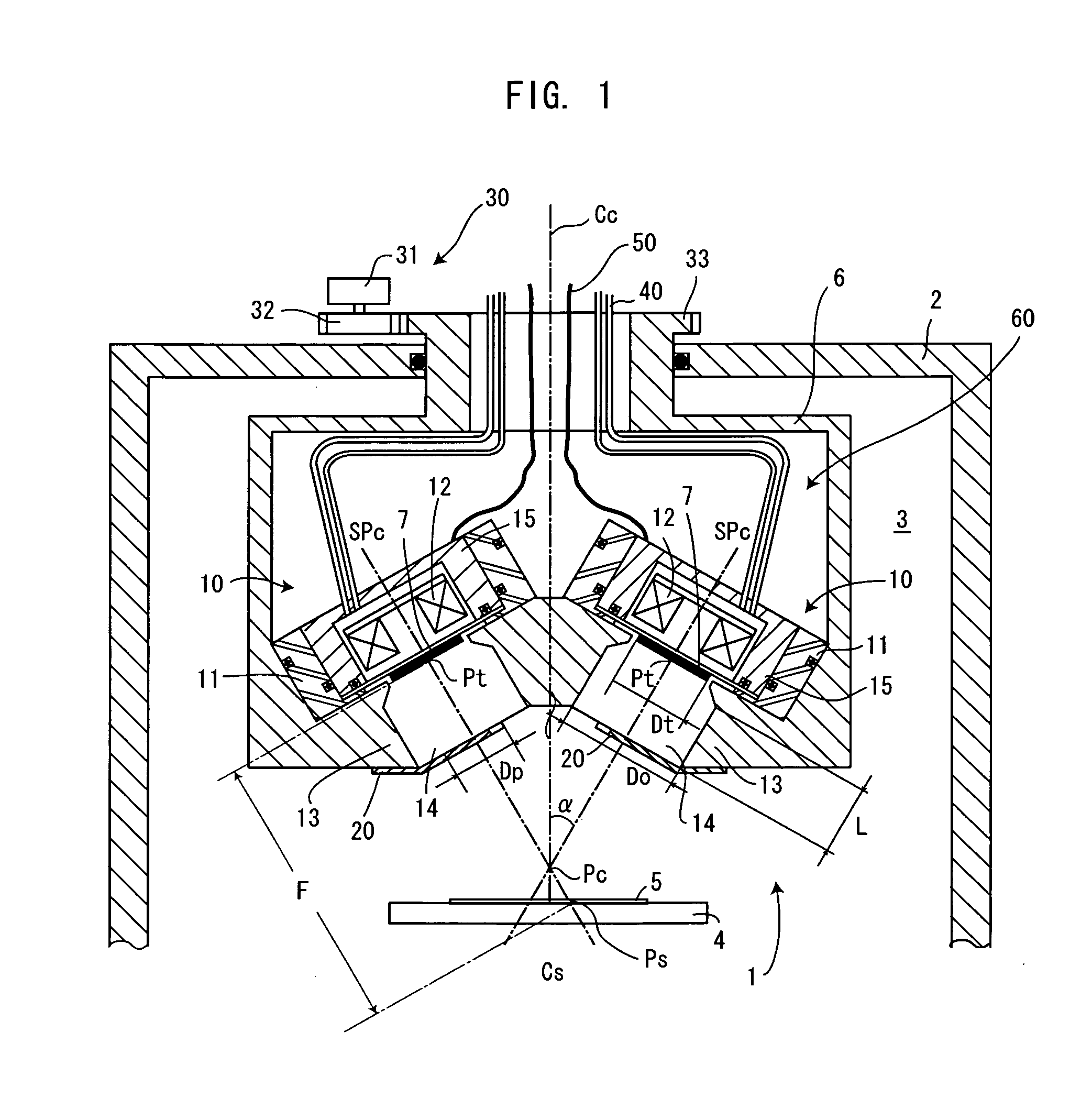

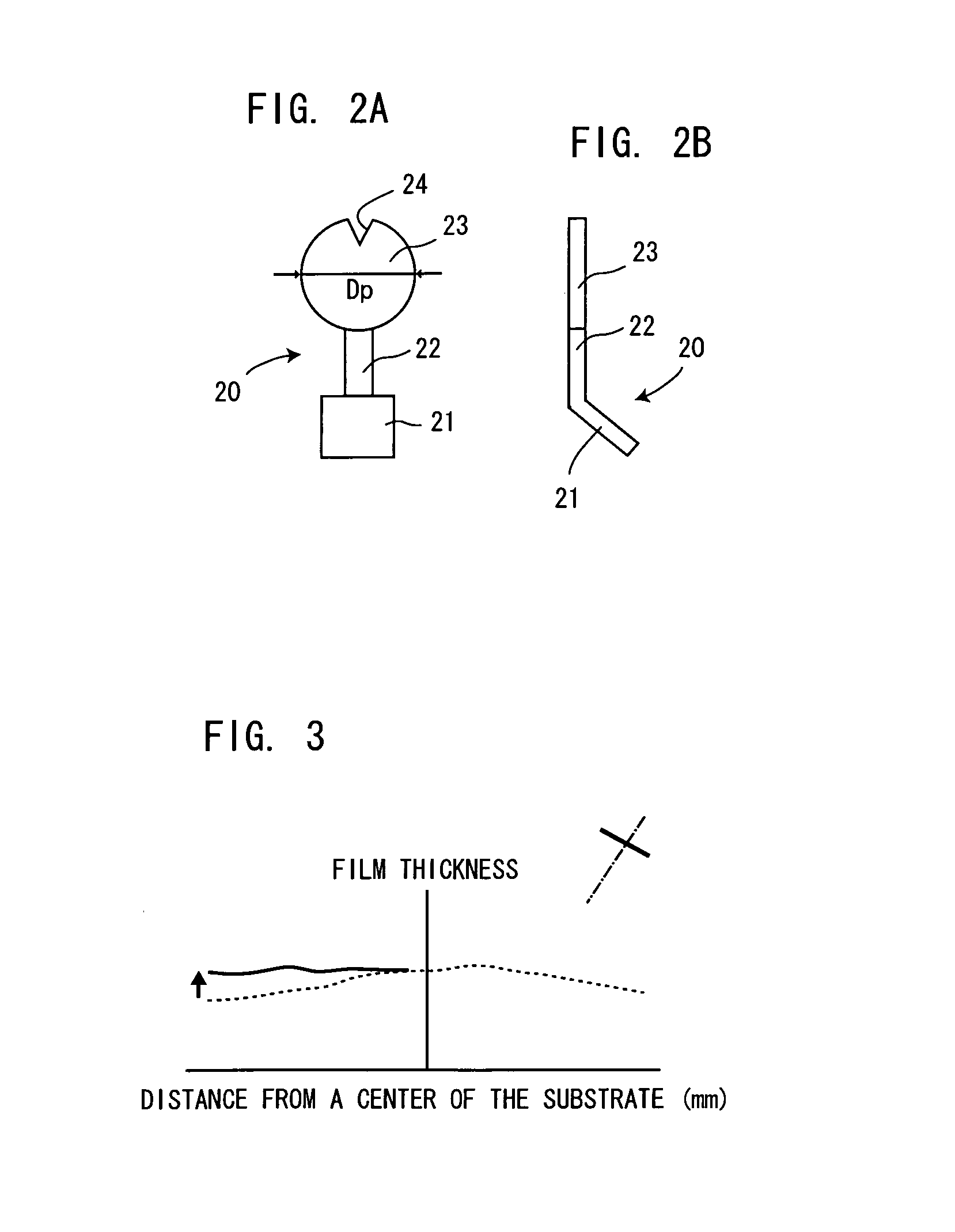

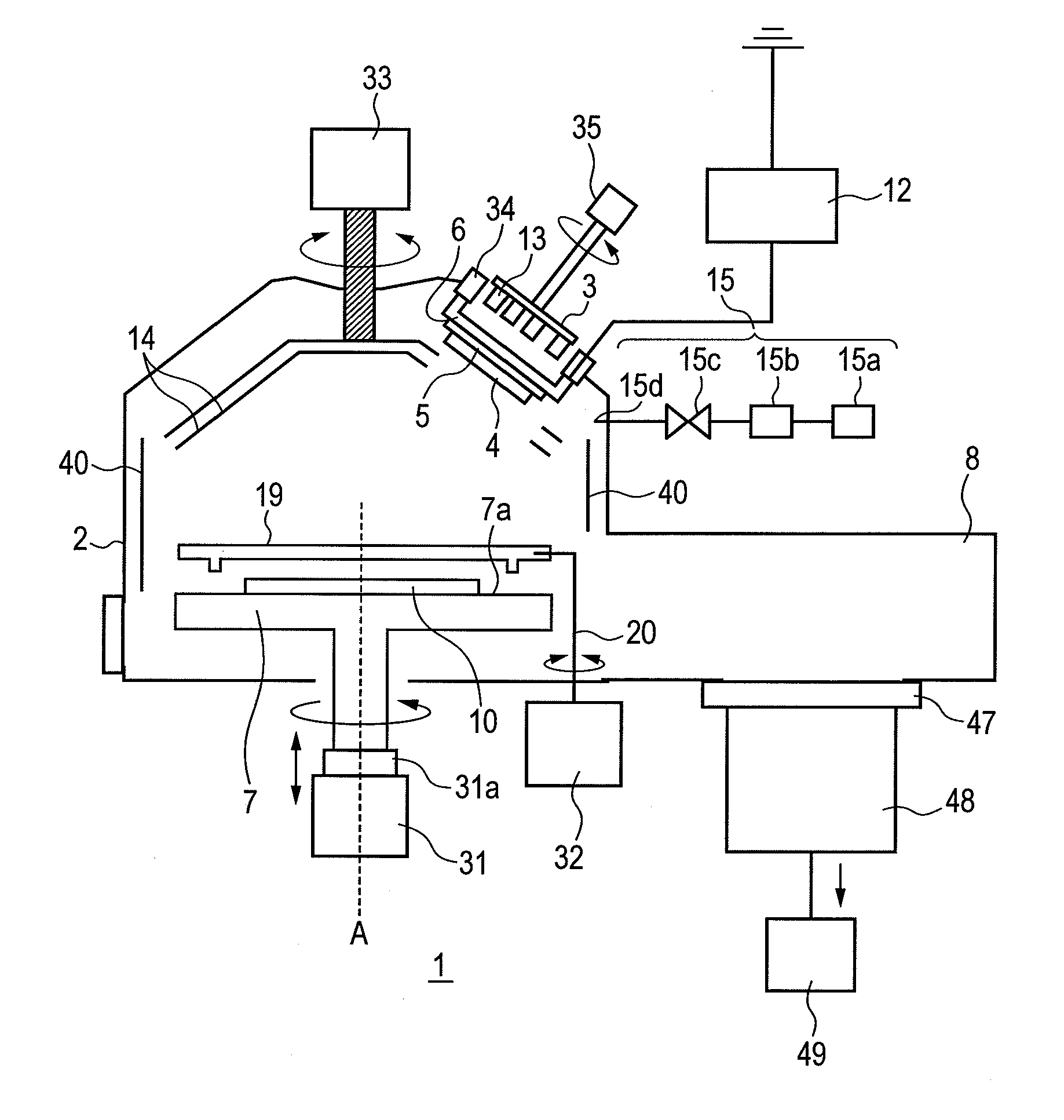

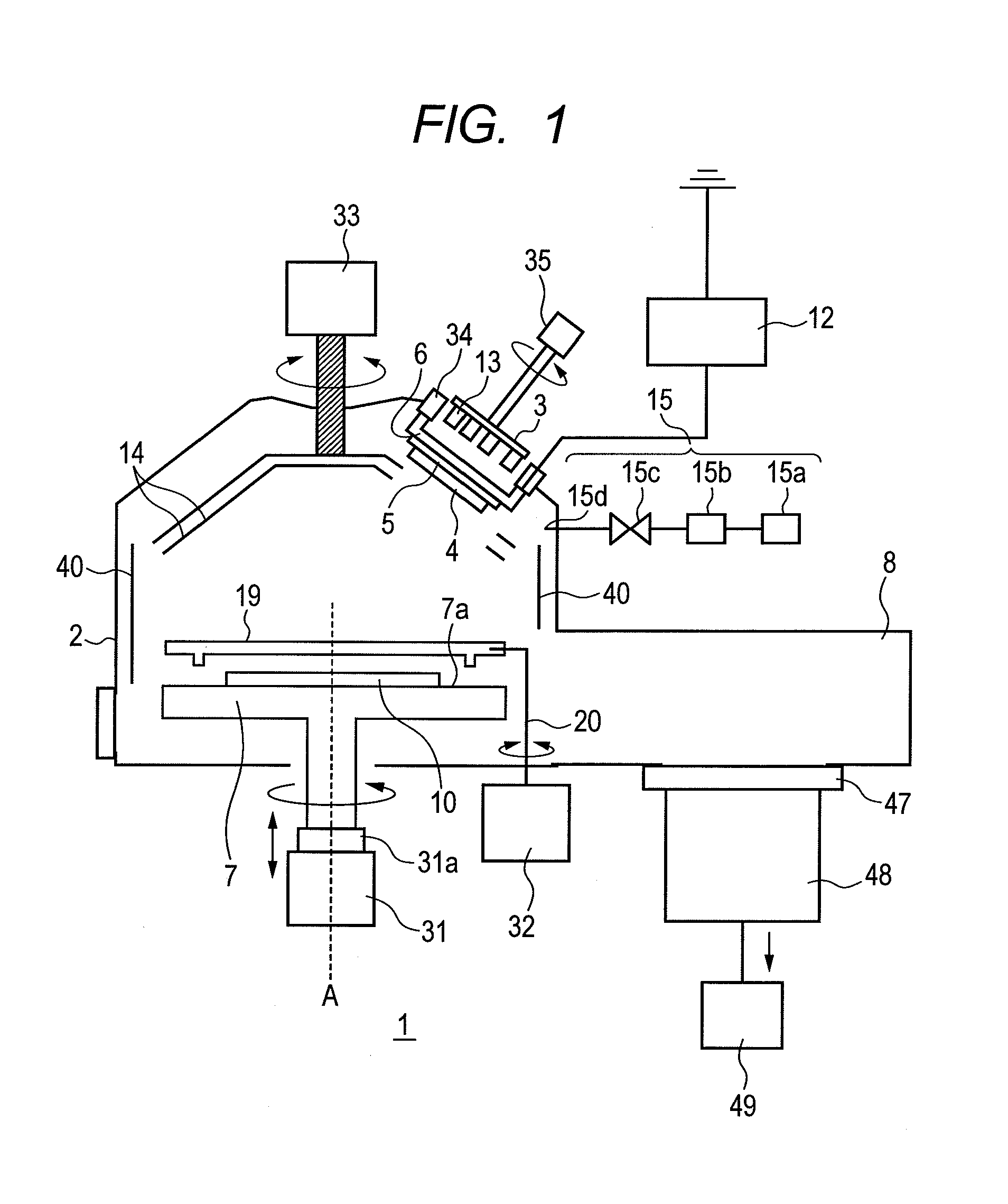

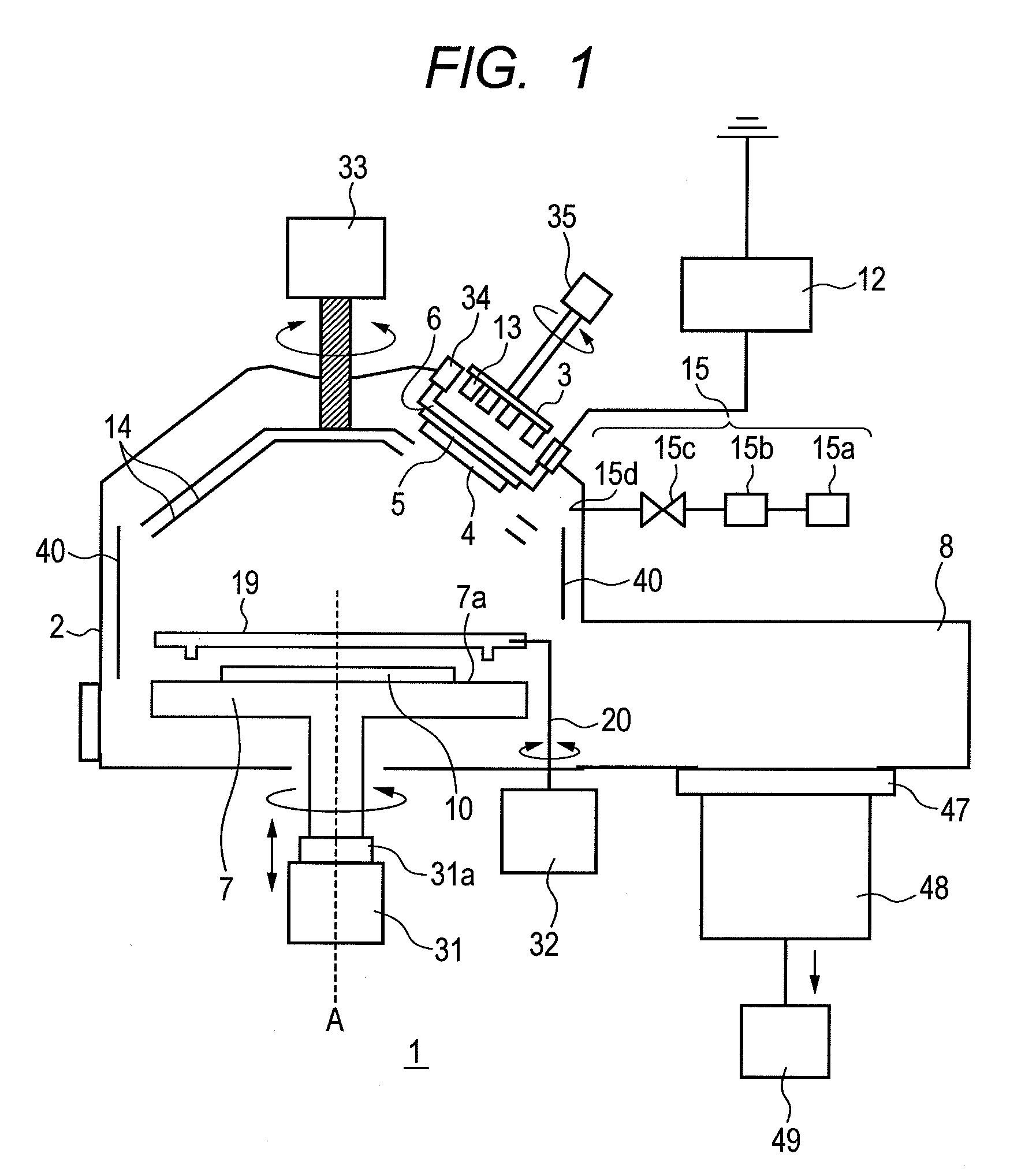

Sputtering device

InactiveUS20070080059A1Film thickness distribution can be increasedGreat degreeCellsElectric discharge tubesSputteringOptoelectronics

A sputtering device according to the present invention comprises at least a vacuum container, a substrate holder arranged in the vacuum container, plural sputtering cathodes each of which has a target for sputtering to a substrate installed on the substrate holder, wherein the plural sputtering cathodes are arranged so that center axes of the targets installed on the sputtering cathodes is inclined at specific angle against an axis of the substrate installed on the substrate holder, and a sputtering cathode unit constituted of the plural sputtering cathodes is held to the vacuum container rotatably around the axis of said substrate.

Owner:CYG CORP

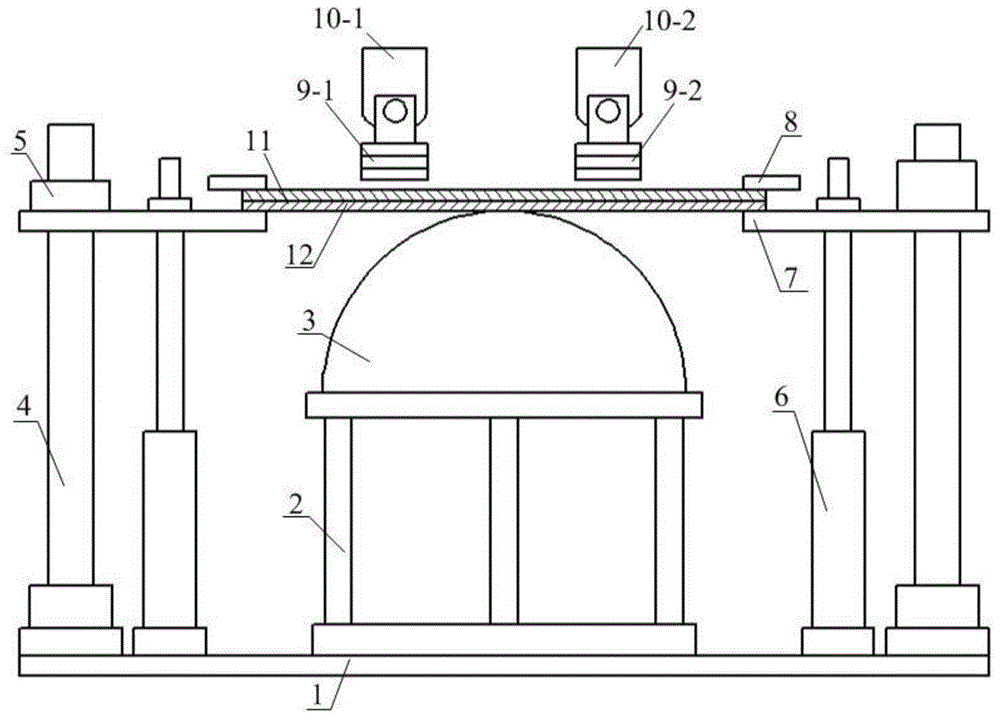

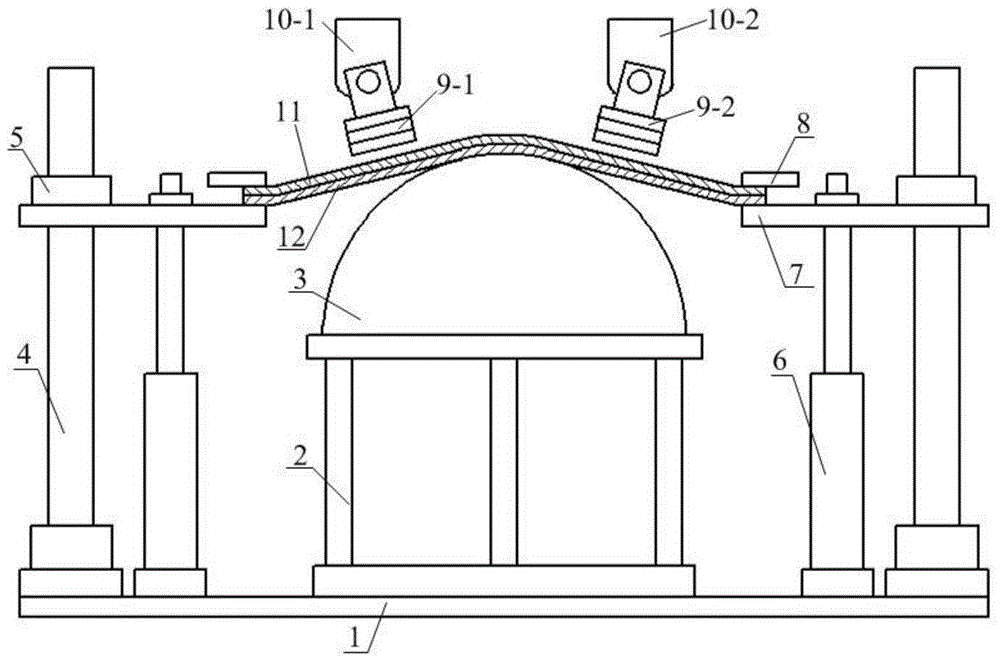

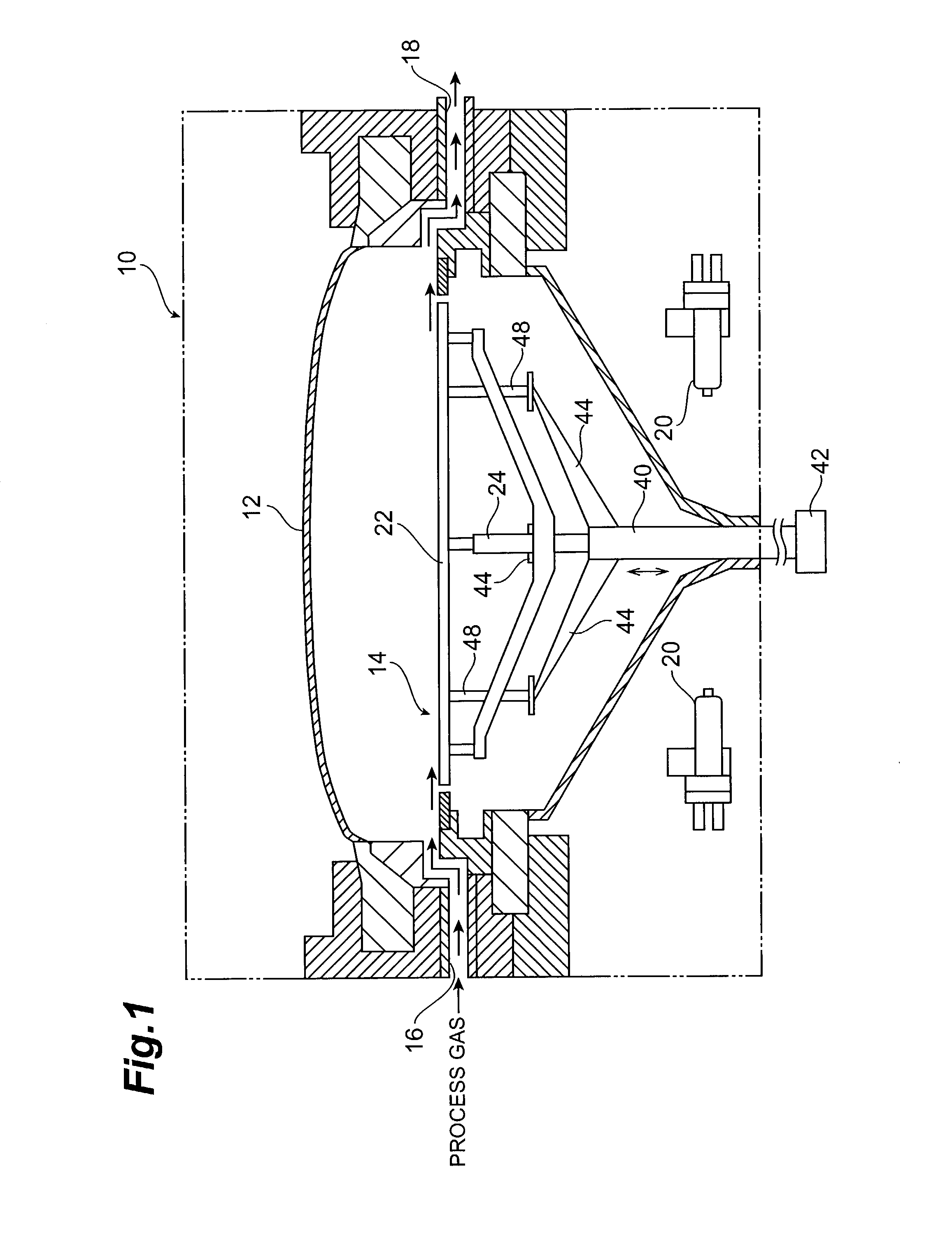

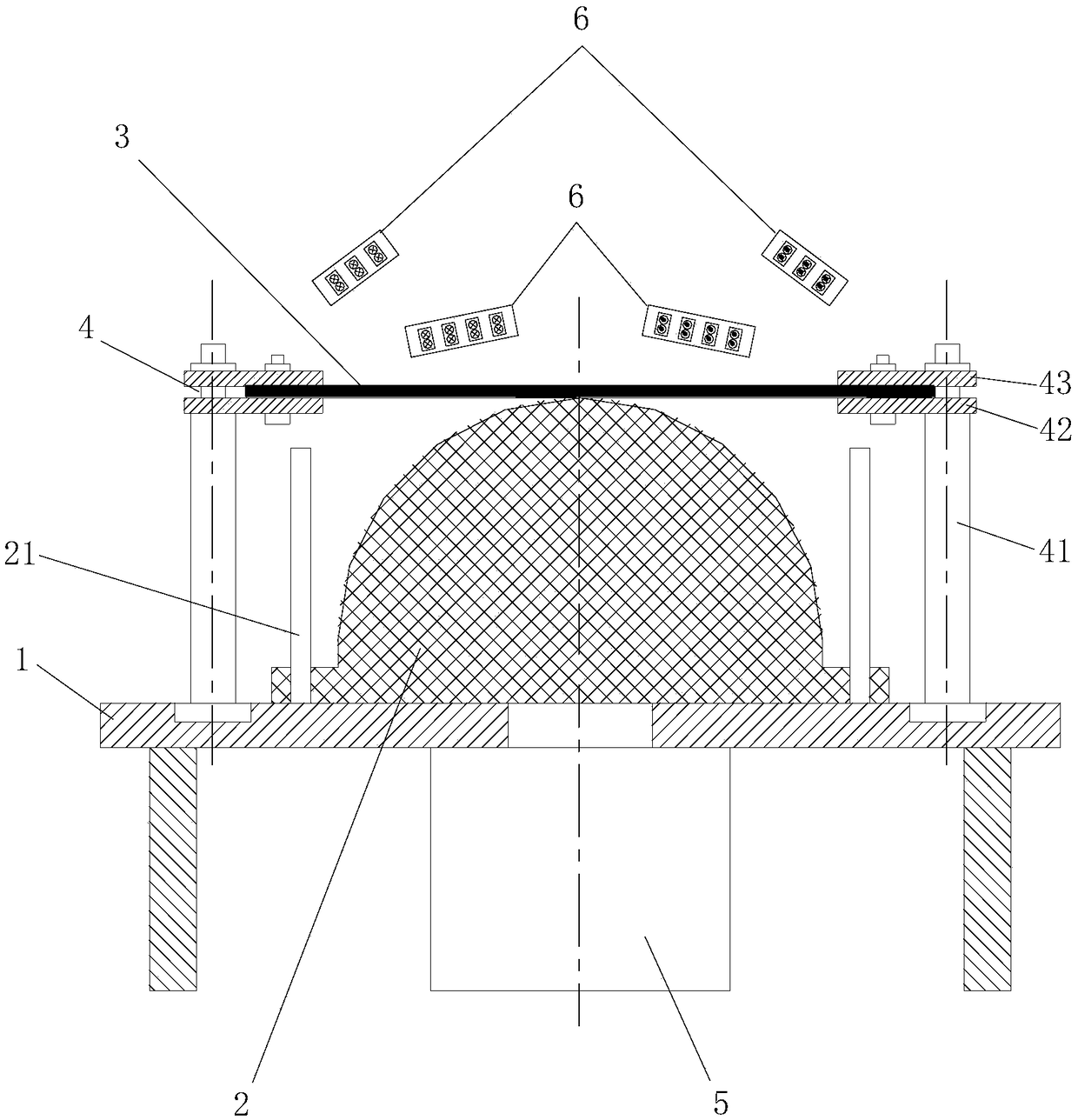

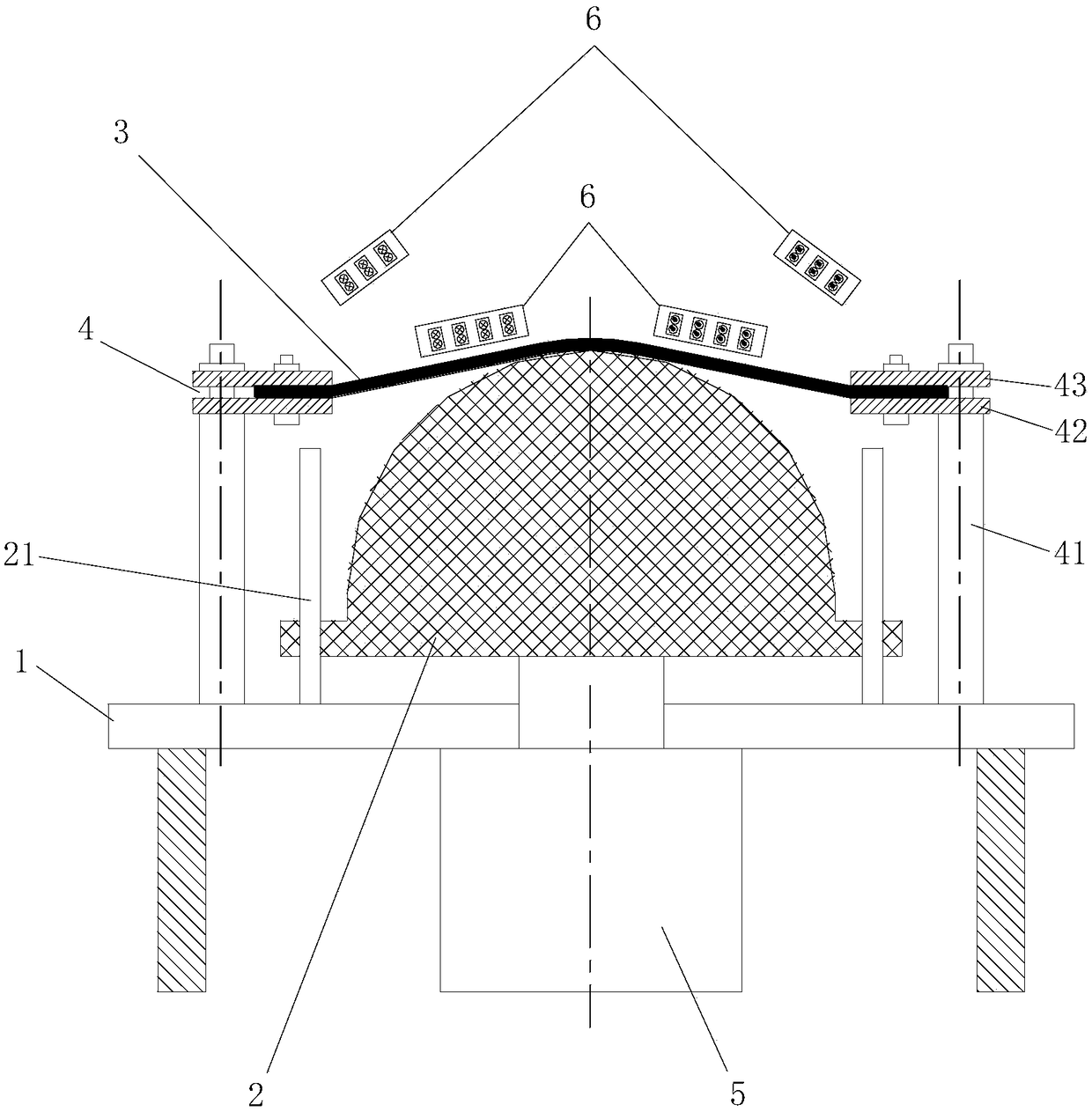

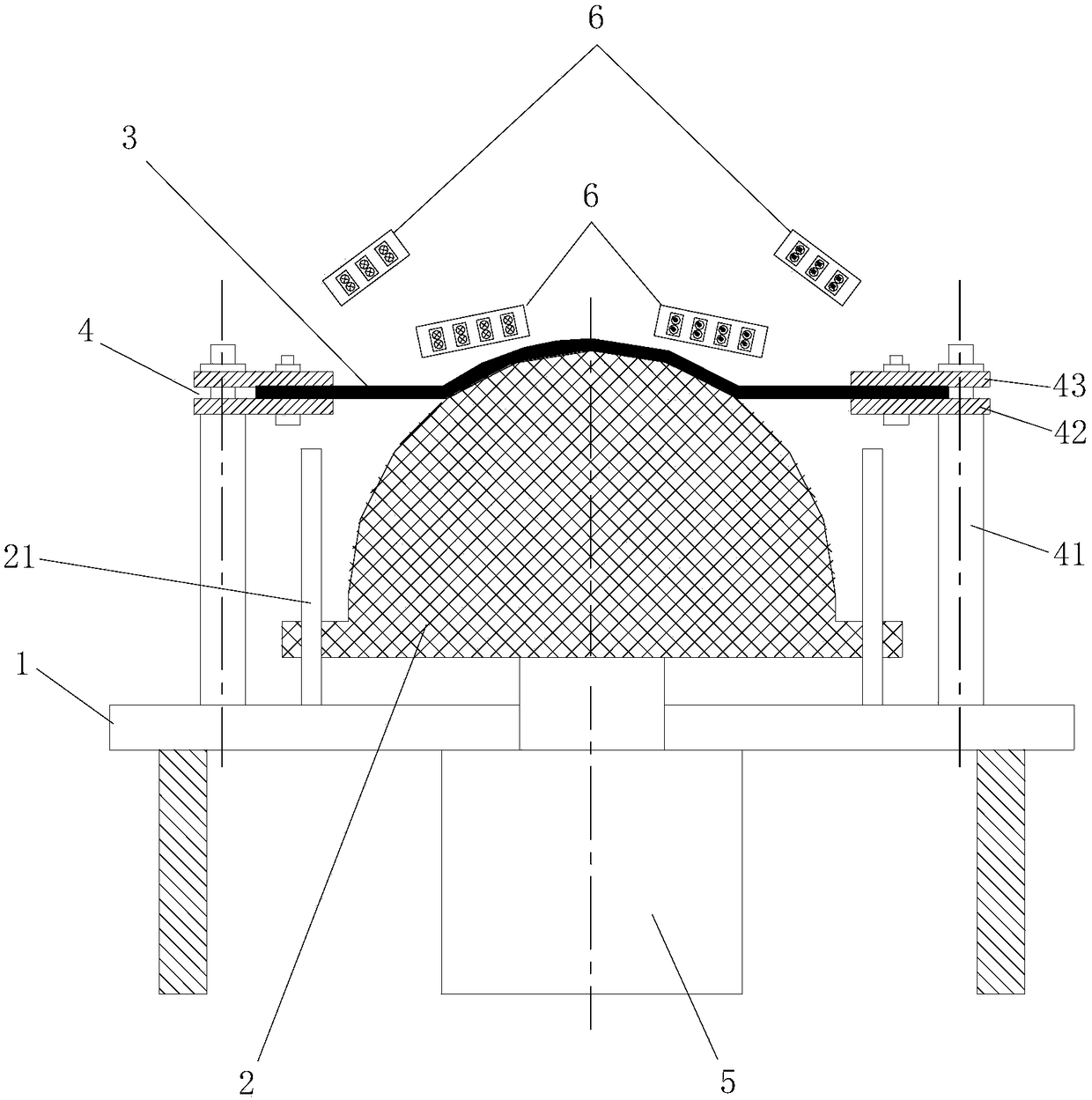

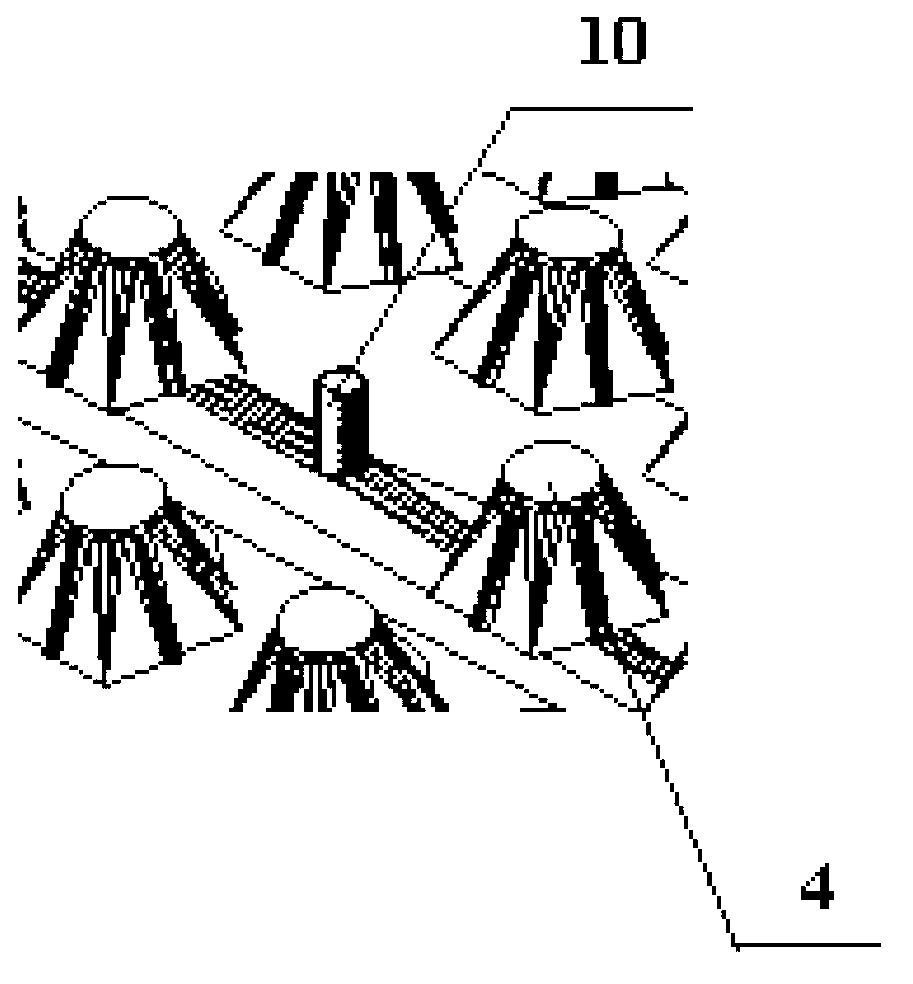

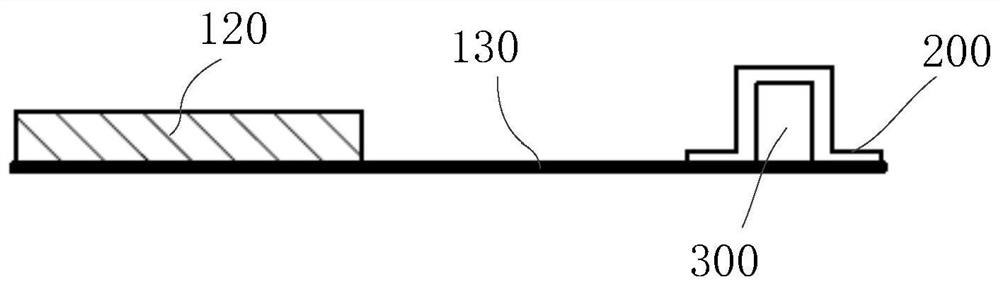

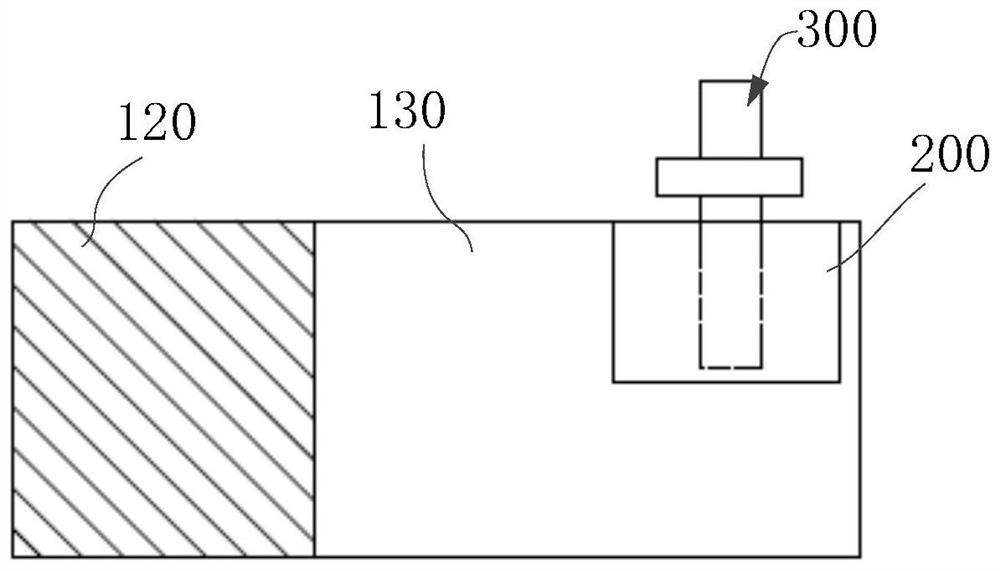

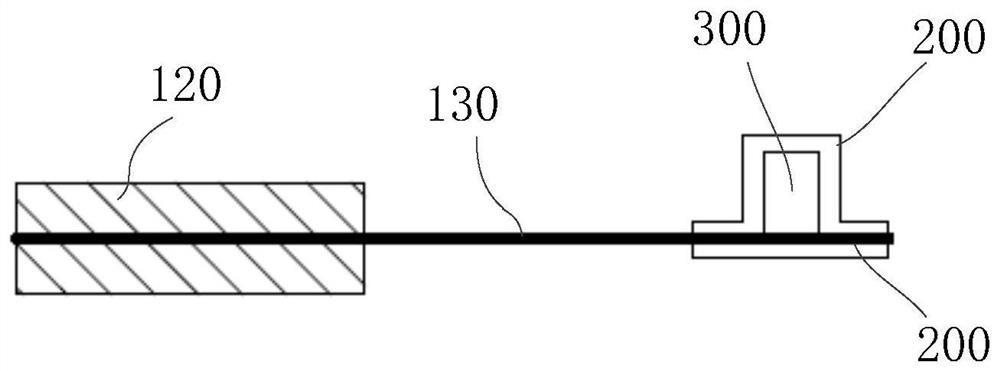

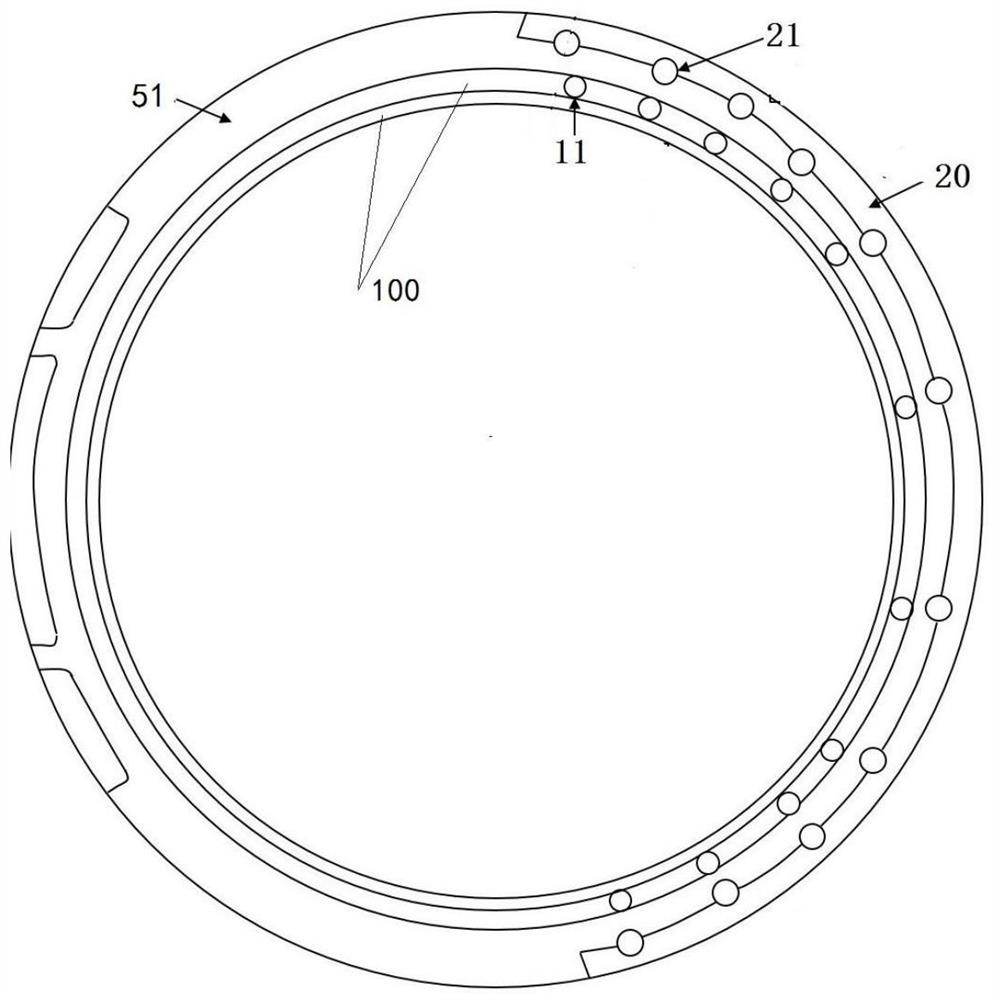

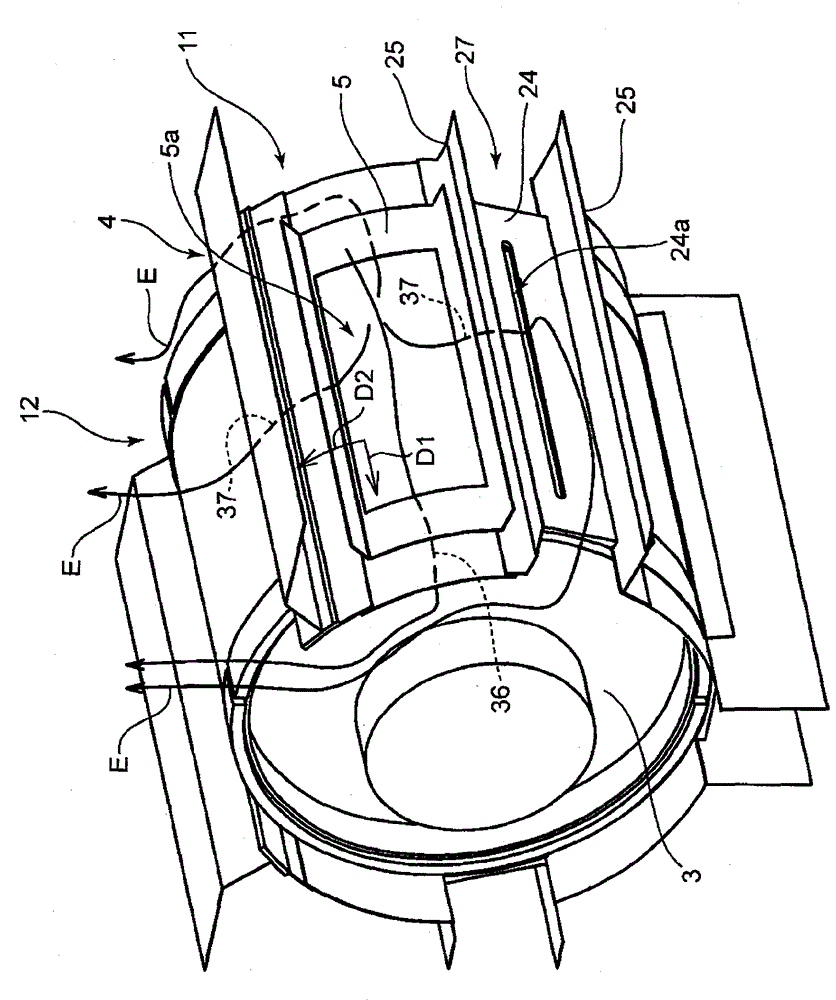

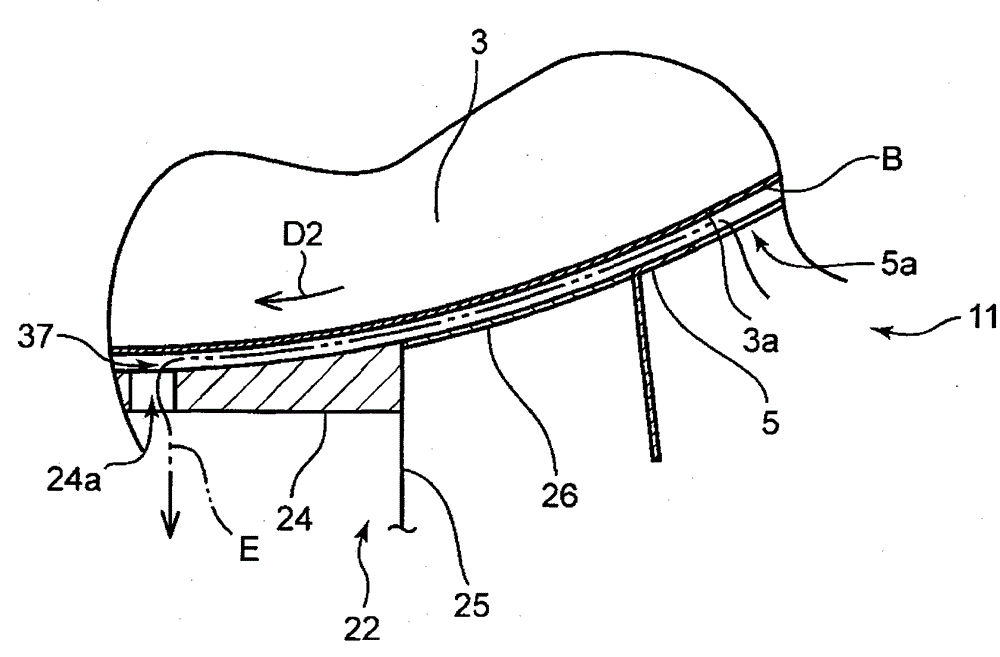

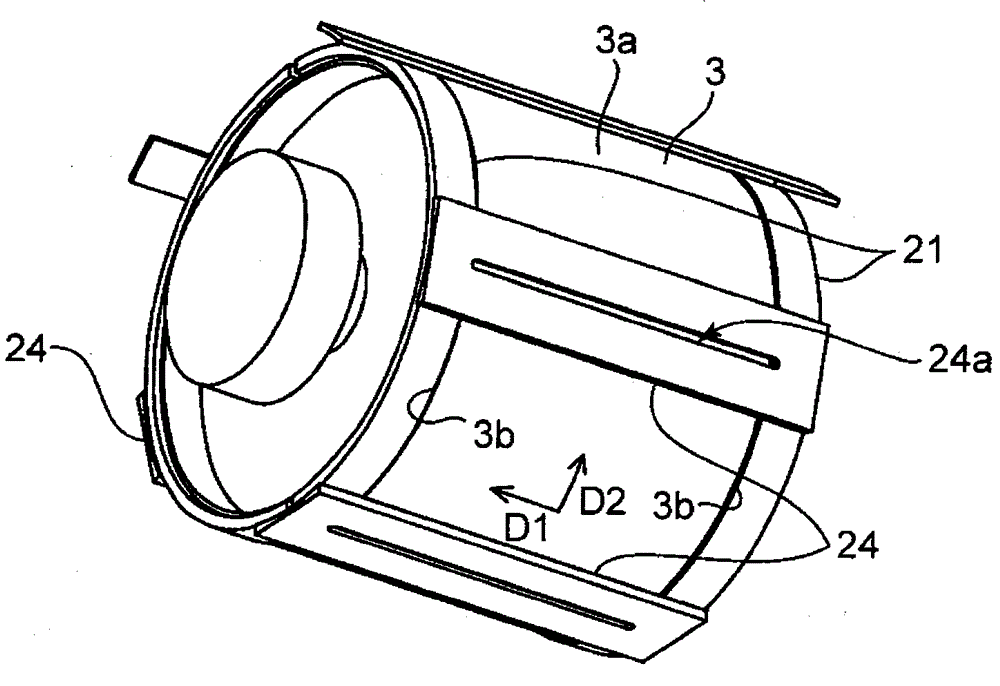

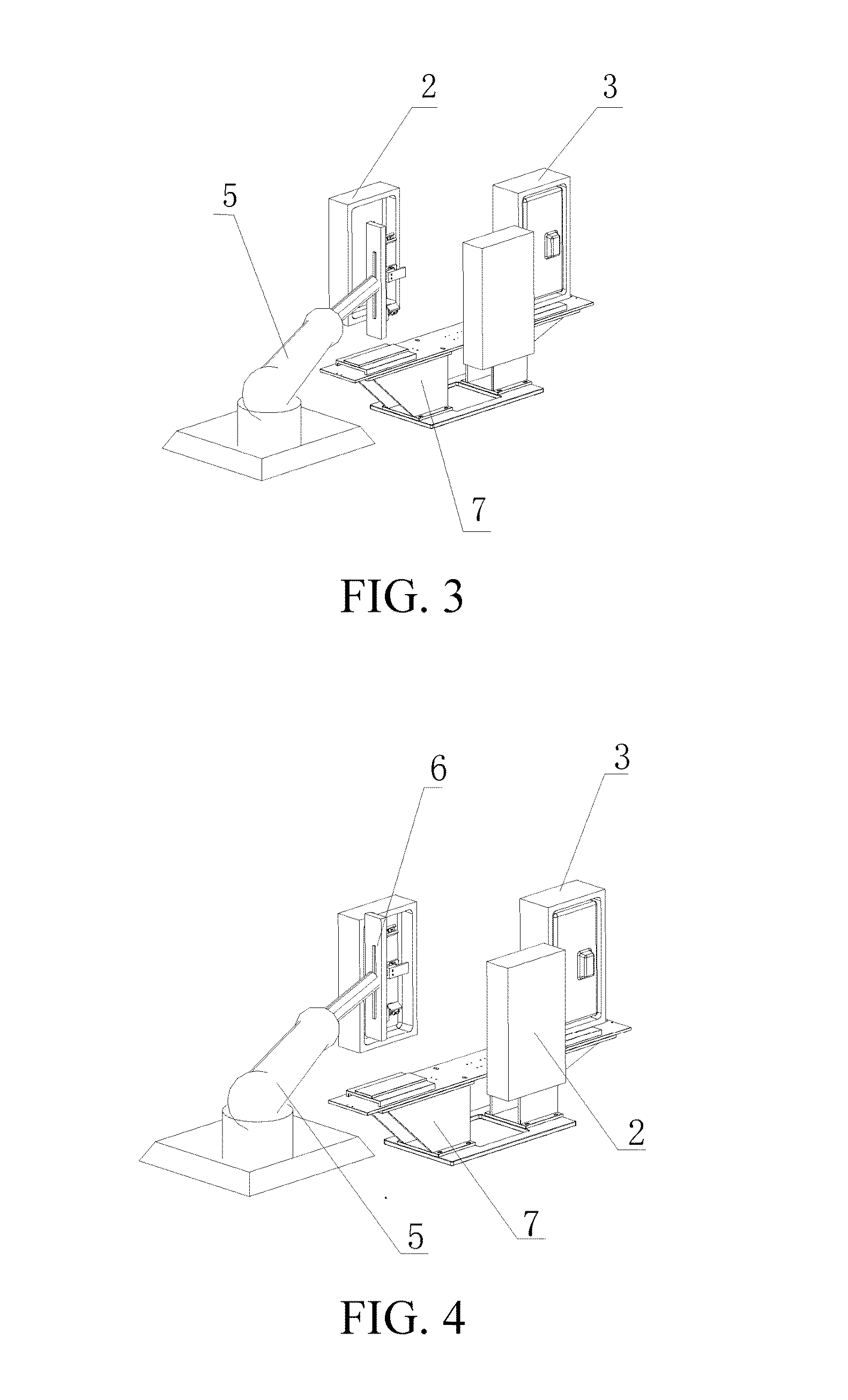

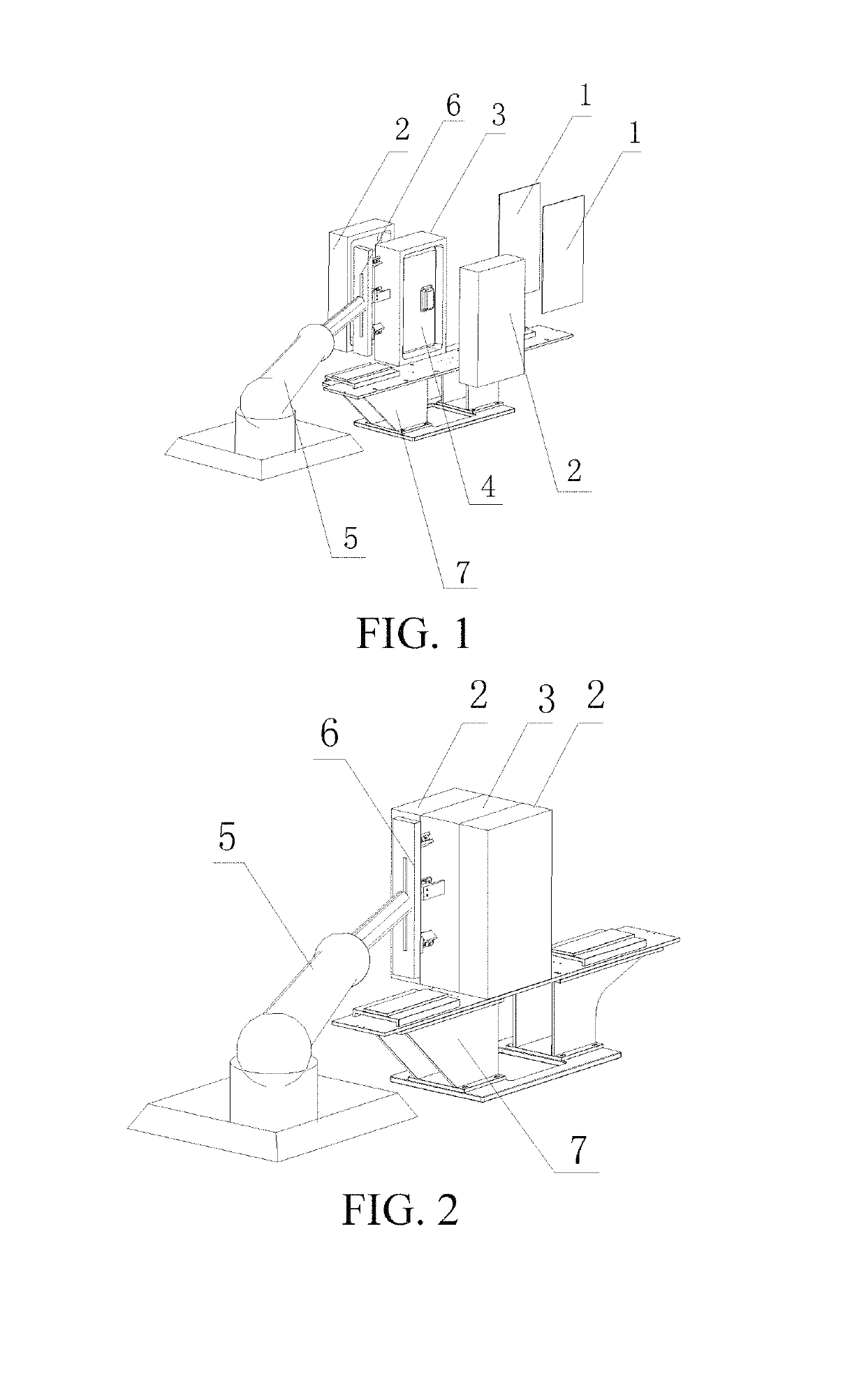

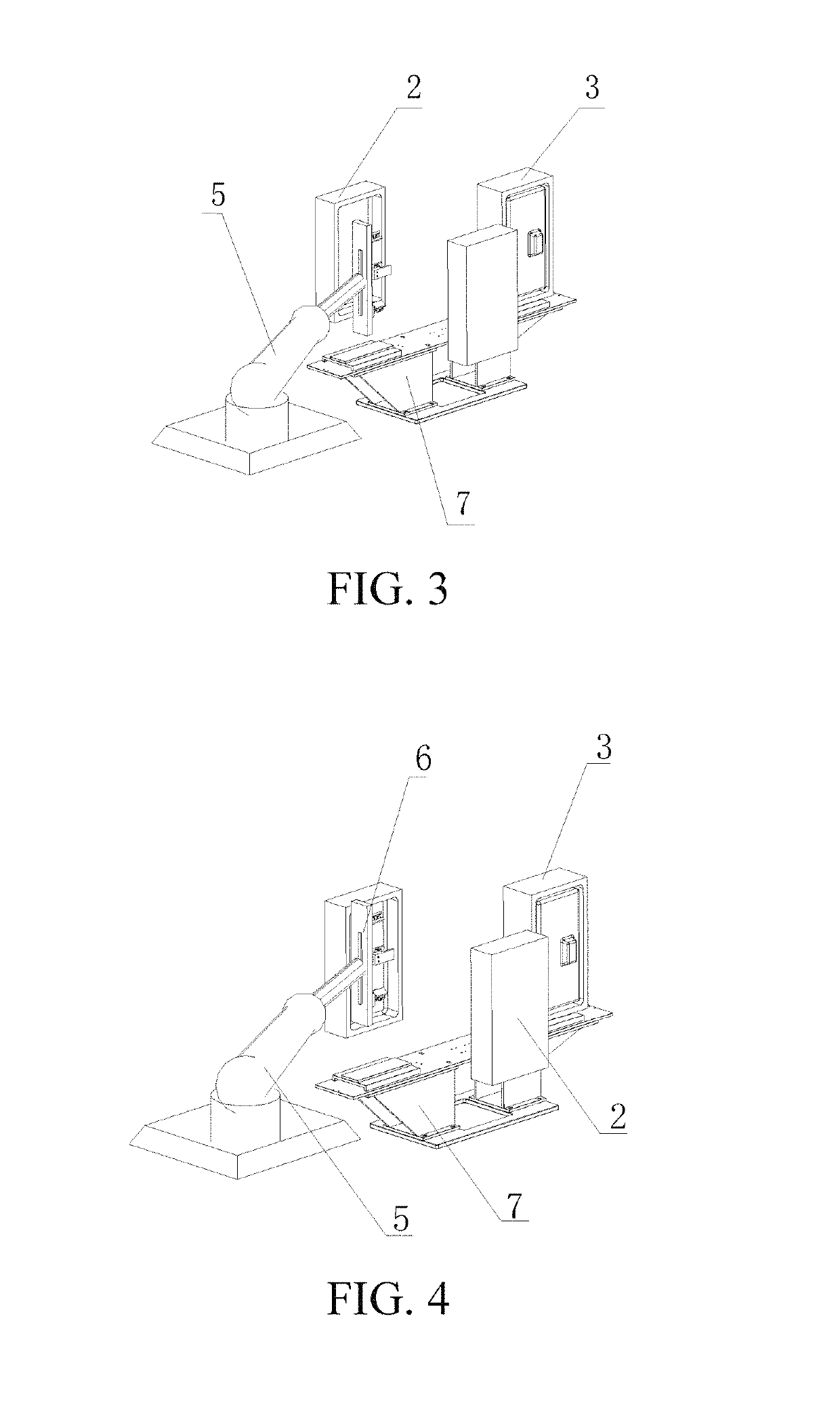

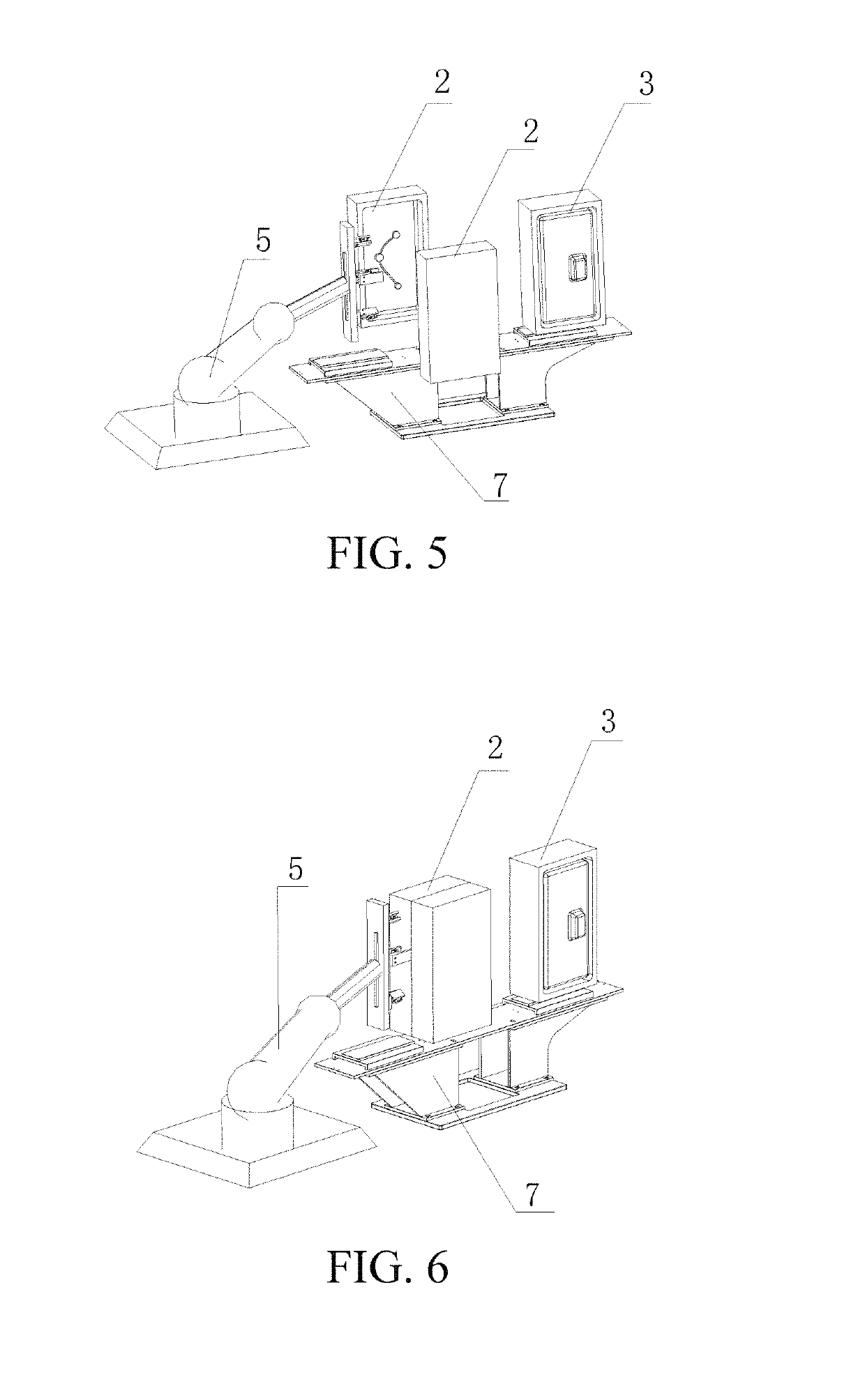

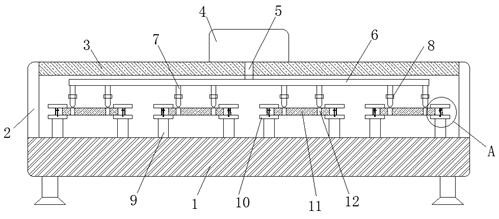

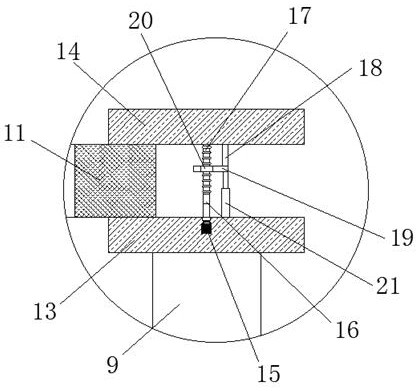

Workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and workpiece electromagnetic incremental forming method

ActiveCN108856444AGuaranteed forming qualityIncrease forming heightEngineeringElectromagnetic forming

The invention discloses a workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and further discloses a workpiece electromagnetic incremental forming method. The workpiece electromagnetic incremental forming device comprises a supporting frame, a mould, a plate, plate clamping assemblies for fixedly clamping the plate, and a driving piece for driving the mould to move so as to conduct stretch forming on the plate, and further comprises the multiple profile-followed arrangement coils. The plate clamping assemblies are arranged on the supporting frame; the plate is fixedly clamped between the plate clamping assemblies; the driving piece is connected with the mould; the profile-followed arrangement coils are arranged on the periphery of the surface of the plate subjected to stretch forming by the mould in a surrounding mode; and all the profile-followed arrangement coils are arranged on layers of different heights above the plate correspondingly. The workpiece electromagnetic incremental forming method comprises the steps of plate fixing, stretch forming of the plate, electromagnetic forming through the profile-followed arrangement coils and the like, and the plate and the mould are attached by repeatedly executing plate stretch forming and electromagnetic forming. The workpiece electromagnetic incremental forming device and methodhave the advantages of being high in forming precision, good in forming quality, high in efficiency, high in utilization rate of discharge energy, low in equipment energy demand and the like.

Owner:CENT SOUTH UNIV

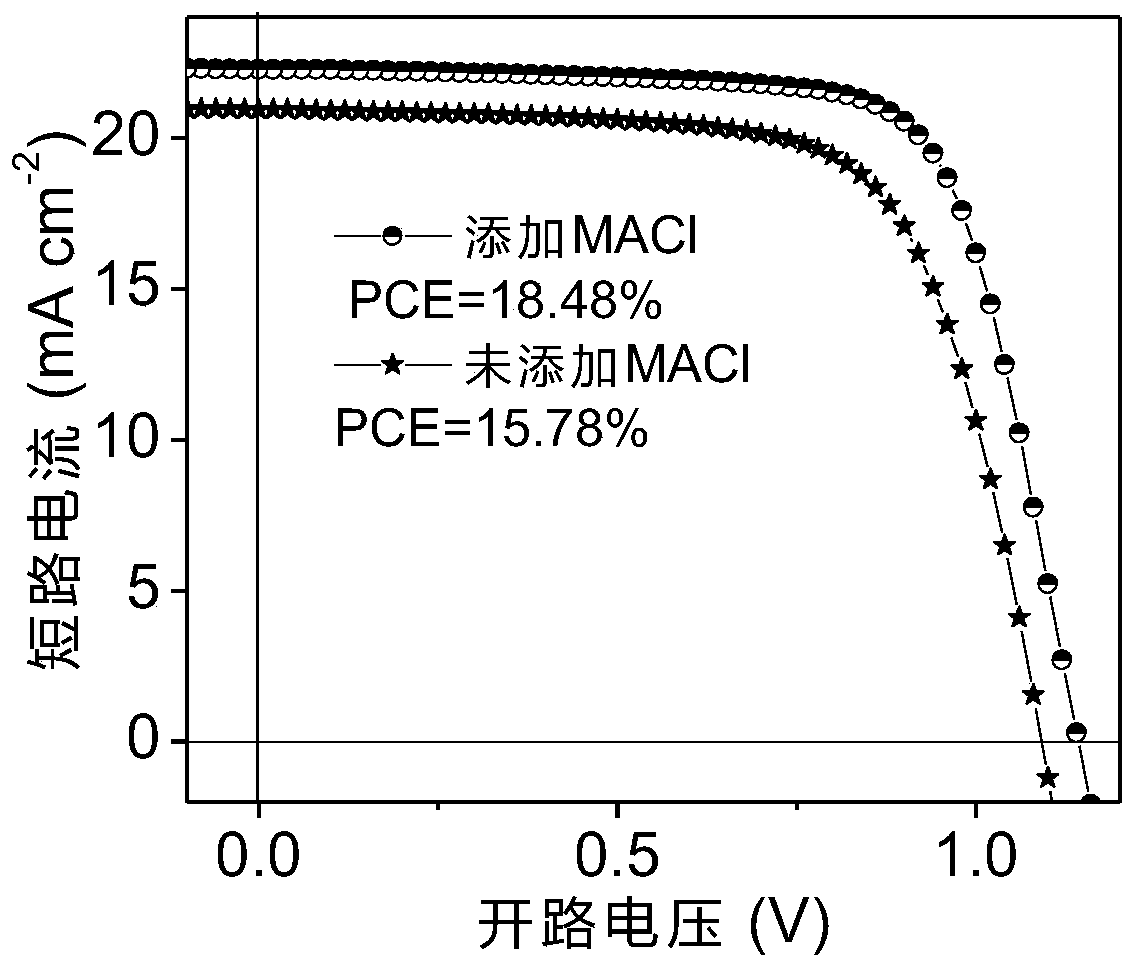

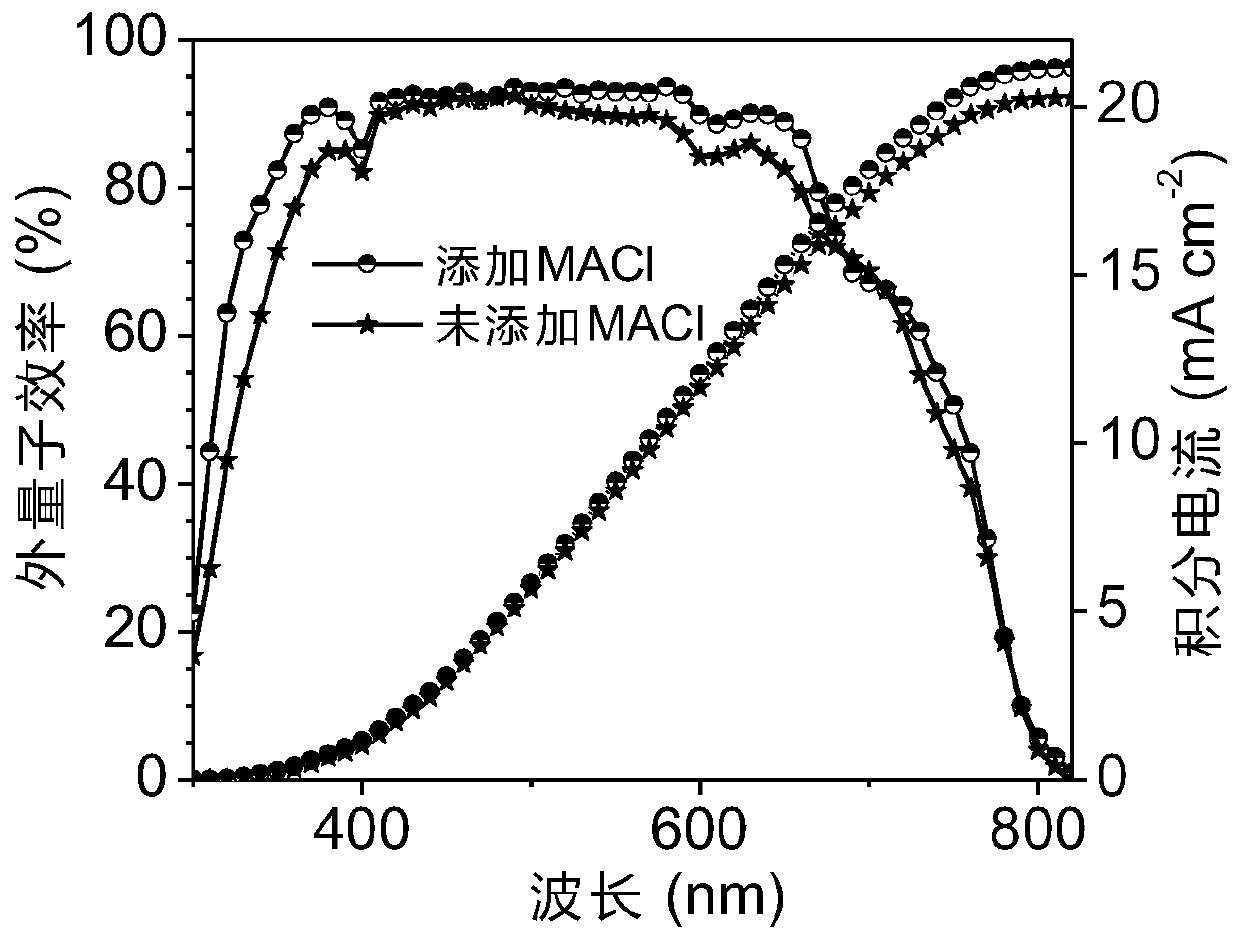

ACI type two-dimensional perovskite solar cell and preparation method thereof

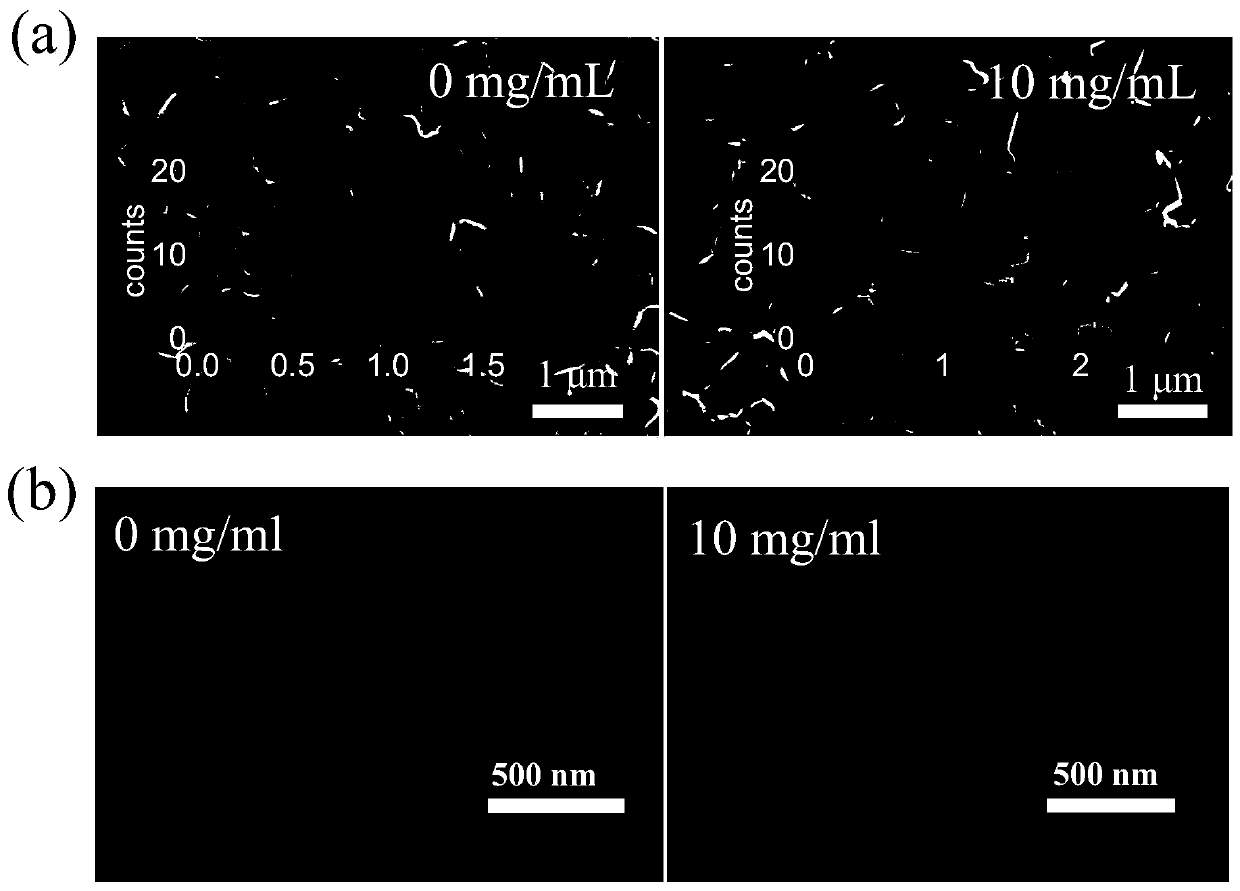

ActiveCN110518128ASlow crystallization rateExtended crystallization timeFinal product manufactureSolid-state devicesPerovskite solar cellGrain boundary

The invention discloses an ACI type two-dimensional perovskite solar cell and a preparation method thereof. The perovskite absorption layer of the solar cell is a mixture of C(NH2)3I, CH3NH3I and PbI2. In the preparation process, CH3NH3Cl is added to serve as an additive. Compared with the conventional two-dimensional perovskite device, the addition of CH3NH3Cl greatly improves the crystallizationquality of the perovskite thin film, increases the grain size, reduces the carrier recombination loss caused by defects at the grain boundary, and prolongs the carrier service life. Meanwhile, effective gradient distribution of different n values is increased, the charge transmission efficiency is improved, the improvement of the photoelectric conversion efficiency of the perovskite battery device is finally directly determined, the series-parallel resistance of the device is improved, and the photoelectric conversion efficiency of 18.48% is finally obtained. The excellent photoelectric properties and device efficiency of the perovskite solar cell are helpful for promoting the commercial application of the perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

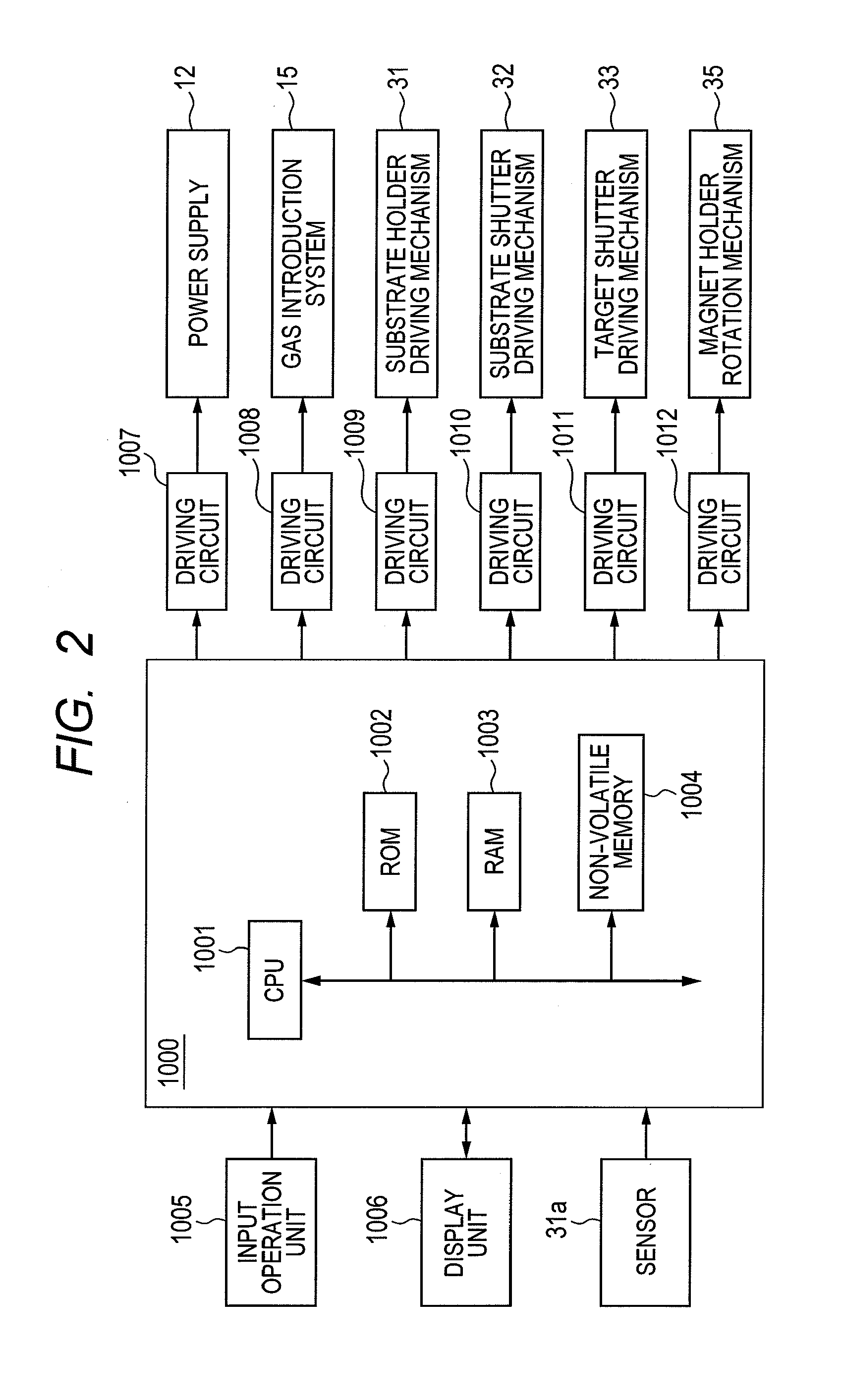

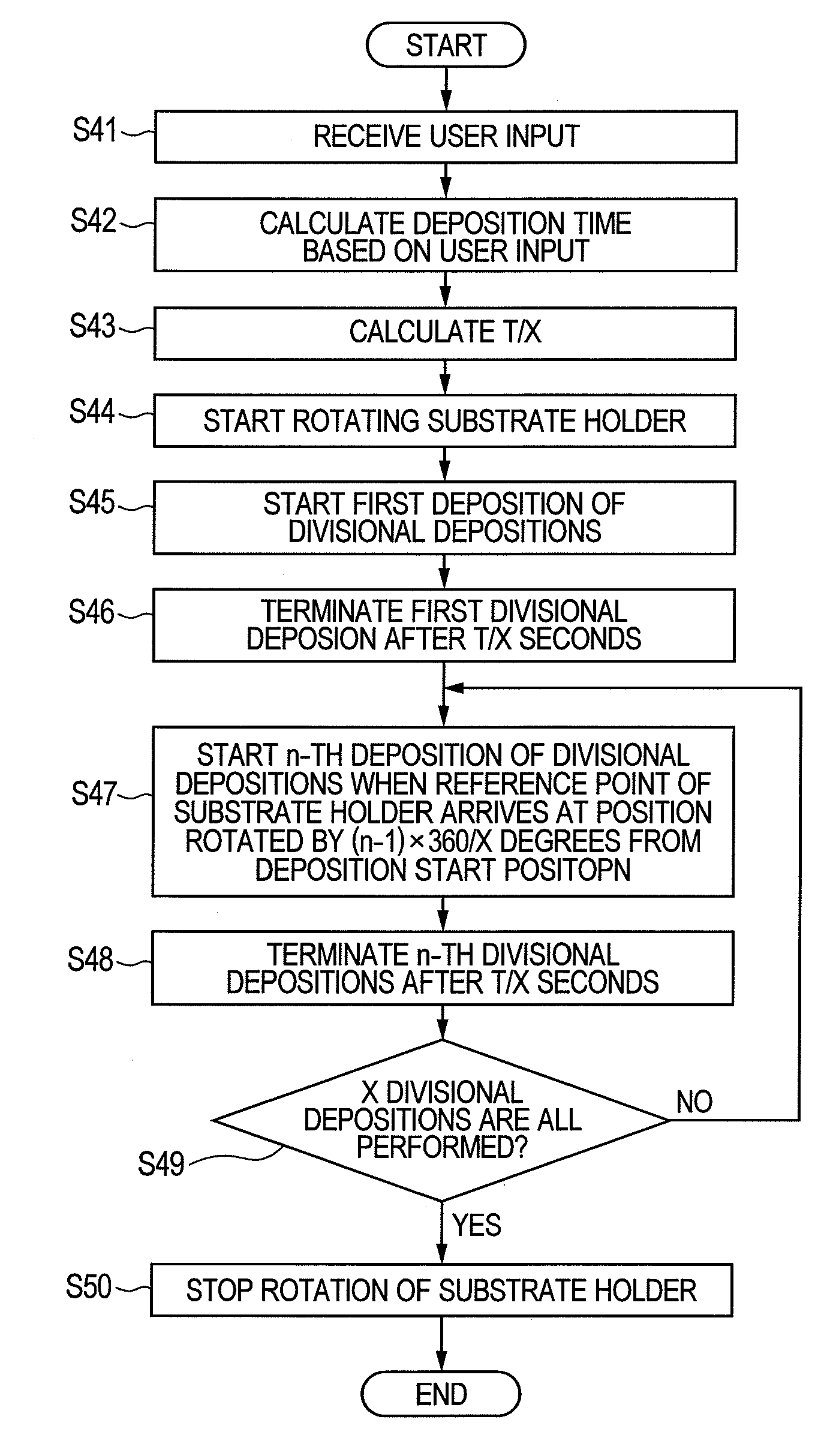

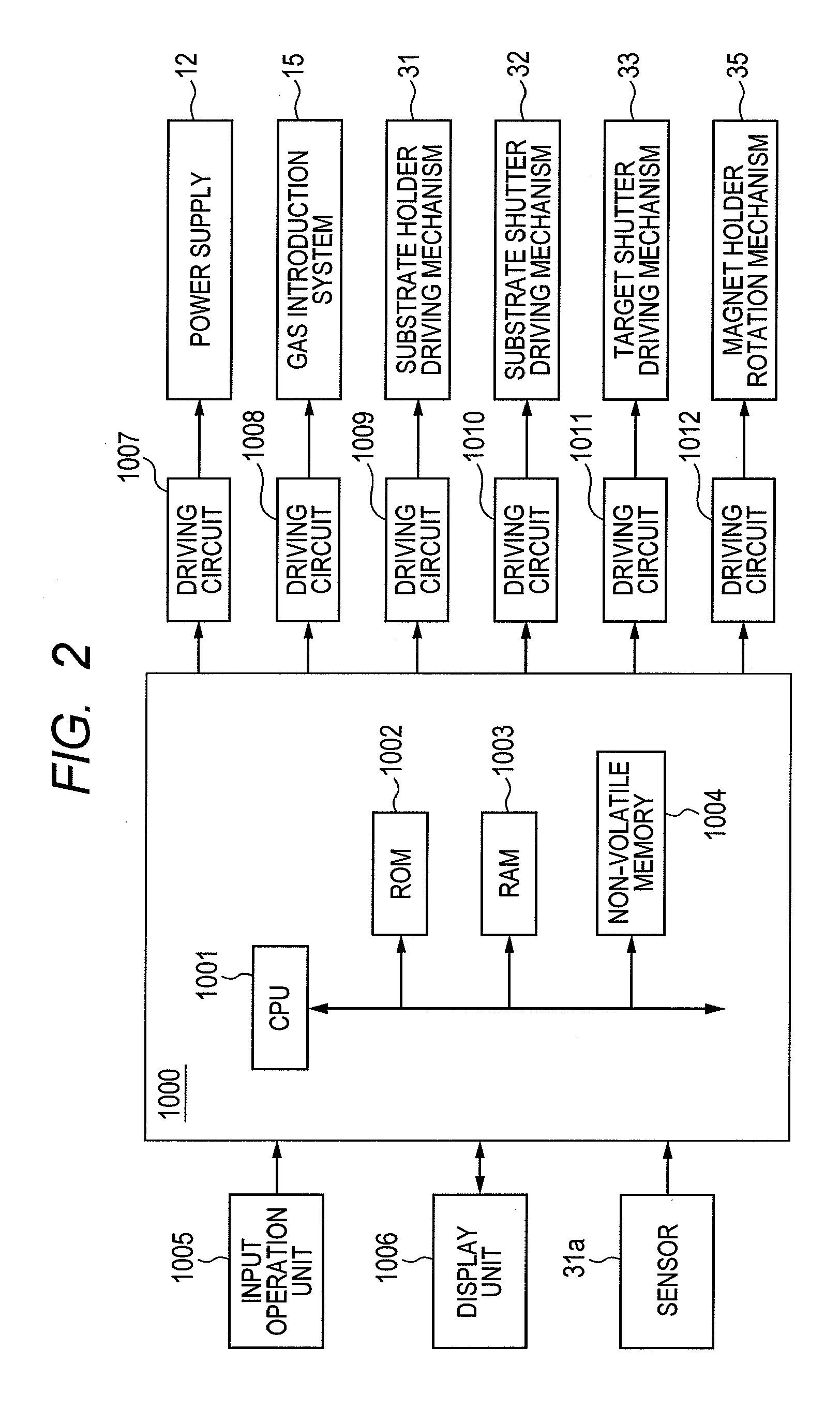

Sputter apparatus, control device for sputter apparatus and film formation method

ActiveUS20130161182A1Improved thickness distributionImprove distributionCellsVacuum evaporation coatingEngineeringMechanical engineering

In an embodiment of the present invention, the following operations are performed while a substrate holder is being rotated at a fixed rotation speed with plasma being generated. Specifically, a first state where a substrate holding surface of the substrate holder is exposed to a target holder is formed to start a first deposition of divisional depositions, and a second state where the surface is shut off from the target holder is formed in T / X seconds after the start of the first divisional deposition. Moreover, the first state is formed to start an n-th deposition of the divisional depositions when a reference point set on the substrate holder arrived at a position rotated by (n−1)×360 / X degrees from a position of the reference point located at the start of the targeted deposition, and the second state is formed in T / X seconds after the start of the n-th divisional deposition.

Owner:CANON ANELVA CORP

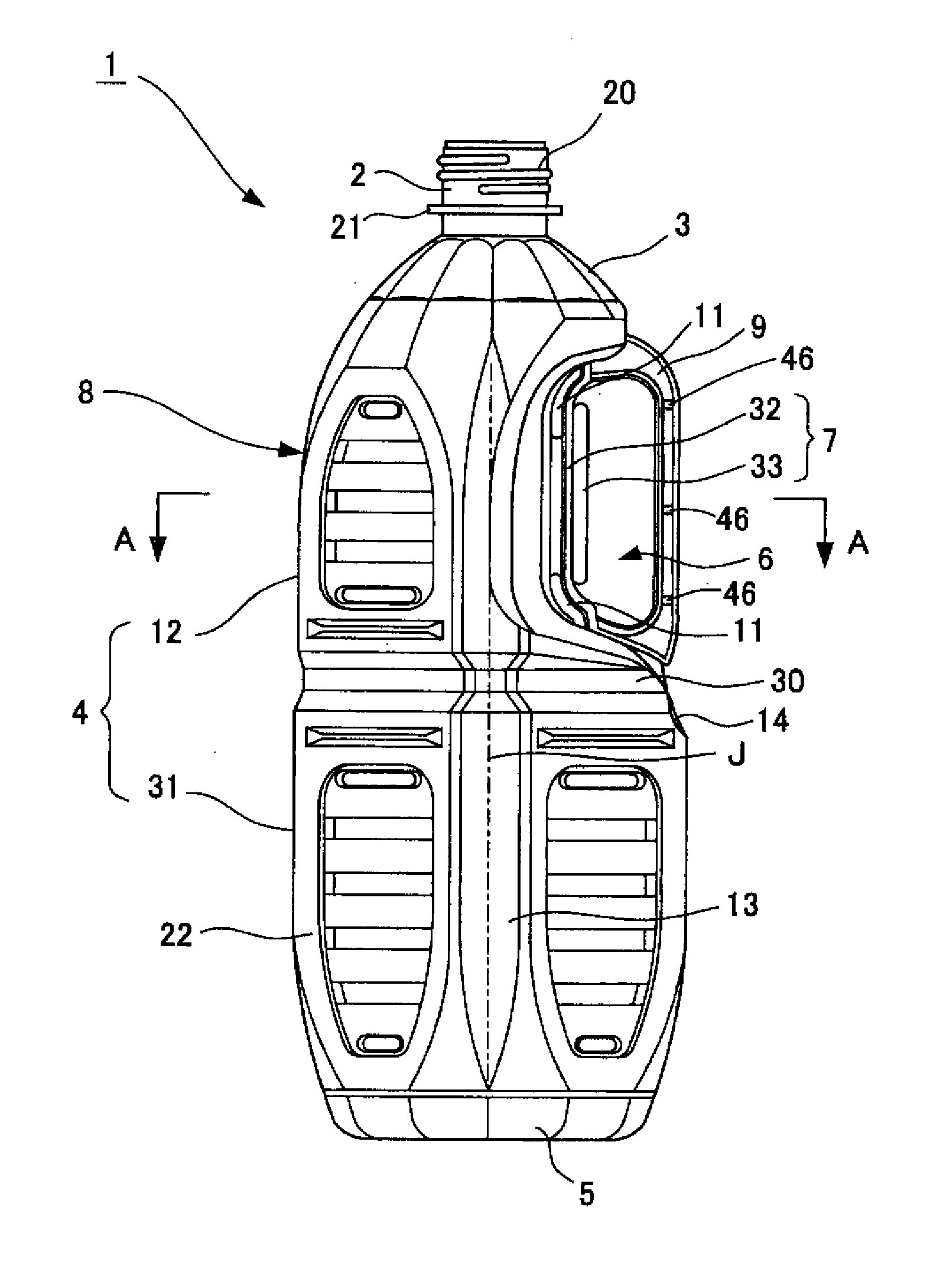

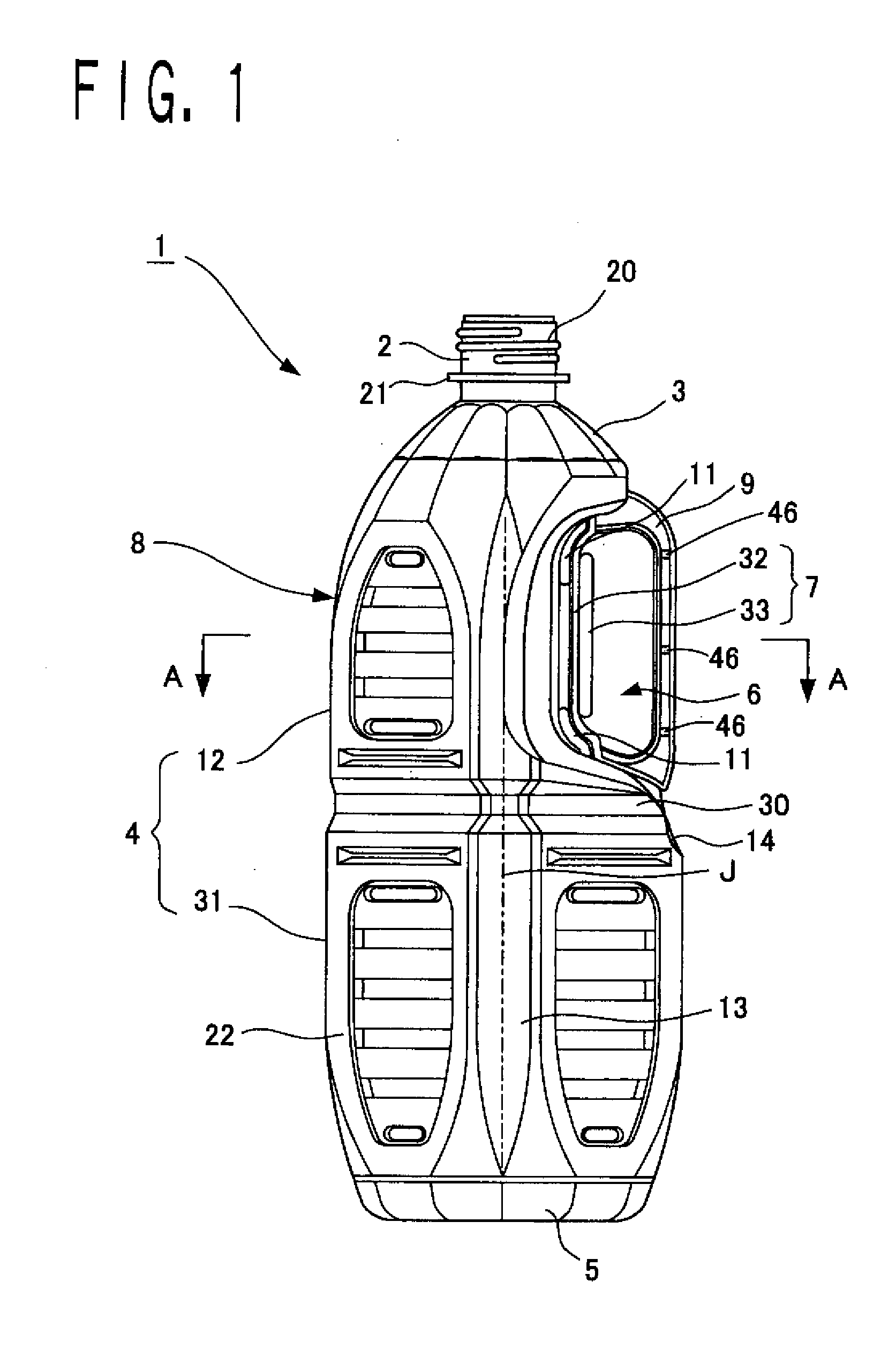

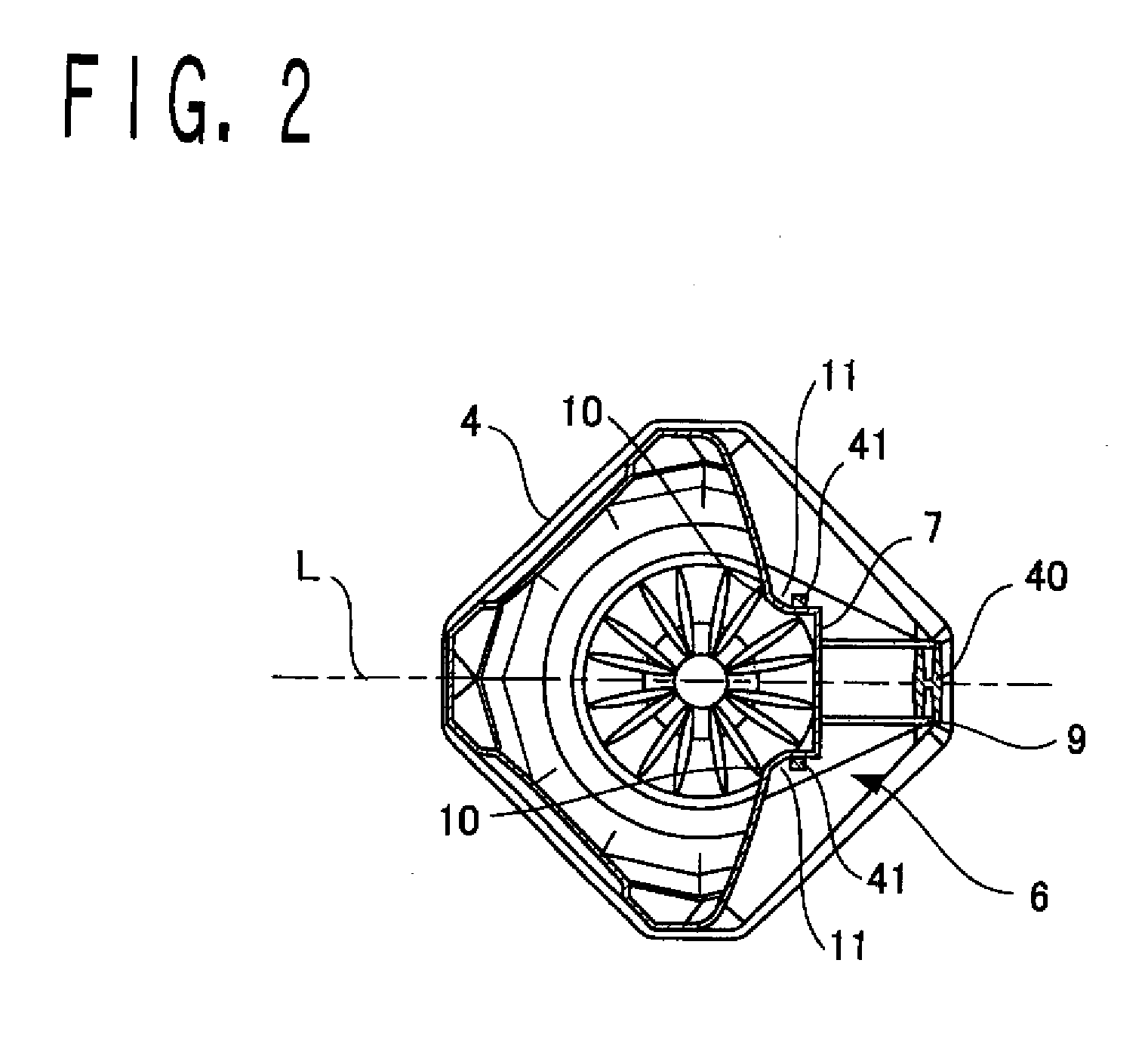

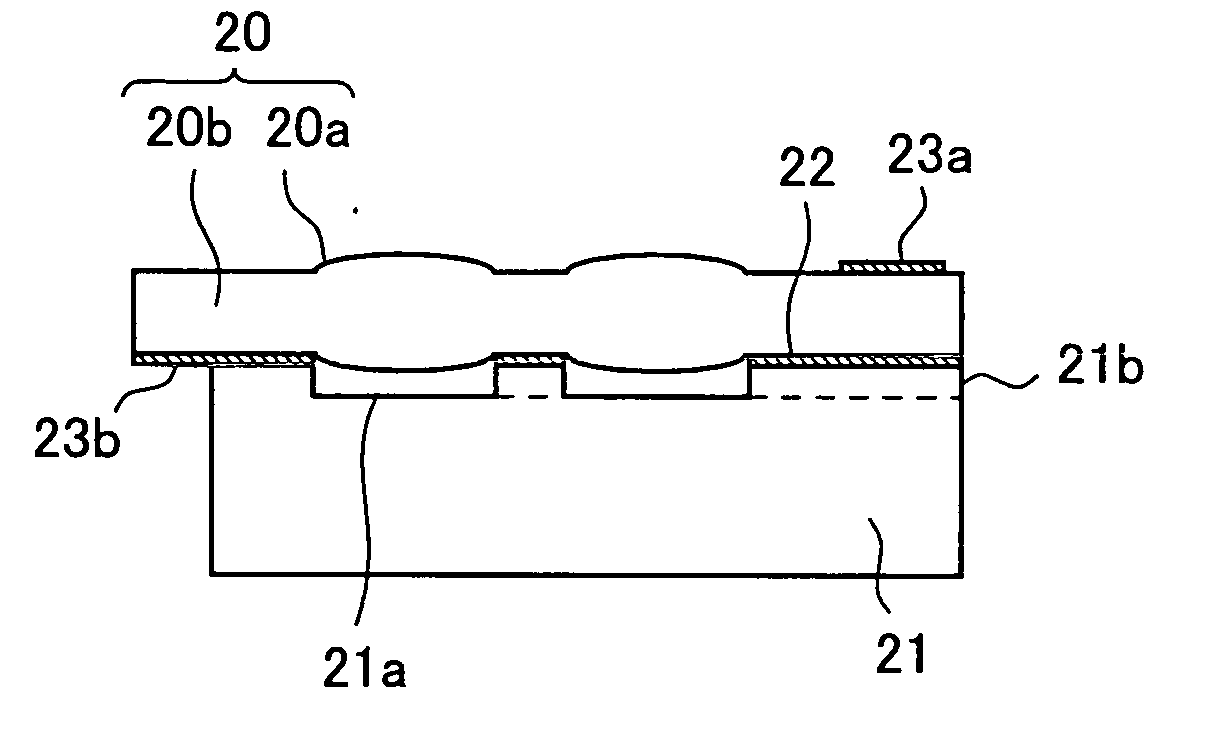

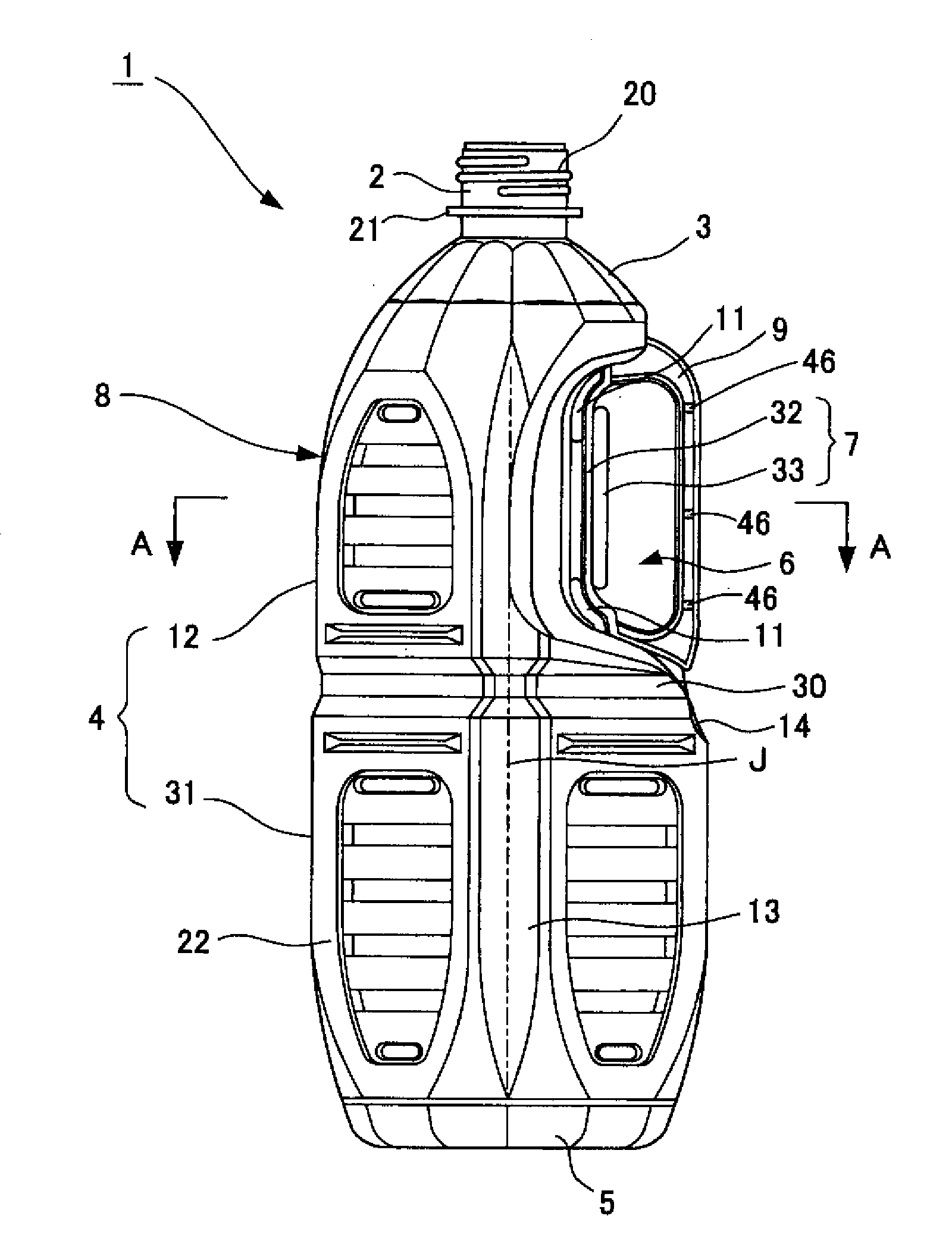

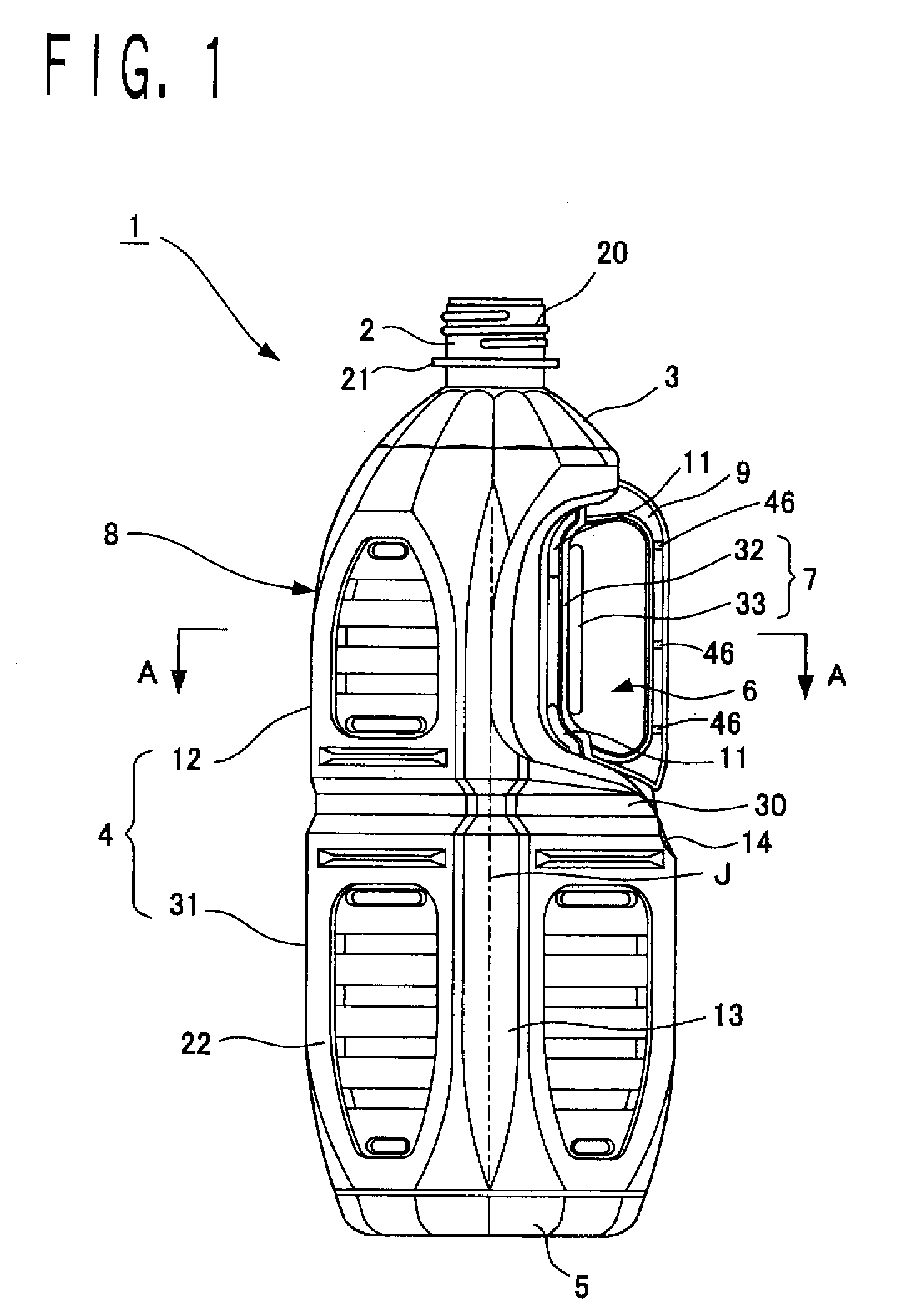

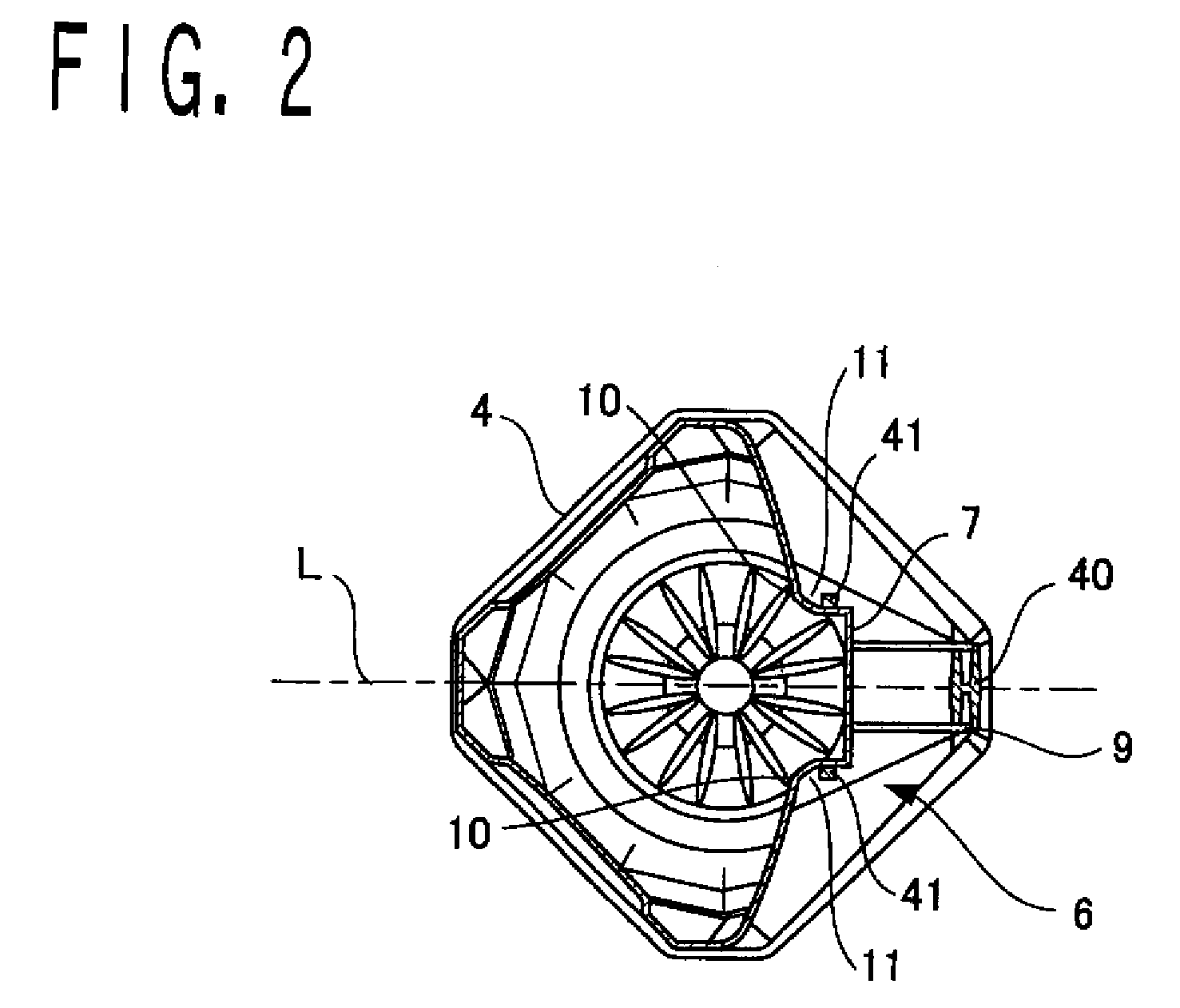

Handle for container, handle-equipped container, and method for manufacturing handle and container

InactiveUS20100187246A1Improve storabilityImprove propertiesBottlesCeramic shaping apparatusBlow moldingPolyester

The present invention provides a handle for a container, a handle-equipped container, and a method for manufacturing same. It is accordingly possible to provide a container that has a cross-sectional shape that is substantially quadrangular and allows for exceptional storability, has favorable blow-molding properties, presents none of a variety of anomalies in the container and the handle, and has adequate strength to withstand drop impact.The present invention is characterized in comprising a polyester container, which has a finish part, a shoulder part, a body part, and a base part in the stated order from a top part; which has a concavity provided to a portion of the body part; and which has a handle-attaching convexity provided to the concavity; and a polyester handle attached to the handle-attaching convexity of the container. A space is provided between the handle and a wall surface that surrounds the handle-attaching convexity in the concavity. A transverse cross-sectional shape of the body part has a substantially quadrangular shape. The concavity is in a corner part of an upper half part of the body part, and the handle-attaching convexity is positioned in a concavity along a diagonal line L of the upper half part.

Owner:TOYO SEIKAN KAISHA LTD

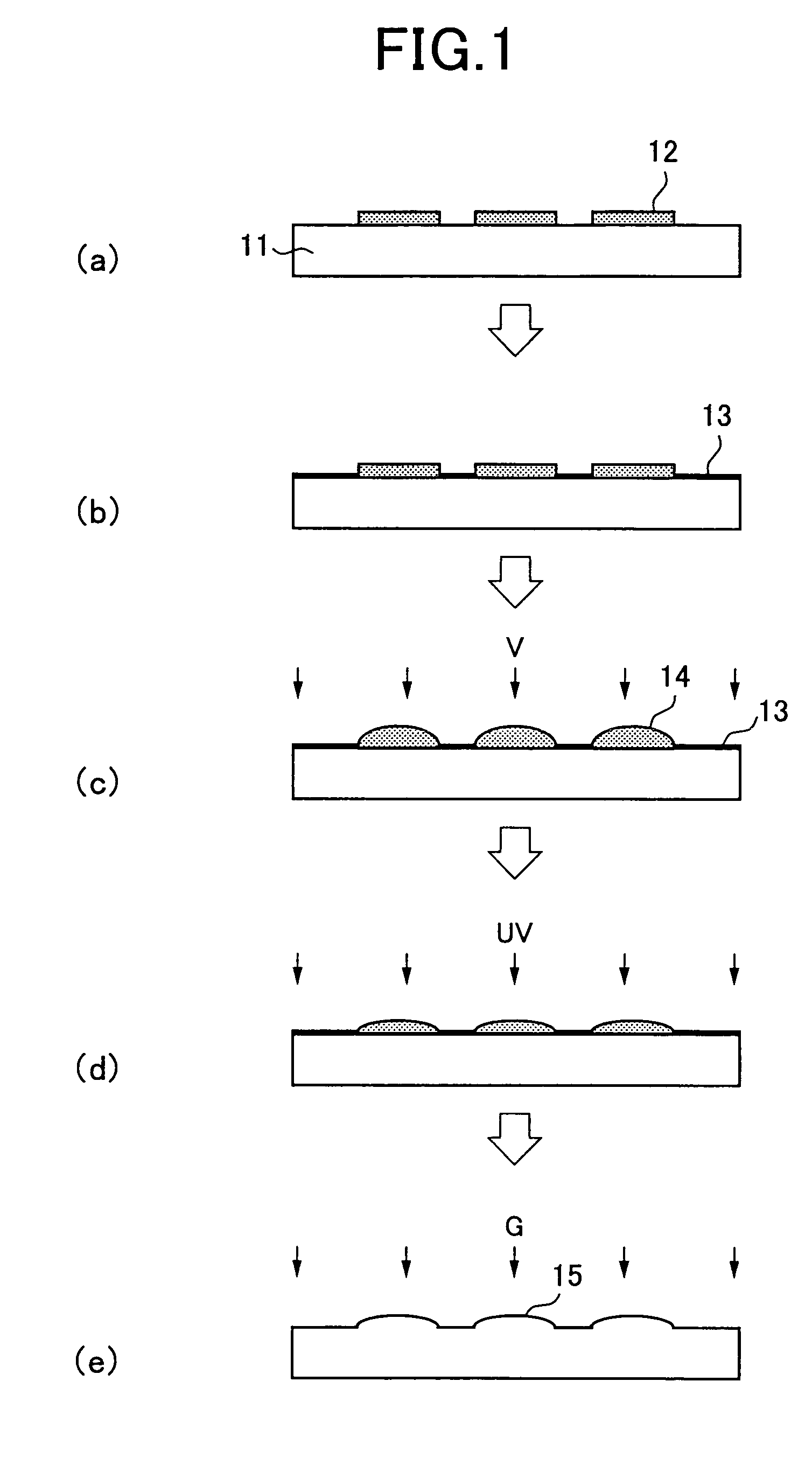

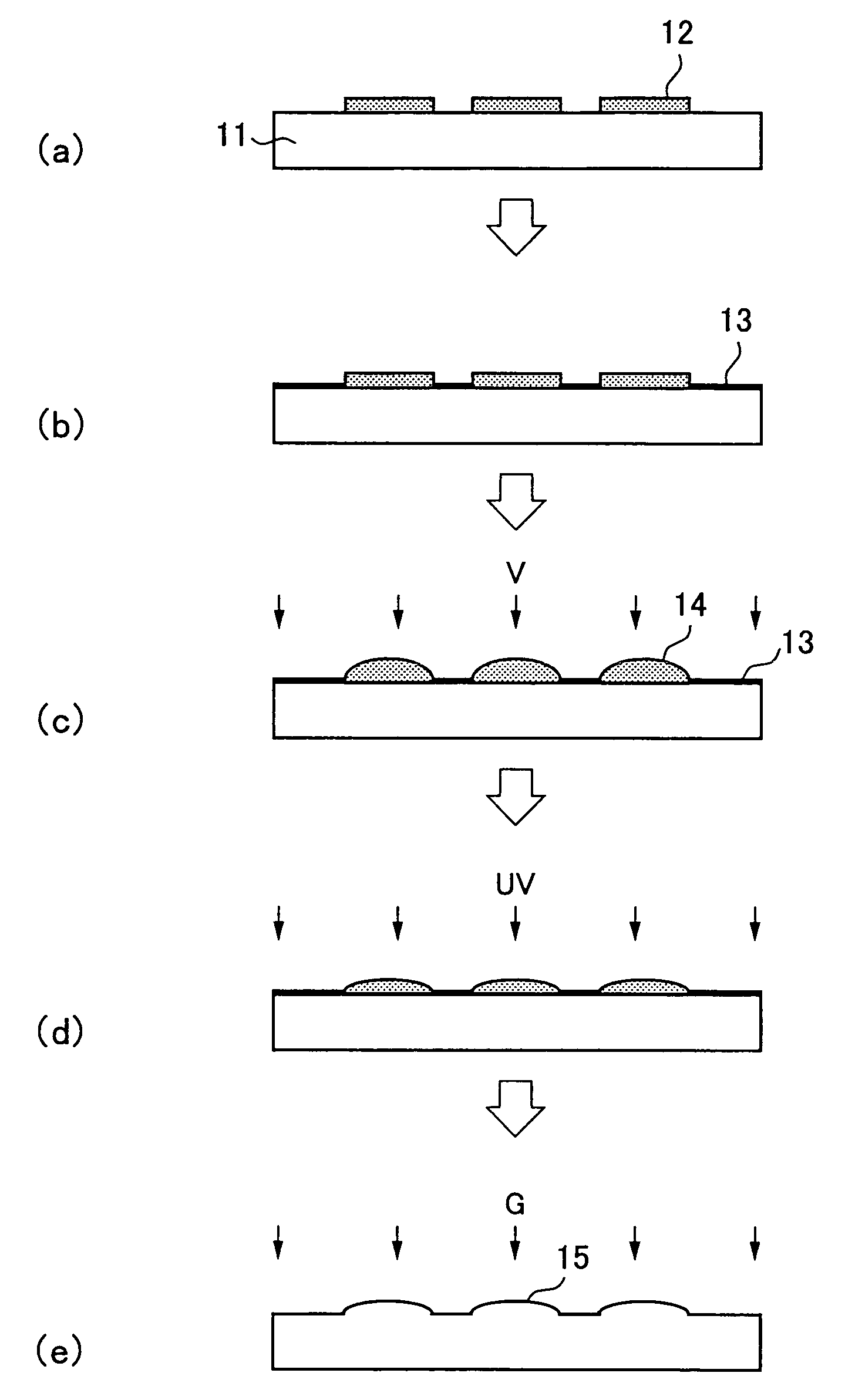

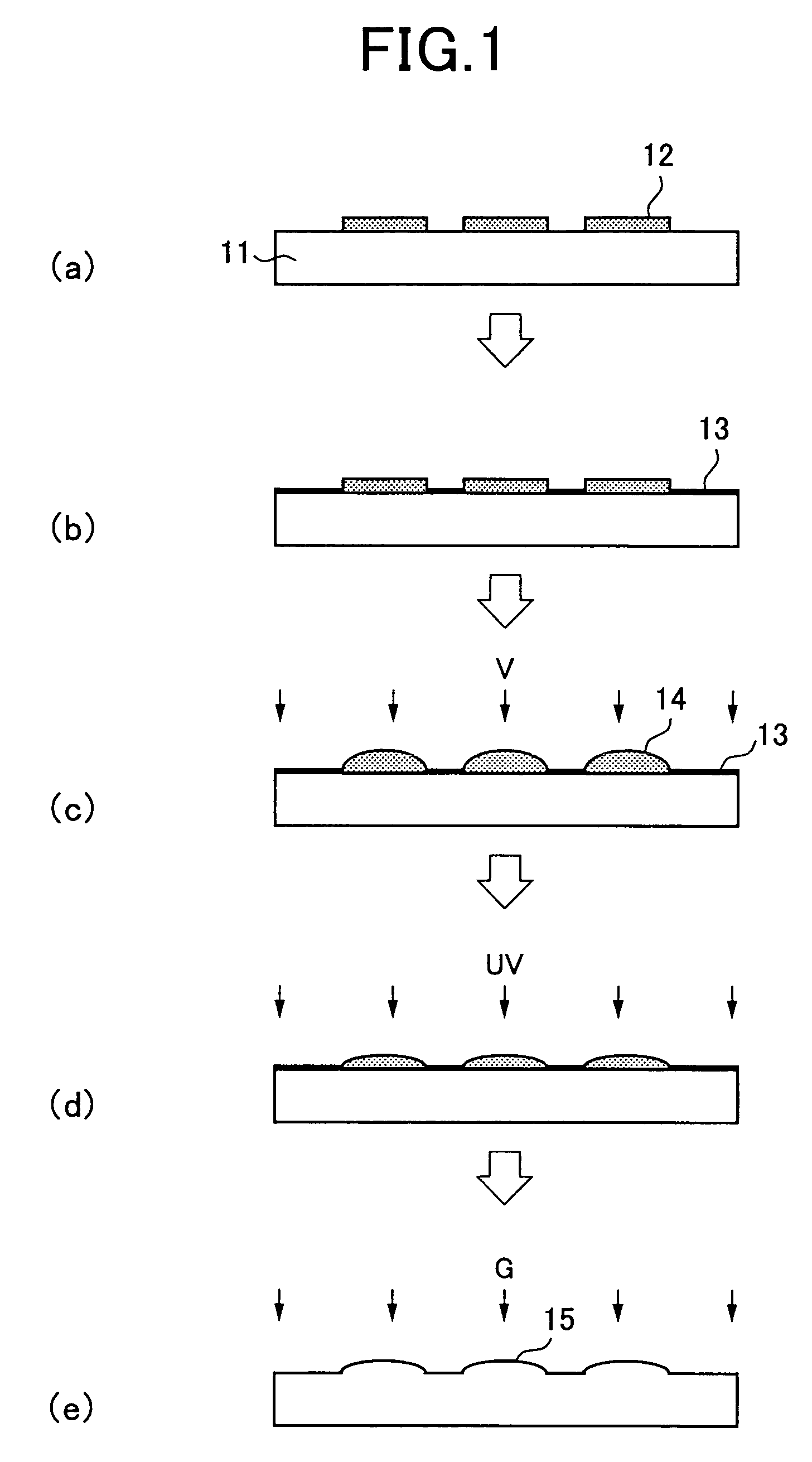

Method for fabricating piezoelectric element

InactiveUS20070130739A1Effective controlEasily impartedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesSolvent vaporSpurious oscillations

A masking agent is applied as a patterned film 12 to a surface of piezoelectric material 11 to be processed, fluidized by contact with a solvent vapor V and dressed to a domed mask 14 by its surface tension. When the piezoelectric material is dry etched together with the domed mask 14, its surface is processed to a convex profile corresponding to thickness distribution of the domed mask 14. Distribution and shape of the domed mask 14 is controlled by treating the piezoelectric material 11 with an oil repellant 13 so as to limit reflow of the masking agent to a specified region(s). The processed piezoelectric material has a surface profile with a big mass at its center suitable for principal oscillation without spurious oscillation.

Owner:JAPAN SCI & TECH CORP

Method for producing piston rings

Owner:FEDERAL MOGUL BURSCHEID

Handle for container, handle-equipped container, and method for manufacturing handle and container

InactiveUS8261932B2Improve storabilityImprove propertiesBottlesLarge containersBlow moldingPolyester

The present invention provides a handle for a container, a handle-equipped container, and a method for manufacturing same. It is accordingly possible to provide a container that has a cross-sectional shape that is substantially quadrangular and allows for exceptional storability, has favorable blow-molding properties, presents none of a variety of anomalies in the container and the handle, and has adequate strength to withstand drop impact.The present invention is characterized in comprising a polyester container, which has a finish part, a shoulder part, a body part, and a base part in the stated order from a top part; which has a concavity provided to a portion of the body part; and which has a handle-attaching convexity provided to the concavity; and a polyester handle attached to the handle-attaching convexity of the container. A space is provided between the handle and a wall surface that surrounds the handle-attaching convexity in the concavity. A transverse cross-sectional shape of the body part has a substantially quadrangular shape. The concavity is in a corner part of an upper half part of the body part, and the handle-attaching convexity is positioned in a concavity along a diagonal line L of the upper half part.

Owner:TOYO SEIKAN KAISHA LTD

Method for fabricating piezoelectric element

InactiveUS7770273B2Effective controlEasily impartedPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksInert gas dilutionSolvent

A piezoelectric element is manufactured by applying a masking agent to a surface of a piezoelectric material to form a film of the masking agent on the surface of the piezoelectric material. The film of the masking agent is patterned into a masking pattern. Oil repellent is selectively applied to surface portions of the substrate which are not covered with the patterned film. The patterned film is held in contact with a vapor of a solvent for the masking agent, diluted with an inert gas, to fluidize the film to a domed shape on the surface of the piezoelectric material. The diluted vapor is formed by bubbling the solvent with the inert gas. The dome-shaped film is then cured and the piezoelectric material is dry etched together with the cured film to process the piezoelectric material into a three-dimensional convex profile corresponding to the thickness distribution of the domed shape.

Owner:JAPAN SCI & TECH CORP

Multi-layer preliminary formed body and method of manufacturing the formed body

InactiveUS7344673B2Good moldabilityIncrease productivityOther chemical processesLaminationBulk fillEngineering

Owner:TEIJIN LTD +1

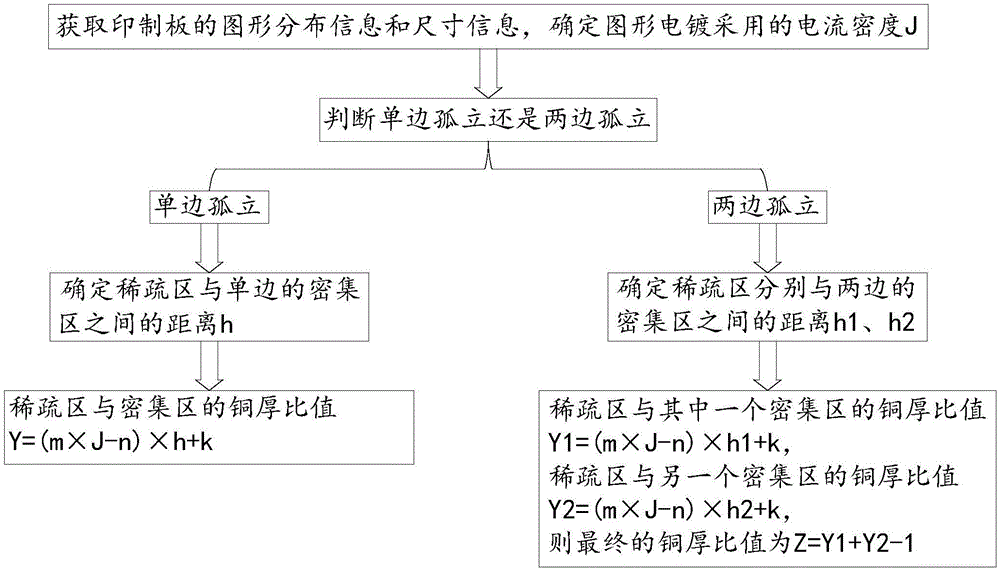

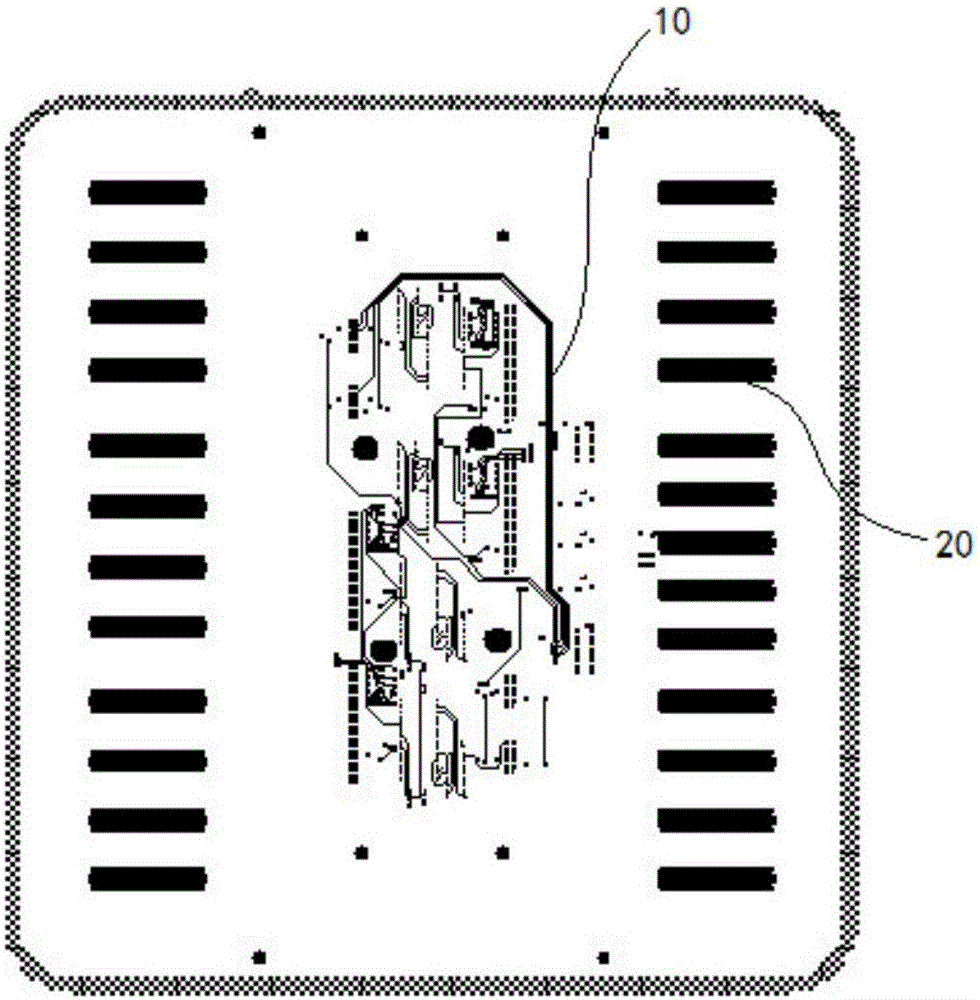

Method for predicting copper thickness ratio of sparse area to dense area in pattern plating

ActiveCN106599518AQuality assuranceReduce scrap ratePrinted circuit manufactureCAD circuit designPrediction methodsElectroplating

The invention relates to a method for predicting a copper thickness ratio of a sparse area to a dense area in pattern plating. The method comprises the following steps: (1) determining a current density J adopted for pattern plating; and (2) selecting a sparse area and a dense area to be monitored, if another dense area is distributed on one side, which is back to the selected dense area, of the sparse area, executing a step a, otherwise, executing a step b; a, determining distances between the sparse area and the two dense areas as h1 and h2 respectively, so that a copper thickness ratio of the sparse area to one of the dense areas is Y1=(mxJ-n)xh1+k, a copper thickness ratio of the sparse area to the other dense area is Y2=(mxJ-n)xh2+k, and a final copper thickness ratio is Z=Y1+Y2-1; b, determining a distance between the sparse area and the dense area as h, so that a copper thickness ratio of the sparse area to the dense area is Y=(mxJ-n)xh+k. Through adoption of the method, the copper thickness ratio of the sparse area to each dense area in pattern plating is predicted according to the current density in pattern plating and the distance between the sparse area and each dense area, so that the pattern plating is monitored in an actual production process, and the quality of a product is ensured.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Ultra-low pressure liquid filling forming system and method for special-shaped component

PendingUS20220055086A1Improve performance and forming precisionImprove efficiencySoldering apparatusPhysicsEngineering

The present disclosure discloses an ultra-low pressure liquid filling forming system for a special-shaped component, including a control system, a supercharger, a driving device, a preforming unit, and a final forming unit. The present disclosure further provides an ultra-low pressure liquid filling forming method for a special-shaped component, including the following steps: S1: making an equal diameter cylindrical coil blank with an overlapping part in a longitudinal direction by using a plate blank; S2: bulging the equal diameter cylindrical coil blank into a variable diameter cylindrical prefabricated coil blank; S3: cutting and welding the overlapping part remaining on the variable diameter cylindrical prefabricated coil blank in the axial direction to obtain a variable diameter prefabricated tube blank; S4: filling liquid and press-forming the variable diameter prefabricated tube blank, so that the variable diameter prefabricated tube blank occurs compressive deformation, thereby forming the special-shaped component.

Owner:HARBIN INST OF TECH

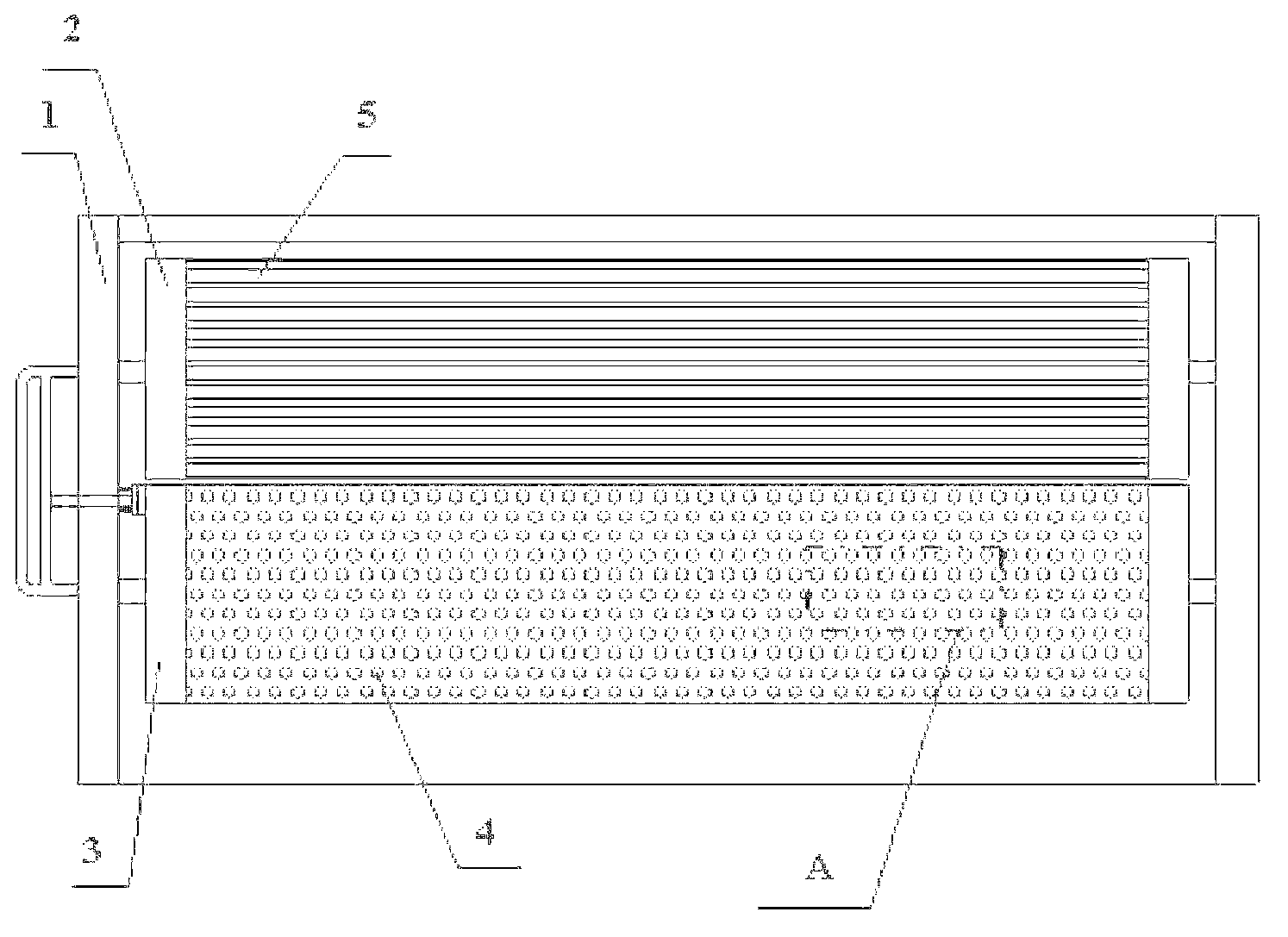

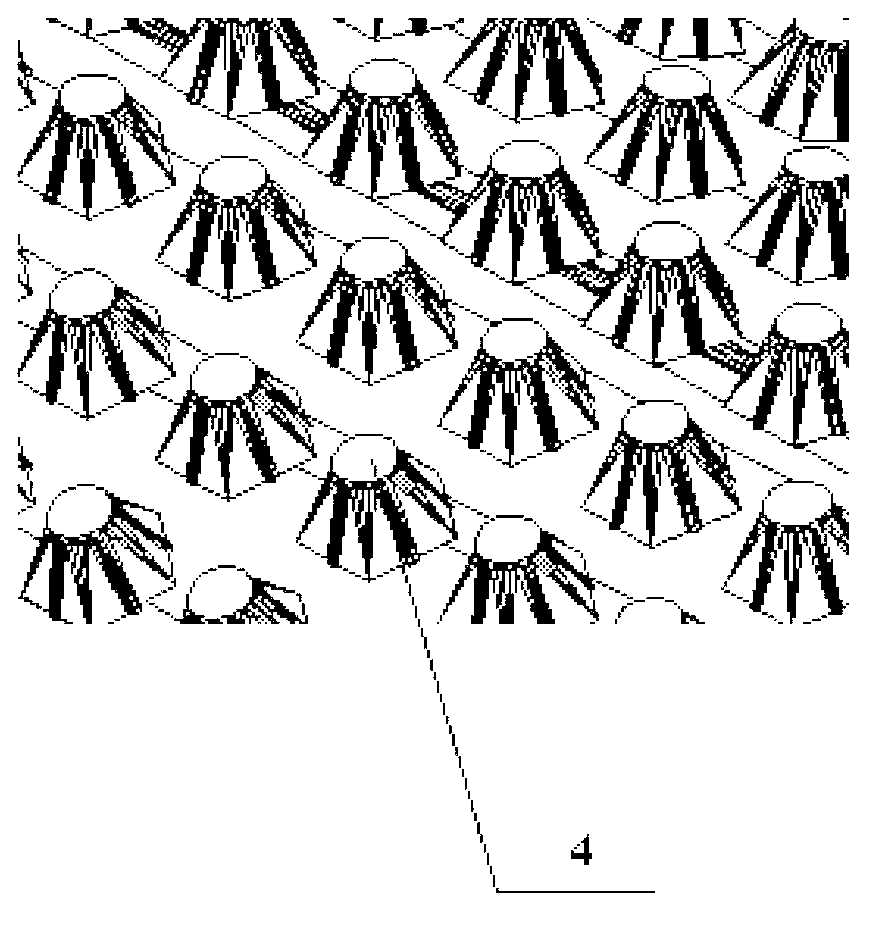

Drainage board and water drainage and storage board forming equipment

The invention relates to drainage board and water drainage and storage board forming equipment which comprises a support frame, and an upper roller and a lower roller which are arranged on the support frame in parallel opposite to each other, wherein boss molds which are arranged in a parallel array mode are arranged on a cylindrical surface of the lower roller; a plurality of array grooves are evenly distributed on the upper roller along the cylindrical surface; each groove is parallel to a central axis of the upper roller; and each array groove is matched with each row of boss molds which are arranged in an array mode. The equipment is easy to manufacture and maintain and easy and convenient to operate, and the boss and bottom plate of the drainage board and the water drainage and storage board can be uniform in thickness distribution, so that the consistency of pressure bearing and other physical mechanical properties can be effectively kept, the problems that partial area is broken and then the whole construction quality and service life are reduced due to non-uniform stress are effectively solved, the economic cost is wholly reduced, the service life is prolonged, a guarantee is provided for the quality and service life of the related construction, and the equipment is suitable for popularization and application in related fields of production of drainage boards and water drainage and storage boards.

Owner:曾立敏

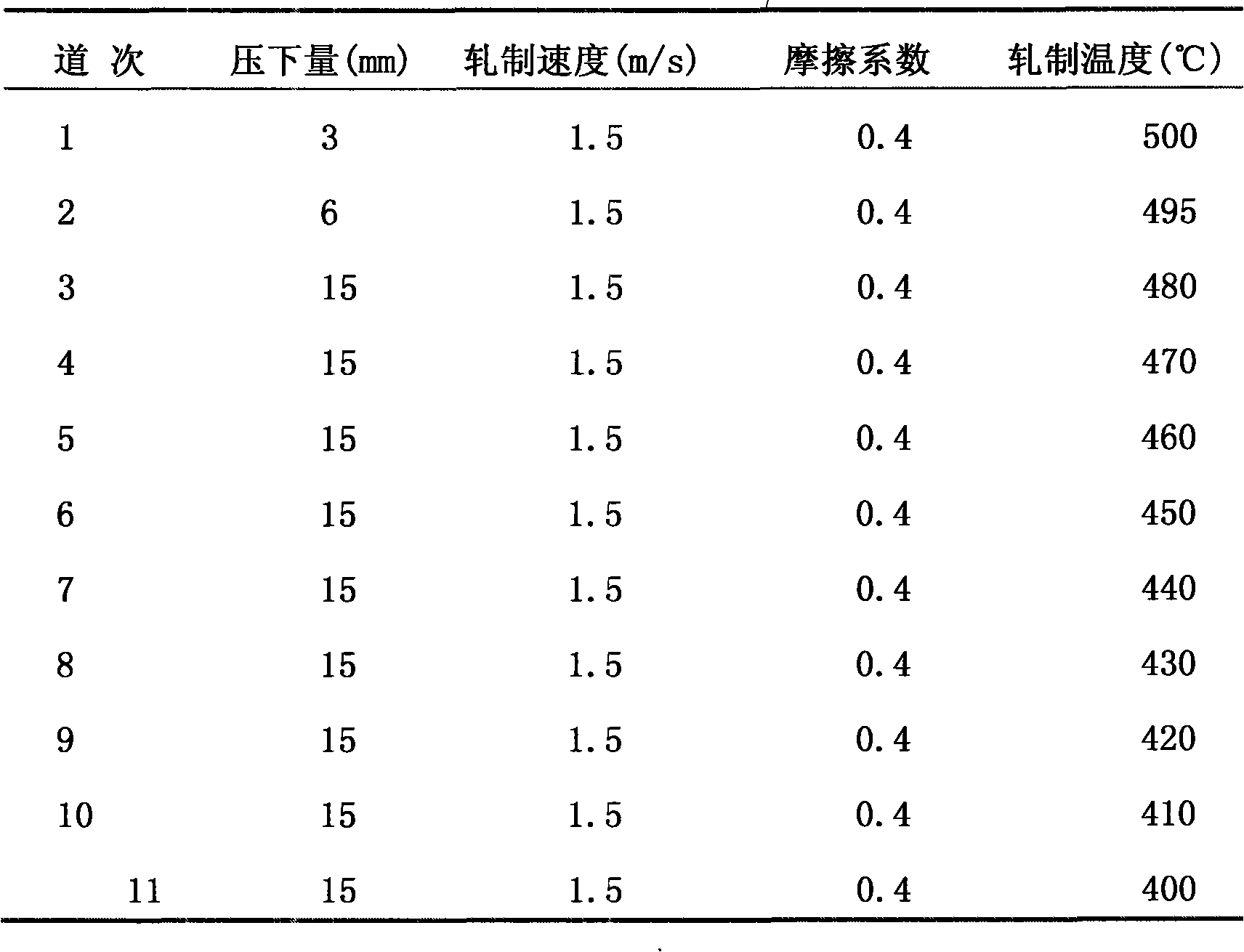

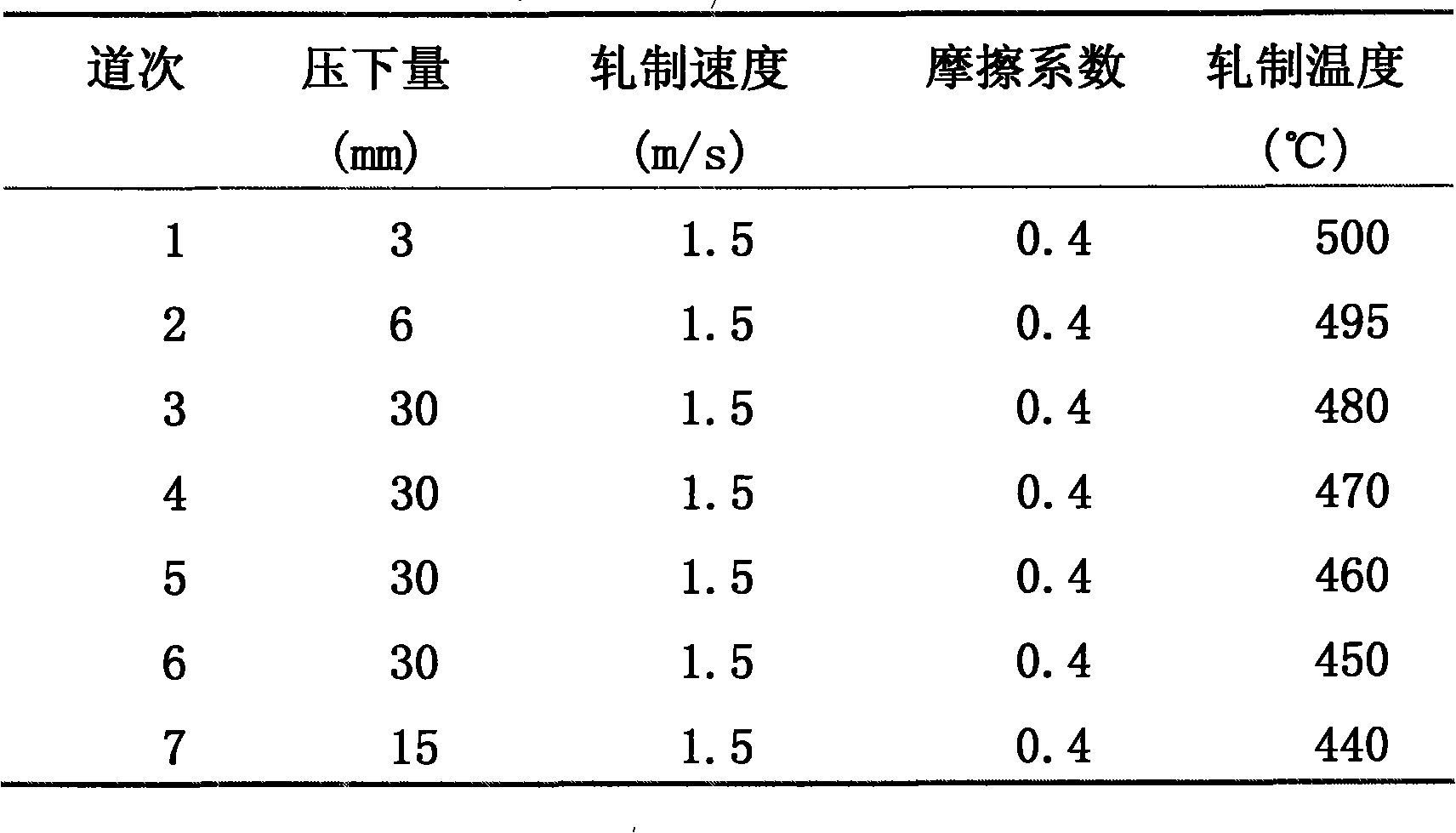

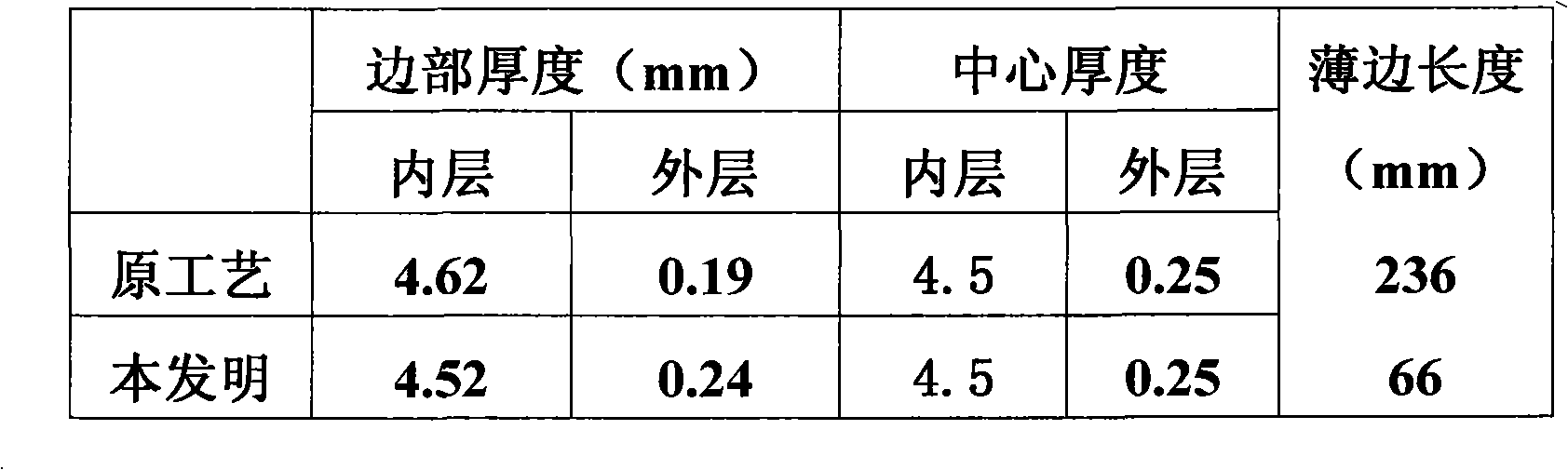

Rolling method for improving outer layer thickness distribution of composite plate

InactiveCN101549358AUniversal adaptabilityImproved thickness distributionRoll mill control devicesMetal rolling arrangementsComposite plateLayer thickness

The invention provides a rolling method for improving the outer layer thickness distribution of a composite plate, which belongs to the technical field of metal plastic processing and molding. The rolling method is a new rolling method of the composite material, according to the metal deformation theory when rolling, each layer thickness equality of the cross section after rolled can be ensured when the equal deformation of metal at the inner and outer layers is ensured, namely, the deformation embedded into the internal of the rolling piece is ensured, simultaneously no serious single bulge occurs. The rolling method is mainly comprises the step of scheduling the entire rolling regulations, the core content is ensuring each pressed value is more than 30%, and ensuring the deformation of each layer is uniform in the transverse direction to achieve the purpose of improving the inner and outer layers thickness uniformity of the composite plate. The rolling method provided by the invention has universal adaptability to the rolling processing of the composite material, and is especially applicable to the processing of the symmetric composite materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Tab, pole piece and lithium ion battery

PendingCN113054328AImproved thickness distributionImprove the problem of poor bondingFinal product manufactureSecondary cellsEngineeringPole piece

The invention provides a tab, a pole piece and a lithium ion battery. The pole piece provided by the invention comprises a current collector, active substance layers and a tab, the active substance layers are arranged on the front and back surfaces of the current collector and / or one of the front and back surfaces of the current collector, at least one end of the current collector in the length direction is provided with an empty foil area without the active material layer, the tab is arranged on the empty foil area at one end of the current collector in the length direction, the tab comprises a first section and a second section connected with the first section, and two sides of the top surface of the first section are respectively provided with a concave part which is sunken downwards. The invention provides a tab, a pole piece and a lithium ion battery, which are used for at least solving the technical problem that the flatness of the surface of a battery cell processed by the pole piece is not ideal due to a tab structure when the pole piece is processed into the lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Air intake and exhaust structure of semiconductor chamber and semiconductor chamber

ActiveCN113445123AReduce air pressureAvoid colliding with each otherSemiconductor/solid-state device manufacturingFrom chemically reactive gasesThermodynamicsEngineering

The invention discloses an air intake and exhaust structure of a semiconductor chamber and the semiconductor chamber, wherein the air intake and exhaust structure is arranged between an upper cover and a lower cover of the semiconductor chamber; the air intake and exhaust structure is characterized in that the air intake and exhaust structure comprises an annular main body and an annular support part extending towards the interior of the semiconductor chamber, wherein the inner edge of the annular support part is used for bearing a preheating ring of the semiconductor chamber, an upper chamber is arranged above the annular support part, and a lower chamber is arranged below the annular support part; the annular main body is provided with an air inlet channel for introducing air to the upper chamber and an exhaust channel for exhausting air in the upper chamber; and the side, close to the exhaust channel, of the annular support part is provided with a longitudinal through hole communicating with the upper chamber and the lower chamber, and gas in the lower chamber is exhausted along the exhaust channel through the longitudinal through hole. The distance between the longitudinal through hole and the exhaust channel is closer, the pressure is lower, hydrogen in the lower chamber tends to flow to the longitudinal through hole with the lower pressure, and the situation that the hydrogen in the lower chamber collides with process gas to generate turbulent flow is avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

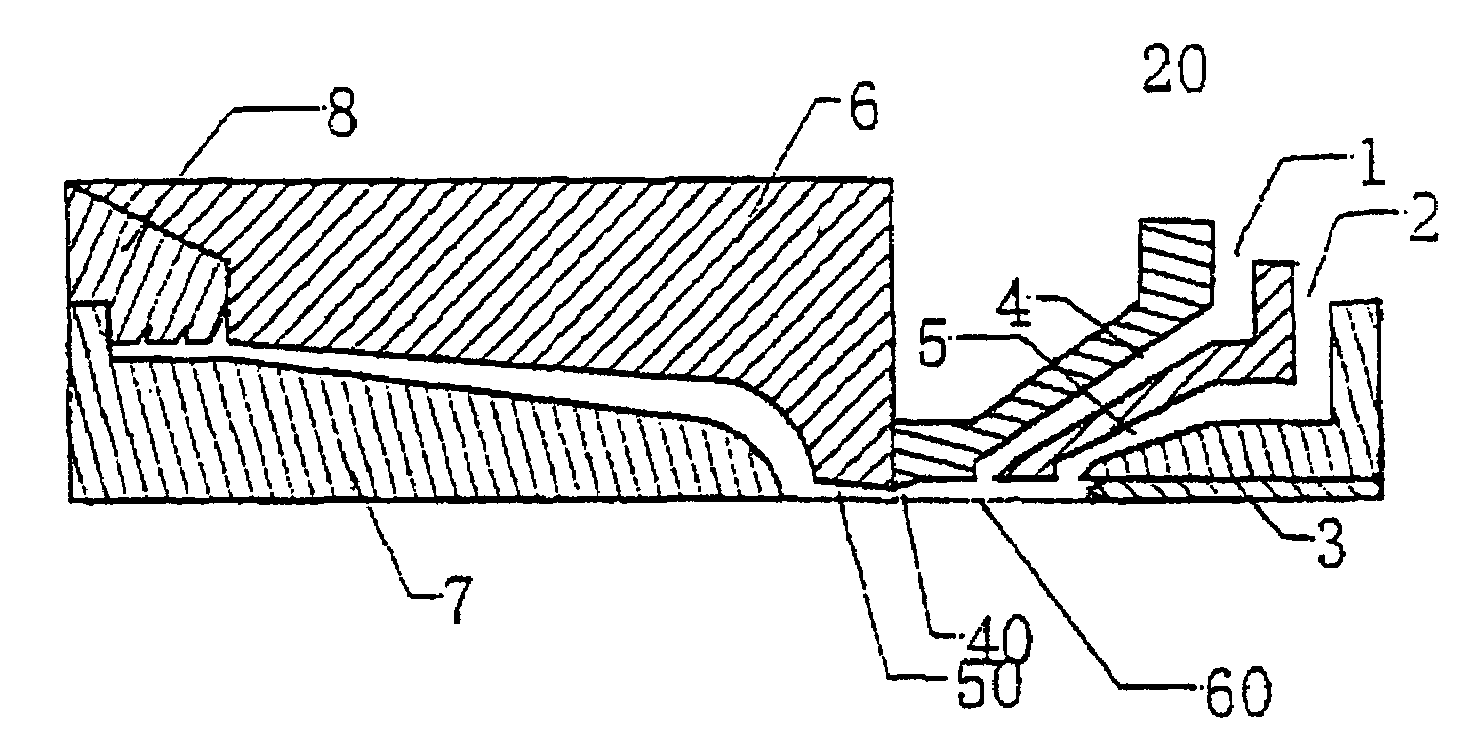

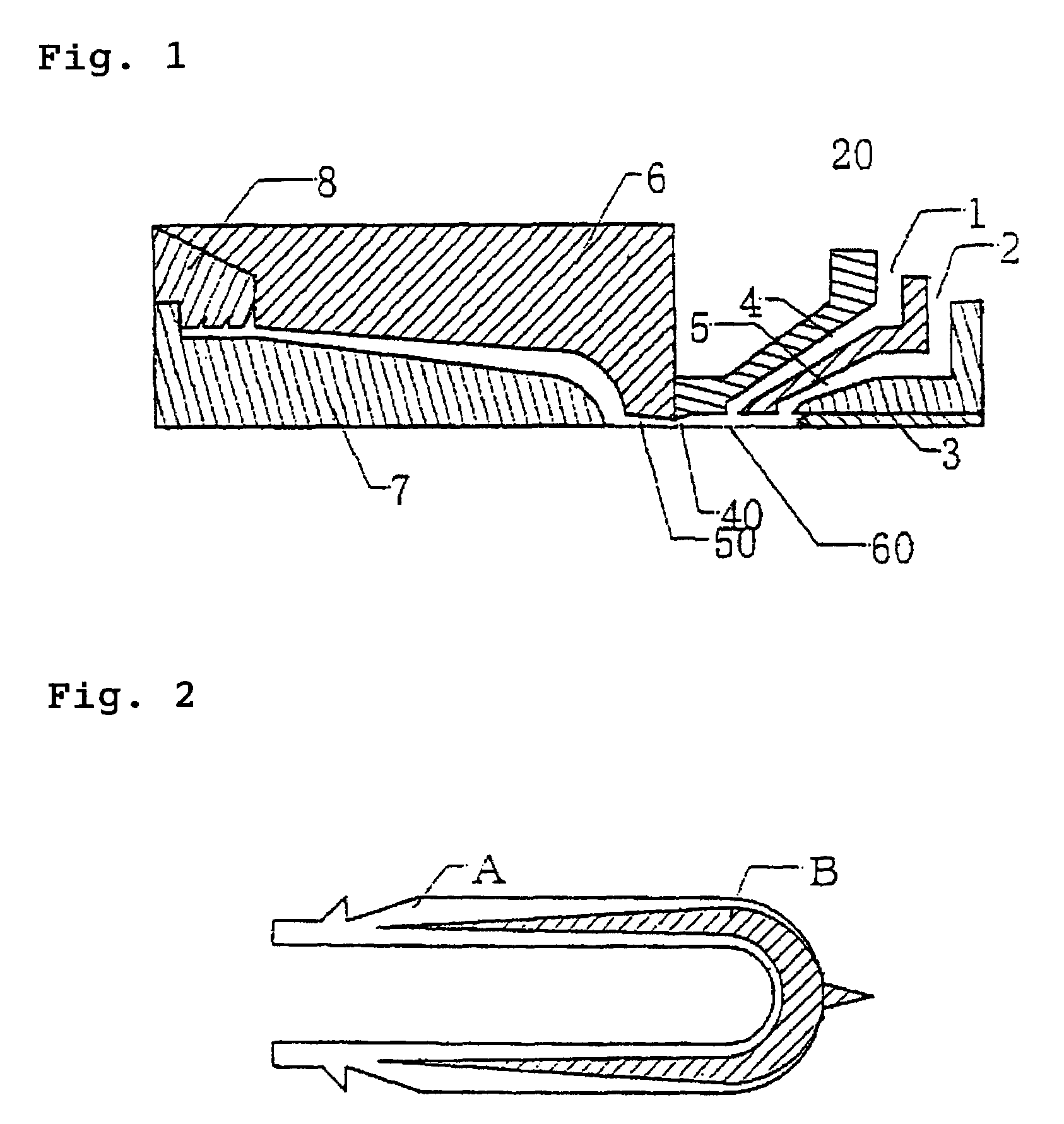

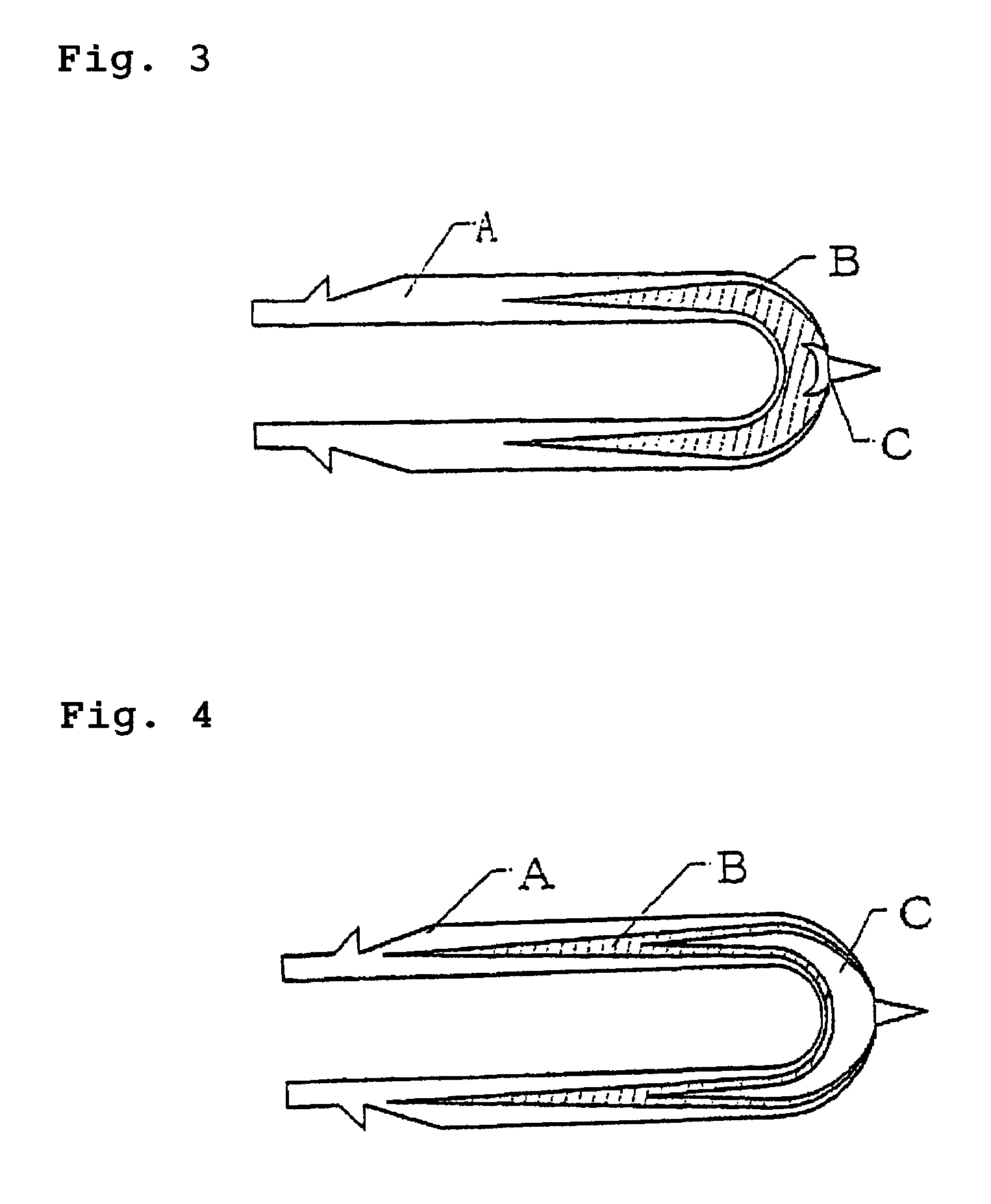

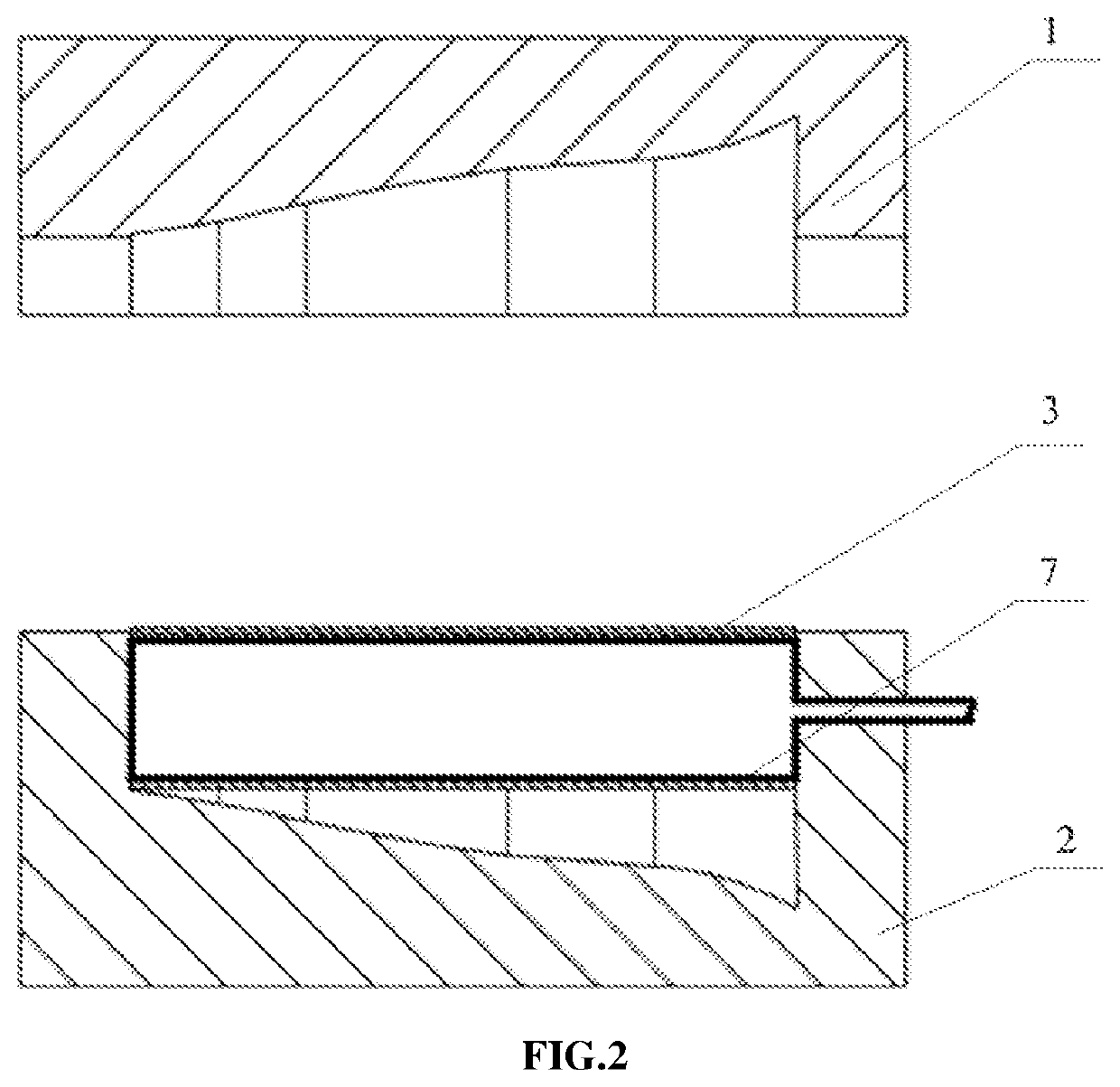

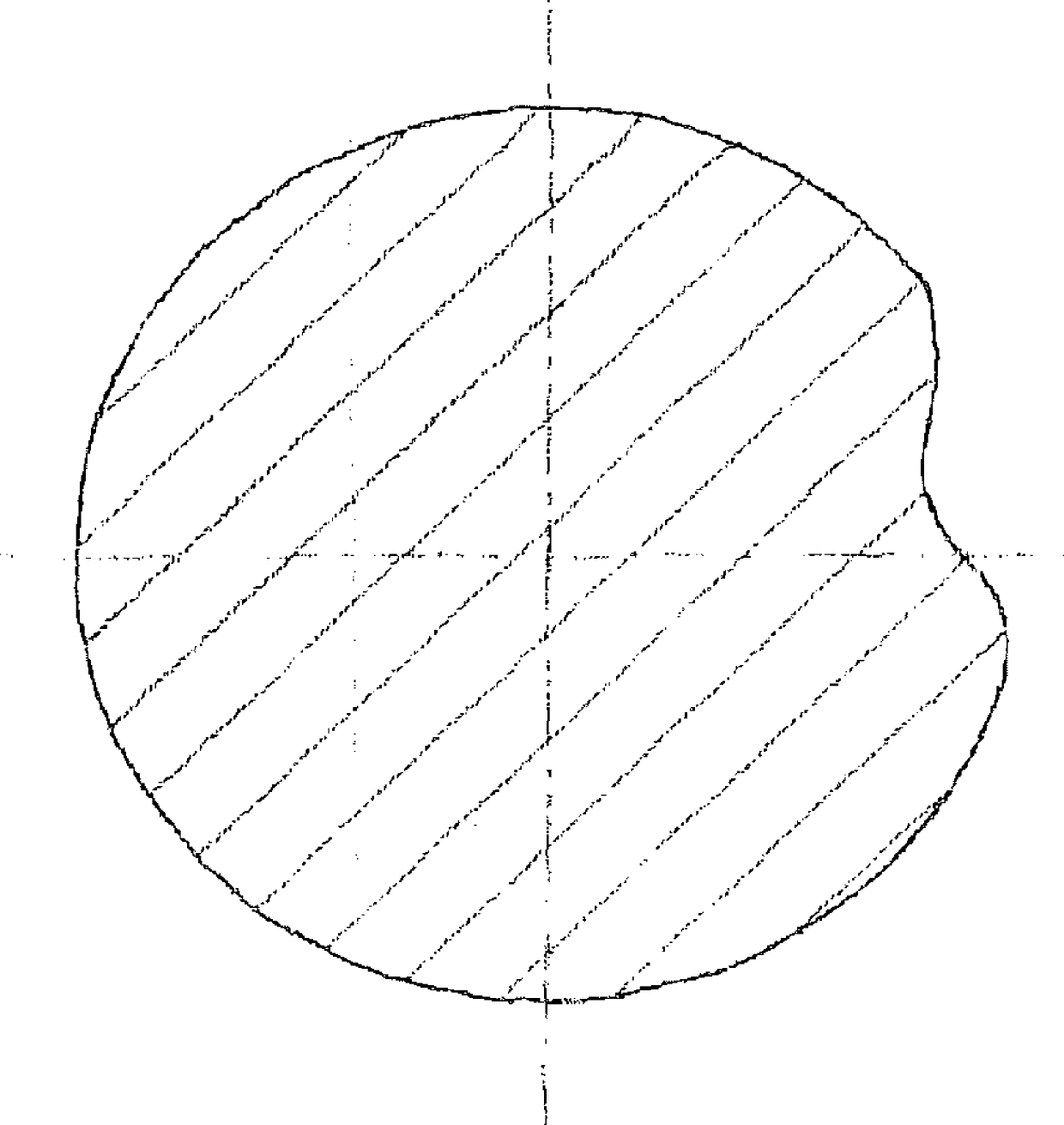

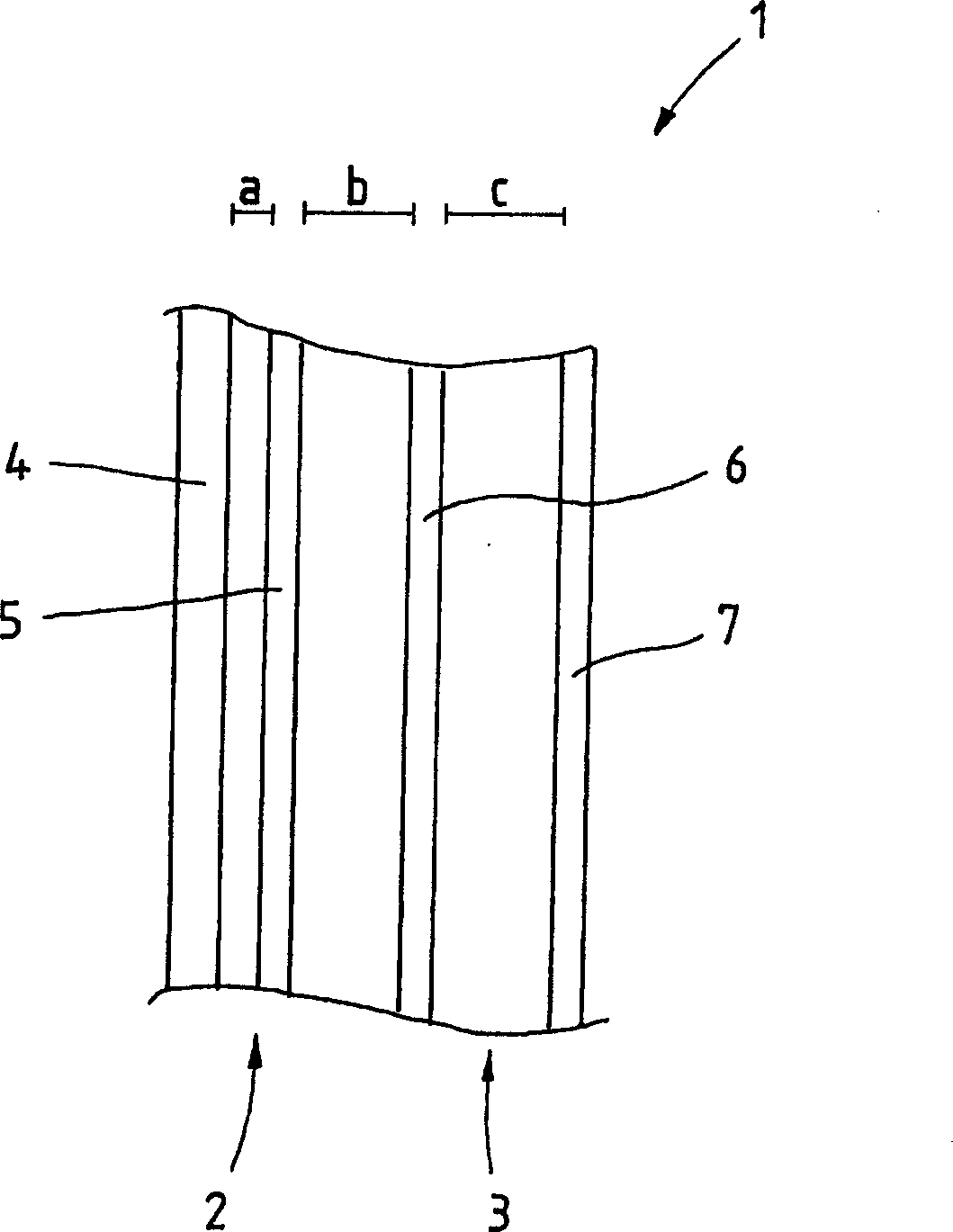

Extrusion head and method for producing hollow bodies

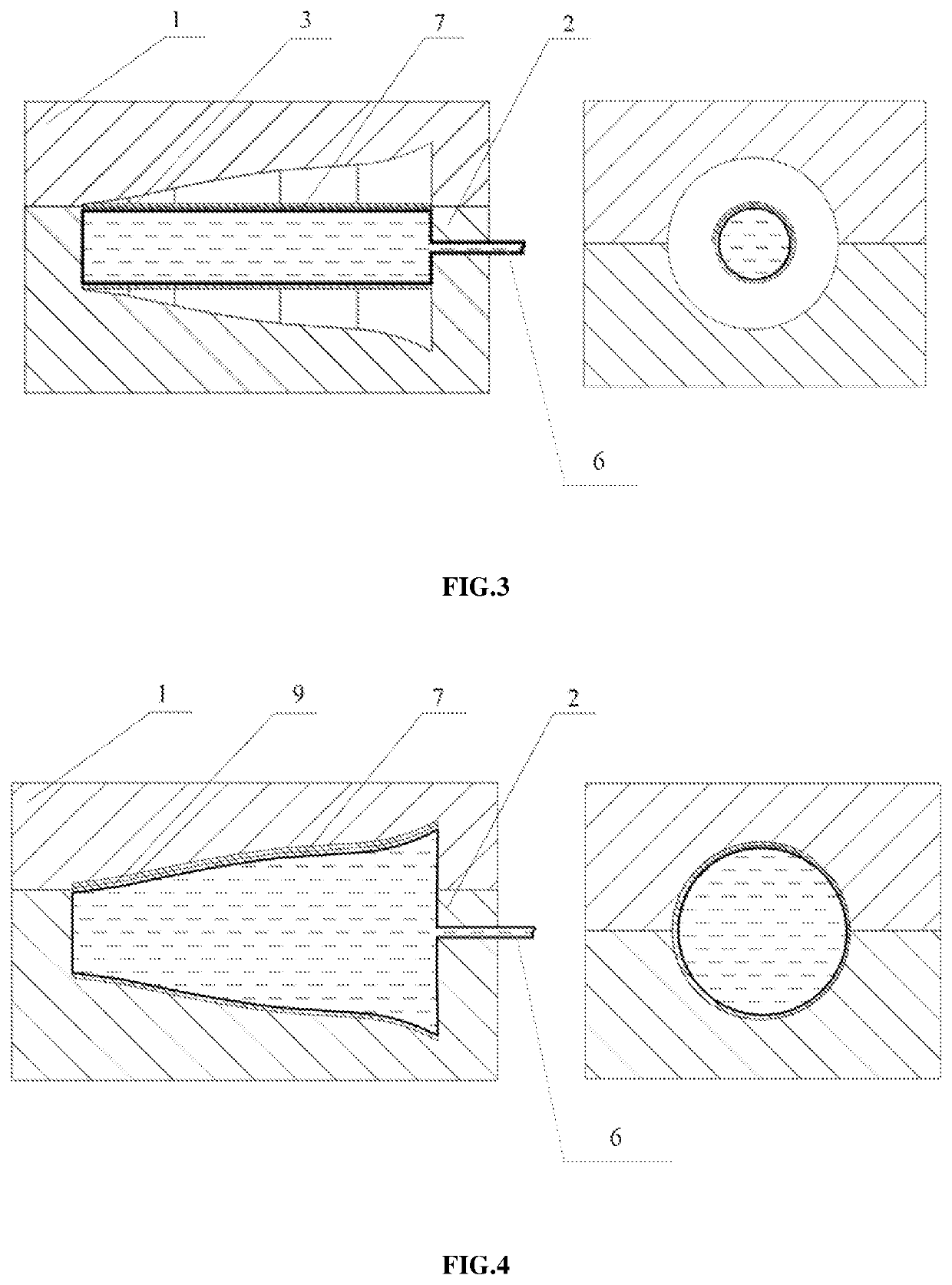

InactiveCN104010791AUniform discharge speedAffect discharge speedDomestic articlesTubular articlesEngineeringExtrusion

The invention relates to an extrusion head and to a method, by way of which for example the thickness distribution of hollow bodies can be further improved. To this end, the extrusion head consists of at least one mandrel (1) and a nozzle (2), which mandrel (1) and nozzle (2) may be geometrically rigid and thus not changeable or else deformable in a regionally flexible manner and which form a flow duct (3), wherein the mandrel (1) and the nozzle (2) are positionally changeable in relation to one another, as a result of which the geometry of an outlet gap (s) of the flow duct (3) is changeable during the discharge of a melt, wherein each head part has at least one head section having a constant cross-sectional area in an outlet region (A) of the extrusion head, and wherein at least one head part has at least two head sections (B) and (C); which each have predominantly constant cross-sectional areas within the head section (B), (C), are axially spaced apart and have different cross-sectional areas from one another.

Owner:海因茨·格罗斯

Film forming device and partition wall structure of same

InactiveCN106011772AUniform gapHigh precisionVacuum evaporation coatingSputtering coatingEngineeringElectrical and Electronics engineering

Provided is a partition wall structure for a film forming apparatus and a film forming apparatus, wherein the partition wall structure of the present invention forms at least one film formation region in the chamber of the film forming apparatus. The partition wall structure includes a circumferential regulating portion and a pair of partition walls. The circumferential restricting portion is connected to the partition wall so that the relative position of the circumferential regulating portion and the partition wall is fixed. The inner side surface of the partition wall faces the outer peripheral surface of the film formation roller with a gap therebetween when the partition wall is attached to the chamber. The circumferential direction regulating portion forms a film formation area facing the outer peripheral surface of the film formation roller. The film forming apparatus of the present invention comprises a pair of partition walls fixed to the chamber and disposed on both sides in the widthwise direction of the film formation roller at positions spaced from the film roll by a partition wall. An outer surface facing the radially outer side of the film formation roll and an inner surface facing radially inward of the film formation roll, the mask being mounted on the outer side surface of the partition wall, the inner side surface of the partition wall being located closer to the outer peripheral surface of the film roll and is positioned radially inwardly of the film formation roller.

Owner:KOBE STEEL LTD

Method for producing bonded wafer

ActiveUS7927972B2High bonding strengthSimple heat treatment processSemiconductor/solid-state device manufacturingOxygen ionsPhysical chemistry

Even if an oxygen ion implanted layer in a wafer for active layer is not a completely continuous SiO2 layer but a layer mixed partially with Si or SiOx, it is removed by here is provided a method for producing a bonded wafer in which it is possible to remove an oxygen ion implanted layer effectively as it is by repetitive treatment with an oxidizing solution and HF solution at a step of removing the oxygen ion implanted layer in a bonded wafer.

Owner:SUMCO CORP

Method for molding two-piece blow molded hollow tank by using auxiliary male molds

ActiveUS20150314514A1Large stretch ratioImprove product molding qualityHollow wall articlesBeltsEngineeringHigh pressure

A method for molding a two-piece blow molded hollow tank by using auxiliary male molds includes the following steps: 1) blanking two parisons; 2) closing mold halves of a mold and a pre-molding template; 3) pre-stretching the molten parisons by using auxiliary male molds in the pre-molding template; 4) performing internal high-pressure blow molding, and pre-molding two housing portions; 5) opening the mold, and withdrawing the pre-molding template; 6) moving in a component built-in mechanism to perform built-in component connection; 7) moving out the component built-in mechanism; 8) closing the mold for the second time and finally blow molding a hollow tank; and 9) opening the mold and taking out the product.

Owner:YAPP AUTOMOTIVE PARTS

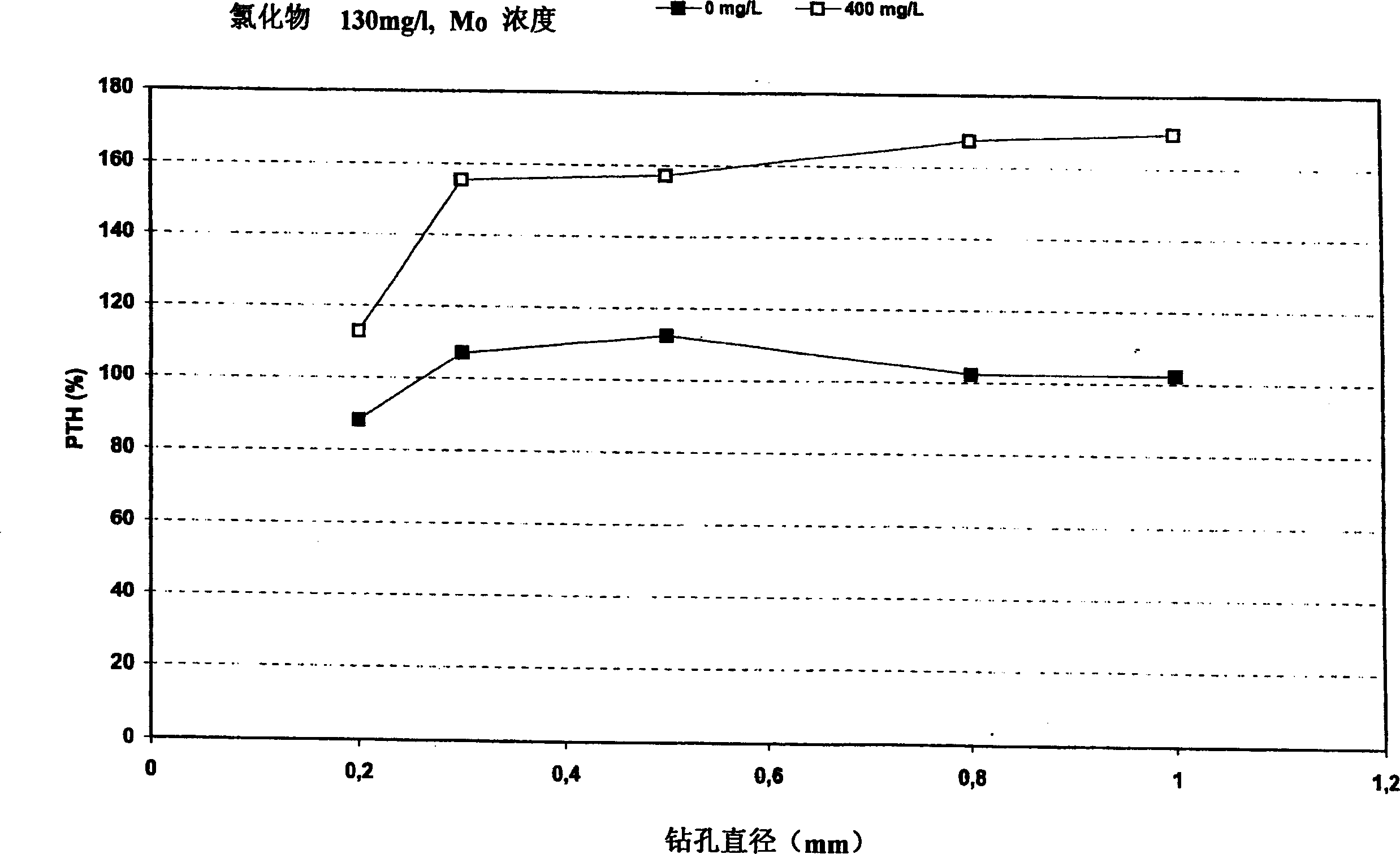

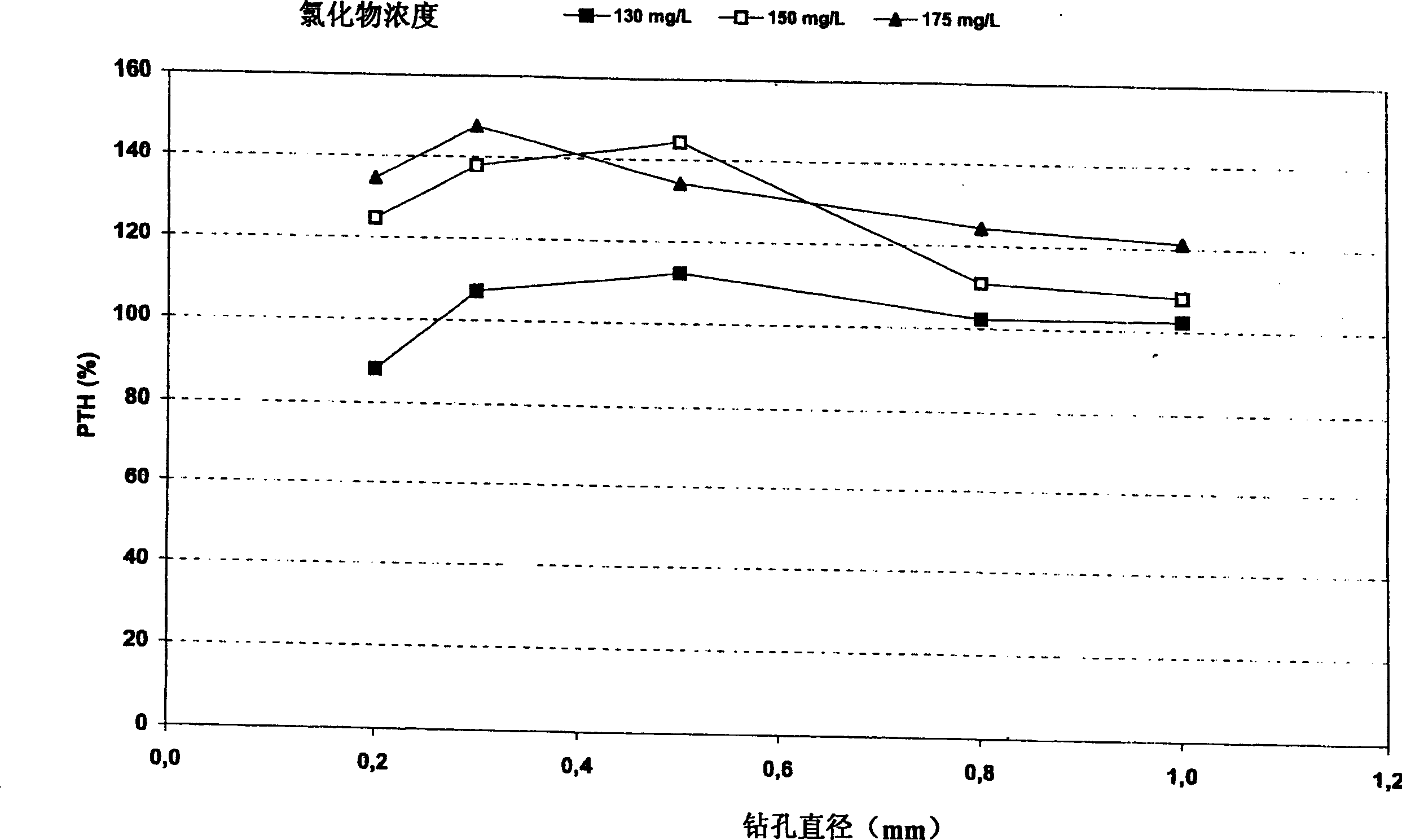

Galvanic bath

A galvanic bath, especially an acidic galvanic bath, comprises an anode, a cathode and an electrolyte. The anode has two or more phases, and the electrolyte comprises more than 70 mg / l chloride and 5-5000 mg / l, especially 200-1200 mg / l of either molybdenum, vanadium, zirconium, tantalum, tungsten, hafnium or titanium in oxo-acidic anion or polyanion form, or acid anhydride cation form.

Owner:ENTHONE INC

PVD process for the deposition of Al2O3 and a coated cutting tool with at least one layer of Al2O3

ActiveUS11326248B2High hardnessModulus is reducedVacuum evaporation coatingSputtering coatingPolycrystalline diamondBoron nitride

A coated cutting tool including a substrate and a single layer or multi-layer hard material coating is provided. The substrate is selected from cemented carbide, cermet, ceramics, cubic boron nitride (cBN), polycrystalline diamond, steel or high-speed steel. The hard material coating includes at least one layer of gamma-Al2O3, exhibiting particularly high hardness and reduced Young's modulus. The gamma-Al2O3 layer of the coated cutting tool is obtainable by means of a reactive magnetron sputtering process using at least one Al target, wherein the deposition is carried out using a reaction gas composition of argon (Ar) and oxygen (O2) at a total reaction gas pressure within the range from at least 1 Pa to at most 5 Pa, at an O2 partial pressure within the range from 0.001 Pa to 0.1 Pa, and at a temperature within the range from 400° C. to 600° C.

Owner:WALTER AG

Sputter apparatus, control device for sputter apparatus and film formation method

ActiveUS9175379B2Improved thickness distributionImprove distributionCellsVacuum evaporation coatingEngineering

In an embodiment of the present invention, the following operations are performed while a substrate holder is being rotated at a fixed rotation speed with plasma being generated. Specifically, a first state where a substrate holding surface of the substrate holder is exposed to a target holder is formed to start a first deposition of divisional depositions, and a second state where the surface is shut off from the target holder is formed in T / X seconds after the start of the first divisional deposition. Moreover, the first state is formed to start an n-th deposition of the divisional depositions when a reference point set on the substrate holder arrived at a position rotated by (n−1)×360 / X degrees from a position of the reference point located at the start of the targeted deposition, and the second state is formed in T / X seconds after the start of the n-th divisional deposition.

Owner:CANON ANELVA CORP

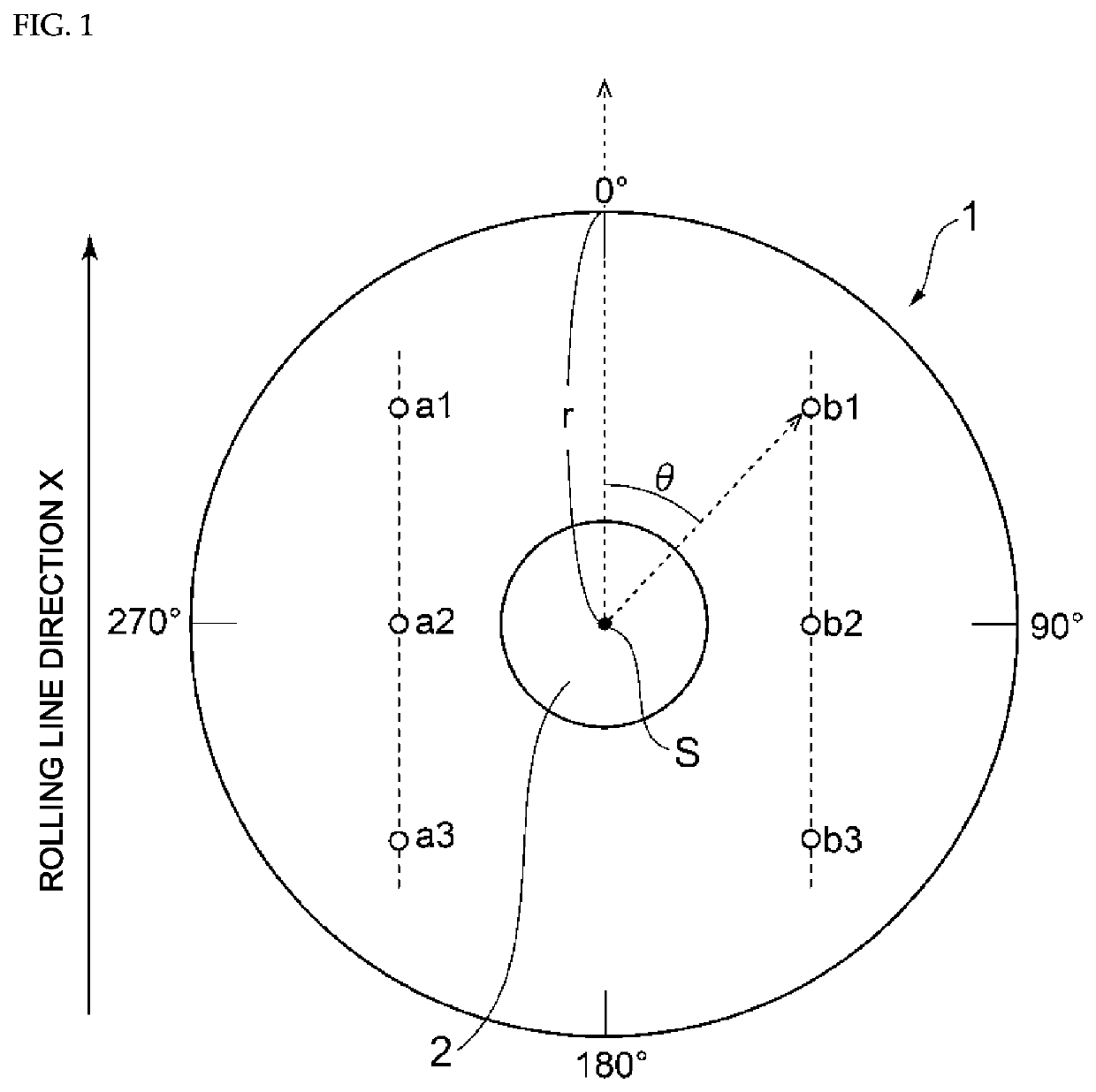

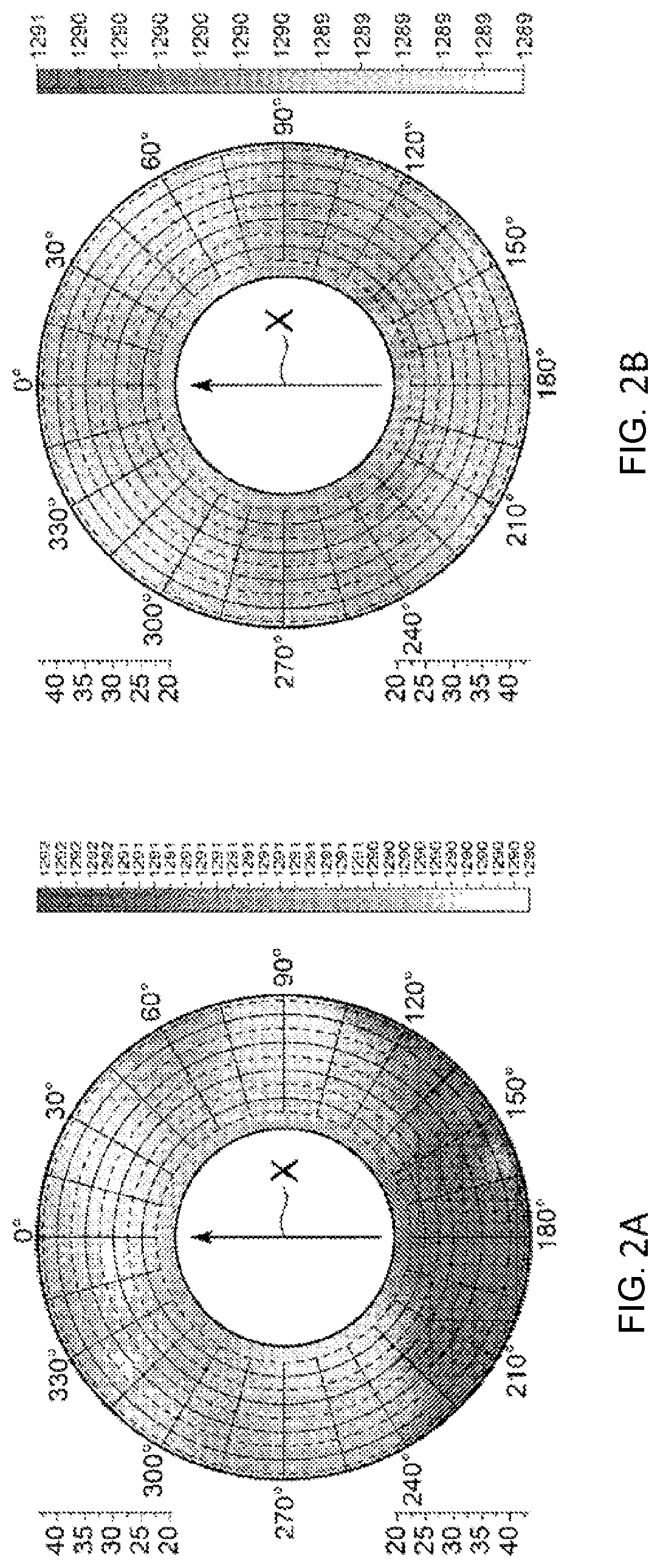

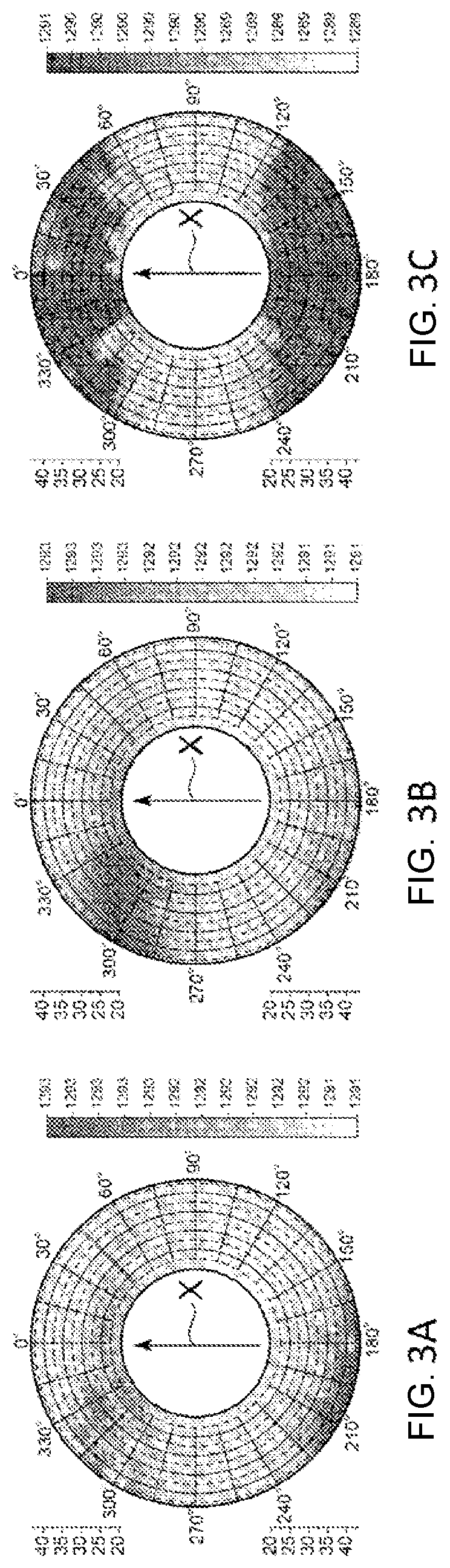

Aluminum alloy substrate for magnetic disk, disk drive device, method for manufacturing aluminum alloy substrate for magnetic disk, and method for measuring aluminum alloy substrate for magnetic disk

ActiveUS11335367B2High planarizationGood magnetic stabilityBase layers for recording layersRecord information storageCircular discAlloy substrate

An aluminum alloy substrate (1) for magnetic disk satisfies at least two of three inequalities of an inequality group [A] and satisfies all of four inequalities of an inequality group [B], or satisfies at least two of the three inequalities of the inequality group [A] and satisfies all of four inequalities of an inequality group [C], when a plate thickness of the disk at a position (b1) is defined as tb1, a plate thickness at a position (b2) is defined as tb2, a plate thickness at a position (b3) is defined as tb3, a plate thickness at a position (a1) is defined as ta1, a plate thickness at a position (a2) is defined as ta2, and a plate thickness at a position (a3) is defined as ta3.

Owner:FURUKAWA ELECTRIC CO LTD +1

Method for molding two-piece blow molded hollow tank by using auxiliary male molds

Owner:YAPP AUTOMOTIVE PARTS

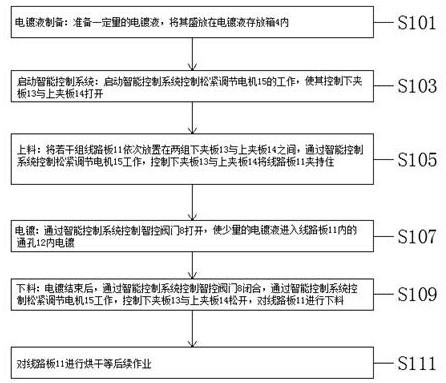

Intelligent electroplating device and method for circuit board

PendingCN112680769AReduce wasteQuality improvementElectrolysis componentsPrinted element electric connection formationEngineeringMaterials science

The invention discloses an intelligent electroplating device and method for a circuit board, and particularly relates to the technical field of circuit board electroplating. The intelligent electroplating device comprises a machine body, two supporting frames are fixedly installed at the two ends of the upper surface of the machine body, an electroplating table is fixedly installed between the upper ends of the two supporting frames, and an electroplating liquid storage box is fixedly installed on the electroplating table. A conveying pipe is installed at the bottom of the electroplating liquid storage box, the conveying pipe penetrates through the electroplating table and extends to one end of the lower side of the electroplating table to be fixedly provided with a liquid uniformizing pipe, a plurality of electroplating pipes are installed below the liquid uniformizing pipe, and a plurality of sets of supporting seat rods are fixedly installed on the machine body. When through holes in the circuit board are electroplated, operation is convenient and fast, electroplating is accurate, electroplating efficiency is improved, meanwhile, waste of electroplating liquid can be reduced, the electroplating liquid used in the method is beneficial for improving hole filling quality, scratches and other microcosmic distribution of the circuit board, and meanwhile macroscopic coating thickness distribution is also better improved.

Owner:深圳市合成快捷电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com