Drainage board and water drainage and storage board forming equipment

A technology for forming equipment and water storage plates, which is applied to the field of forming equipment for drainage plates and water storage plates, can solve the problems of uneven bearing capacity of the drainage plates and water storage plates, affecting the quality and life of the project, and complicated manufacturing of forming equipment. , to achieve the effect of easy manufacturing and maintenance, reducing economic costs and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

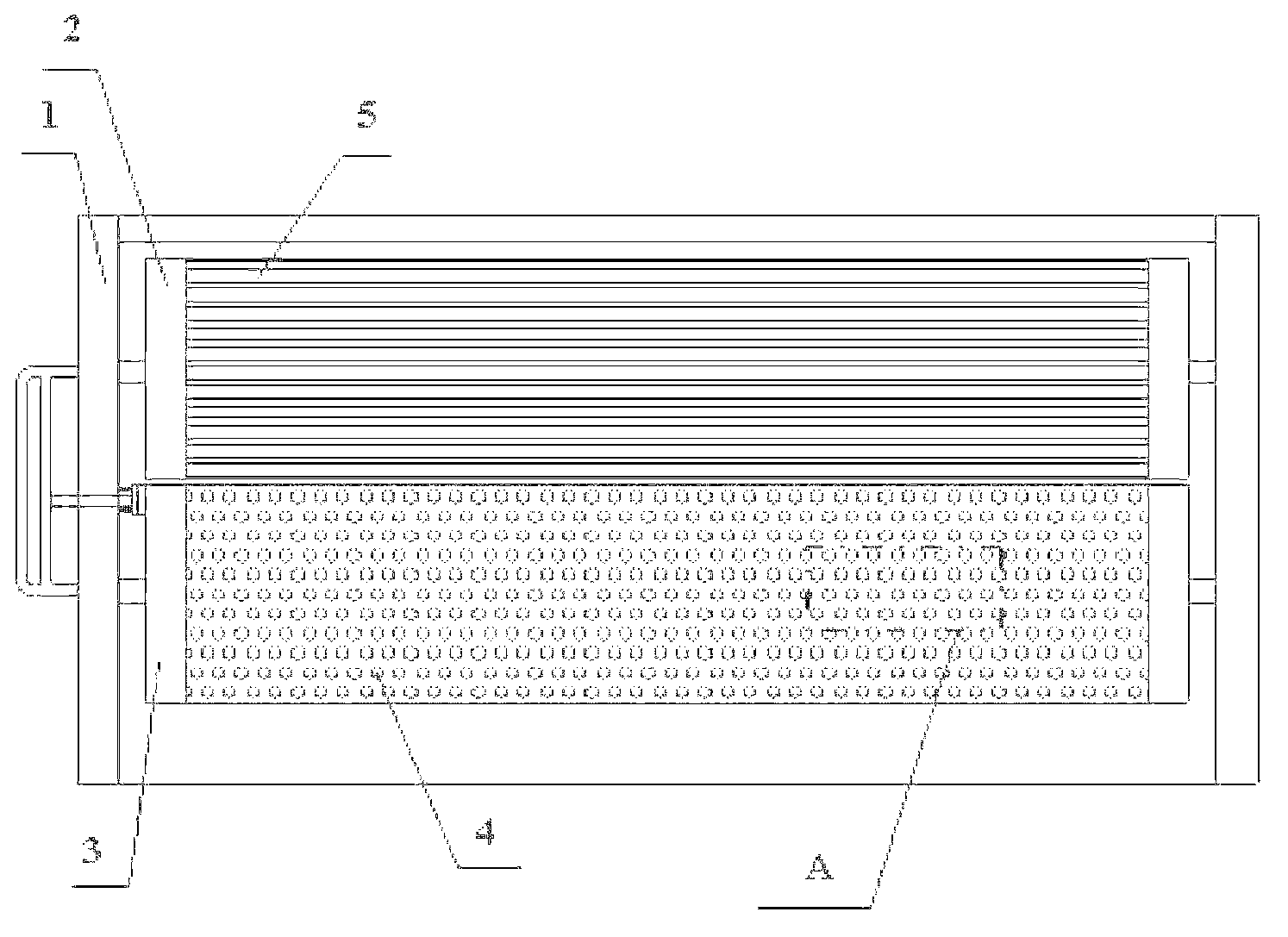

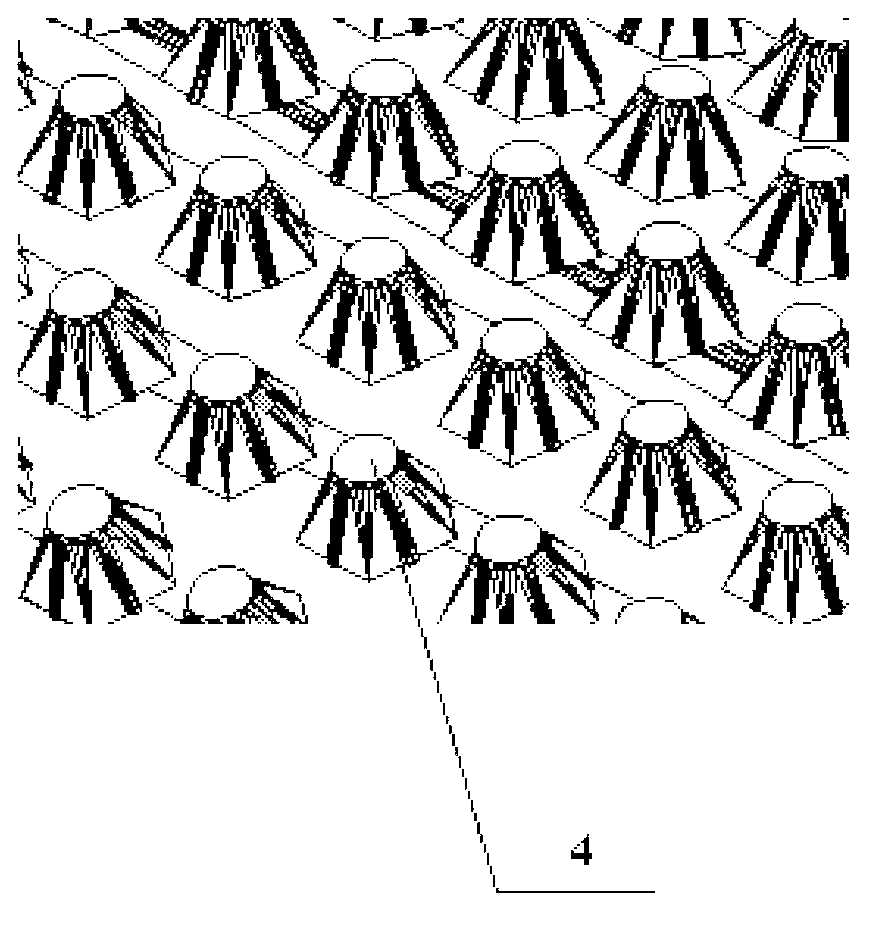

[0022] like figure 1 As shown, a drainage board and drainage water storage board forming equipment, including a support frame 1 and an upper roller 2 and a lower roller 3 arranged relatively parallel on the support frame 1, the upper roller 2 and the lower roller 3 are both Cylindrical, the cylindrical surfaces of the upper drum 2 and the lower drum 3 are relatively parallel to each other, and the circular sides of the upper drum 2 and the lower drum 3 are respectively connected with the support frame 1, and on the column of the lower drum 3 There are a plurality of boss molds 4 arranged on the surface, wherein the boss molds 4 arranged on the cylindrical surface of the lower roller 3 are arranged in parallel arrays, and a plurality of arrays are evenly distributed along the cylindrical surface on the upper roller 2 Each groove 5 is parallel to the central axis of the upper cylinder 2, the central axis is perpendicular to the two circular sides of the upper cylinder 2, each of...

Embodiment 2

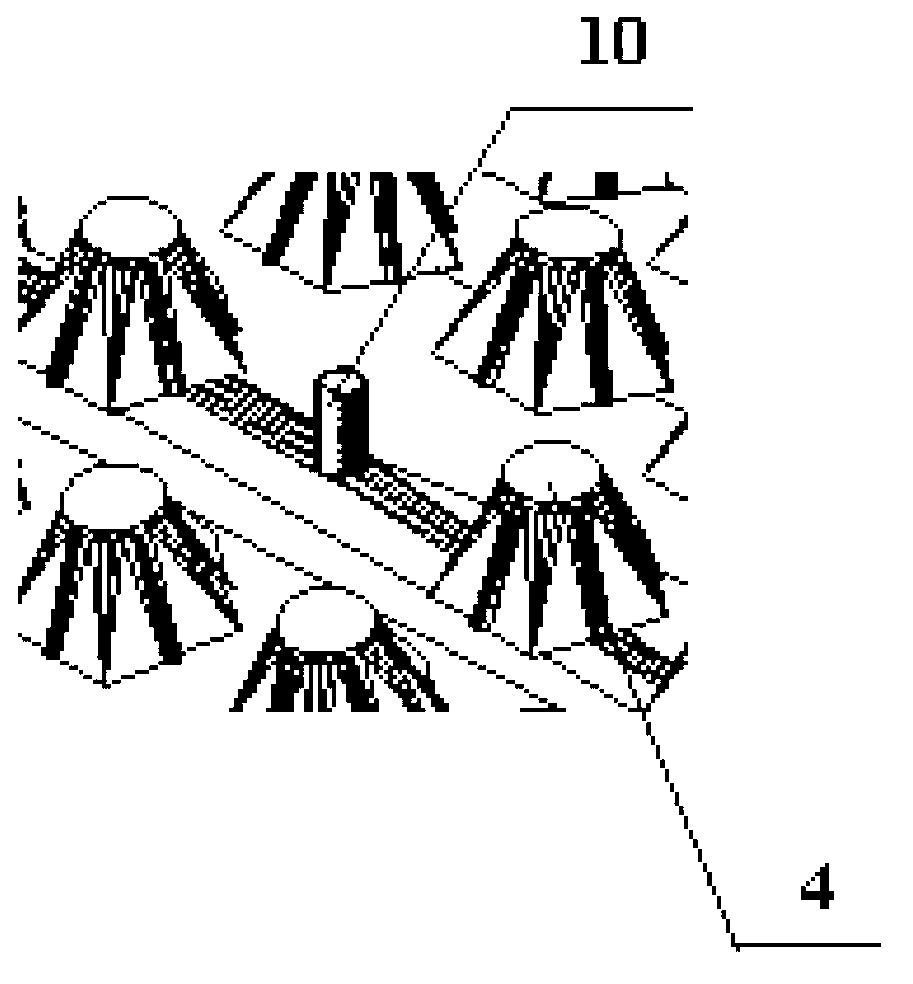

[0027] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the setting, distribution and application of a drainage board and drainage and water storage board forming equipment are the same as in Example 1, except that the settings of the devices related to negative pressure are set as follows:

[0028] A plurality of air holes 6 are arranged along the circumference on one of the two circular sides of the lower drum 3, and the other circular side is closed;

[0029]A baffle plate 7 is arranged between the lower drum 3 and the support frame 1, and the baffle plate 7 can cover the air hole 6 on the circular side of the circular side of the lower drum 3 closest to the upper drum; An air suction pipe hole and a support arm 8 are arranged on the shielding plate 7, and an air suction pipe 9 is arranged at the air suction pipe hole, and the air suction pipe 9 is connected to an air suction pump (not shown in the figure) , the support arm 8 is located around the suction pi...

Embodiment 3

[0036] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the setting, distribution and application of a drainage board and drainage and water storage board forming equipment are the same as in Example 2, the difference is that the settings of the negative pressure related devices are set as follows:

[0037] An air passage is provided on the shielding plate, and the suction pipe hole is located in the air passage, and the number of the air passages capable of covering the air holes on the circular side of the lower drum is more than 2, preferably 3; This setting can make the contact between the shielding plate 7 and the circular side of the lower drum 3 where the air hole 6 is arranged more closely, so that the negative pressure suction effect is more sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com