Tab, pole piece and lithium ion battery

A technology of lithium-ion batteries and tabs, which is applied to secondary batteries, battery pack components, non-aqueous electrolyte battery electrodes, etc., can solve the problems of unsatisfactory cell surface flatness, etc., and achieve uneven internal stress and improved The effect of poor bonding, flatness and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

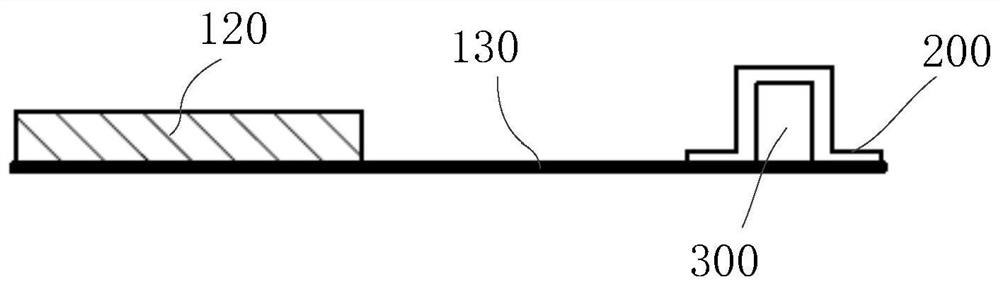

[0114] refer to Figure 15 As shown, when the tab 300 on the negative electrode sheet 420 and the tab 300 on the positive electrode sheet 430 are both located in the inner ring layer of the battery cell 400:

[0115] Along the width direction of the first section 310, the side of the first section 310 close to the active material layer 120 is a limiting surface 311, and the side surface of the active material layer 120 close to the limiting surface 311 and the limiting surface 311 The distance is pitch H2. The distance H2 is greater than twice the thickness h of the first segment 310, and the difference between the distance H2 and twice the thickness h of the first segment 310 is δ1, and the value range of δ1 is: 2mm≤δ1≤10mm.

[0116] The inner width L2 of the cell 400 is the width of the inner ring layer of the cell 400 in the orthographic projection direction, and the width D of the tab 300 on the negative electrode sheet 420 and the tab 300 on the positive electrode sheet ...

Embodiment 2

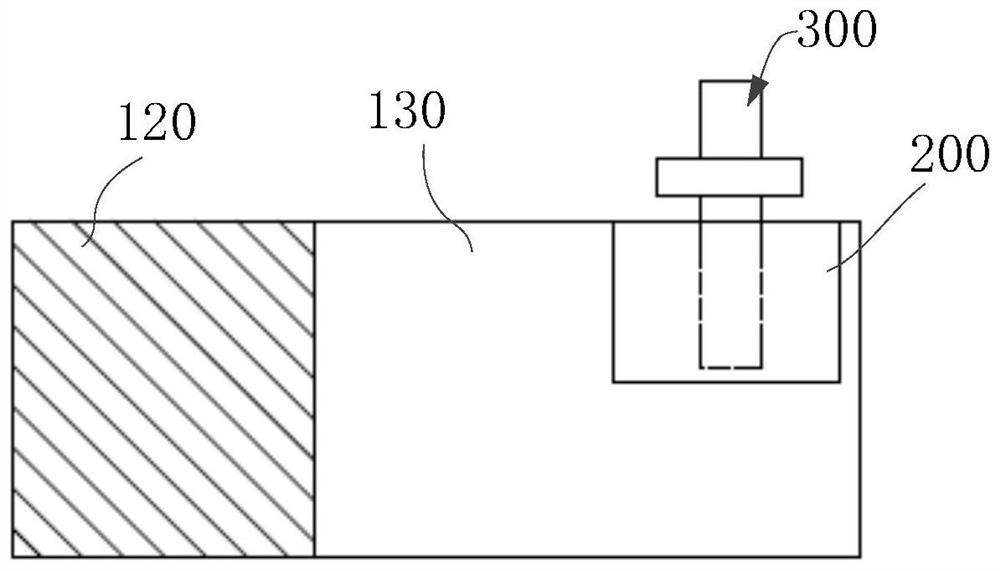

[0124] refer to Figure 16 As shown, when the tab 300 on the negative electrode sheet 420 is located on the inner ring layer of the cell 400, and the tab 300 on the positive electrode sheet 430 is located on the outer ring layer of the cell 400:

[0125] For the tab 300 on the negative electrode sheet 420:

[0126] Along the width direction of the first section 310, the side of the first section 310 close to the active material layer 120 is a limiting surface 311, and the side surface of the active material layer 120 close to the limiting surface 311 and the limiting surface 311 The distance is pitch H2. The distance H2 is greater than twice the thickness h of the first segment 310, and the difference between the distance H2 and twice the thickness h of the first segment 310 is δ1, and the value range of δ1 is: 2mm≤δ1≤10mm.

[0127] The inner width L2 of the battery cell 400 is the width of the inner ring layer of the battery cell 400 in the orthographic projection direction...

Embodiment 3

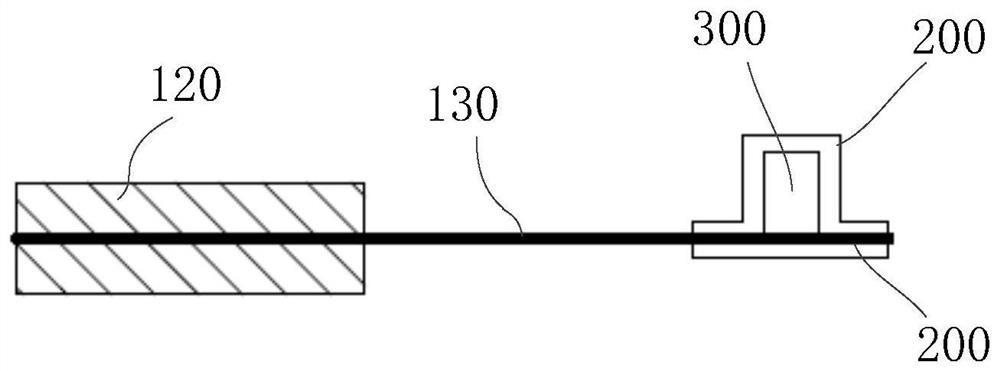

[0138] refer to Figure 17 As shown, when the tab 300 on the positive electrode sheet 430 is located on the inner ring layer of the cell 400, and the tab 300 on the negative electrode sheet 420 is located on the outer ring layer of the cell 400:

[0139] For the tab 300 on the positive electrode sheet 430:

[0140] Along the width direction of the first section 310, the side of the first section 310 close to the active material layer 120 is a limiting surface 311, and the side surface of the active material layer 120 close to the limiting surface 311 and the limiting surface 311 The distance is pitch H2. The distance H2 is greater than twice the thickness h of the first segment 310, and the difference between the distance H2 and twice the thickness h of the first segment 310 is δ1, and the value range of δ1 is: 2mm≤δ1≤10mm.

[0141] The inner width L2 of the battery cell 400 is the width of the inner ring layer of the battery cell 400 in the orthographic projection direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com