Carbon fiber three-dimensional fabric knitting machine

A three-dimensional fabric, carbon fiber technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems of unguaranteed quality consistency, low production efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

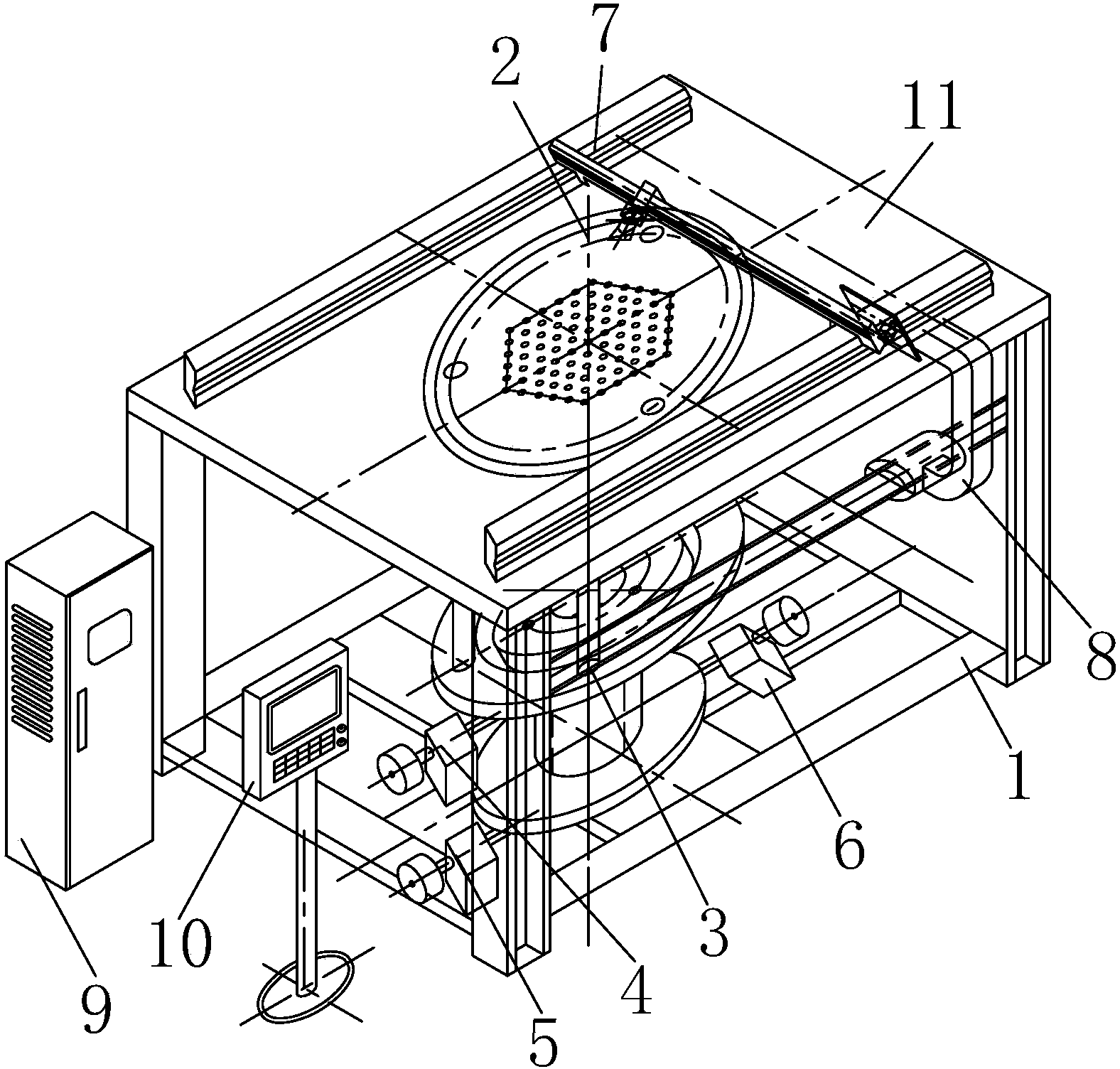

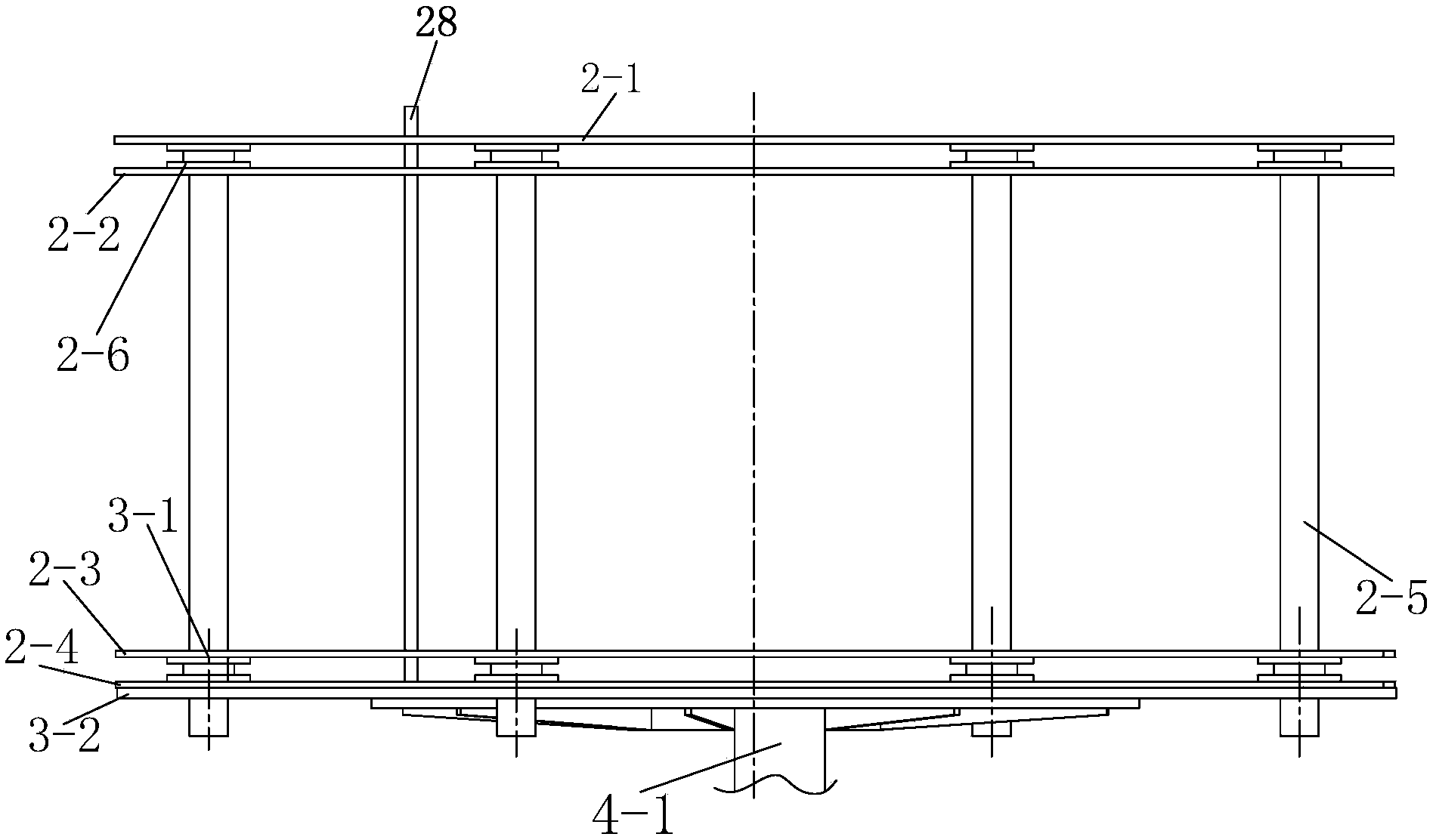

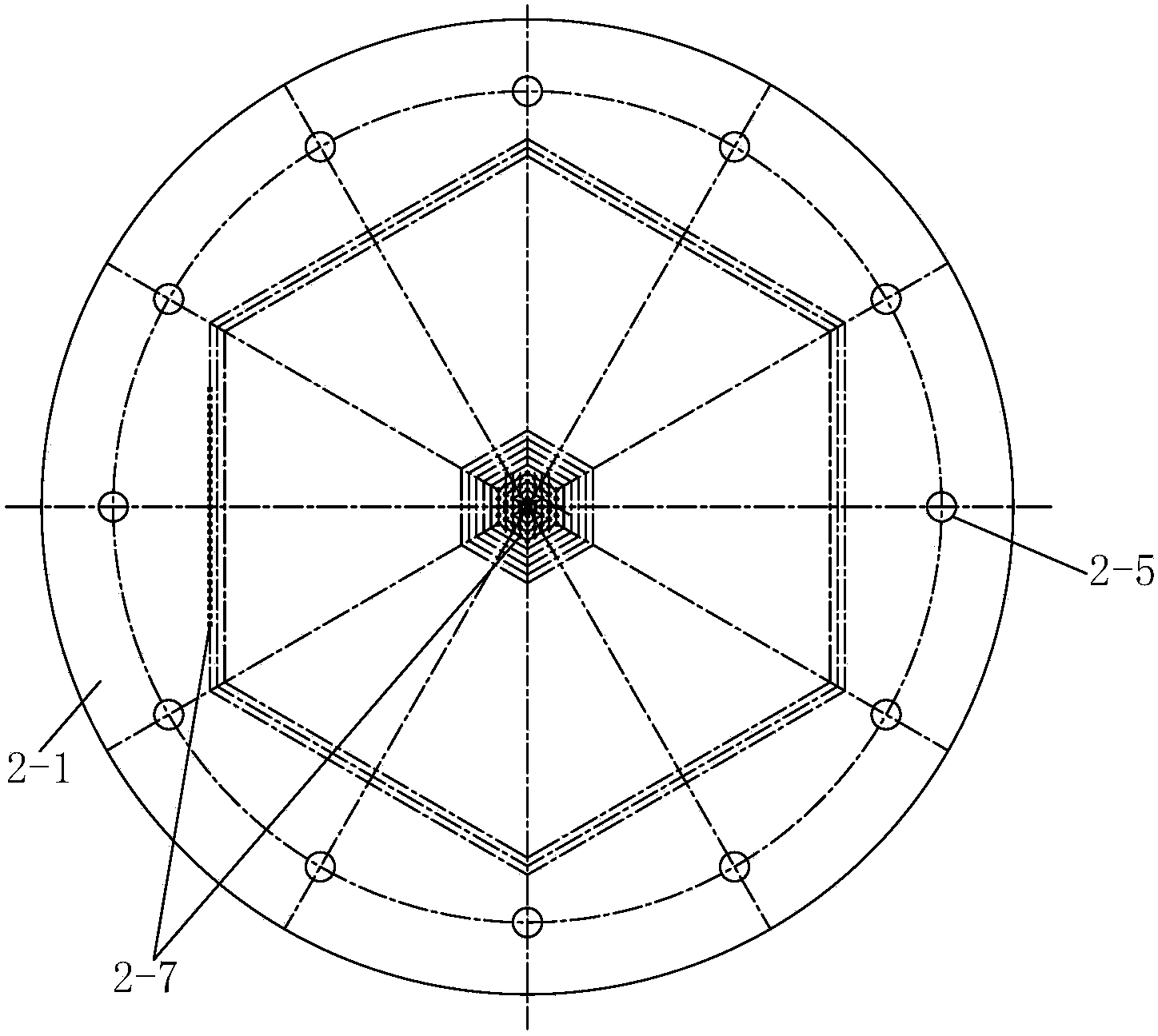

[0102] Such as figure 1 and Figure 15 As shown, the present invention comprises a frame 1 and a carbon rod fixing frame mechanism 2 arranged on the frame 1, a carbon rod fixing frame positioning and clamping mechanism 3, a carbon rod quantitative lifting mechanism 4, a braided fabric quantitative lifting mechanism 5, a carbon rod Fixed frame 120 ° positioning rotation mechanism 6, X guide yarn running mechanism 7 and Y guide yarn running mechanism 8, the top plane of the frame 1 is a work table 11, and the side of the frame 1 is provided with an electric control box 9 And control panel box 10; Described electrical control box 9 is provided with electrical control system, and described electrical control system comprises main controller unit 12 and the carbon rod lifting control unit 13 that joins with main controller unit 12, braid lifting Control unit 14, carbon rod fixed frame rotation control unit 15, X guide yarn control unit 16 and Y guide yarn control unit 17, describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com