Method for predicting copper thickness ratio of sparse area to dense area in pattern plating

A graphic electroplating and prediction method technology, which is applied in the direction of electrical components, printed circuits, and printed circuit manufacturing, can solve problems such as graphic electroplating monitoring, prediction of thickness difference between sparse areas and dense areas, and excessive line width tolerance, so as to improve production benefit, reduce the scrap rate, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

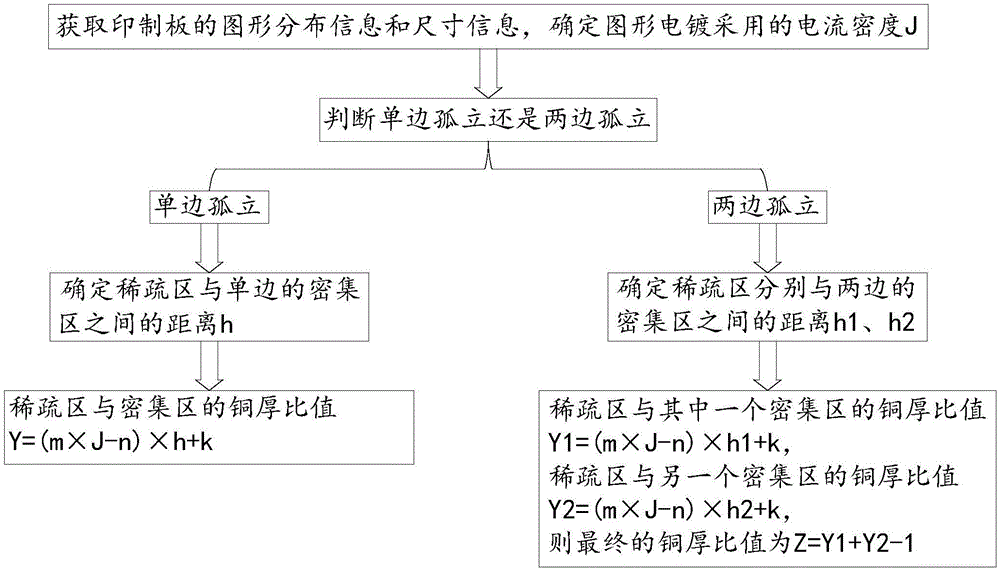

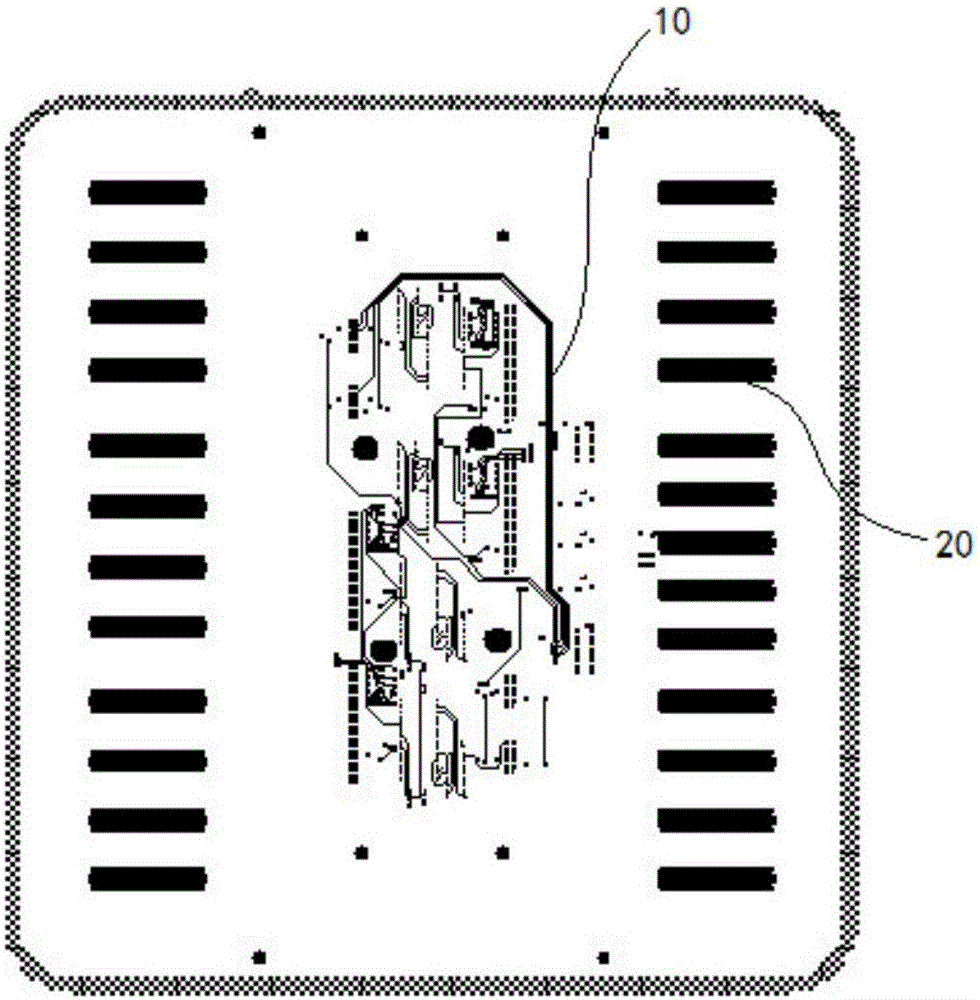

[0025] Such as figure 1 As shown, a method for predicting the copper thickness ratio of the sparse area and the dense area of graphic electroplating includes the following steps:

[0026] (1) Obtain the graphic distribution information and size information of the printed board, and determine the current density J used in graphic electroplating, and the unit is ASF;

[0027] (2) Select a sparse area and a dense area for monitoring. If there is a dense area distributed on the side of the sparse area facing away from the selected dense area, it belongs to the situation of isolation on both sides, and execute step a, otherwise it belongs to unilateral isolation In the case of , perform step b;

[0028] a. Determine the distance between the sparse area and the two dense areas as h1 and h2 respectively, then the ratio of copper thickness between the sparse area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com