Method for producing piston rings

A technology of piston ring and piston pressure ring, applied in the field of piston pressure ring, can solve the problems of time-consuming and cost, and achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

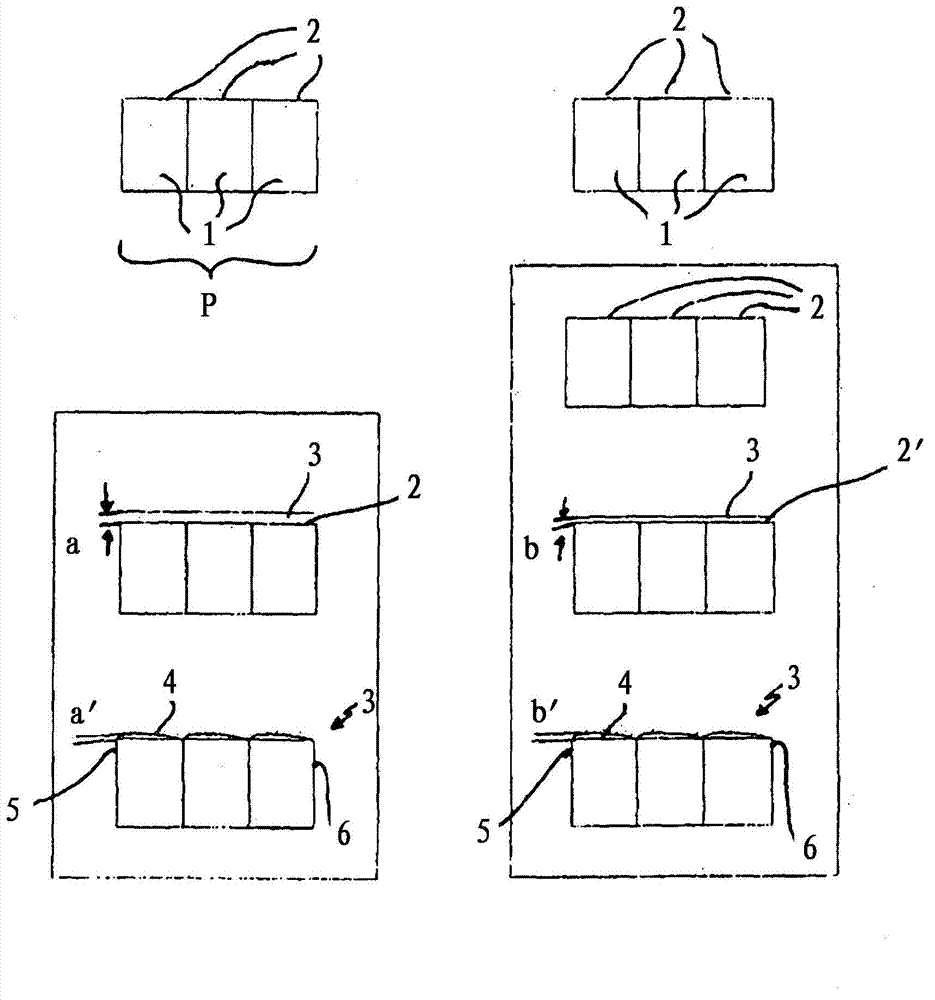

[0022] In the example on the left, an electroplated, wear-resistant chromium layer 3 of a predeterminable layer thickness a is applied directly to the cylindrical peripheral surface 2 . Now only the layer 3 is processed by means of a profile grinding tool (not shown) in such a way that a convex profile 4 is produced, which in this example has a maximum layer thickness a' in one of the working surface edge regions 5 , while the minimum layer thickness is provided towards the edge region 6 of the other working surface.

[0023] In the example on the right, the cylindrical profile turning is followed by a further machining process, namely cylindrical grinding, whereby the profile turned cylindrical peripheral surface 2 now forms material with a further minimal material removal. Another reduced cylindrical outer peripheral surface 2'. Similar to the example on the left, the outer circumferential surface 2 ′ now produced is provided with a galvanically produced, wear-resistant chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com