Patents

Literature

33 results about "Bulk fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

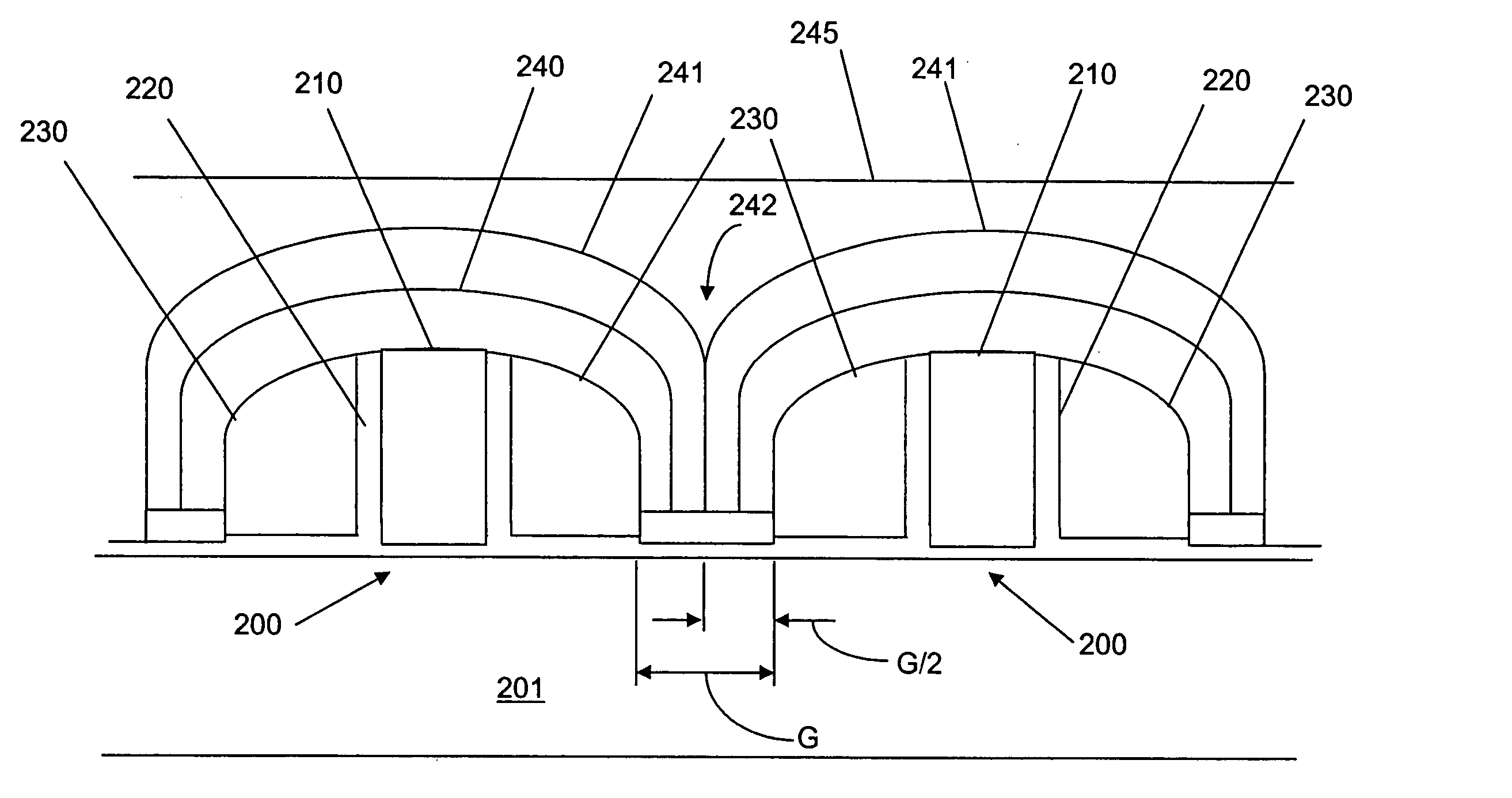

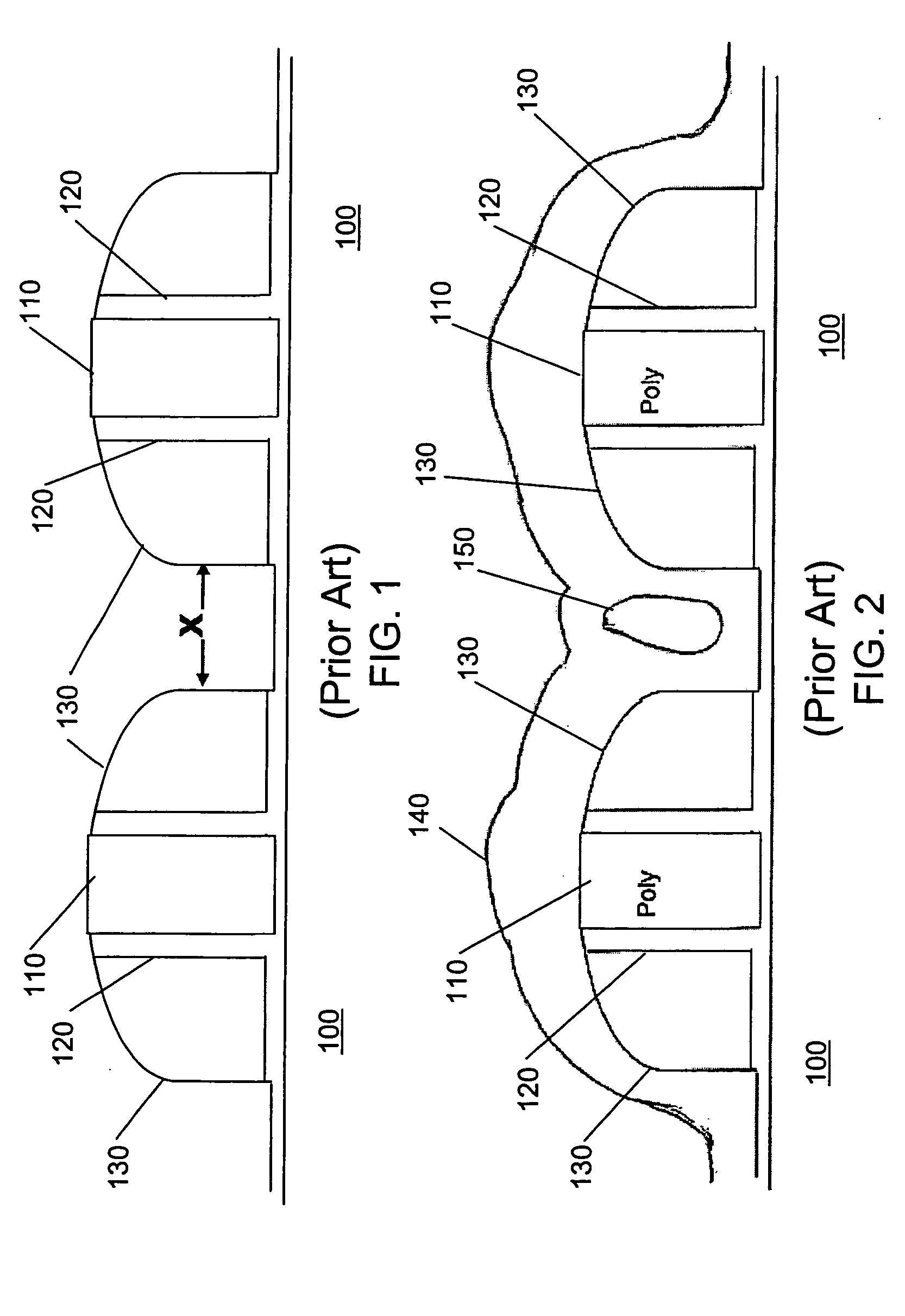

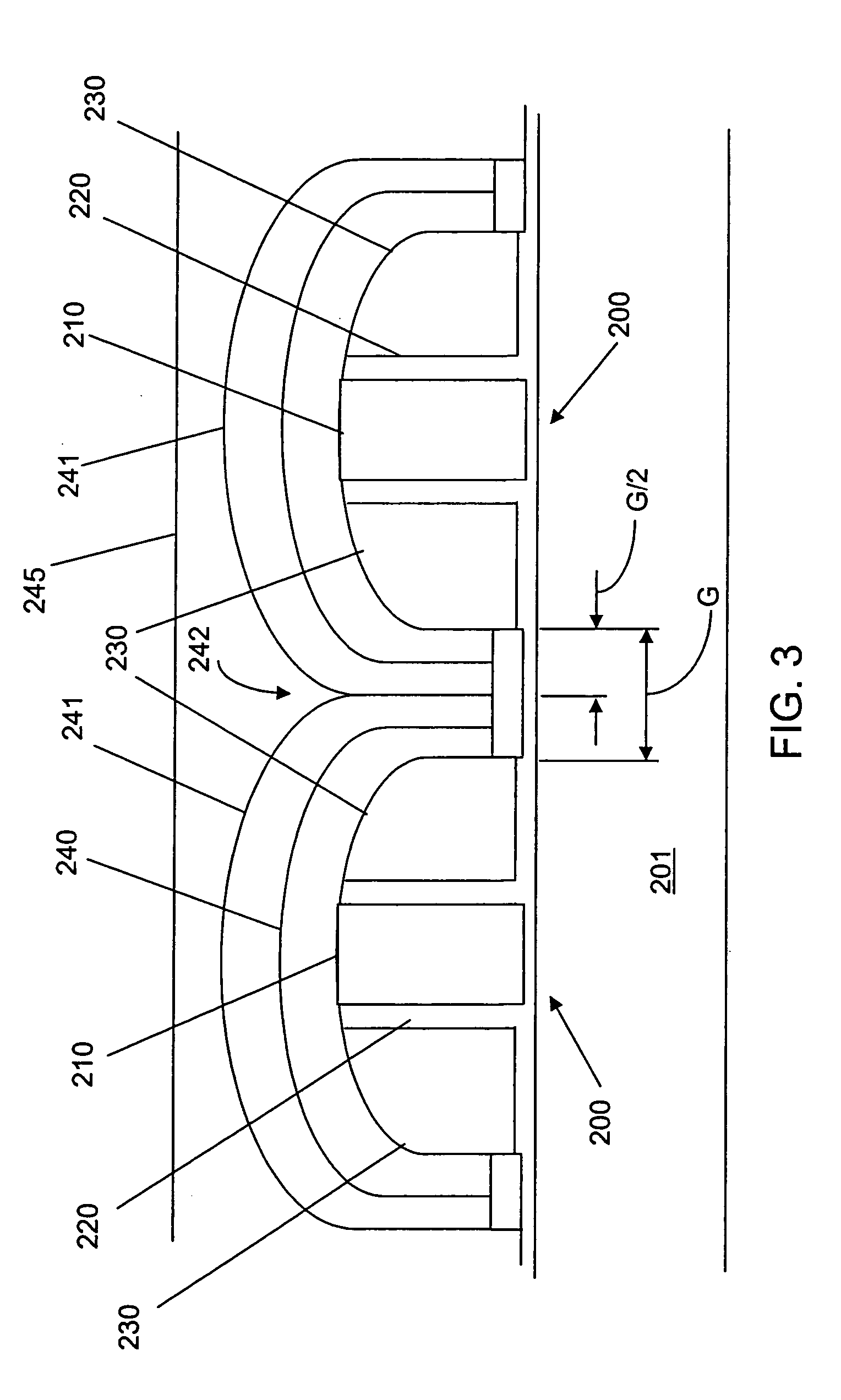

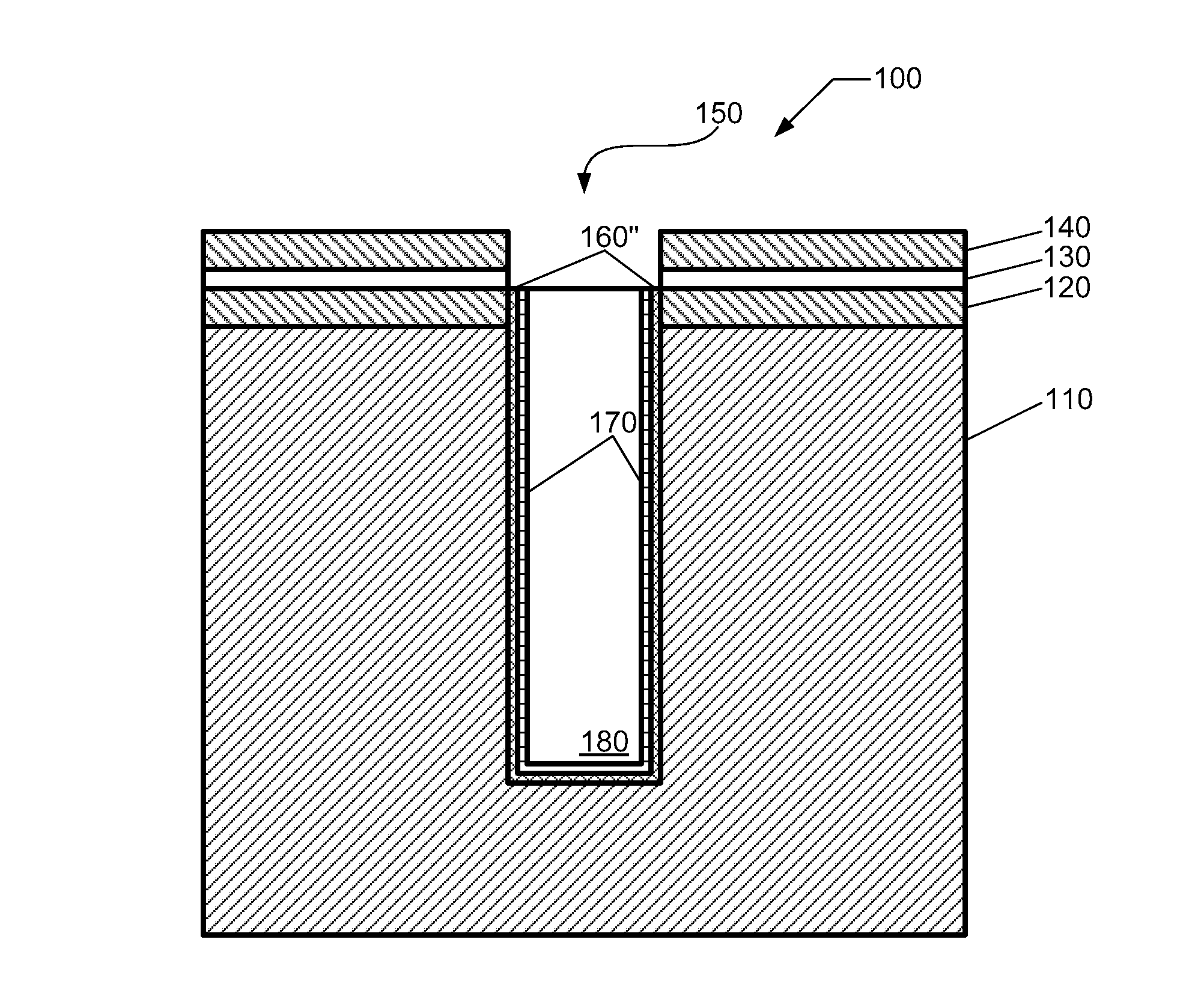

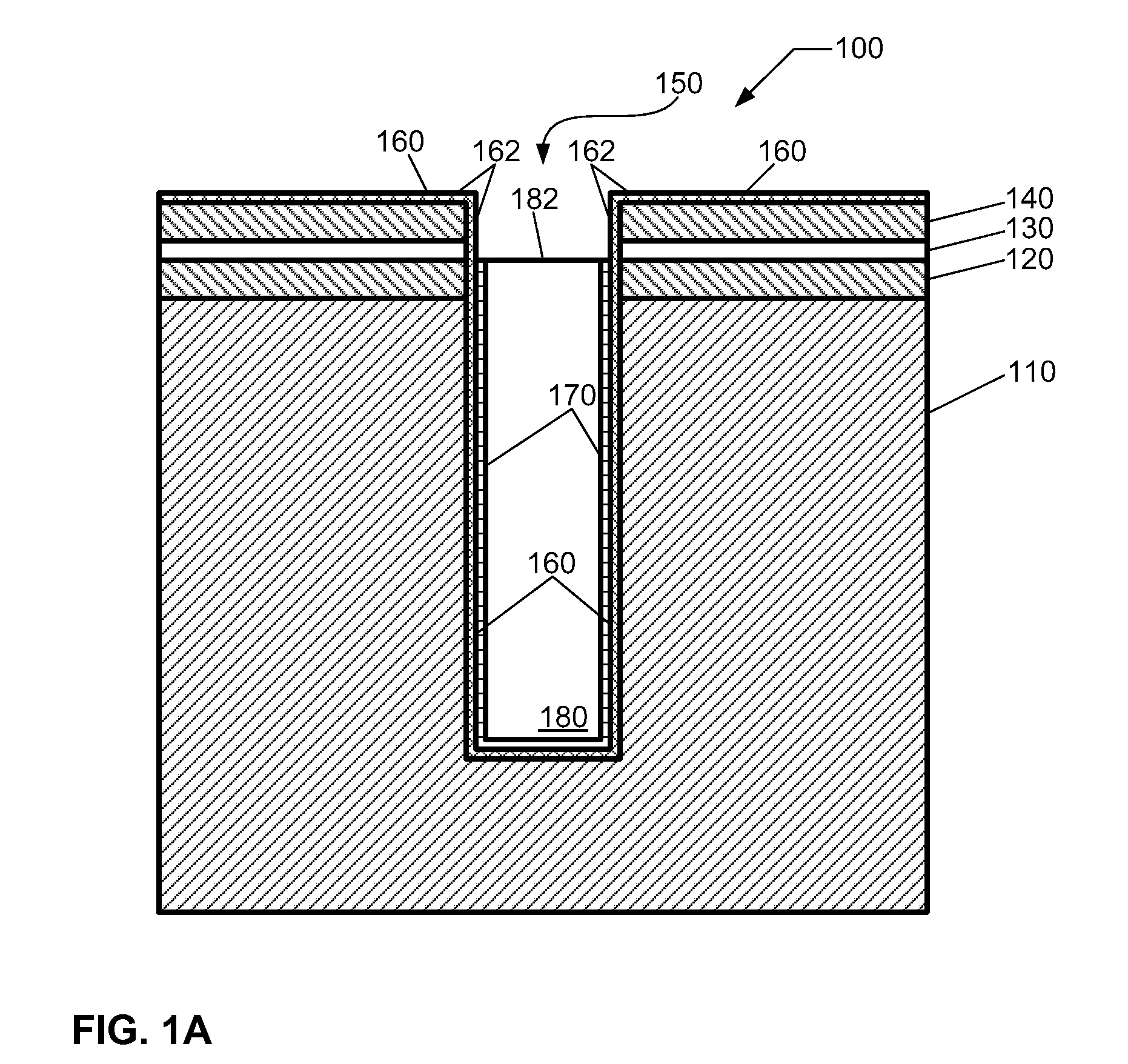

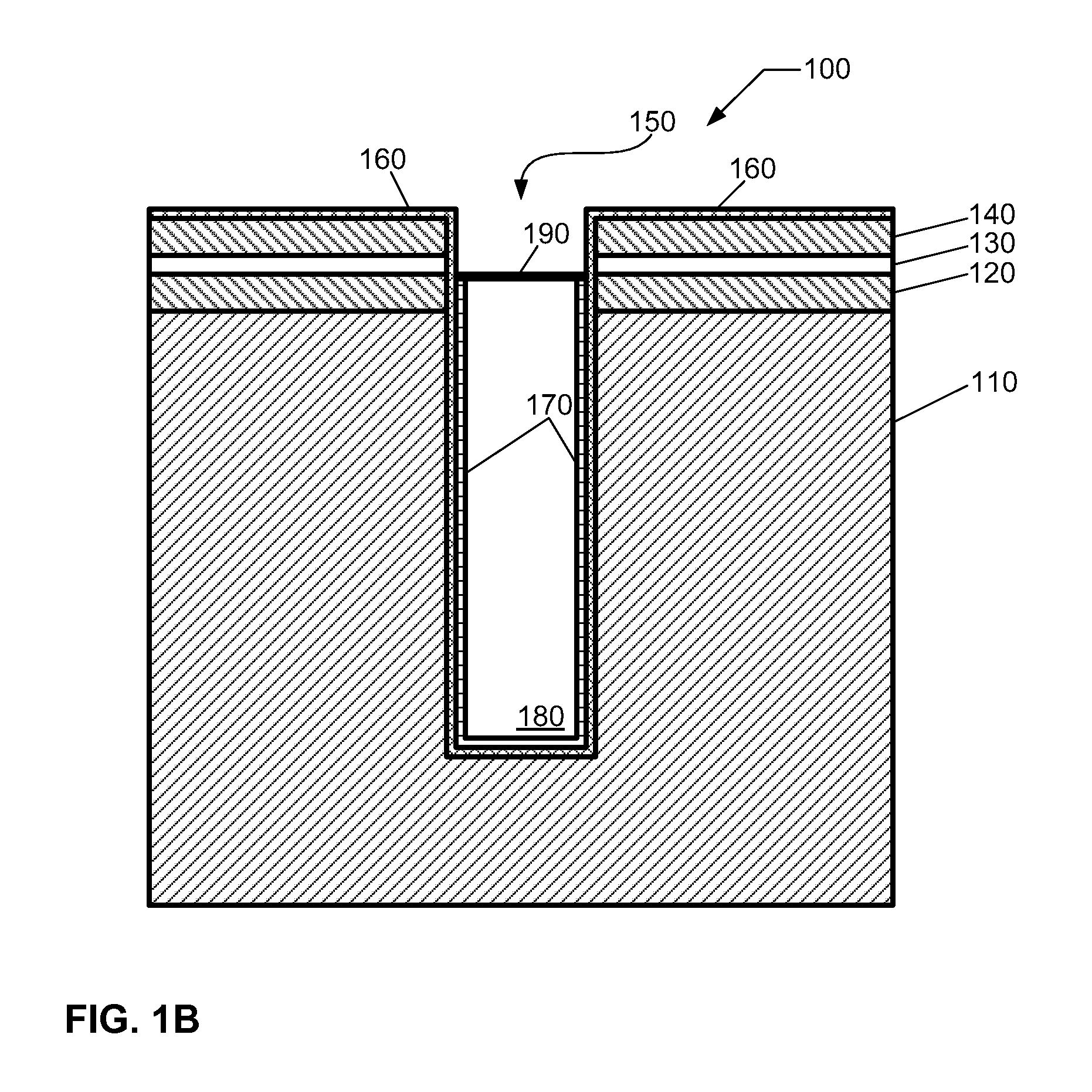

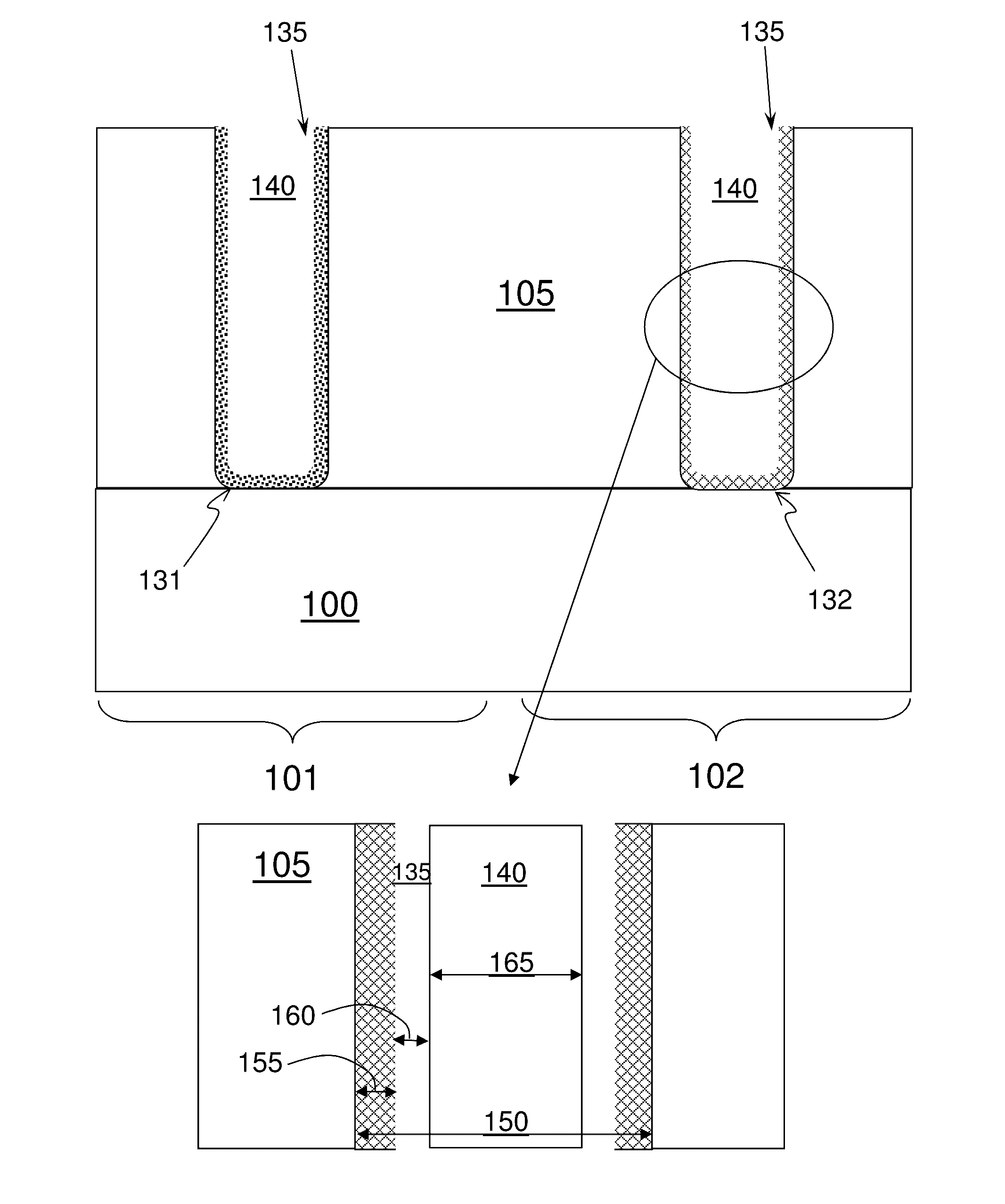

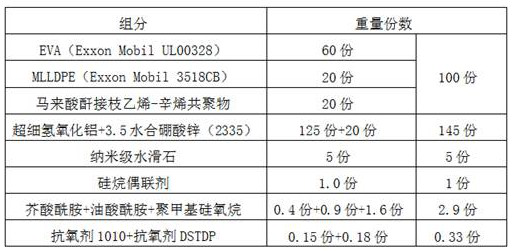

Atomic layer deposition for filling a gap between devices

A method is provided for filling a trench or gap between a pair of semiconductor devices formed above a substrate. A liner is applied in a trench or gap between a pair of devices by atomic layer deposition to partially fill the trench or gap. The trench or gap is filled by a bulk fill process.

Owner:TAIWAN SEMICON MFG CO LTD

Bowls comprising acrylic plastics filled with alumina trihydrate, and processes for making same

Processes for producing durable three-dimensional bowls such as water basins comprising acrylic plastics heavily filled with alumina trihydrate, some embodiments including colorants and visible particles such as those used for simulating stone such as granite. A preferred process for manufacturing the bowls of such material includes defining a flat rigid blank in the approximate top outline shape of bowl to be formed, e.g., the blank being a flat oval for an oval bowl and circular for a circular bowl. The flat blank is provided a smooth side or sides which will be the concave finished side in use. The blank is heated to a point of softening and of uniform temperature throughout, and located within a molding die such as a matched molding die having a female cavity of the desired bowl shape. The heated blank is indexed to the die, but left generally unrestrained so that the heated blank and edges thereof are un-clamped, thereby allowing the edges to be moved inward to help minimize tension loads during forming. Force is applied to the blank, such as from a male portion of the die, to compress the blank into the female cavity and desired bowl shape. The bowl is cooled, removed from the die, the top edge trimmed, a drain hole with surrounding bevel applied, and as-needed re-facing is applied on the exposed or finished side(s).

Owner:TRANSFER FLOW INT

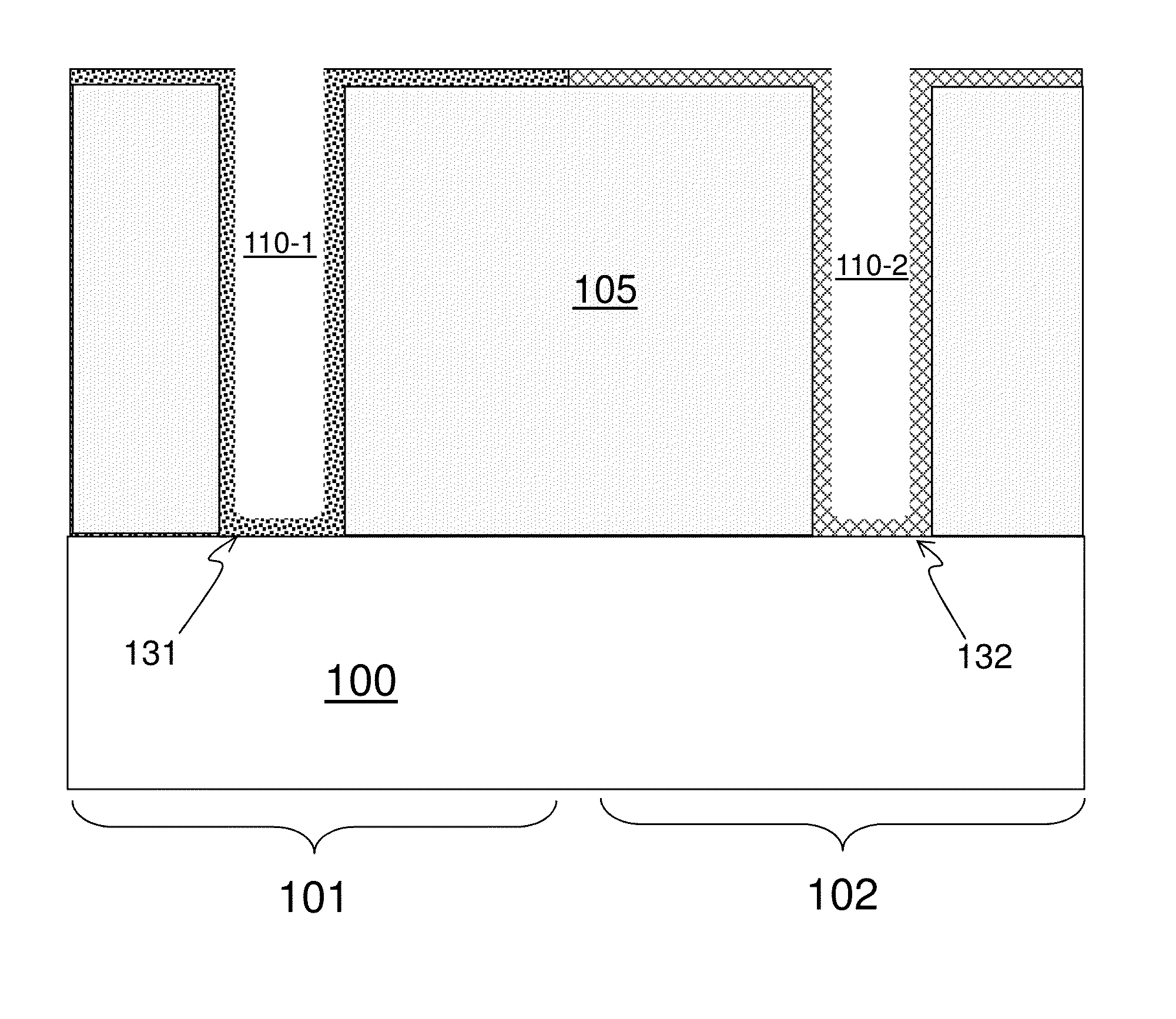

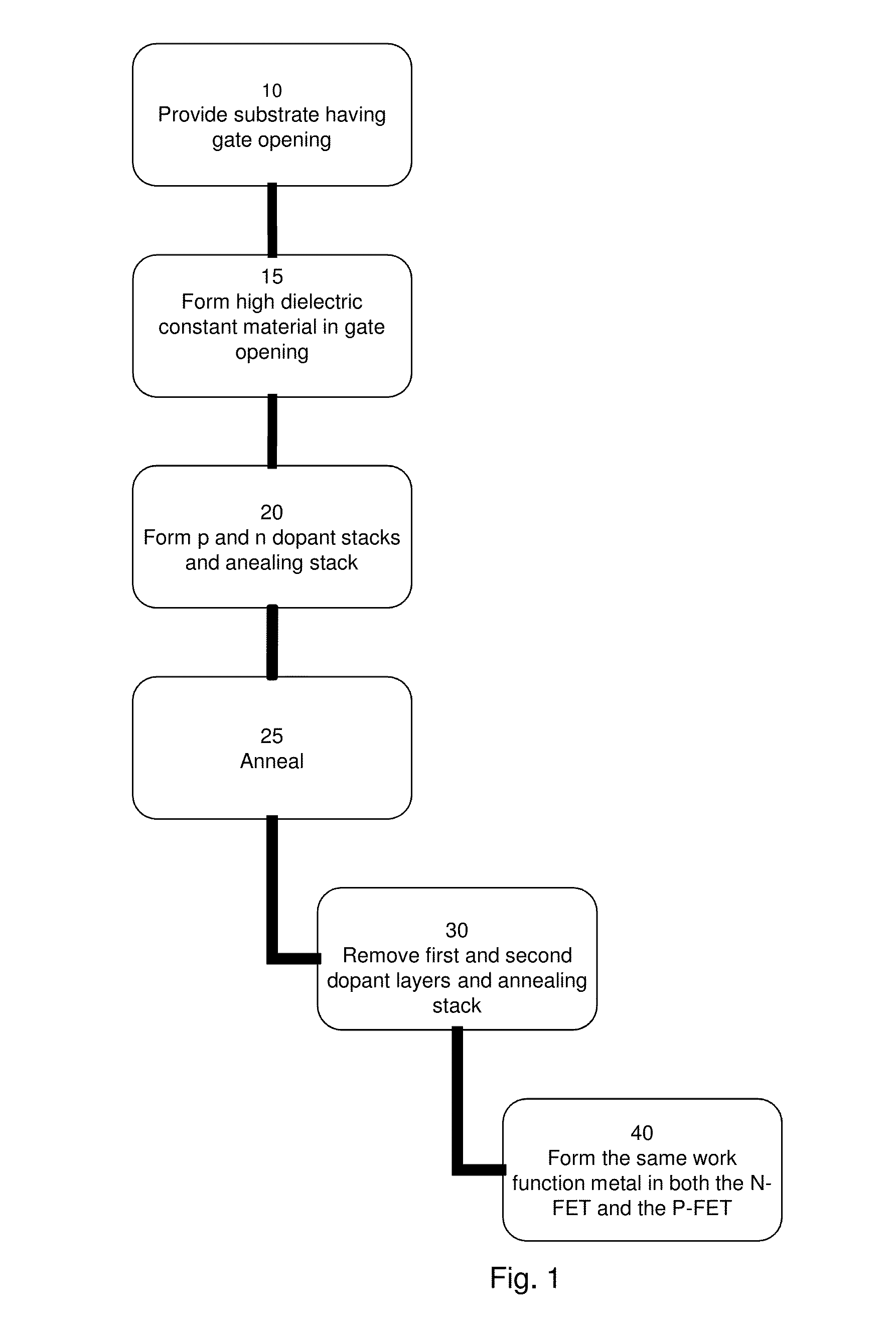

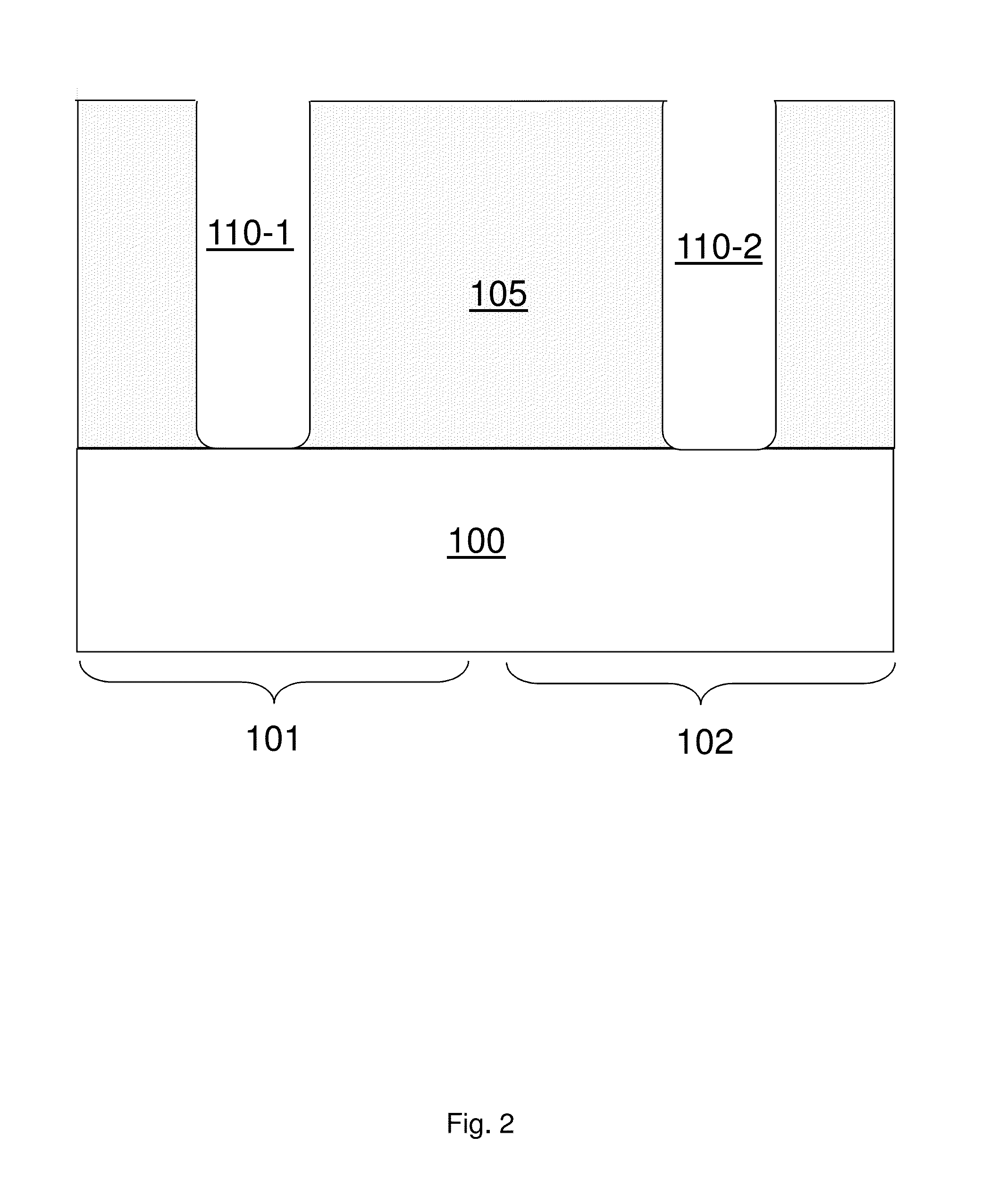

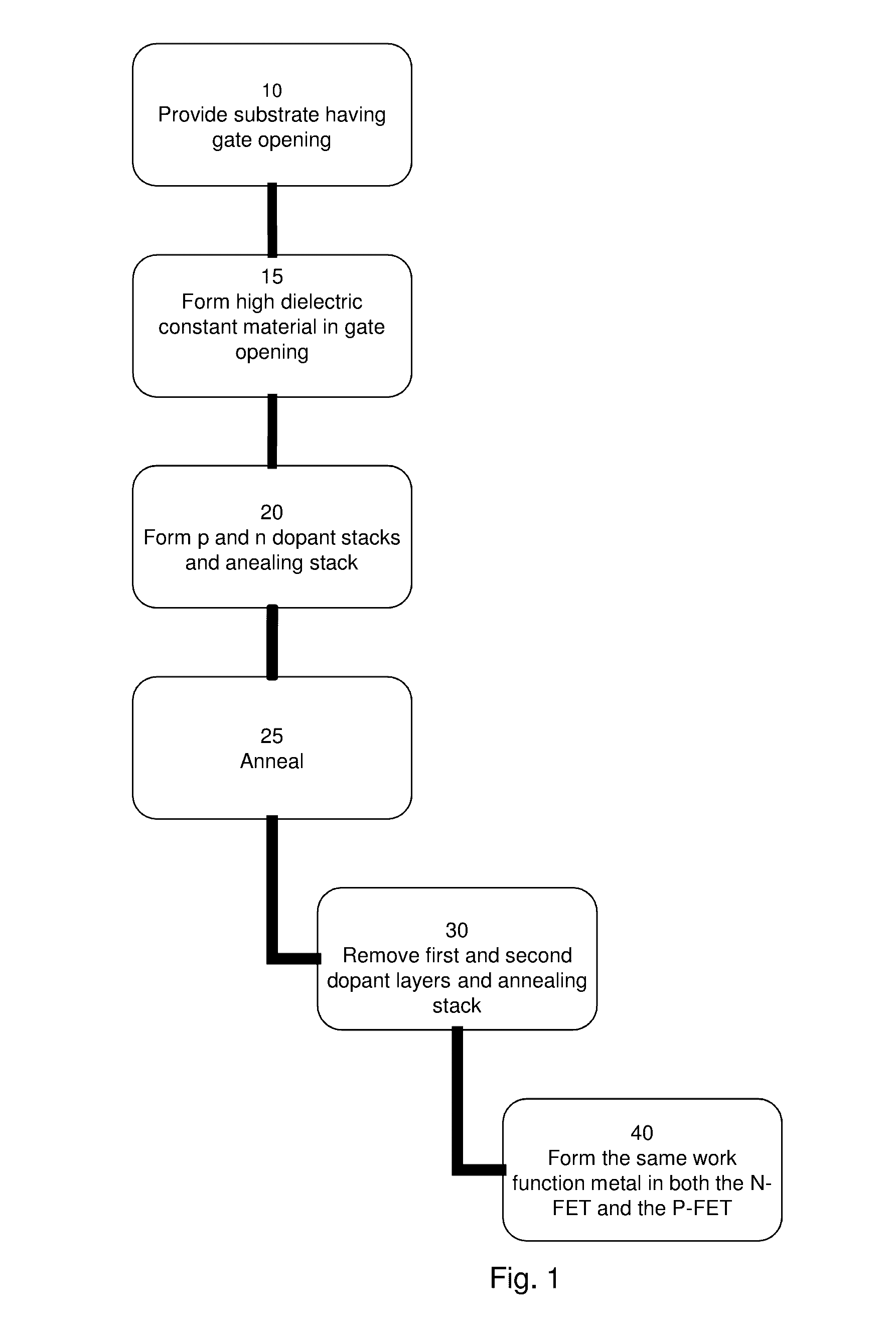

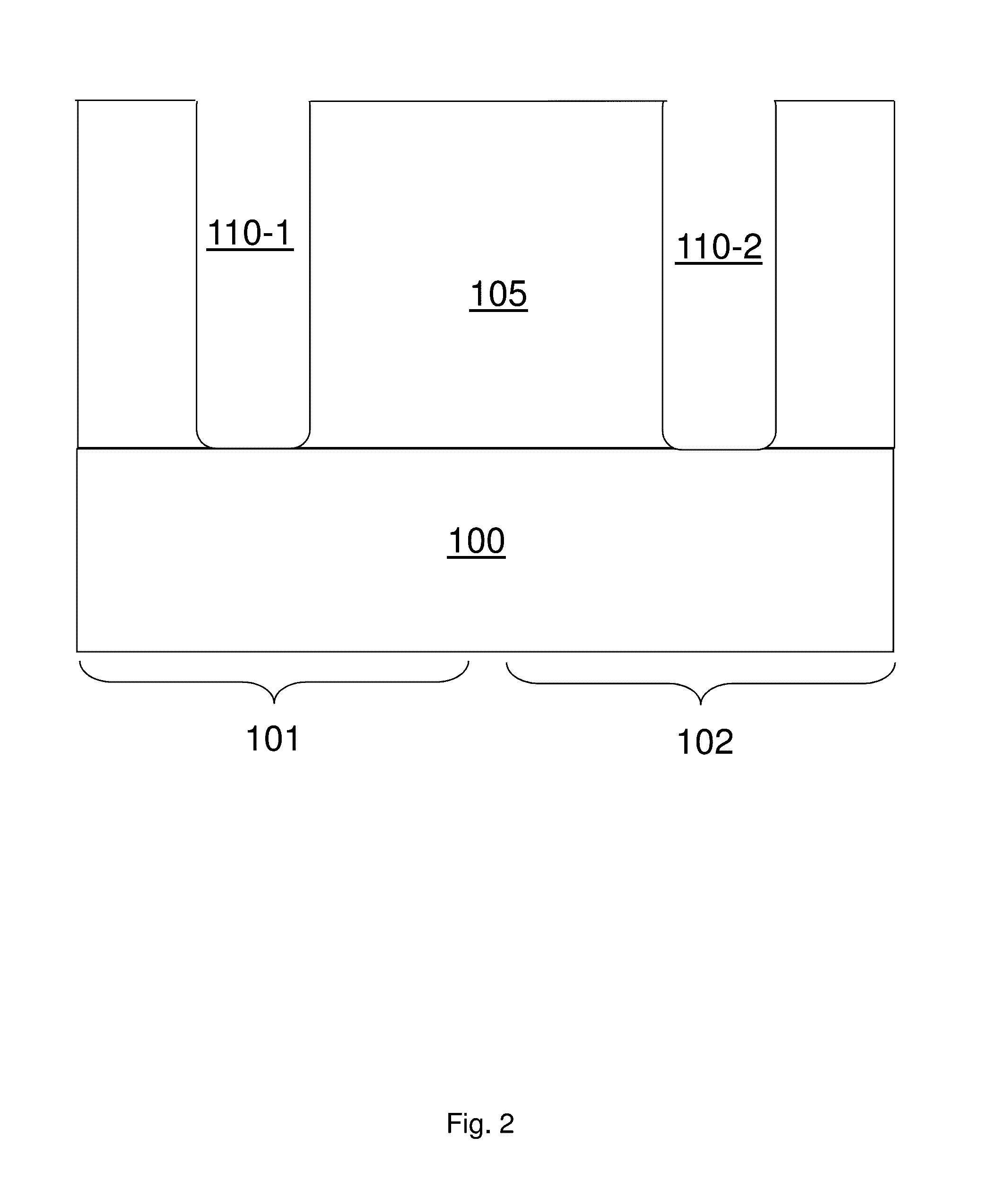

Methods and structure to form high k metal gate stack with single work-function metal

ActiveUS20150255463A1Simplify and improve performanceLower gate resistanceTransistorSolid-state devicesElectrical resistance and conductanceLithographic artist

A method for forming a replacement metal gate structure sharing a single work function metal for both the N-FET and the P-FET gates. The method oppositely dopes a high-k material of the N-FET and P-FET gate, respectively, using a single lithography step. The doping allows use of a single work function metal which in turn provides more space in the metal gate opening so that a bulk fill material may occupy more volume of the opening resulting in a lower resistance gate.

Owner:TESSERA LLC

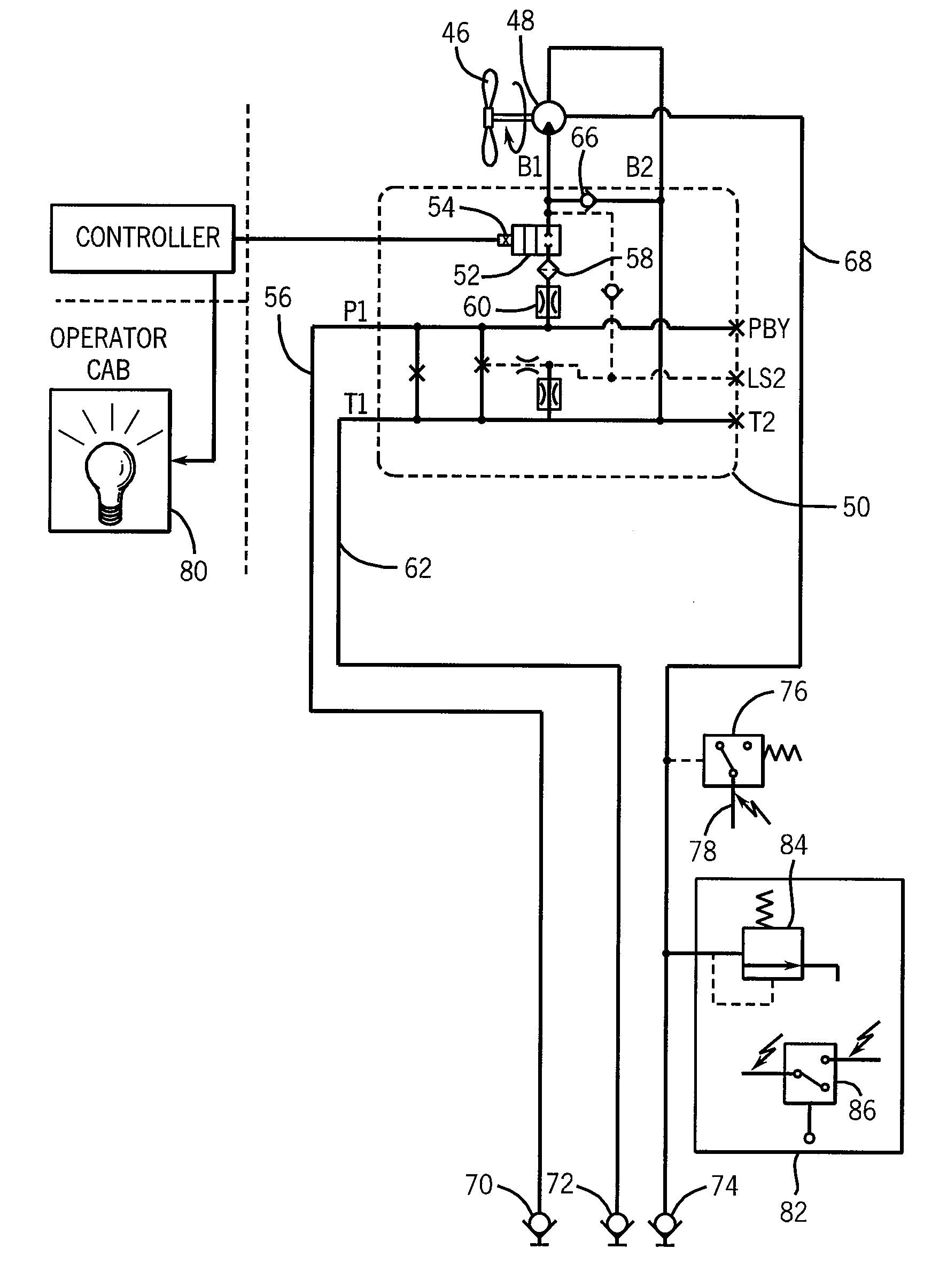

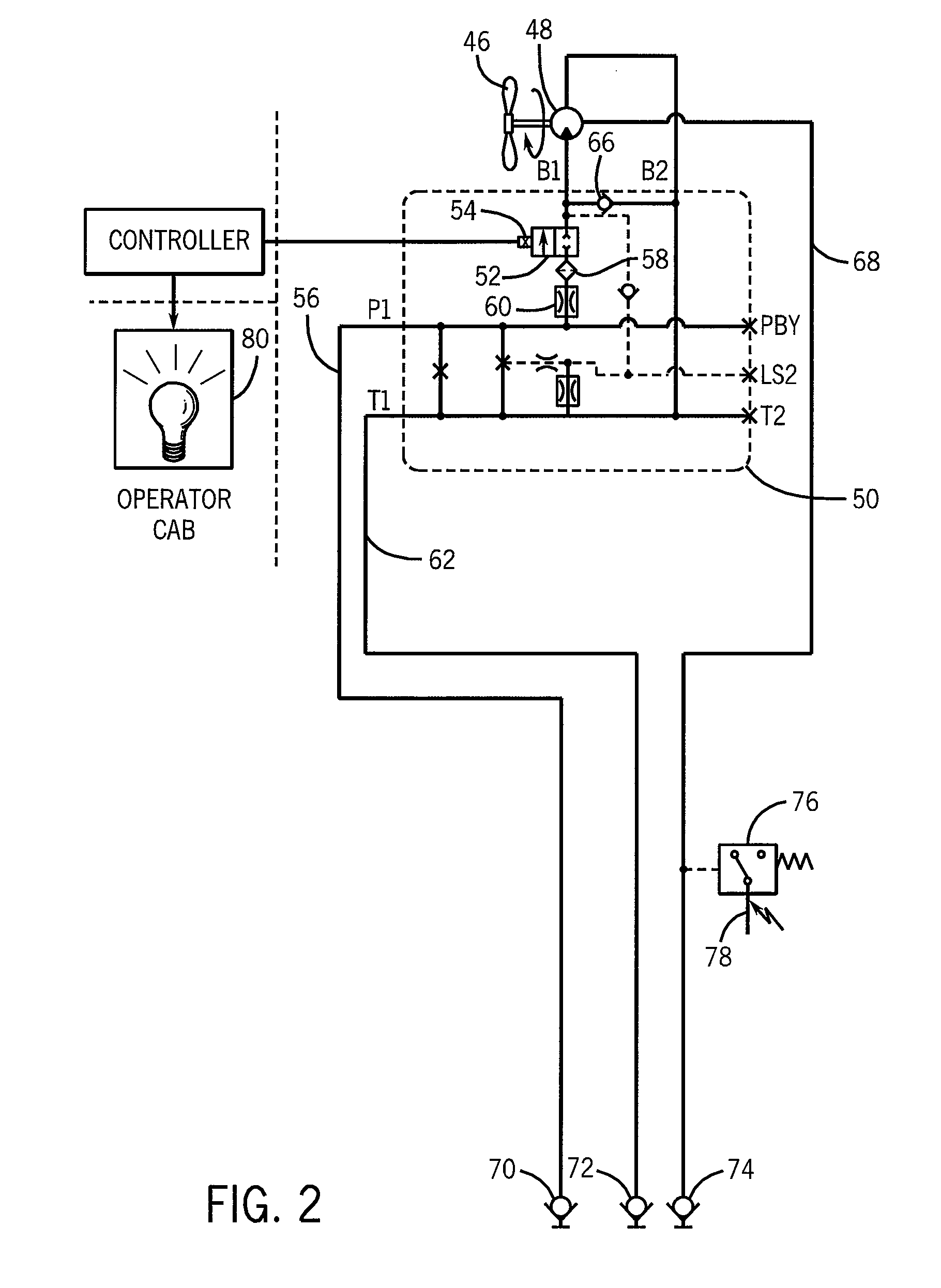

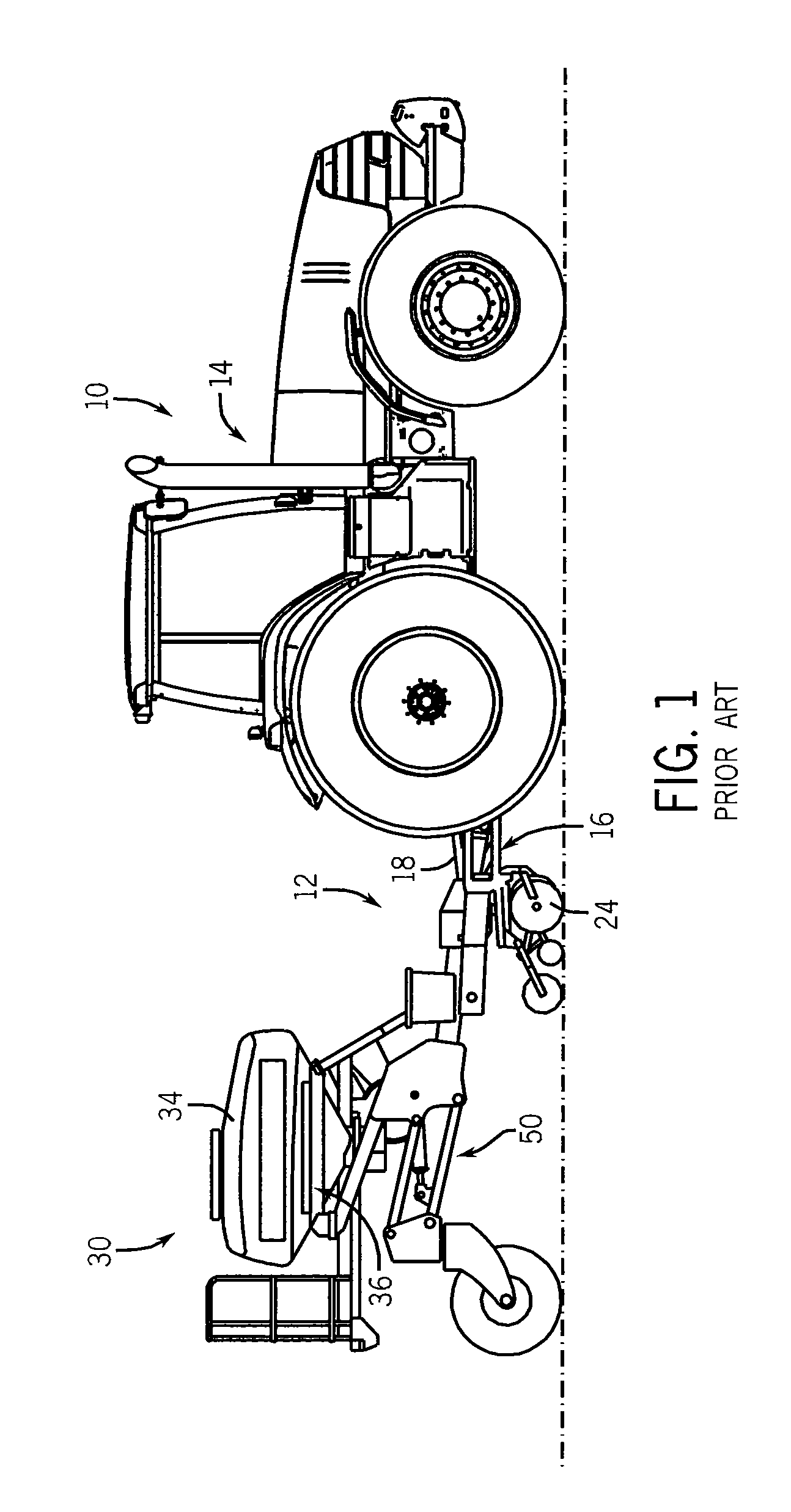

Case Drain Line Pressure Switch With Automatic Fan Drive Motor Shutdown

InactiveUS20100205953A1Effectively shutdownFluid-pressure actuator safetyFluid couplingsBulk fillDrive motor

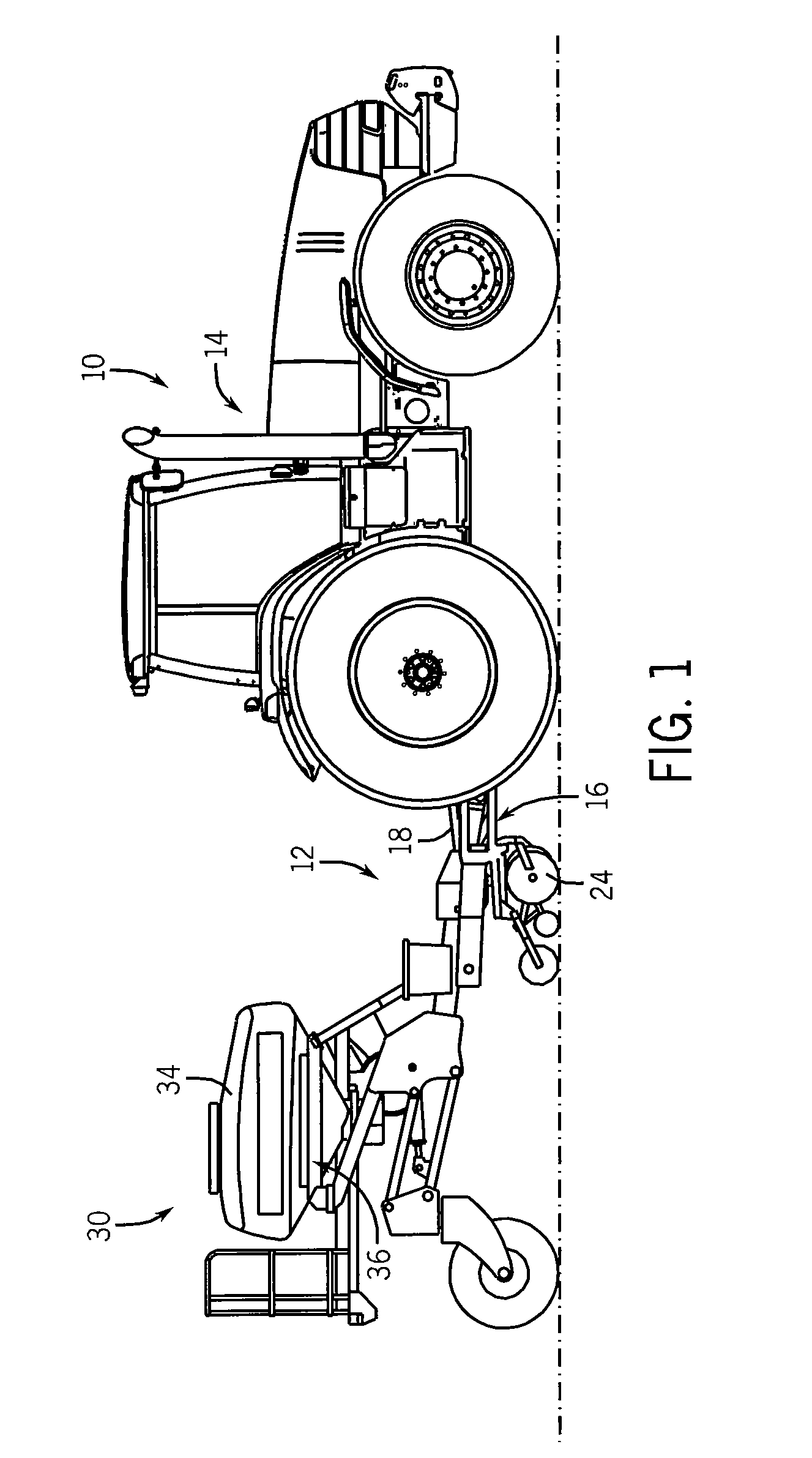

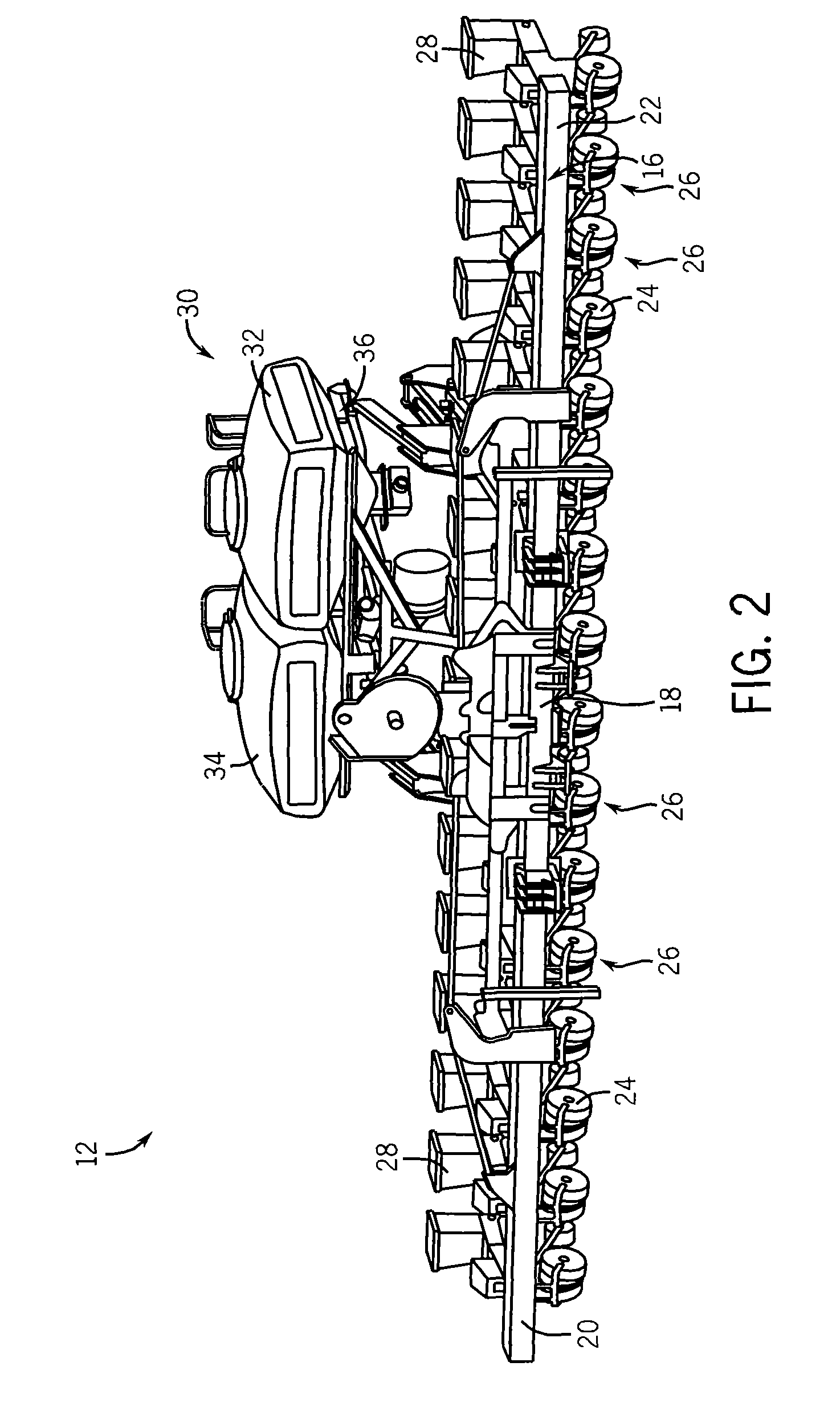

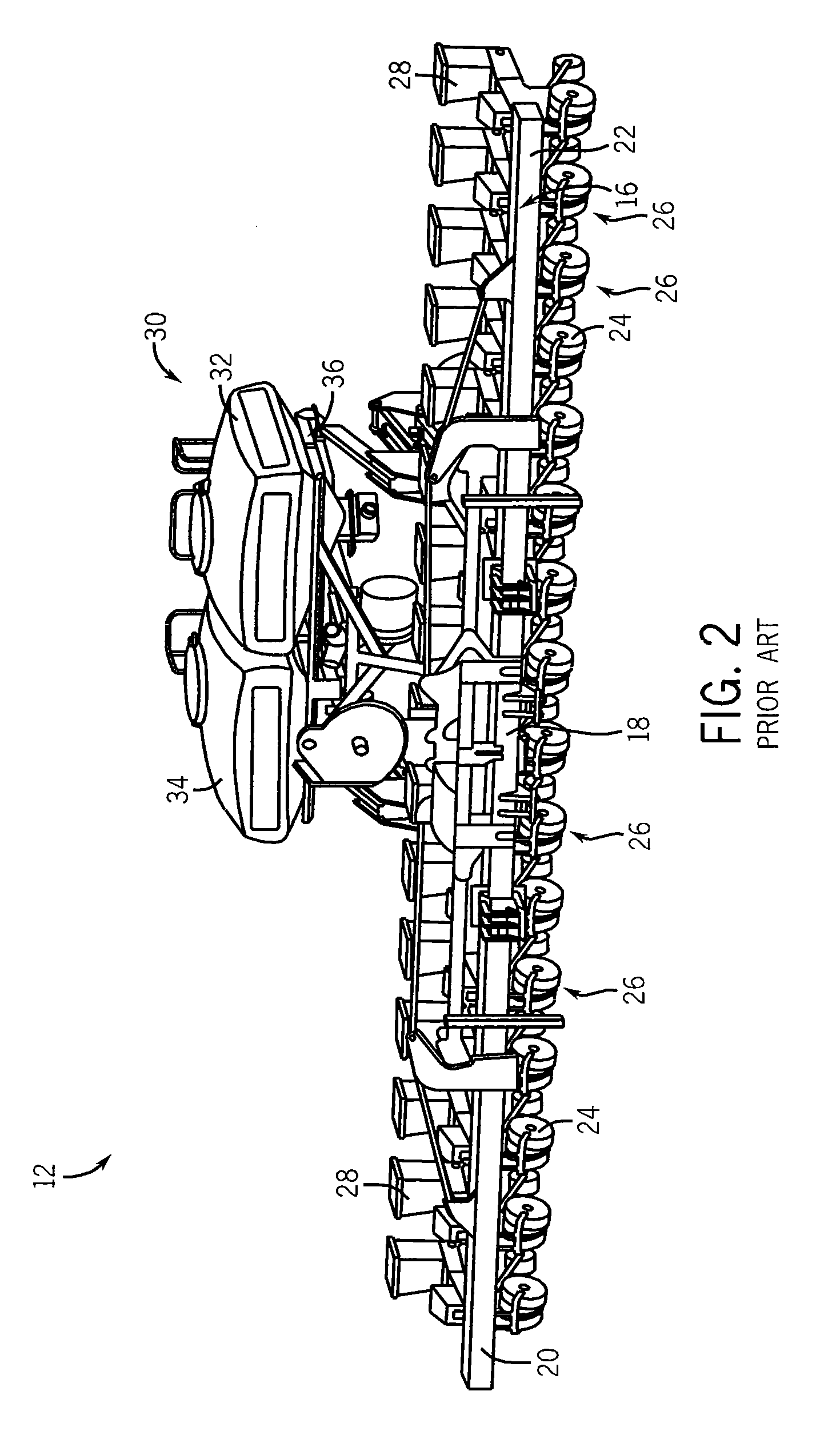

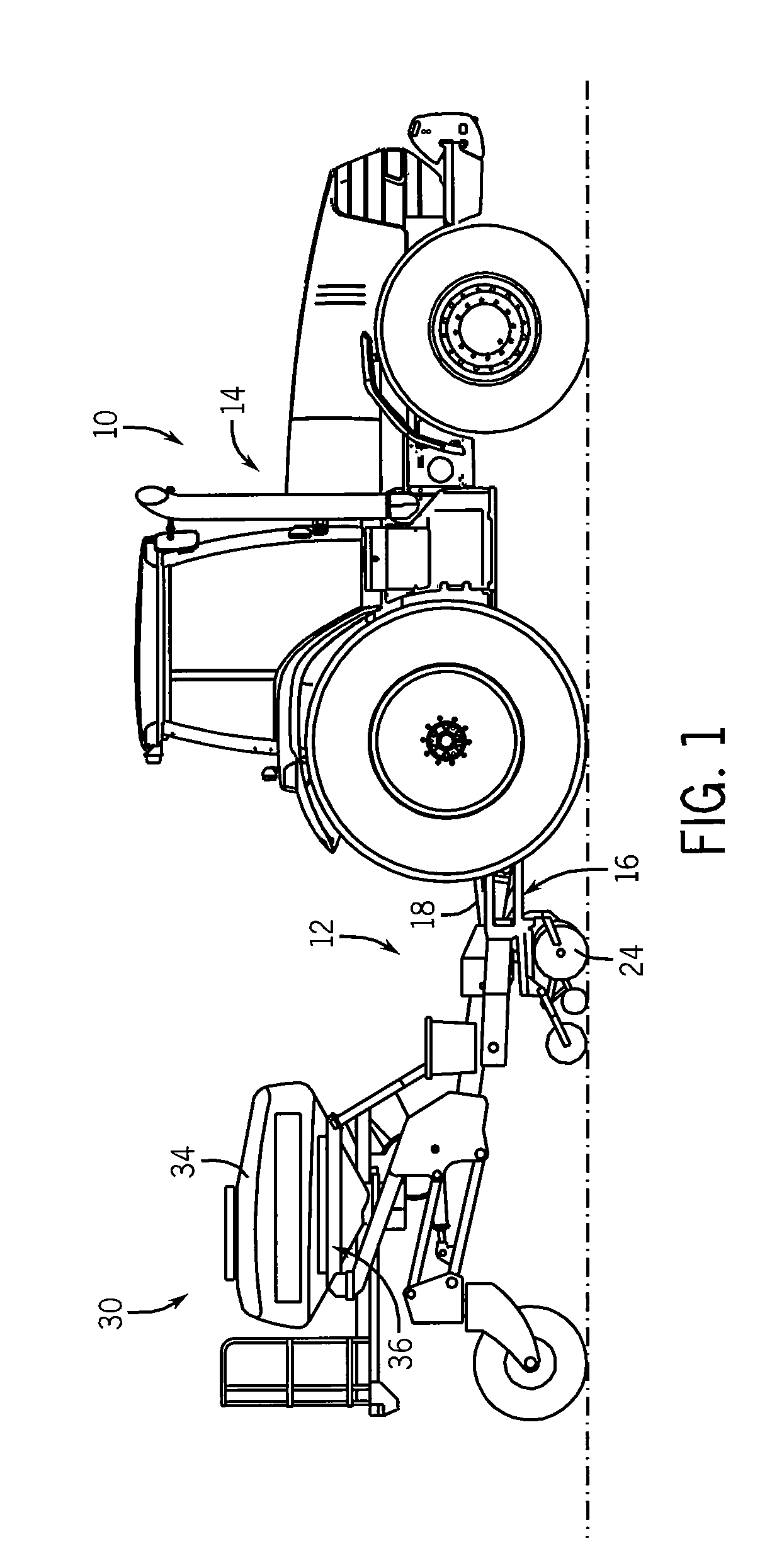

A case drain circuit particularly well suited for use with a bulk fill subassembly or a vacuum fan assembly of an agricultural implement towed by a tractor or similar vehicle includes a pressure switch that may cause illumination of an in-cab warning light and / or sounding of an in-cab alarm when pressure in the case drain circuit exceeds a predetermined threshold. A fan is driven by a solenoid controlled hydraulic motor which is supplied hydraulic fluid under pressure from a flow control valve to the motor in accordance with electrical signals that are supplied to the solenoid by a controller. The case drain circuit provides a pathway along which leakage fluid from the motor may be delivered to a fluid reservoir, preferably carried by the towing vehicle. During undesirable high pressure conditions in the case drain circuit, the pressure switch provides a corresponding high pressure signal to the controller that in turn cuts electrical current to the solenoid to cut the flow of hydraulic fluid to the motor.

Owner:CNH IND AMERICA LLC

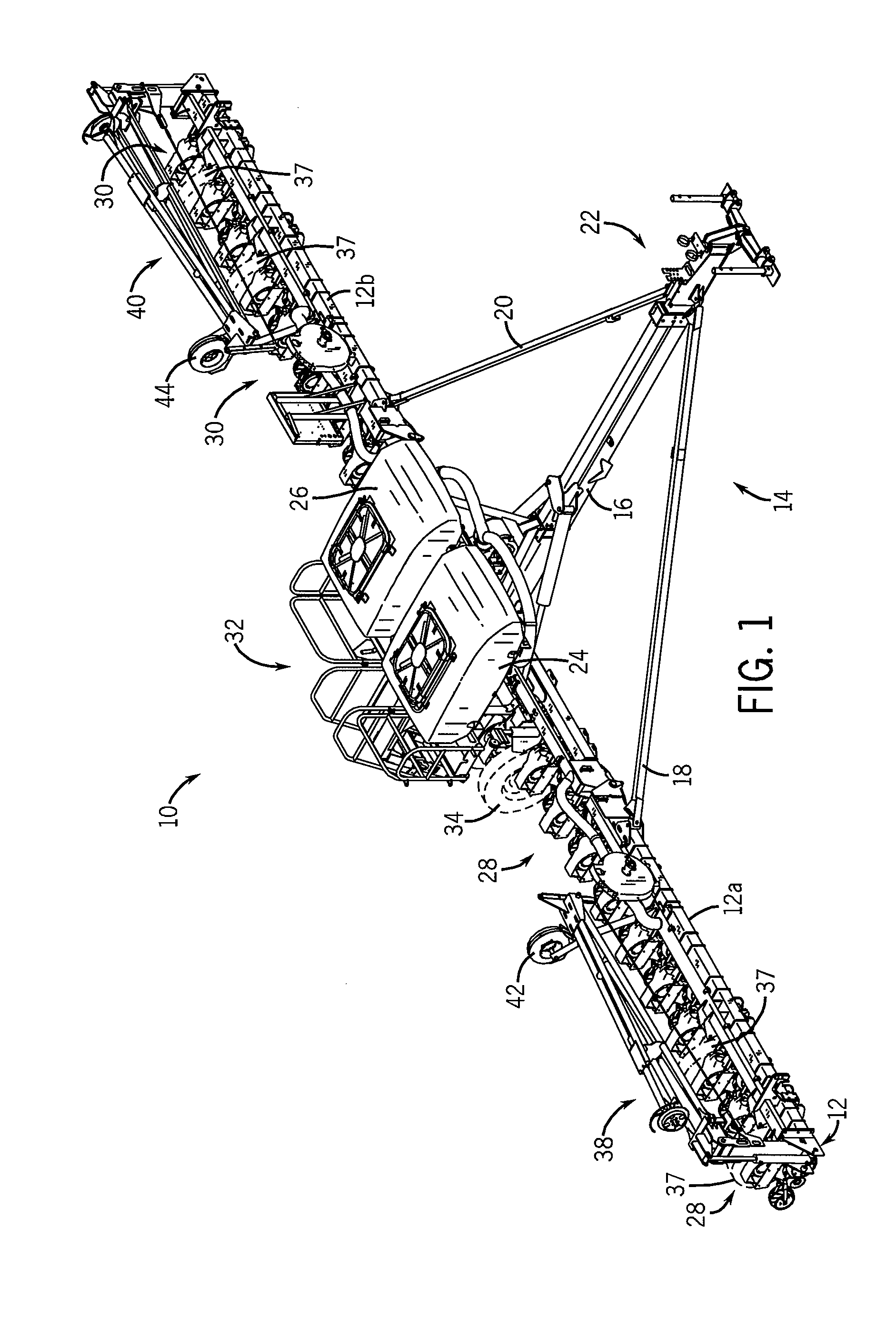

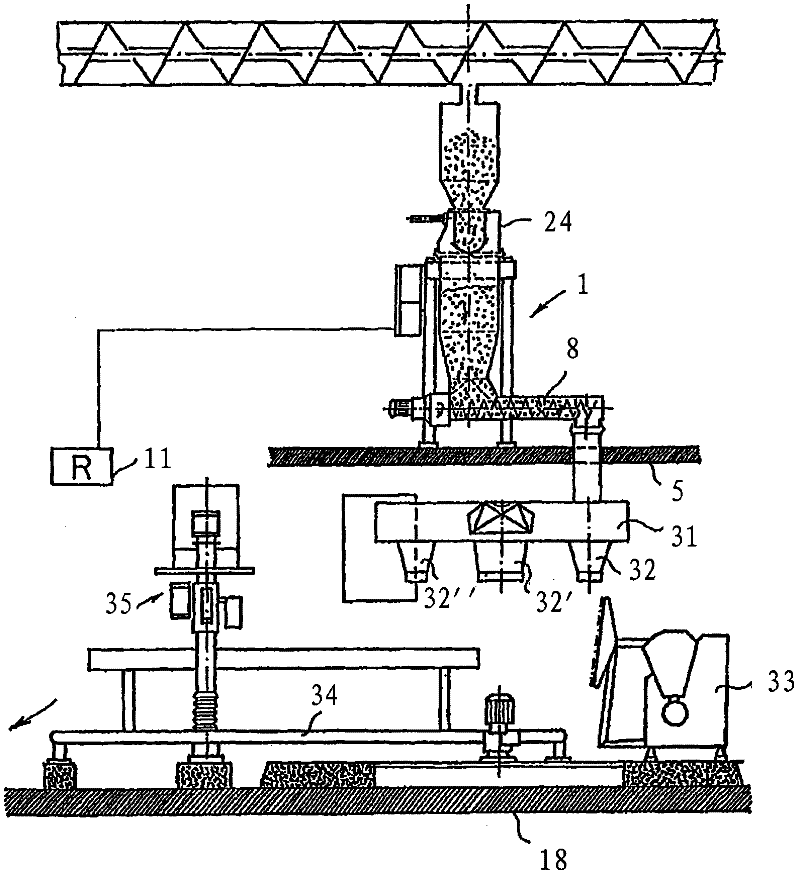

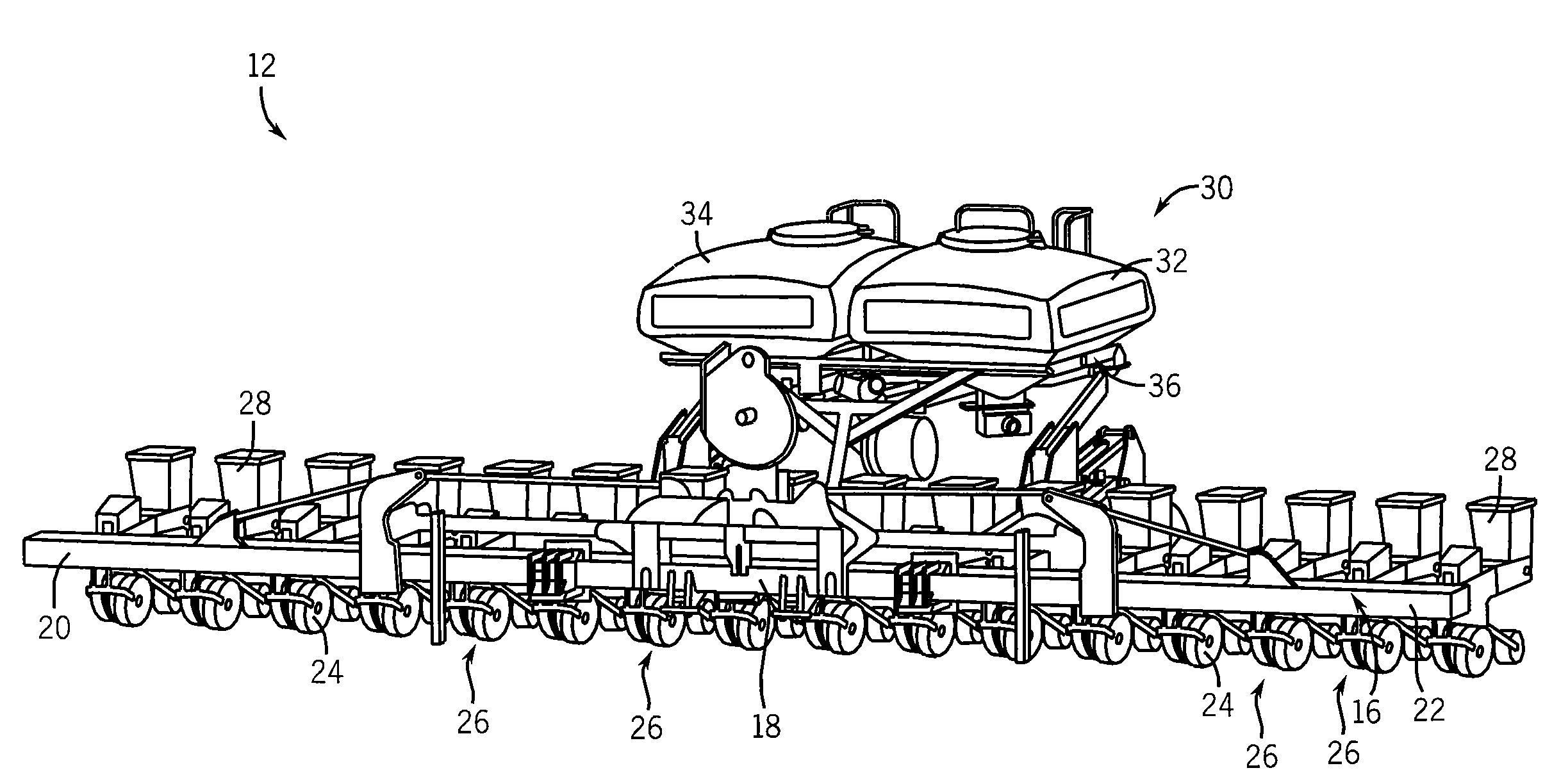

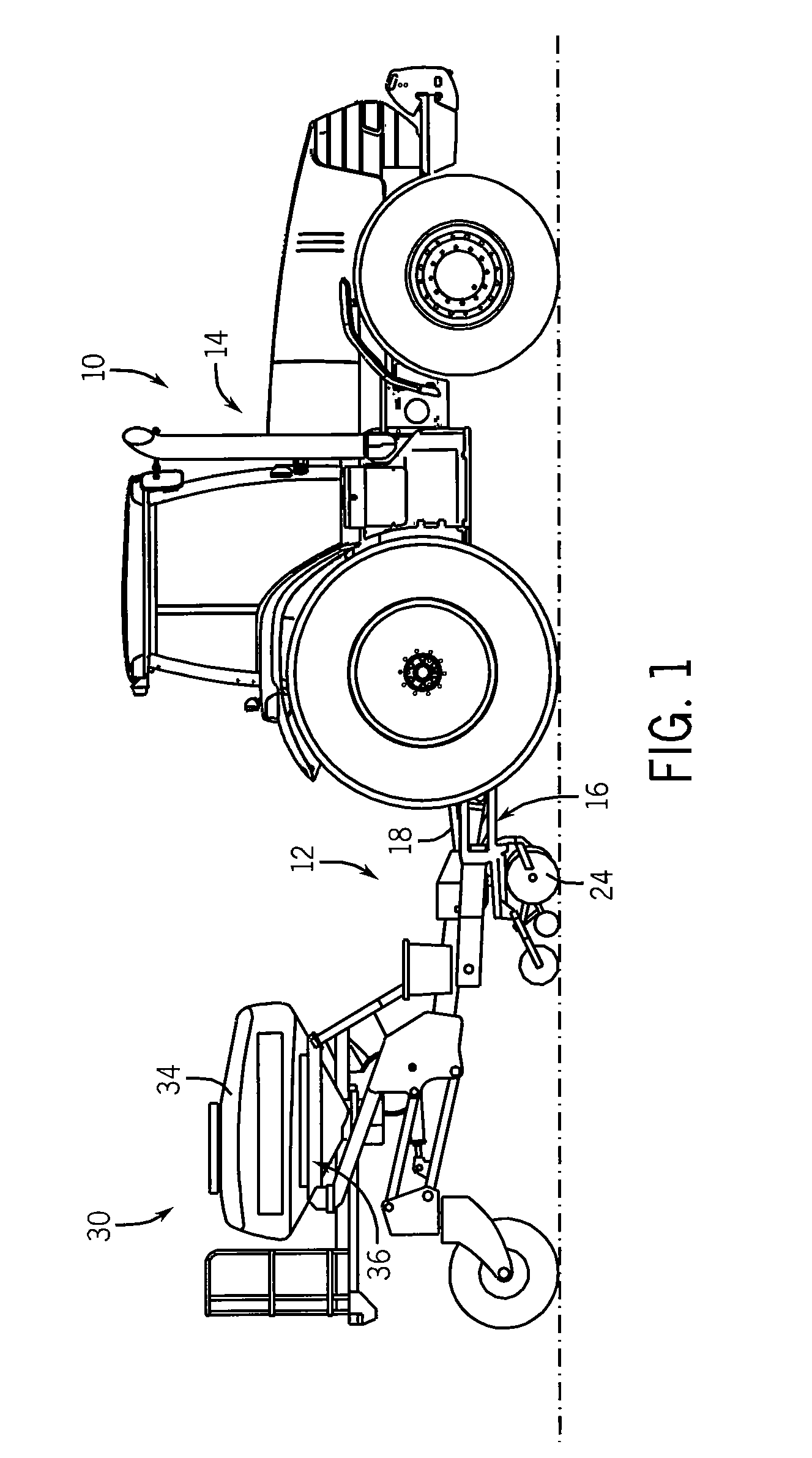

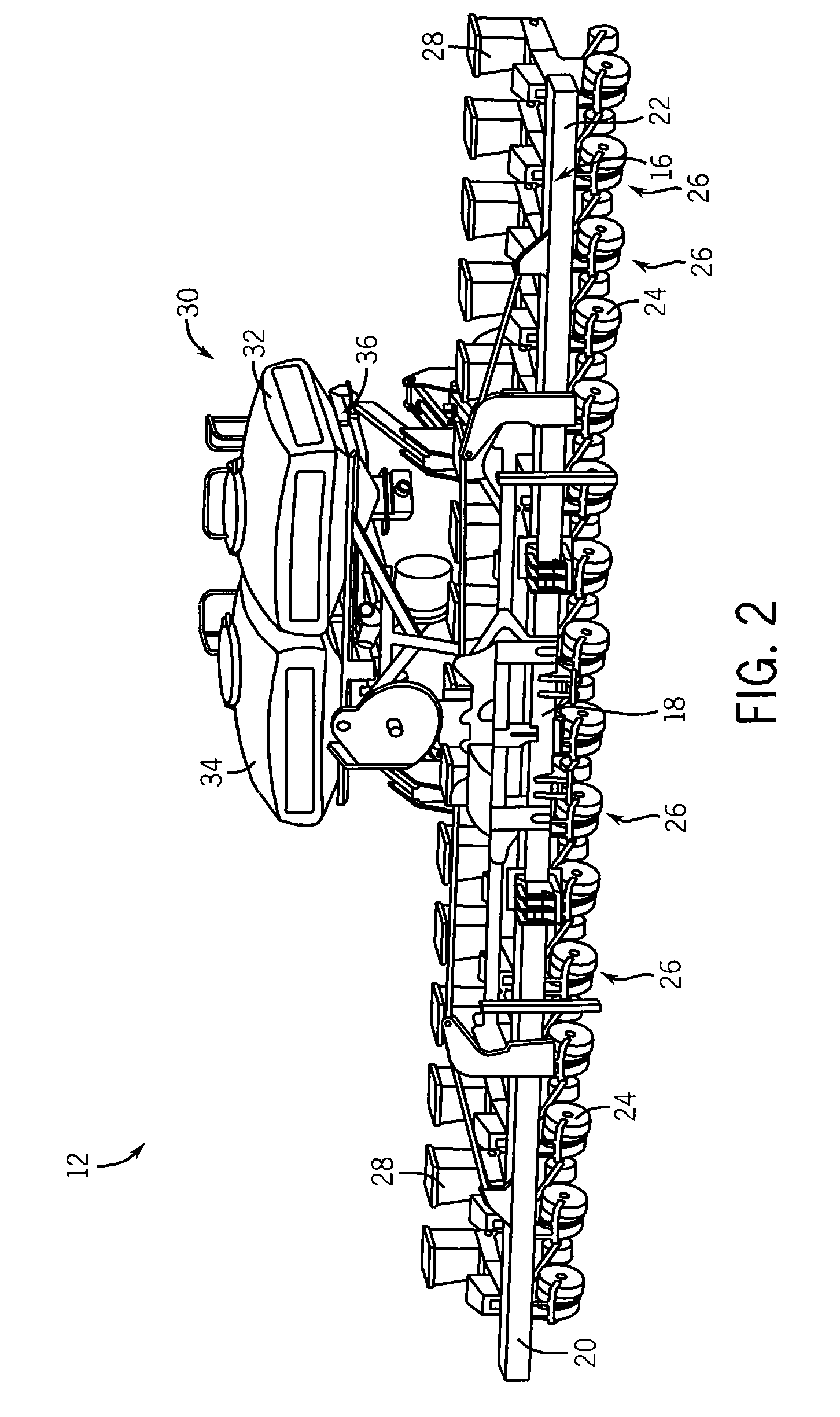

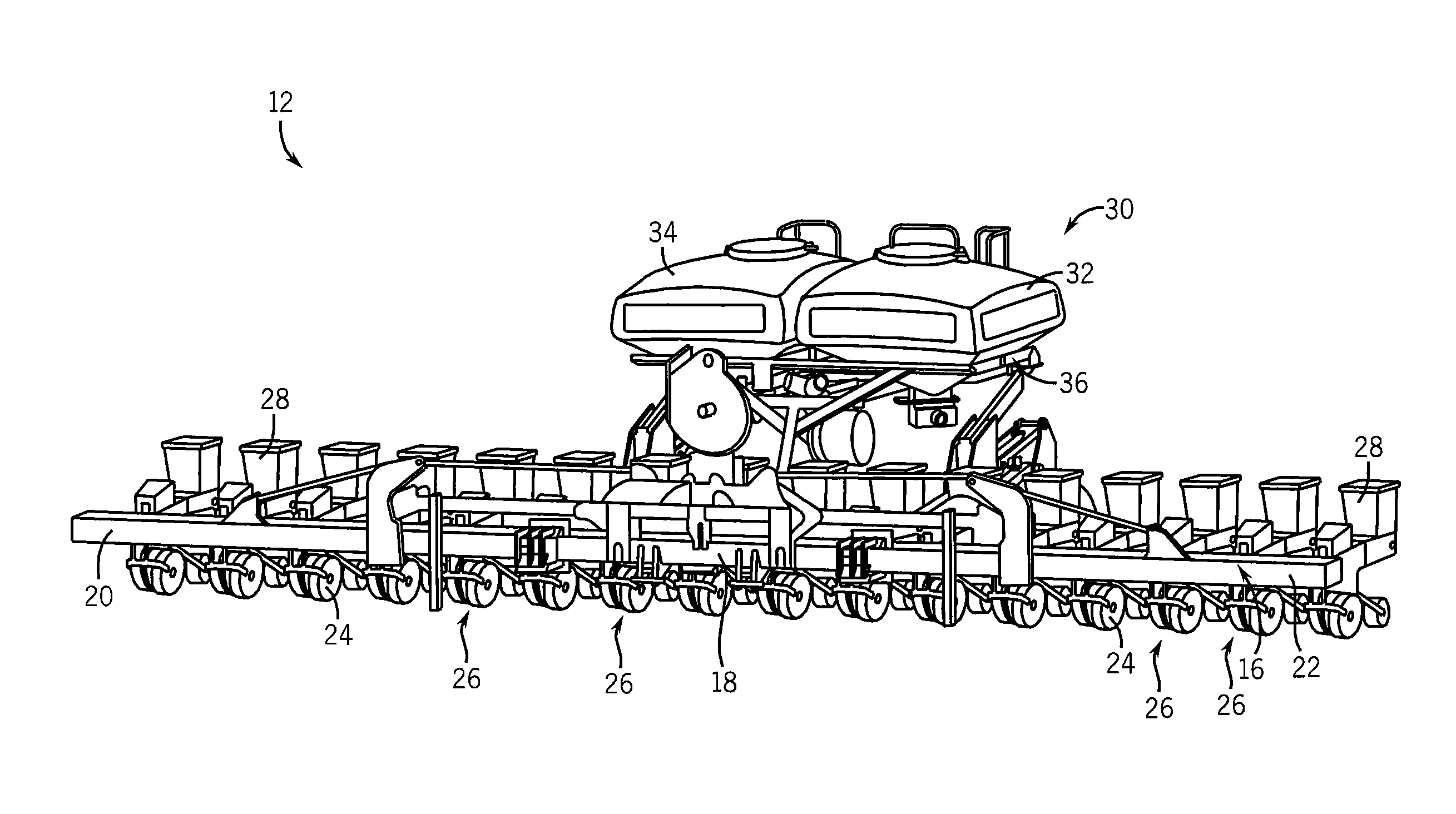

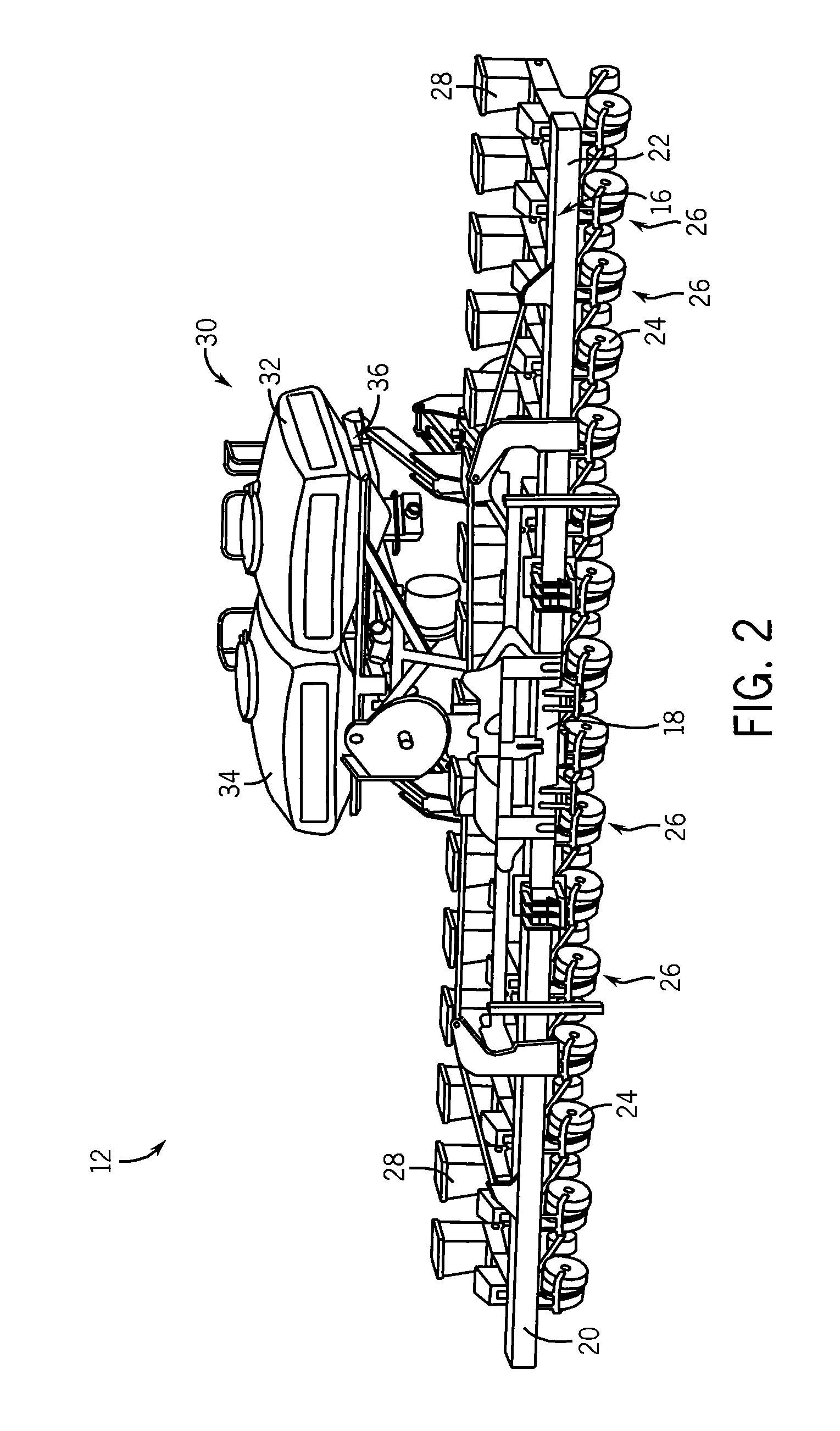

Stack-fold implement having bulk fill system

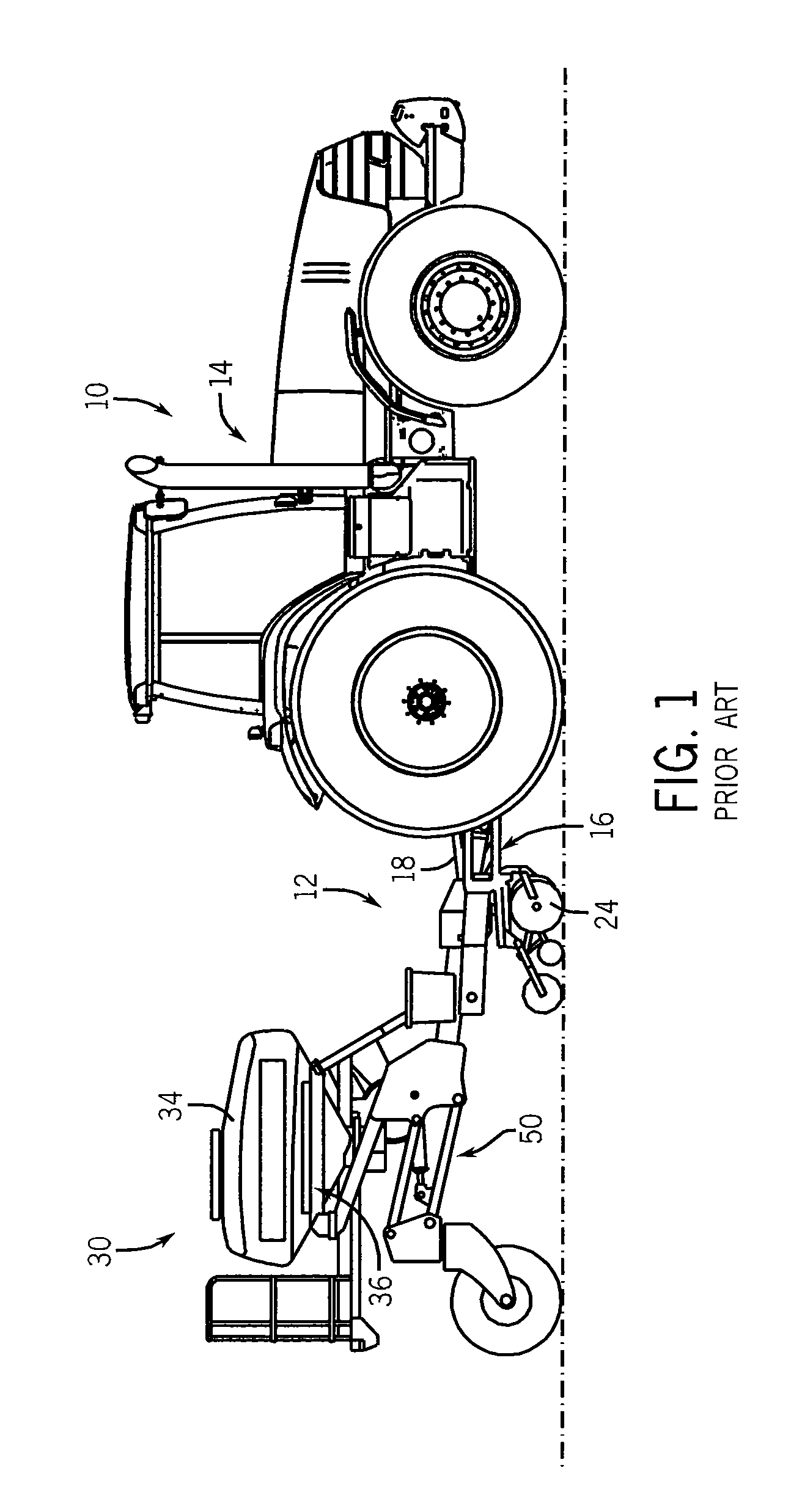

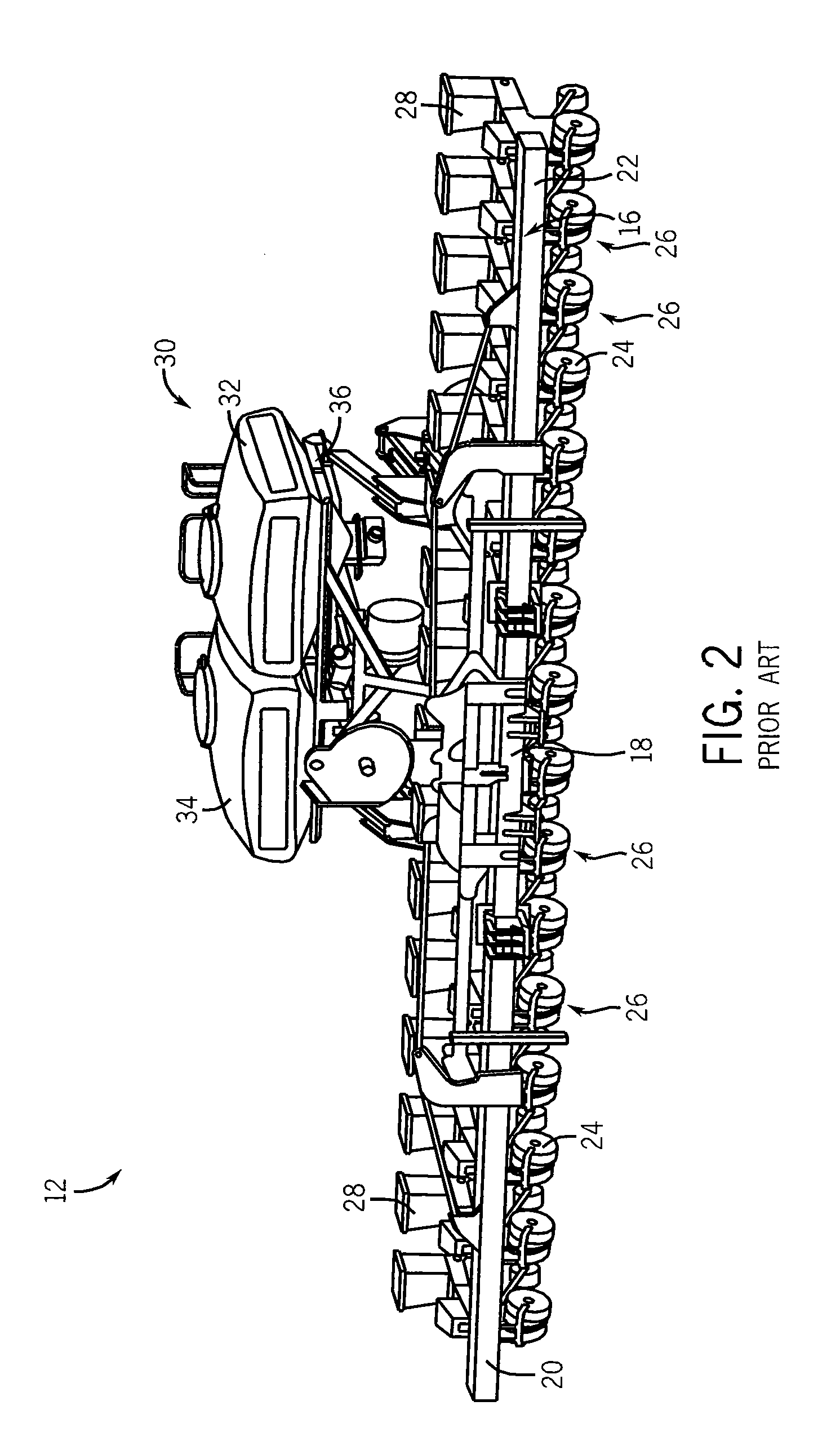

A stack-fold implement having a central bulk fill hopper assembly is provided. The bulk fill hopper assembly is mounted to the center frame section of the stack-fold implement and does not affect the narrowness of the stack-fold implement when it's in a stacked, transport position. The hopper assembly includes a pair of bulk fill hoppers or tanks supported by cradle that is in turn supported by a pair of wheels. The cradle is removably coupled to the center frame section by a plurality of rigid frame members.

Owner:CNH IND CANADA

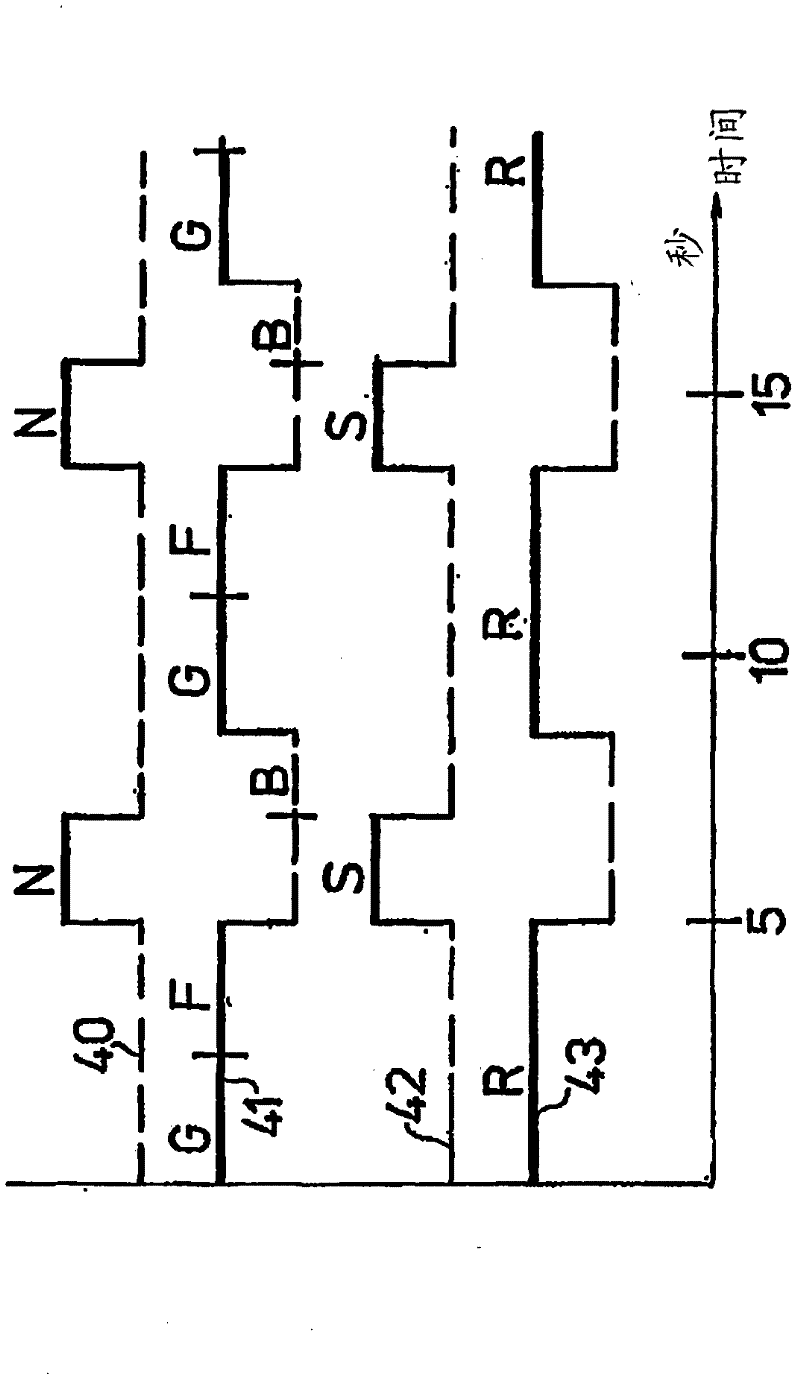

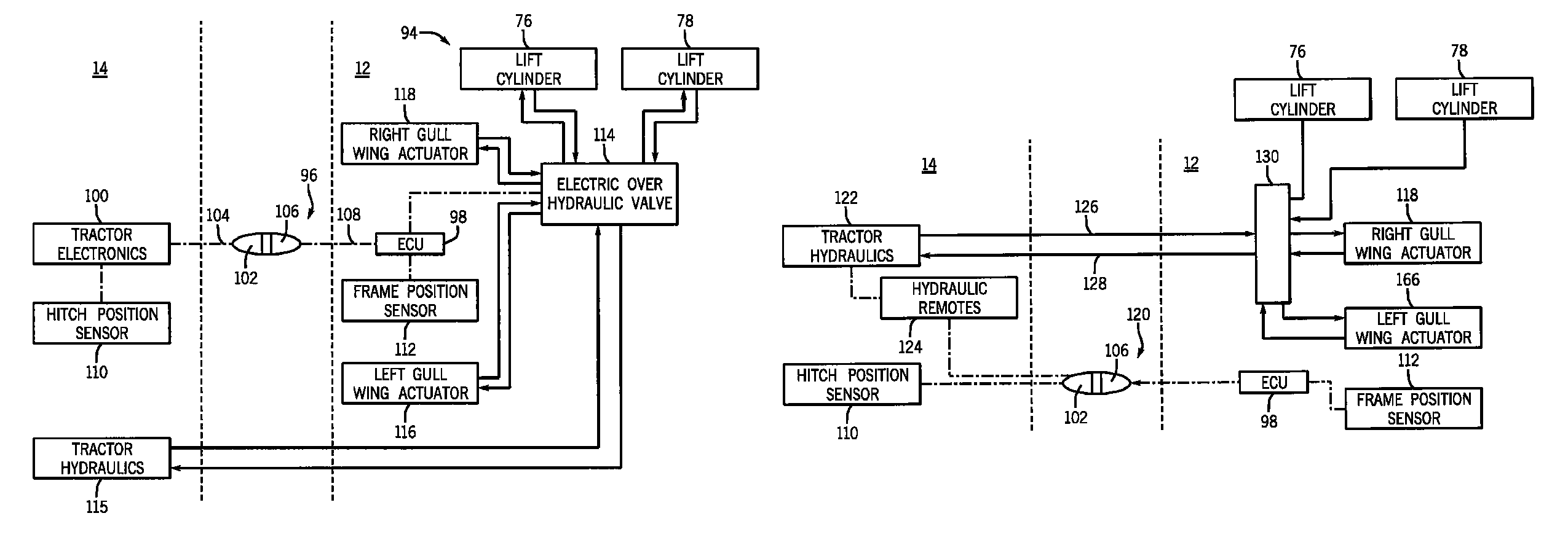

Method And Apparatus For Auto-Leveling Of Bulk Fill Hopper Frame

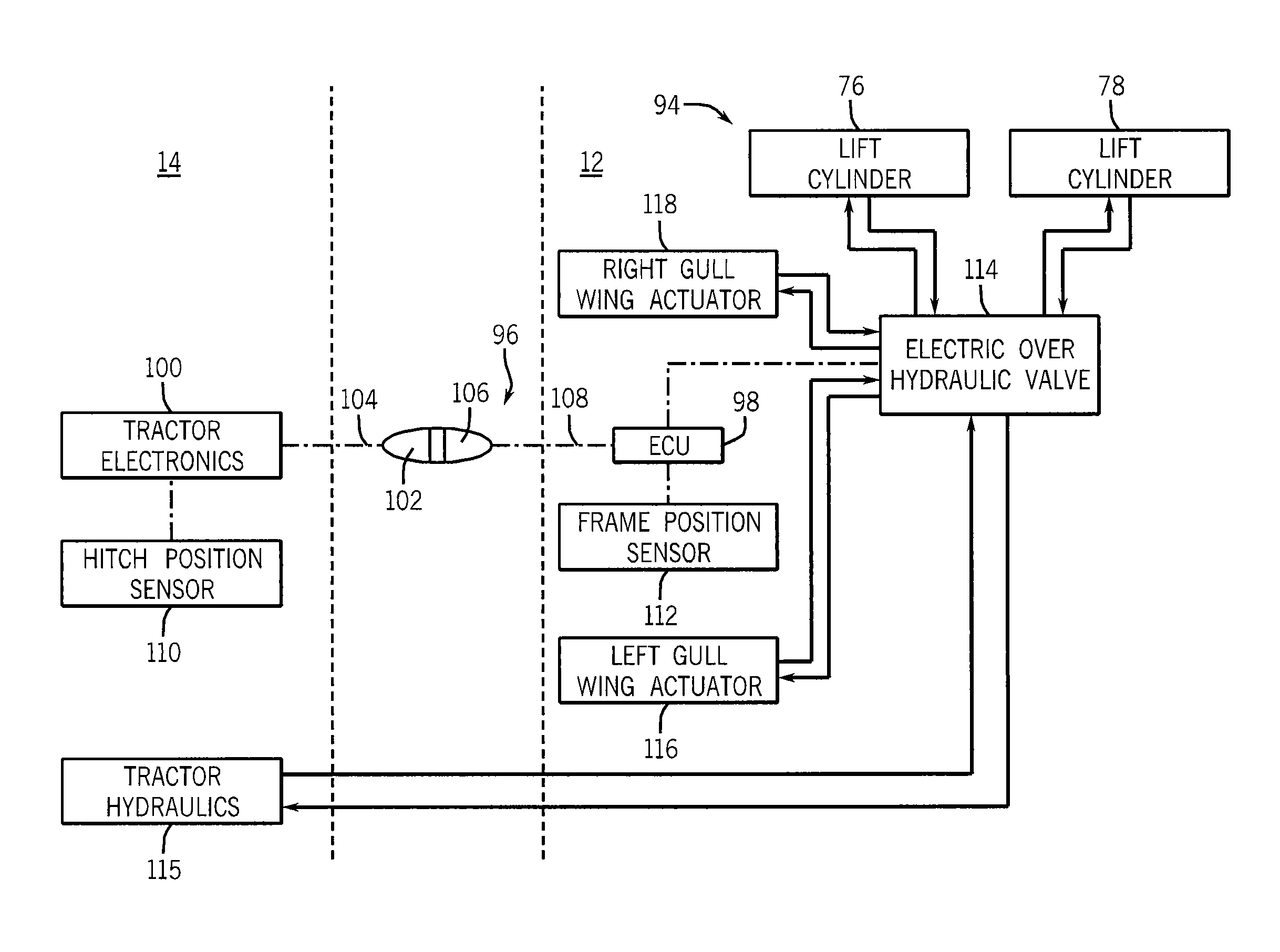

A method and apparatus for automating some of the tasks that heretofore required operator action at headland turns or similar events are provided. The present invention automates operation of lift assist wheels and / or gull wings, such as those found on a stack-fold implement, based on the position of the tractor hitch to which the implement is coupled. An operator may control the position of the implement, such as at a headland turn, by raising and lowering the tractor hitch using a remote control. The invention enables the planter to compare the tractor hitch position relative to an implement position and control operation of the implement accordingly without additional user inputs.

Owner:CNH IND CANADA

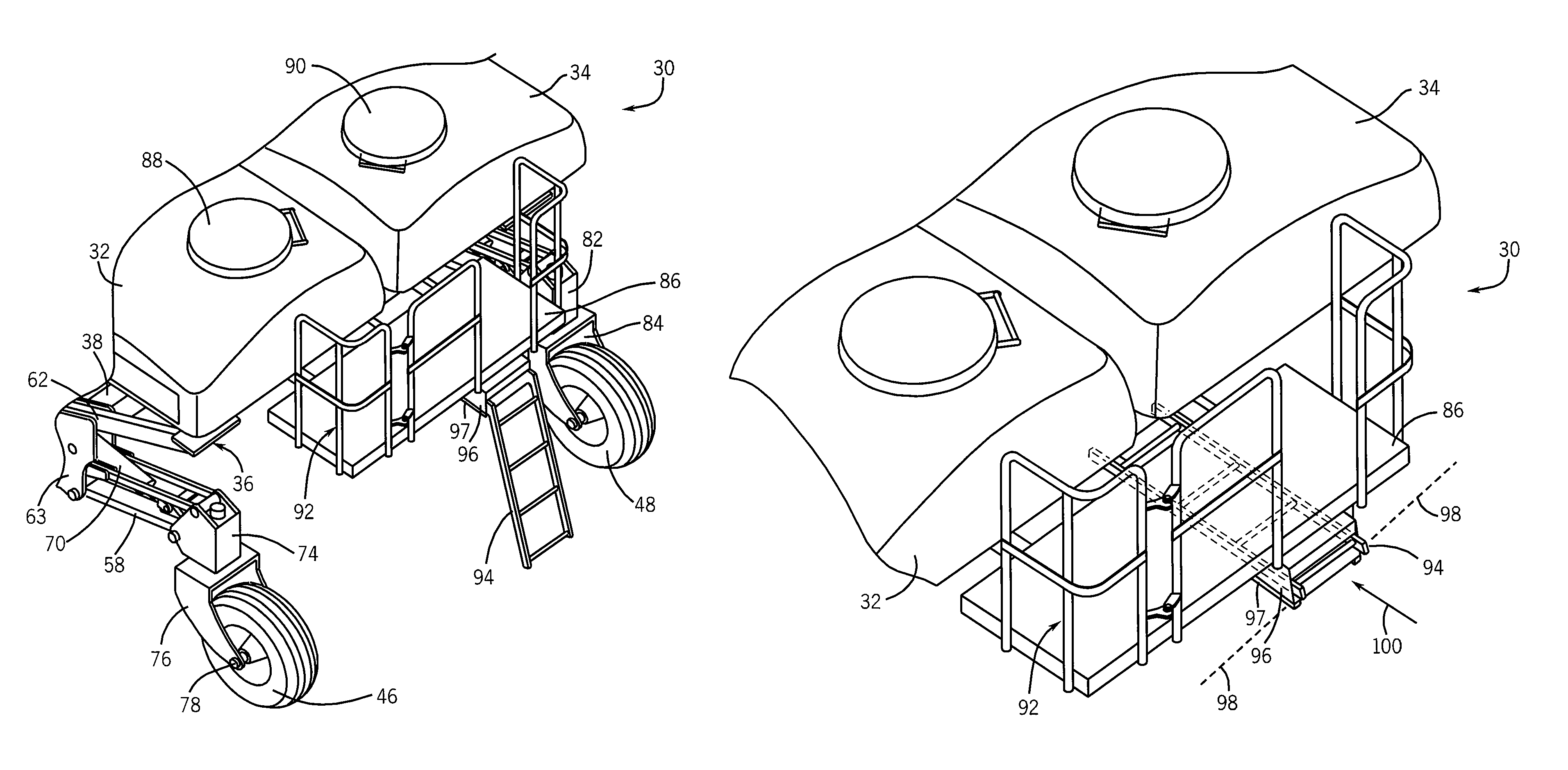

Central bulk fill system having stowable ladder for stack-fold farm implement

ActiveUS8434593B2Prevent removalLarge capacitySpadesAgricultural machinesBulk fillMechanical engineering

Owner:CNH IND CANADA

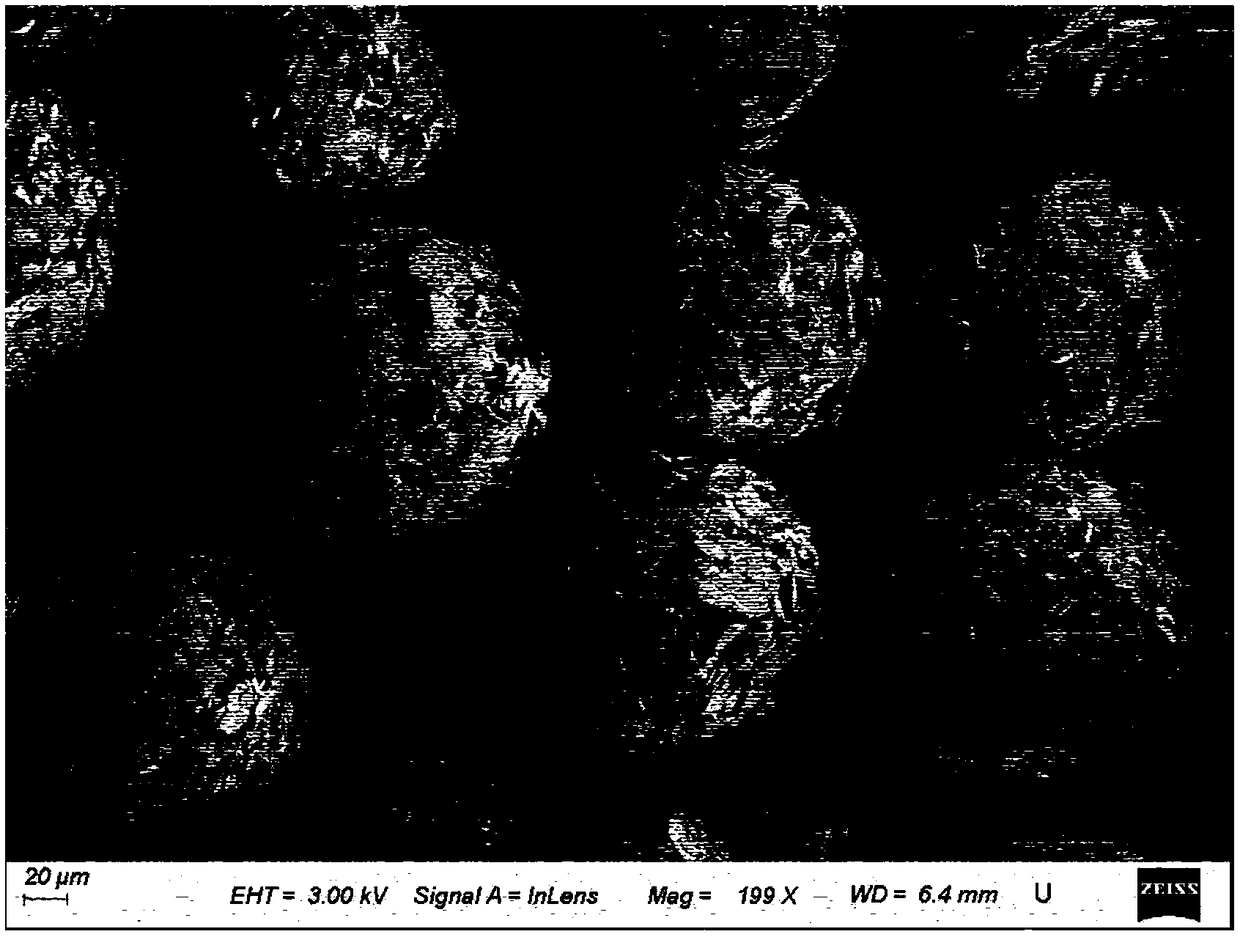

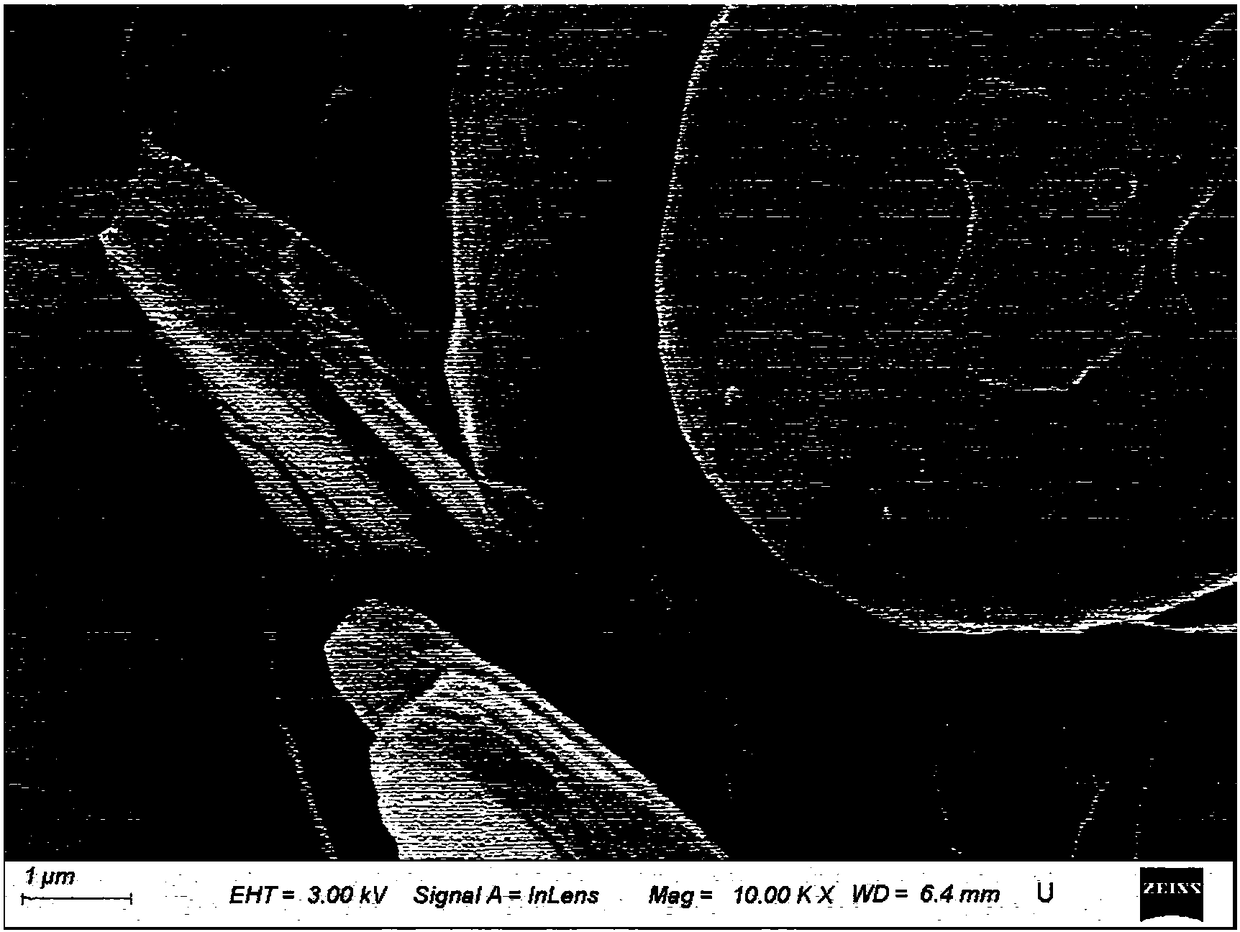

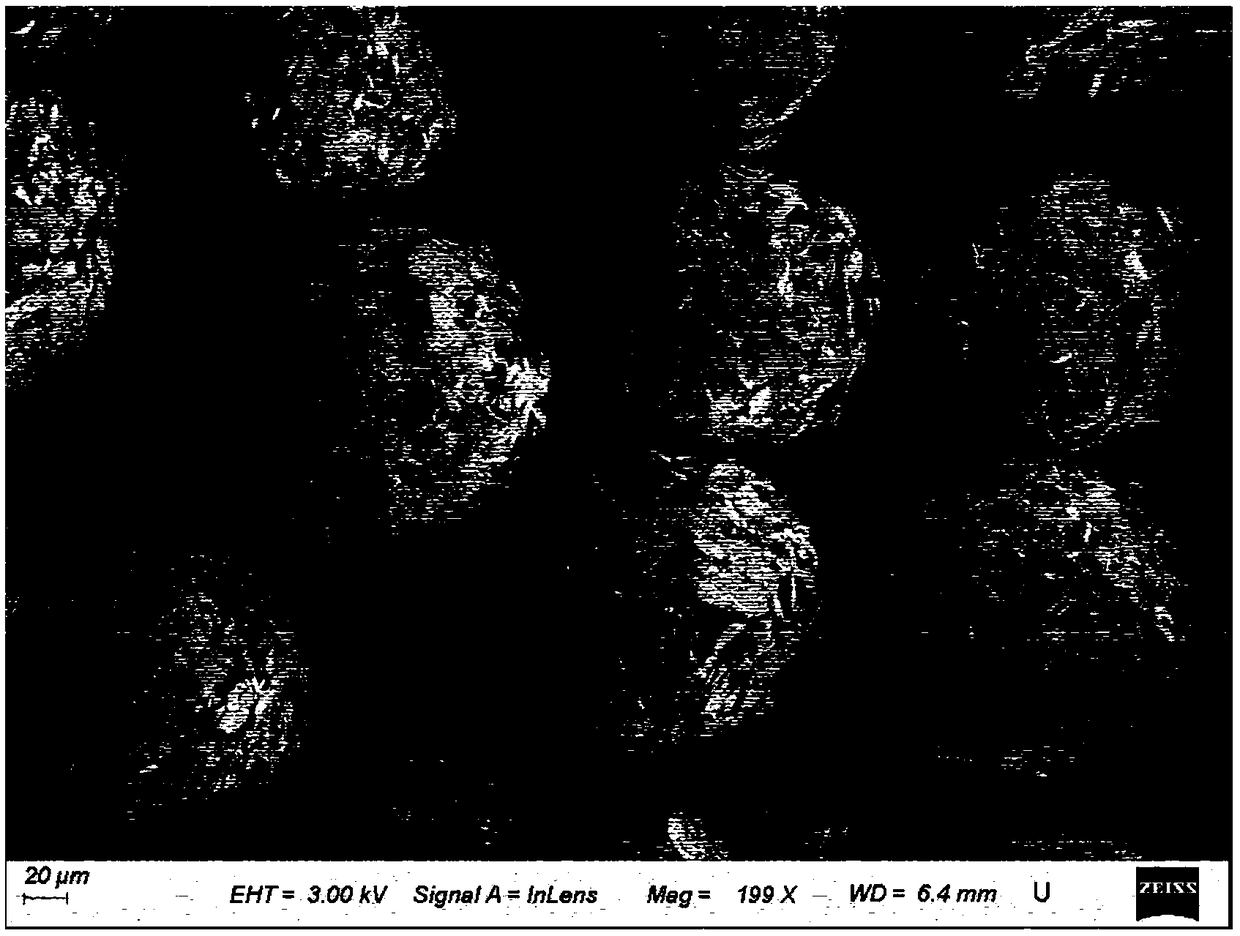

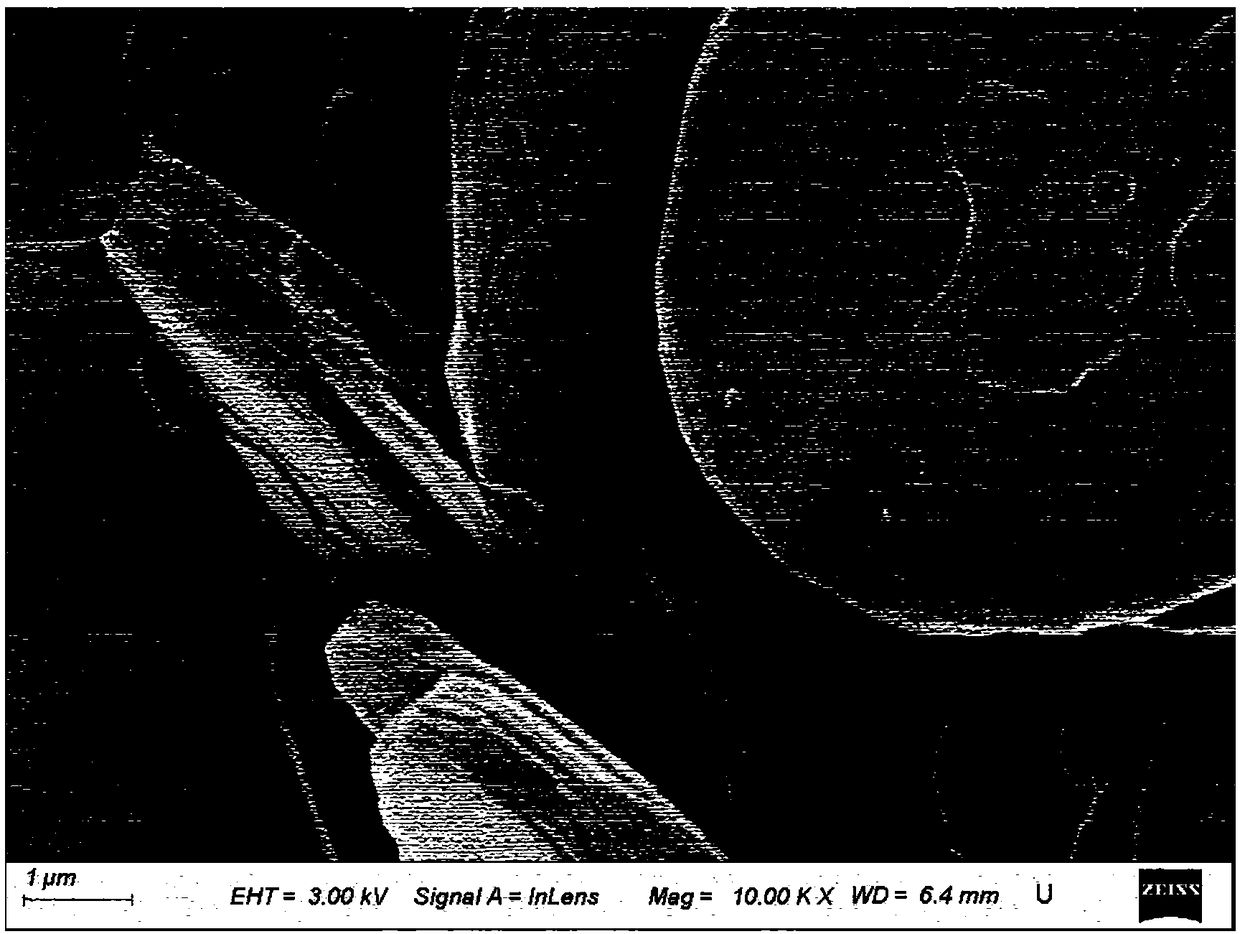

Preparation method of spherical hexagonal boron nitride aggregate

The invention provides a preparation method of a spherical hexagonal boron nitride aggregate, and relates to the preparation method of the spherical hexagonal boron nitride aggregate. The invention aims at solving the problems that orientation and difficulty in filling of a large amount are easy to generate during dispersion of layered hexagonal boron nitride in a system. The method comprises thefollowing steps: (1) preparation of an alkaline earth metal carbonate-oxide composite sintering aid; (2) hexagonal boron nitride, a dispersant, an adhesive and a sintering aid are used for preparing water base slurry; (3) spraying and granulation are carried out; (4) rubber discharging is carried out; (5) sintering is carried out in order to obtain the spherical hexagonal boron nitride aggregate.The spherical hexagonal boron nitride aggregate has high sphericility, a continuous bridge forming and overlapping mode appears between primary particles for aggregation with isotropy, and the methodhas a simple process and is friendly to environment.

Owner:上海百图高新材料科技有限公司

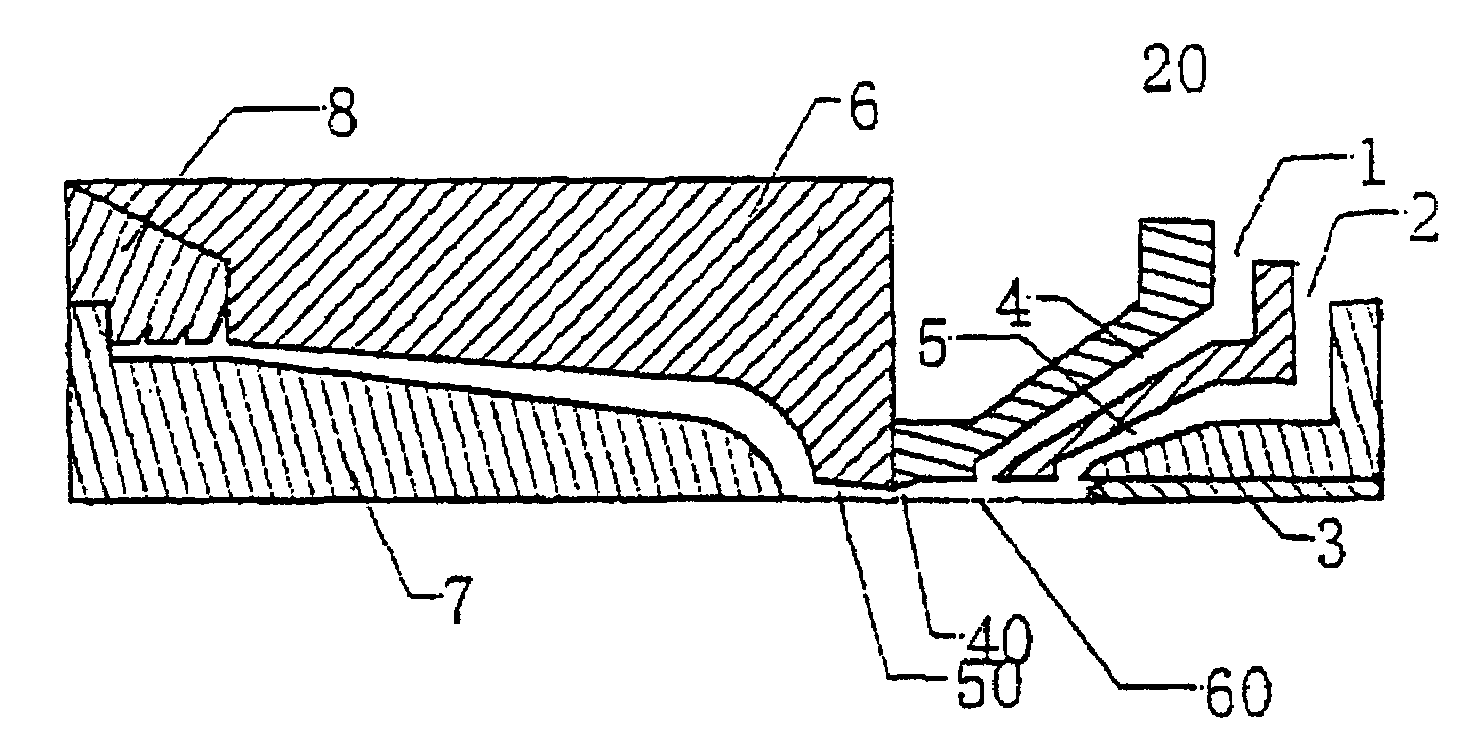

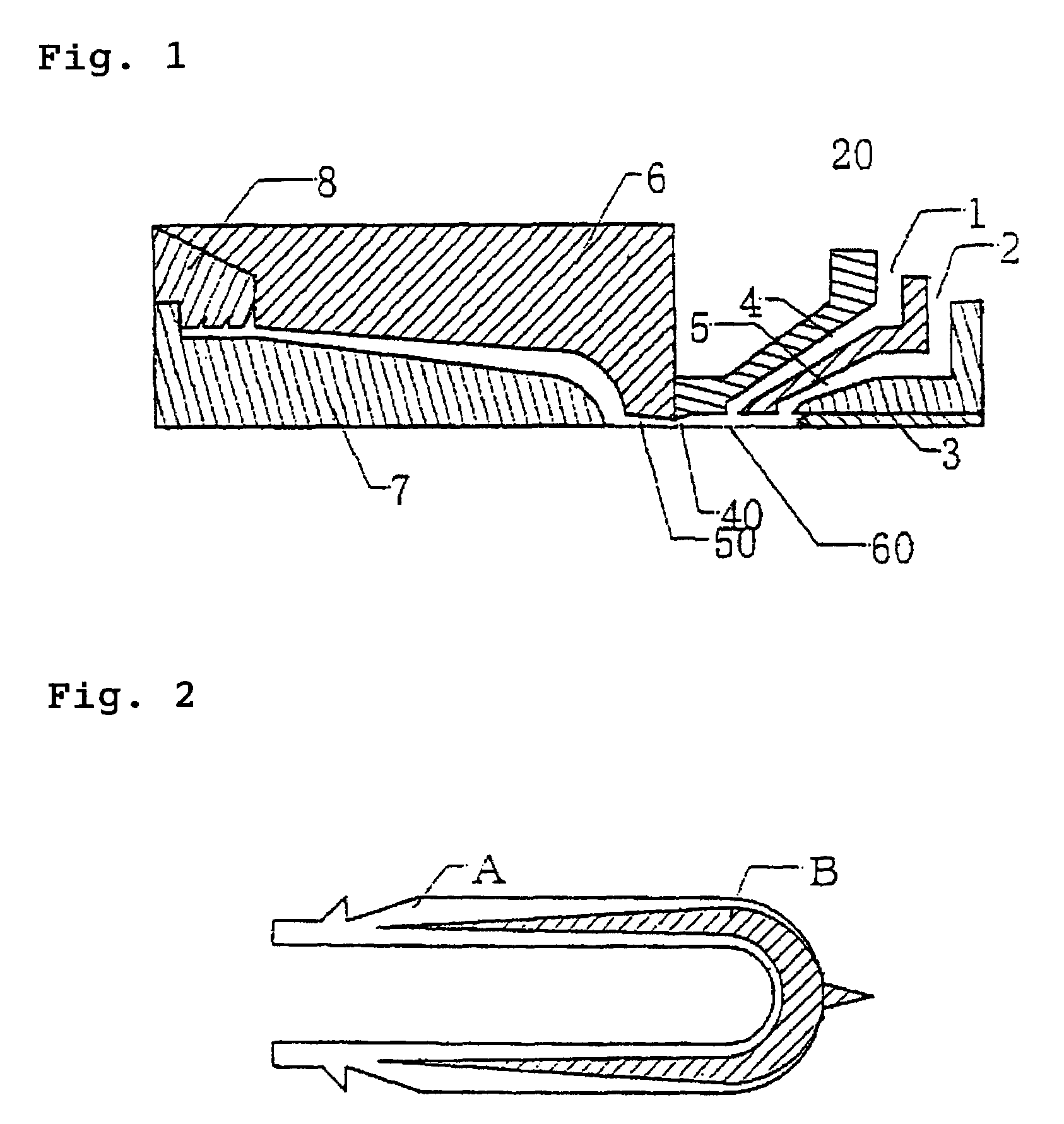

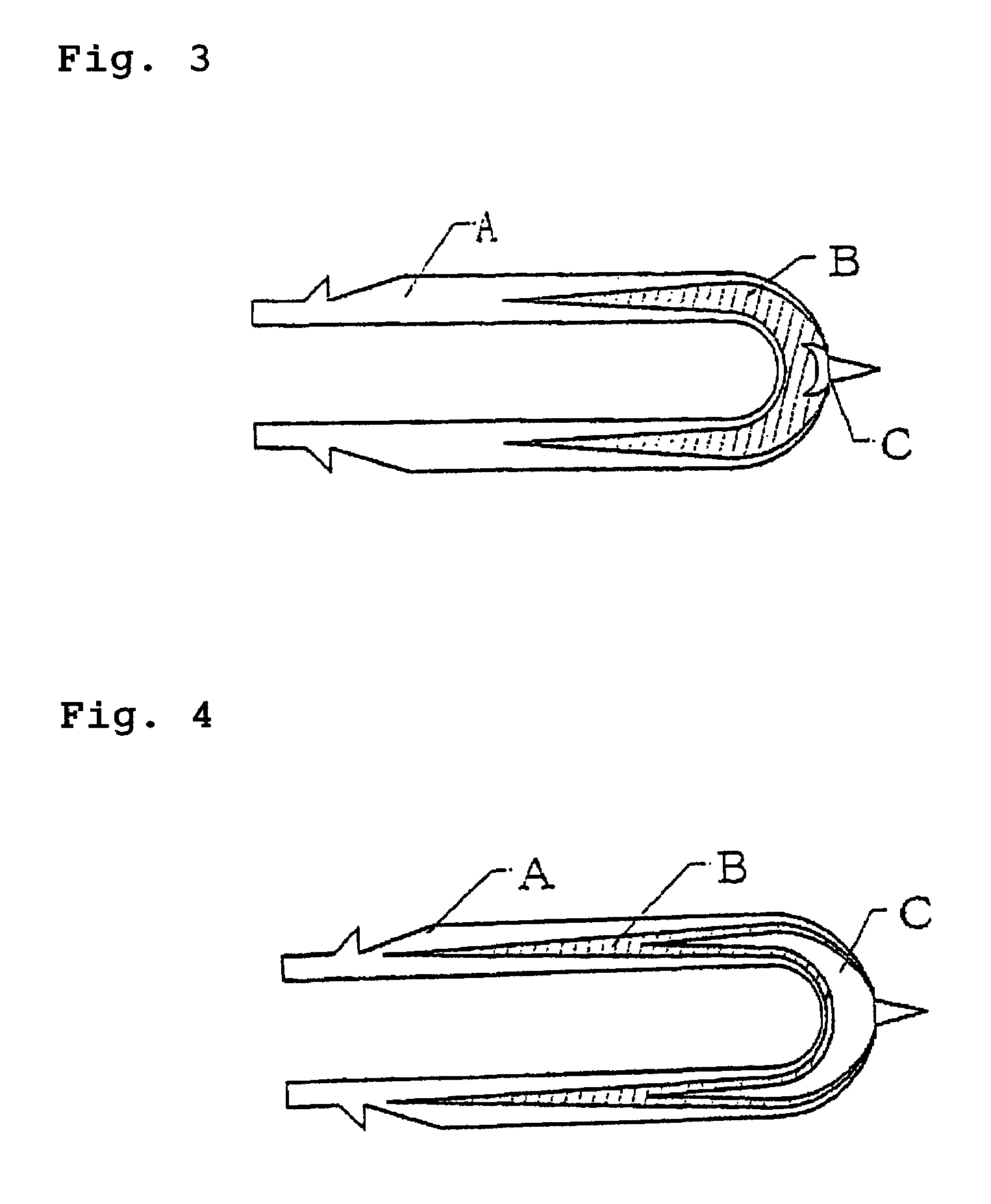

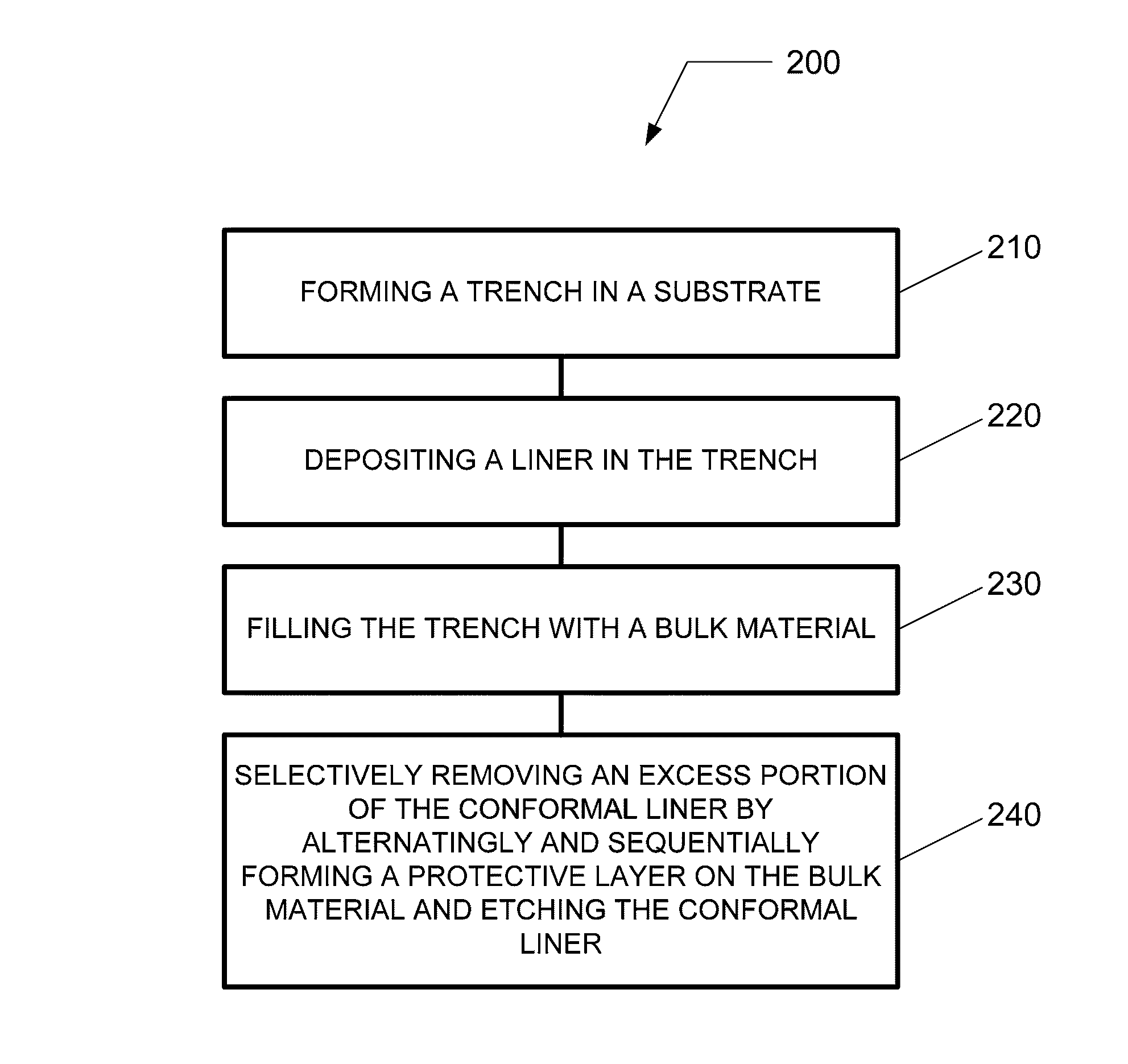

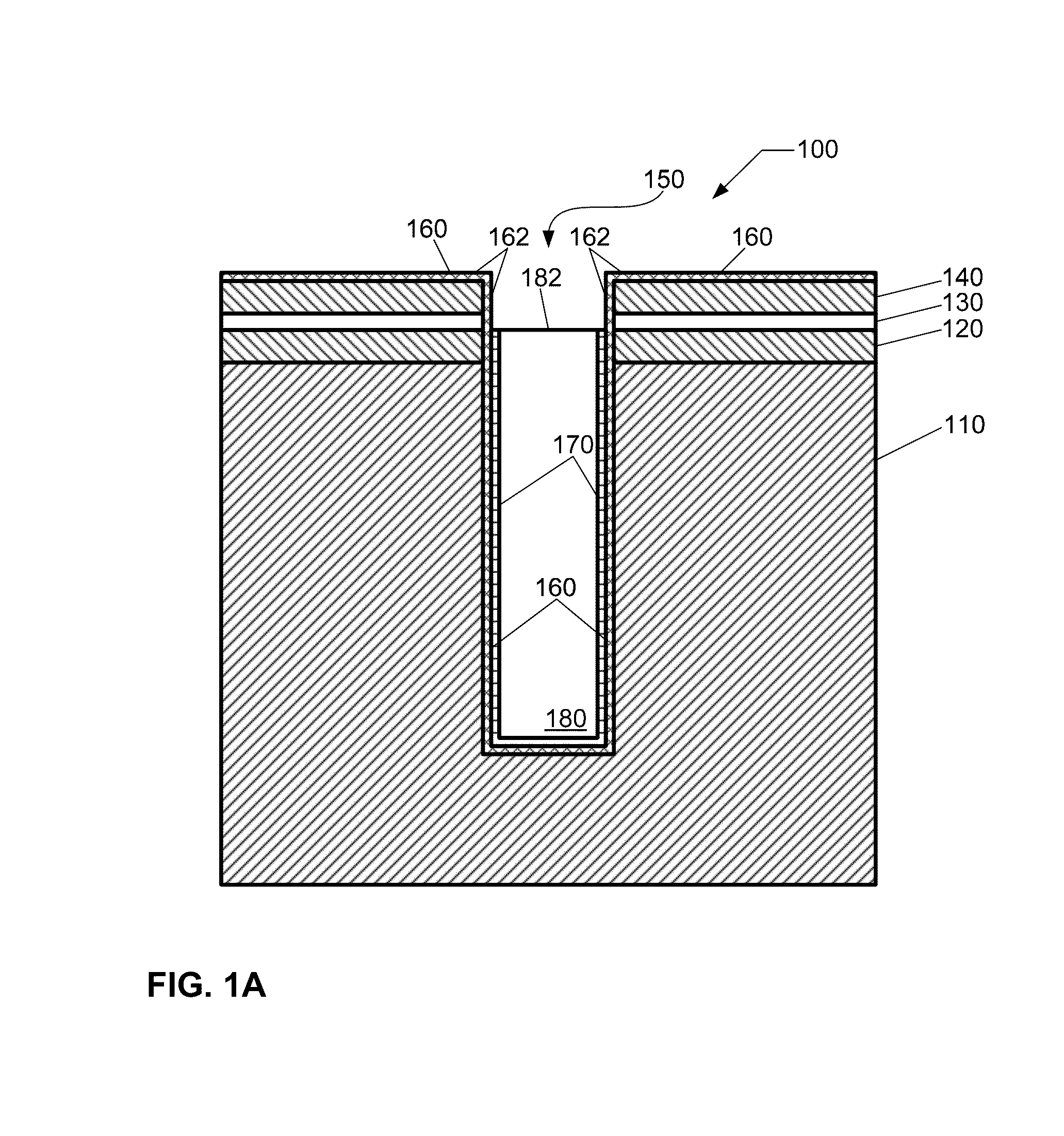

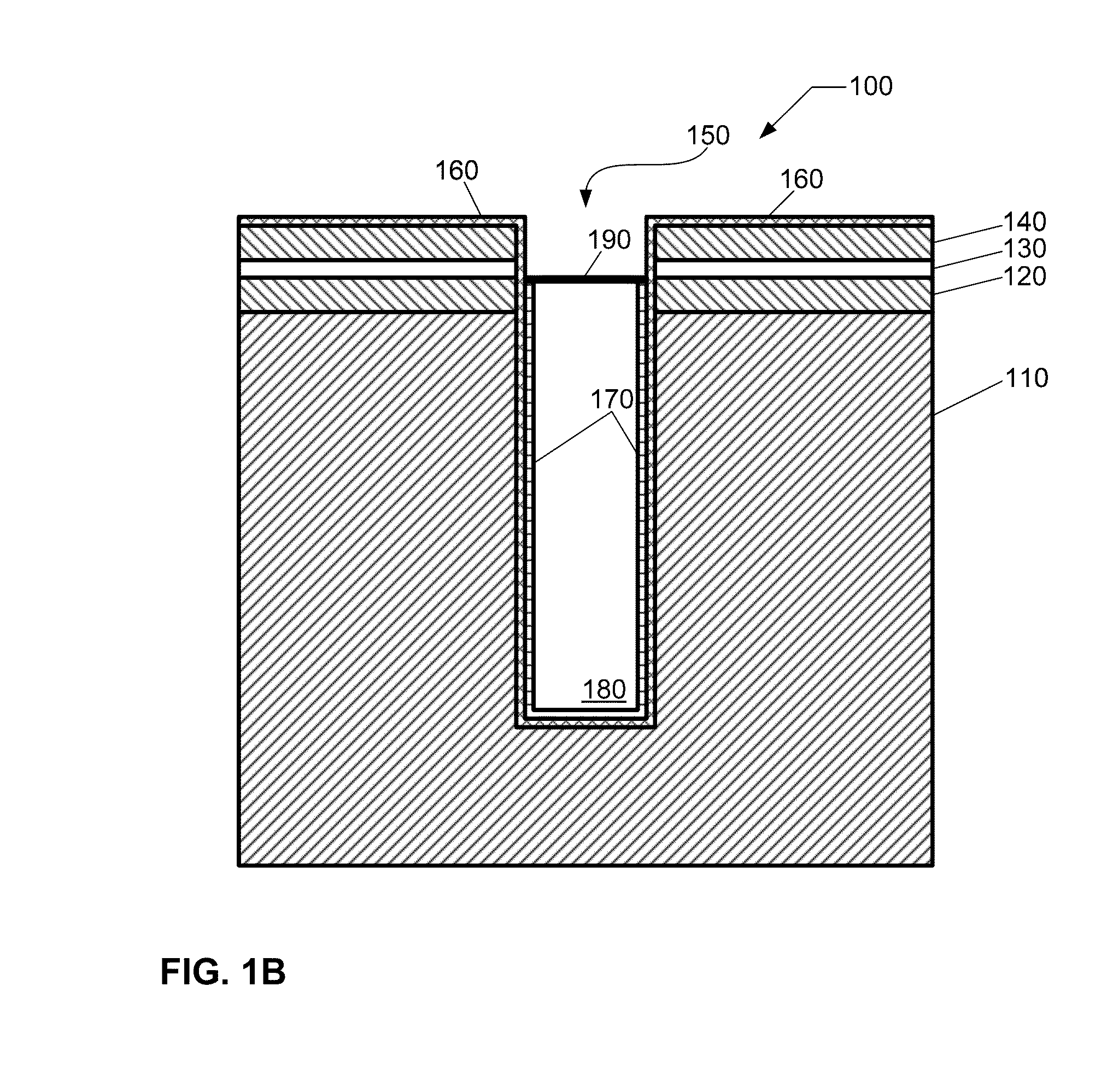

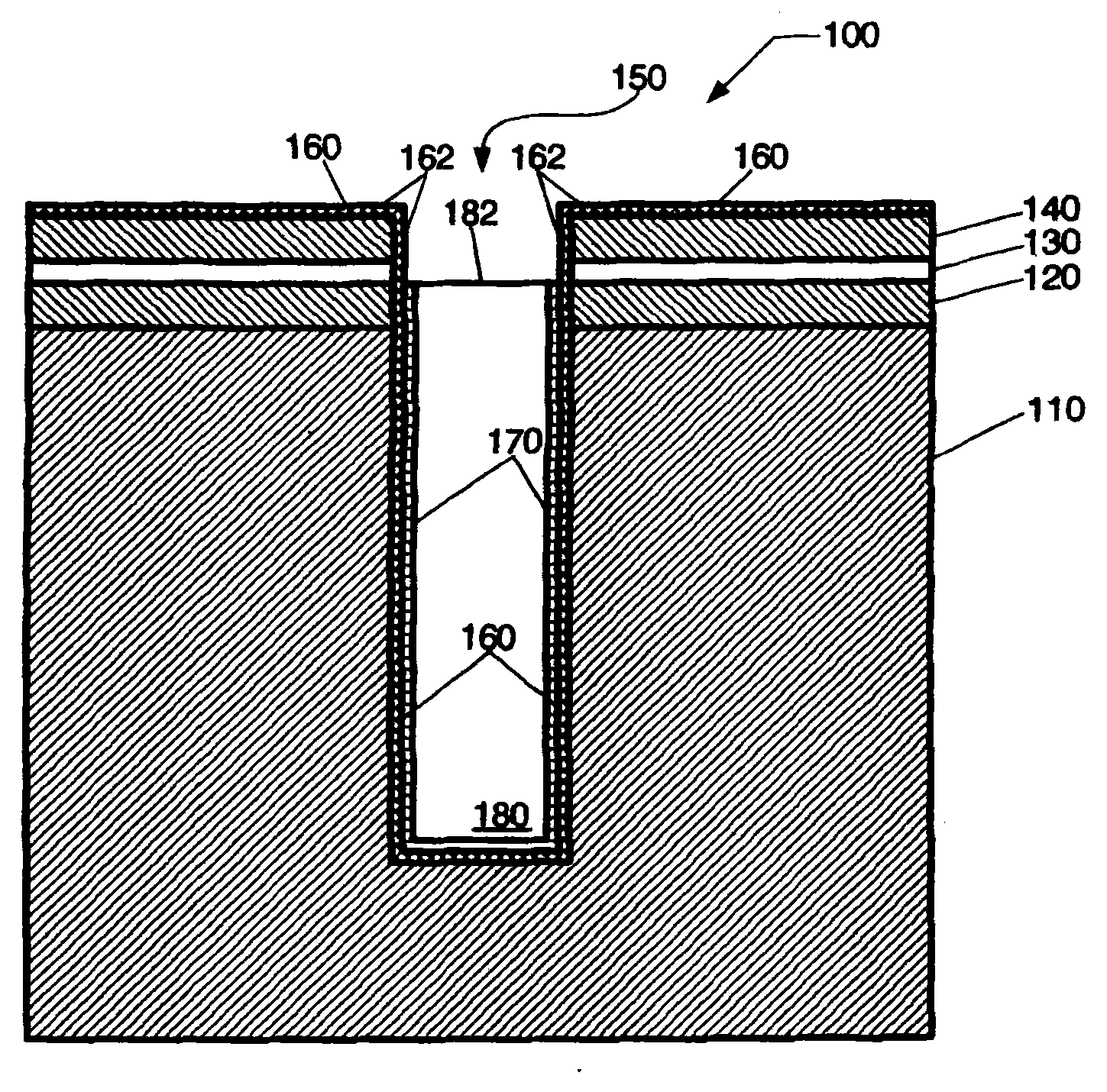

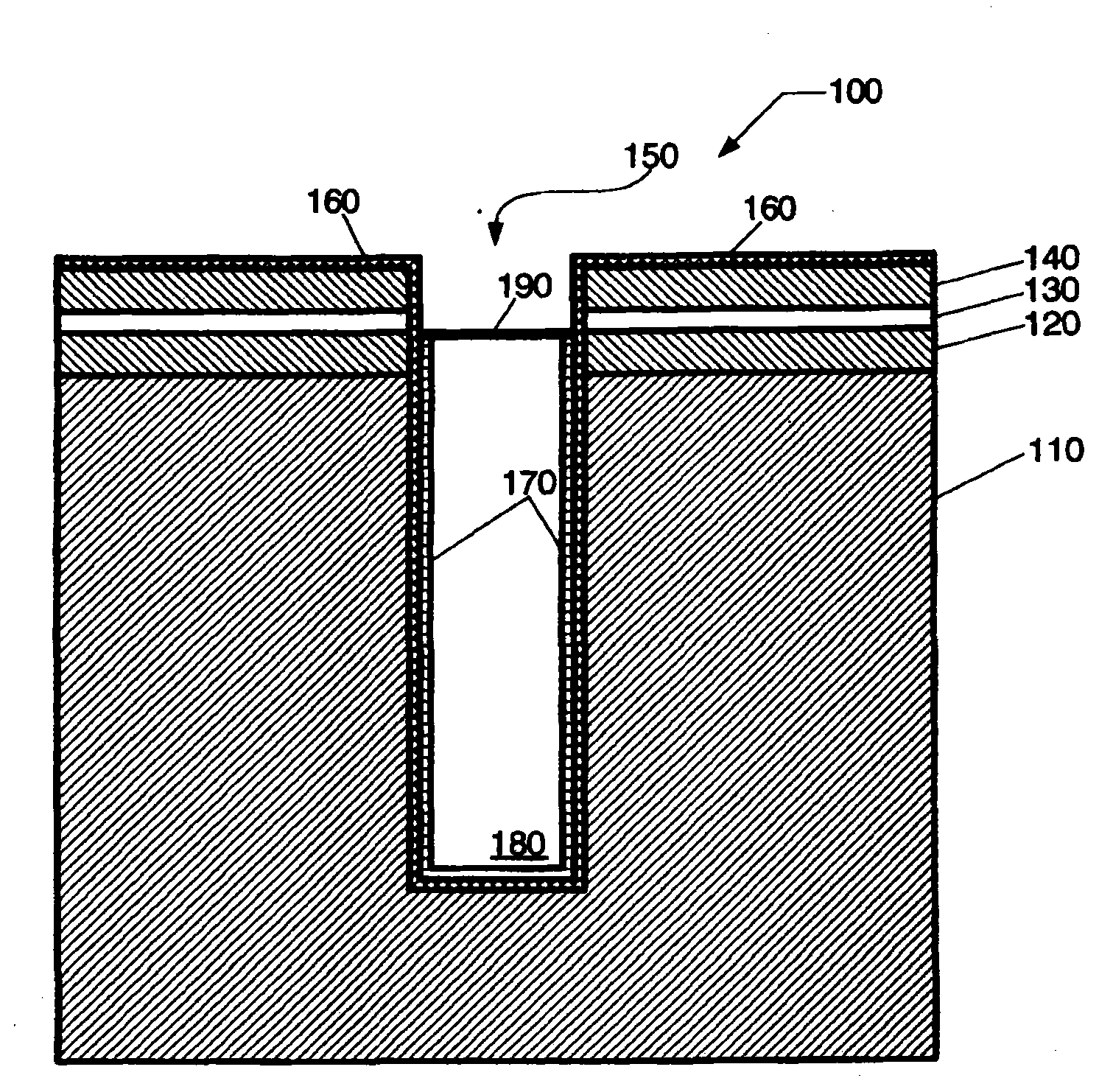

Deep trench liner removal process

ActiveUS20110108517A1Reducing and minimizing damageElectric discharge tubesElectrolytic capacitorsFilling materialsBulk fill

A liner removal process is described, wherein an excess portion of a conformal liner formed in a trench is substantially removed while reducing or minimizing damage to a bulk fill material in the trench.

Owner:TOKYO ELECTRON LTD

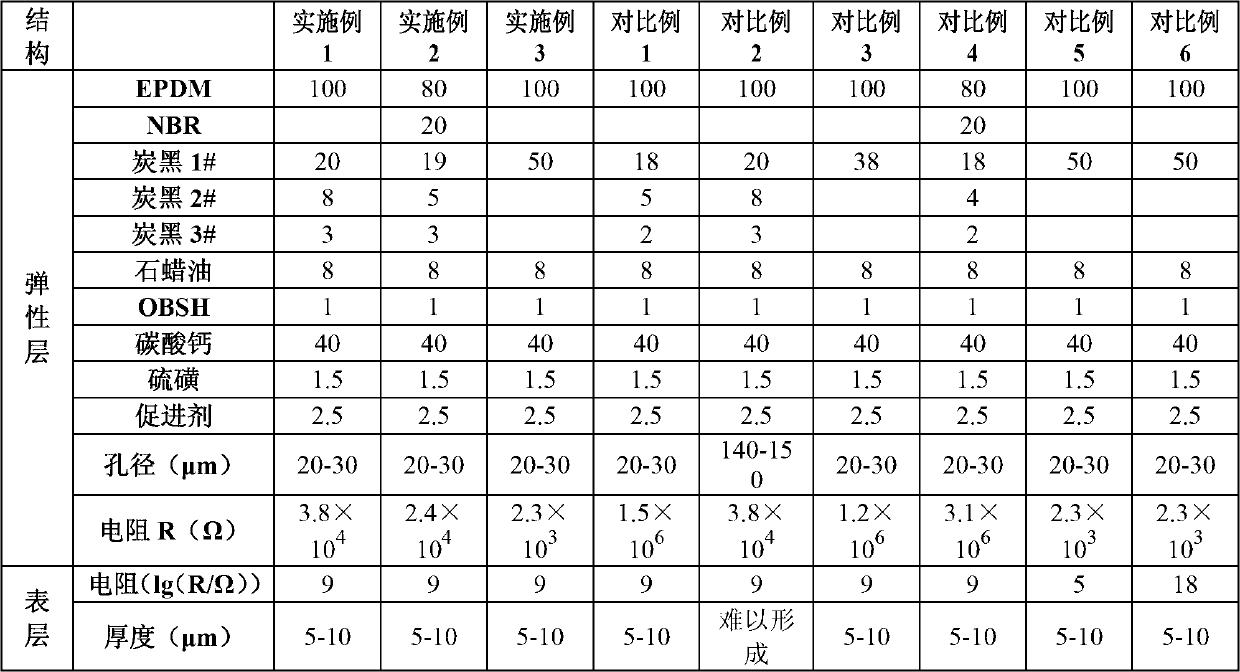

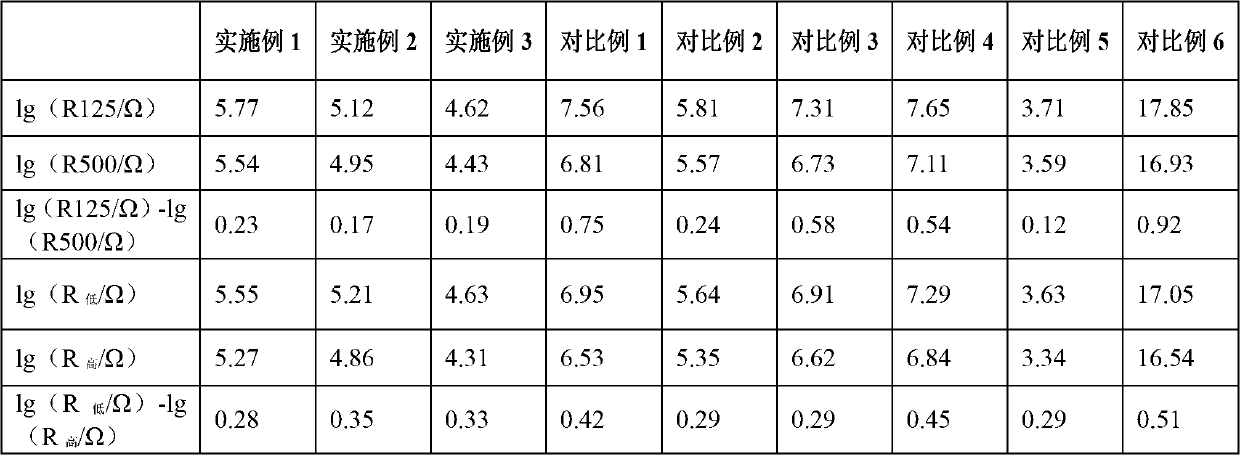

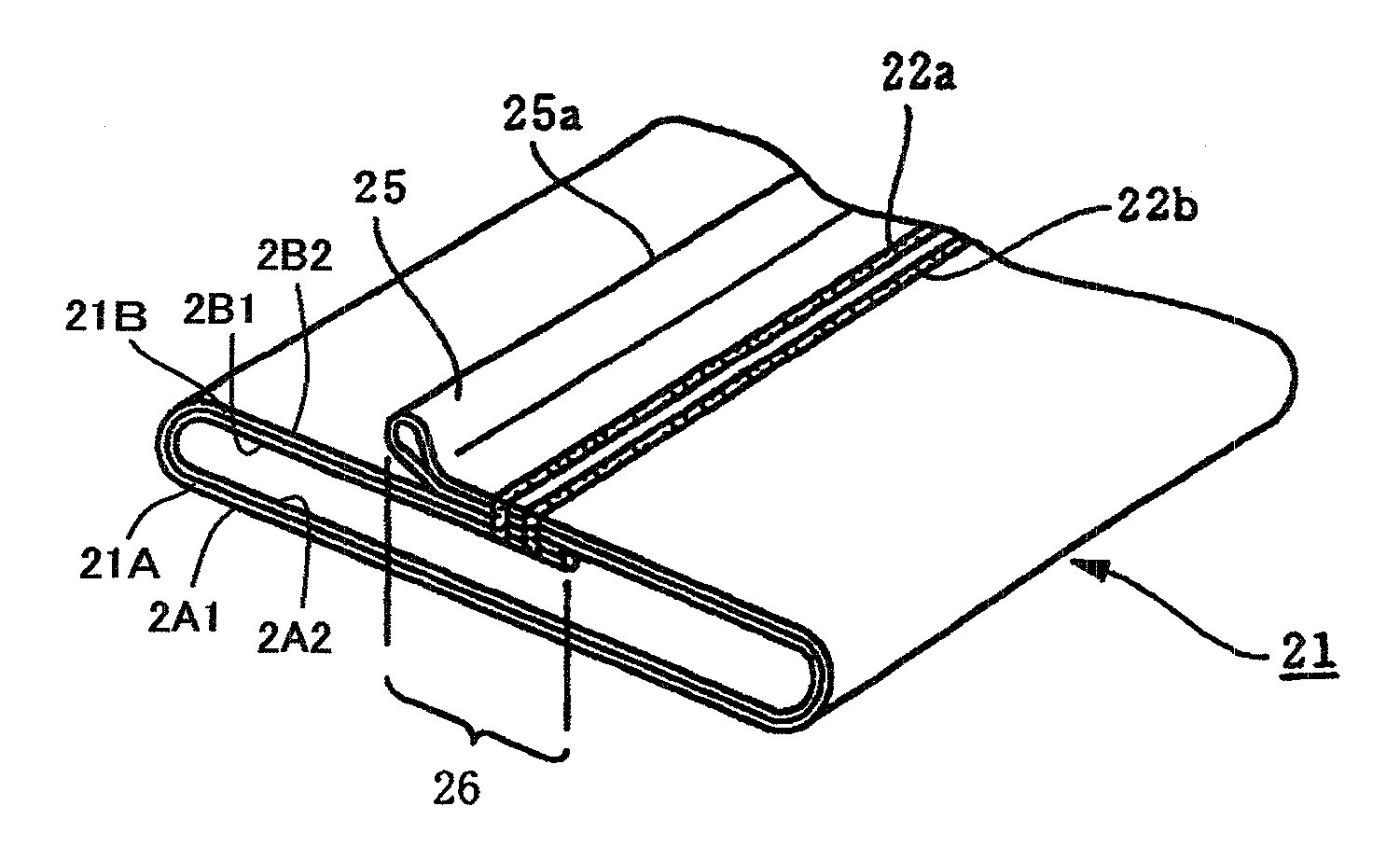

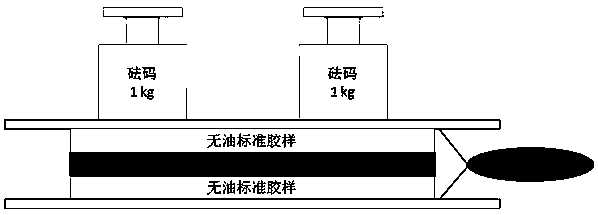

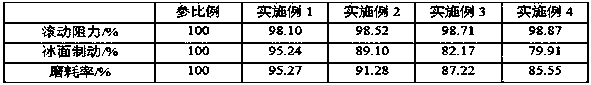

Conductive rubber roller and imaging device

ActiveCN103105761AMeet the resistance value requirementsLow voltage dependencePolyurea/polyurethane coatingsElectrographic process apparatusSurface layerBulk fill

The invention provides a conductive rubber roller. The conductive rubber roller comprises a metal shaft core, an elastic layer packed outside the metal shaft core and a surface layer formed outside the elastic layer, wherein the elastic layer consists of rubber A and at least one of conductive fillers filled in the rubber A; the threshold value range of the conductive fillers in the rubber is as follows: a conductive filler valve is greater than or equal to Zb and is less than or equal to Yb; and b / Yb+c / Yc+...q / Yx is greater than or equal to 1 if the filling fractions of the conductive fillers B, C,...X in the rubber A are respectively set to be b, c,...q. According to the conductive rubber roller provided by the invention, the filling number of the conductive fillers of the elastic layer is limited, and an integral resistance value of the rubber roller is adjusted according to the resistance difference between an inner layer structure and an outer structure layer, so that the conductive rubber roller is less in dependency to voltage, and is less fluctuated by the environment change, the resistance is even in distribution, and the increase of the rigidity of the rubber roller since a mass of the conductive fillers are filled into the elastic layer can be avoided; and therefore, not only can the cost of the material be reduced, but also the whole flexibility of the rubber roller can be guaranteed. The invention further discloses an imaging device which comprises the conductive rubber roller.

Owner:SHENZHEN LEPUTAI TECH CO LTD

Modified calcium carbonate and application thereof to preparation of silicon rubber

InactiveCN108752981AGood compatibilityGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentBulk fillPalmitates

The invention discloses modified calcium carbonate and the application thereof to preparation of silicon rubber. The modified calcium carbonate is subjected to twice surface modification by a surfacetreating agent consisting of pentaerythritol palmitate and sodium polysiloxane succinate amide sulfonate as well as polyurethane methyl sesquisiloxane and vegetable oil fatty acid alkanolamide borate.The modified calcium carbonate has the advantages of high dispersibility, high toughness, weather resistance, high-temperature and low-temperature resistance and the like, can be filled with a largeamount of silicon rubber, and gives high strength, high toughness, high-temperature and low-temperature resistance, high impact resistance, high flame resistance, corrosion resistance, tensile strength and high breaking elongation to the silicon rubber after filling.

Owner:贺州钟山县双文碳酸钙新材料有限公司

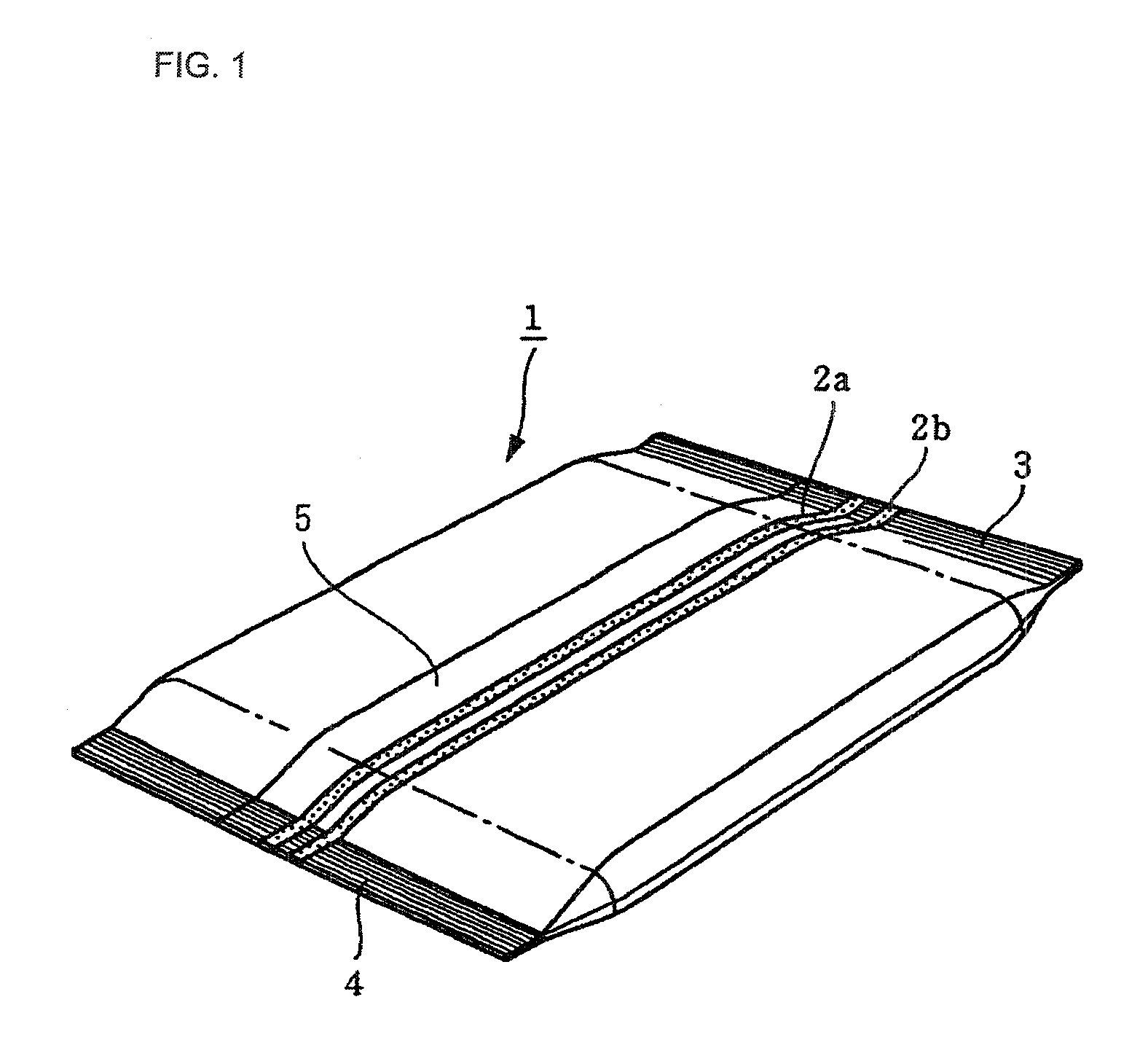

Material-filled package

ActiveUS8142078B2Easy-to-unseal propertyEasy to openFlexible coversWrappersLow-density polyethyleneFilling materials

Owner:KYORAKU CO LTD

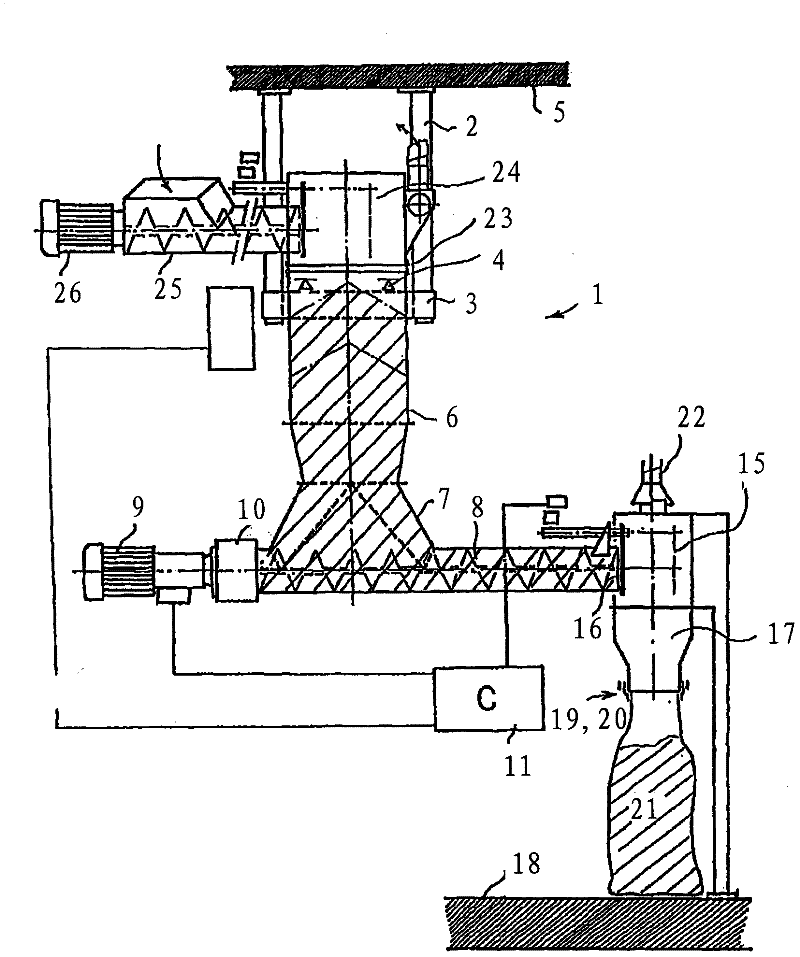

Bulk material bagging device

InactiveCN102202976ASimple structureSimplify transport handlingSolid materialWeighing apparatus with automatic feed/dischargeBulk fillEngineering

The device according to the invention relates to a bulk material bagging device comprising a bagging carousel (31), a dosing device and a control device, said bagging device issuing pre-defined bulk fill amounts into transport containers (21). Bagging nozzles (32) are provided at the bagging carousel, said nozzles having a pneumatic for hanging a transport container thereon. The bagging carousel (31) comprises at least one device, or a combination of the following devices: Each bagging nozzle (32) comprises at least a switch, preferably a hand switch and especially preferred a retractable hand operated lever valve (206) for actuating the pneumatics; the bagging carousel (31) comprises a foot switch for actuating the pneumatics; the bagging carousel (31) comprises a slide that is mounted prior to the bagging nozzle (32) in the transport direction of the bulk material during dosing.

Owner:BUEHLER AG

Snow tire, snow tire tread rubber composition and rubber composition mixing method

The invention belongs to the field of rubber tire manufacturing, and discloses a snow tire, a snow tire tread rubber composition and a rubber composition mixing method. The snow tire tread rubber composition comprises in parts by weight: 100 parts of a rubber component, 35-55 parts of liquid polybutadiene rubber, and 70-90 parts of silica, wherein the mass percentage of the liquid polybutadiene rubber is 13% or more in the total composition. The liquid polybutadiene rubber is introduced into the composition, the plasticizing property of the liquid polybutadiene rubber is utilized, a part of environment-friendly oil is replaced by the liquid polybutadiene rubber, the oil content in tread rubber is reduced, and the liquid polybutadiene rubber has a relatively low glass transition temperature, so that effects of low hardness, low modulus, and low low-temperature hardening degree of the tread rubber can be achieved when a relatively large amount of the liquid polybutadiene rubber is used for filling.

Owner:ZHONGCE RUBBER GRP CO LTD

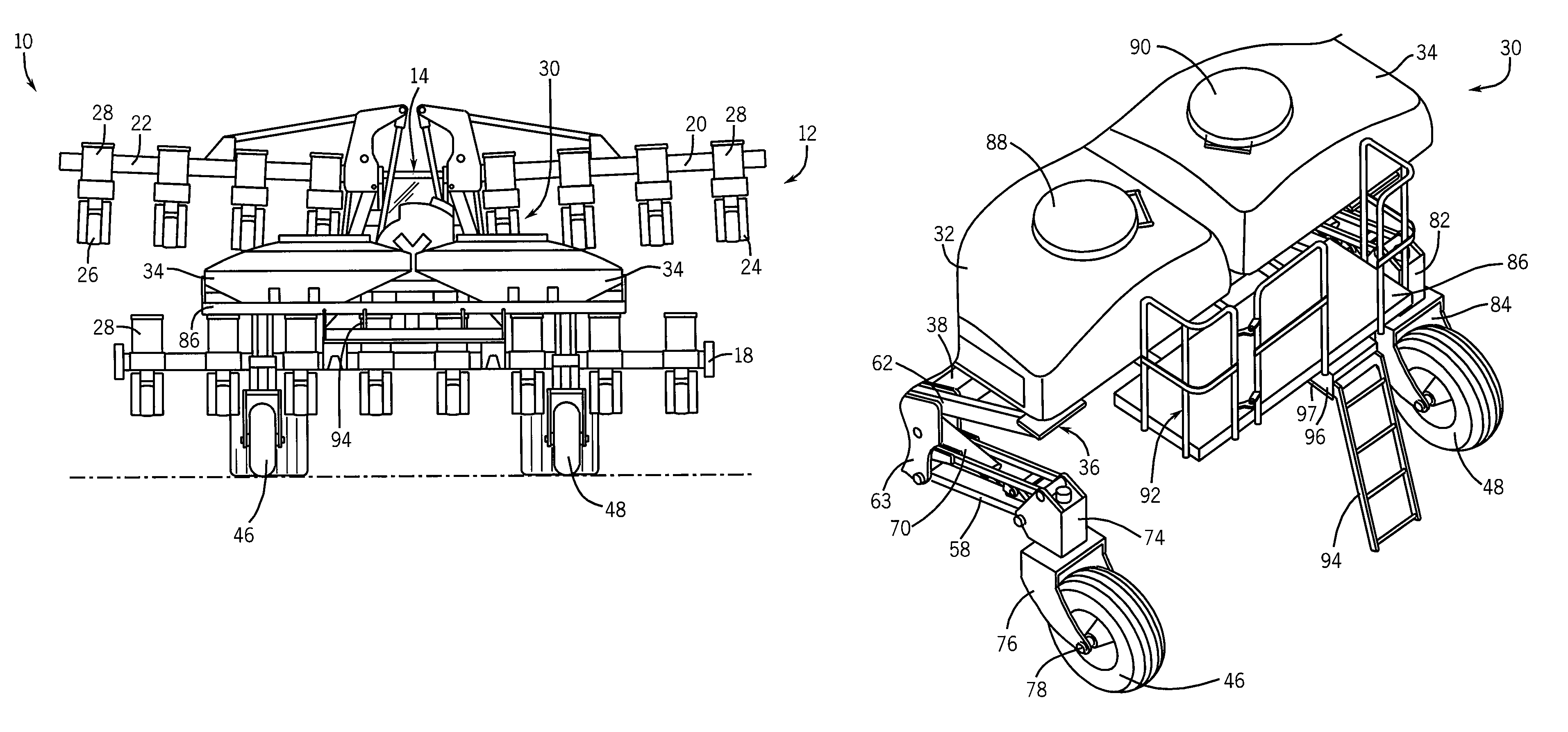

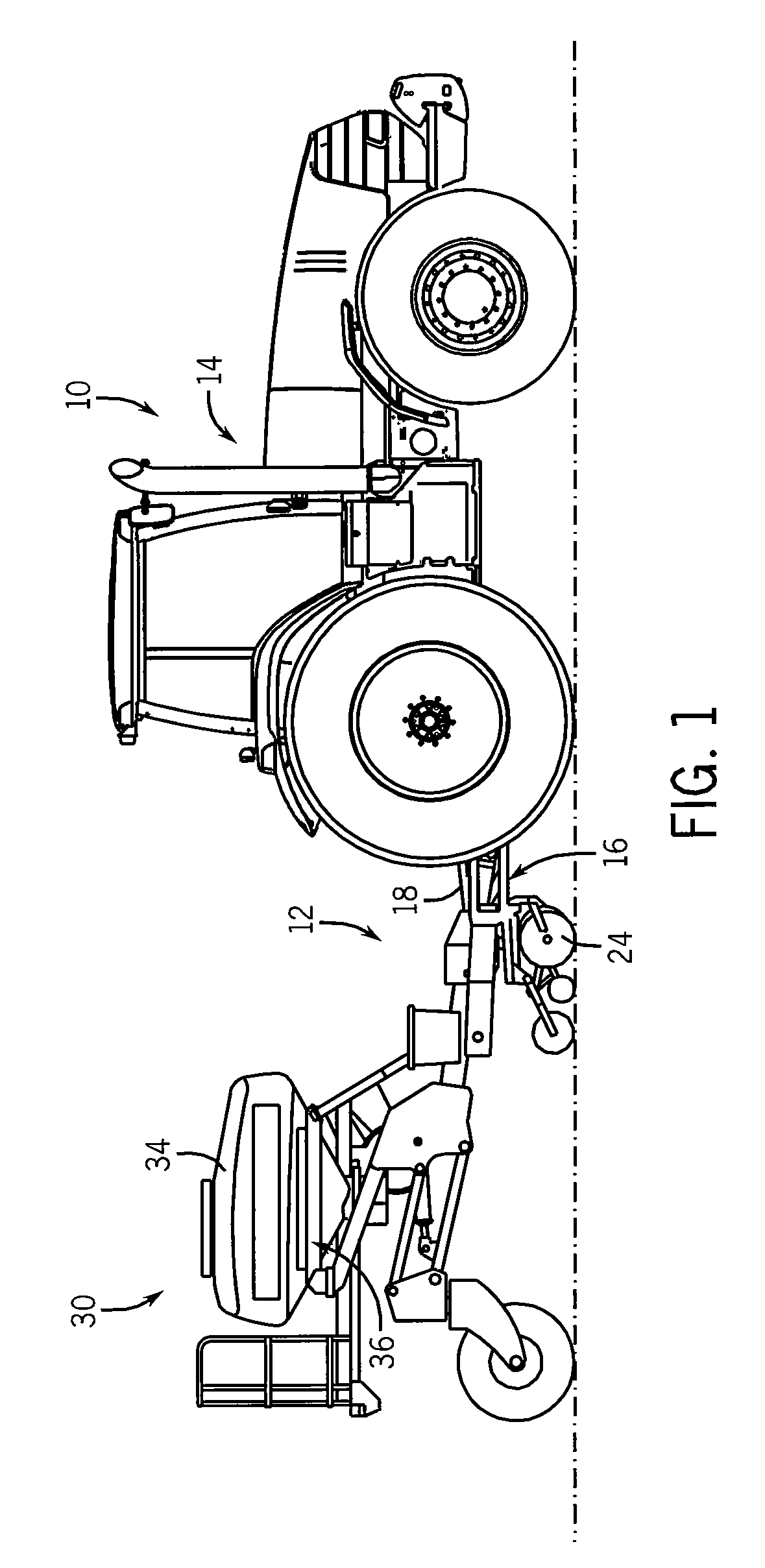

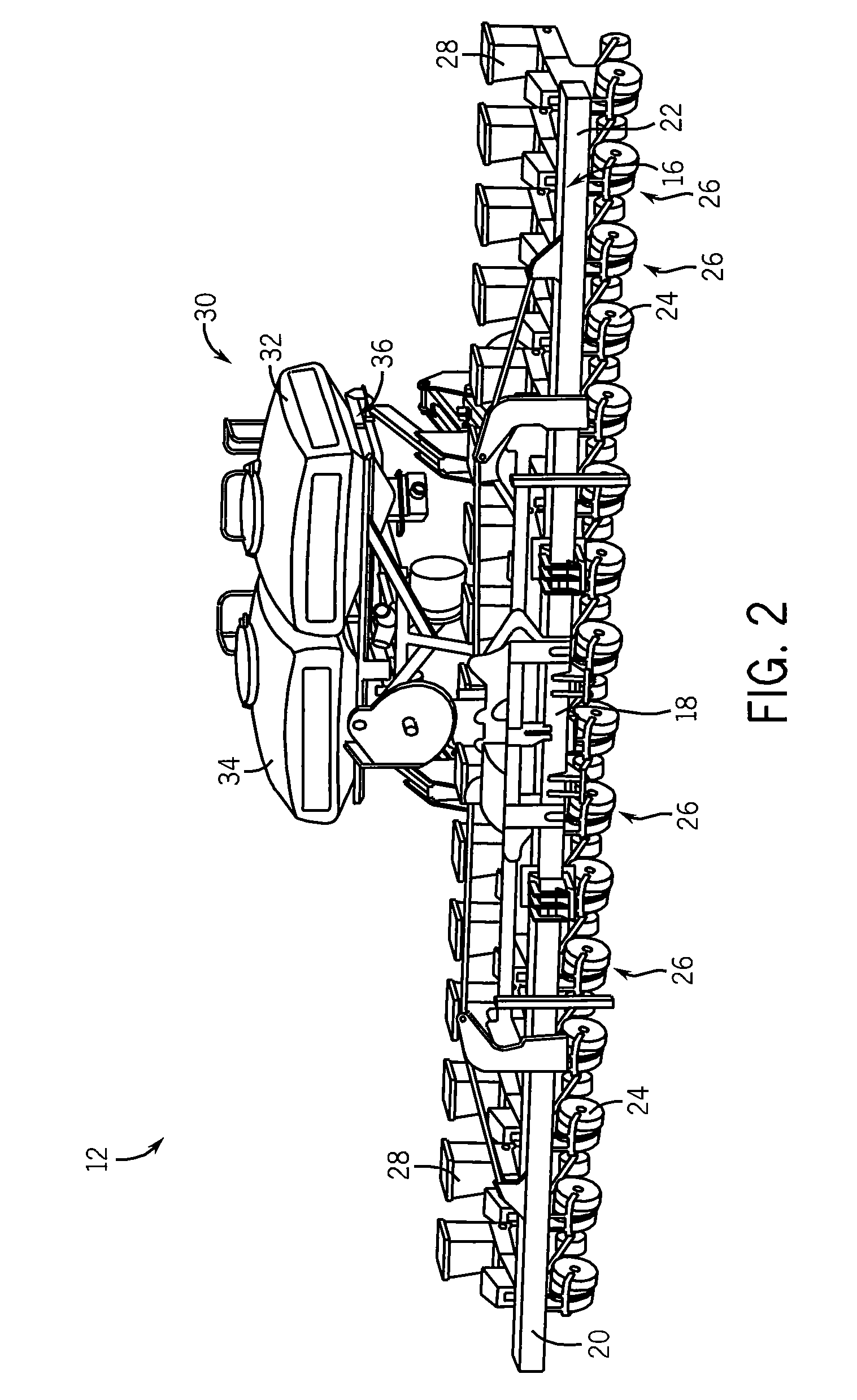

Central Bulk Fill System Having Stowable Ladder For Stack-Fold Farm Implement

ActiveUS20120000405A1Unintentional removal can be preventedPrevent removalSpadesAgricultural machinesBulk fillEngineering

A stack-fold implement having a central bulk fill hopper assembly is provided. The bulk fill hopper assembly is mounted to the center frame section of the stack-fold implement and does not affect the narrowness of the stack-fold implement when it's in a stacked, transport position. The hopper assembly includes a pair of bulk fill hoppers or tanks supported by cradle that is in turn supported by a pair of wheels. The cradle is removably coupled to the center frame section by a plurality of rigid frame members. A retractable ladder may be stowed beneath the hopper assembly.

Owner:CNH IND CANADA

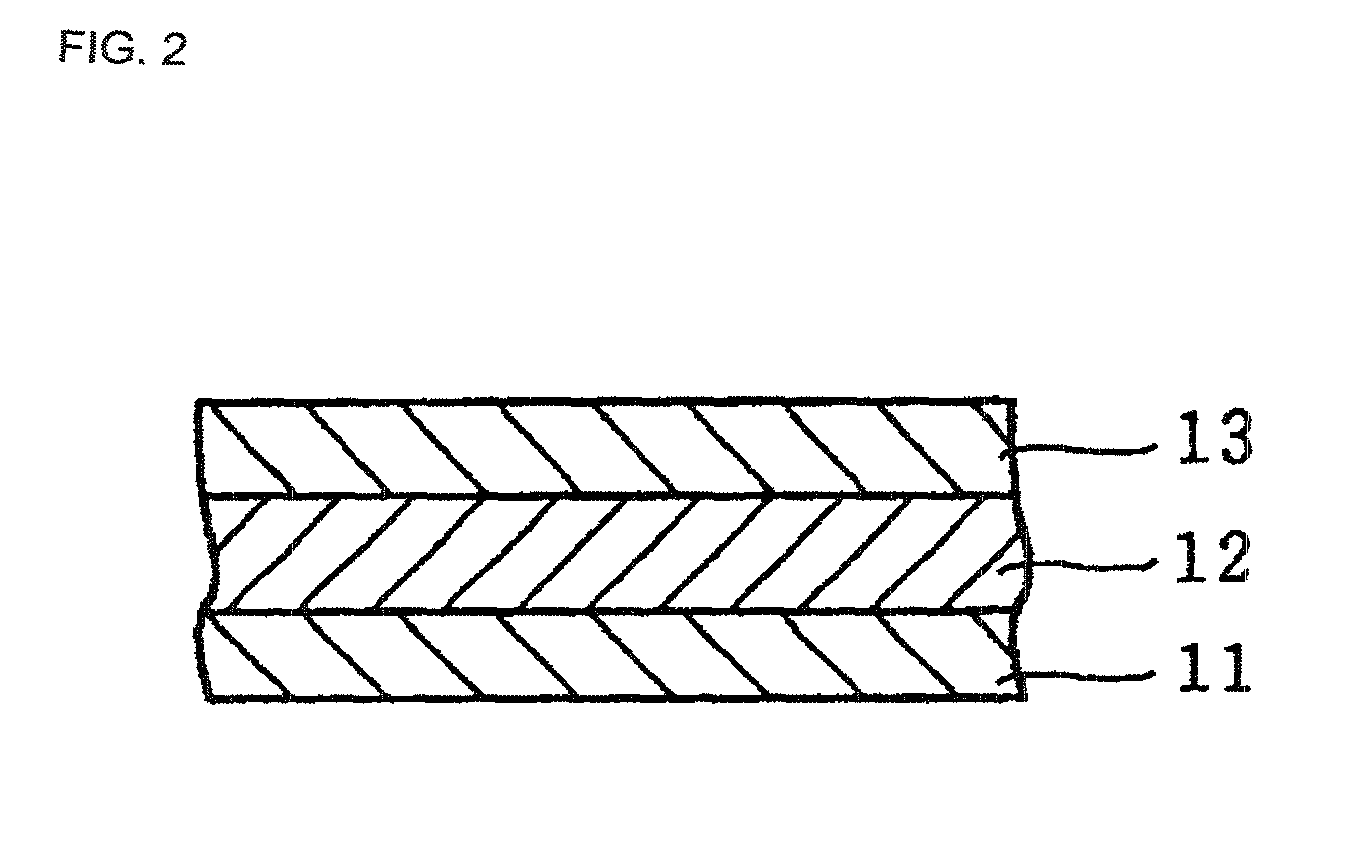

Multi-layer preliminary formed body and method of manufacturing the formed body

InactiveUS7344673B2Good moldabilityIncrease productivityOther chemical processesLaminationBulk fillEngineering

Owner:TEIJIN LTD +1

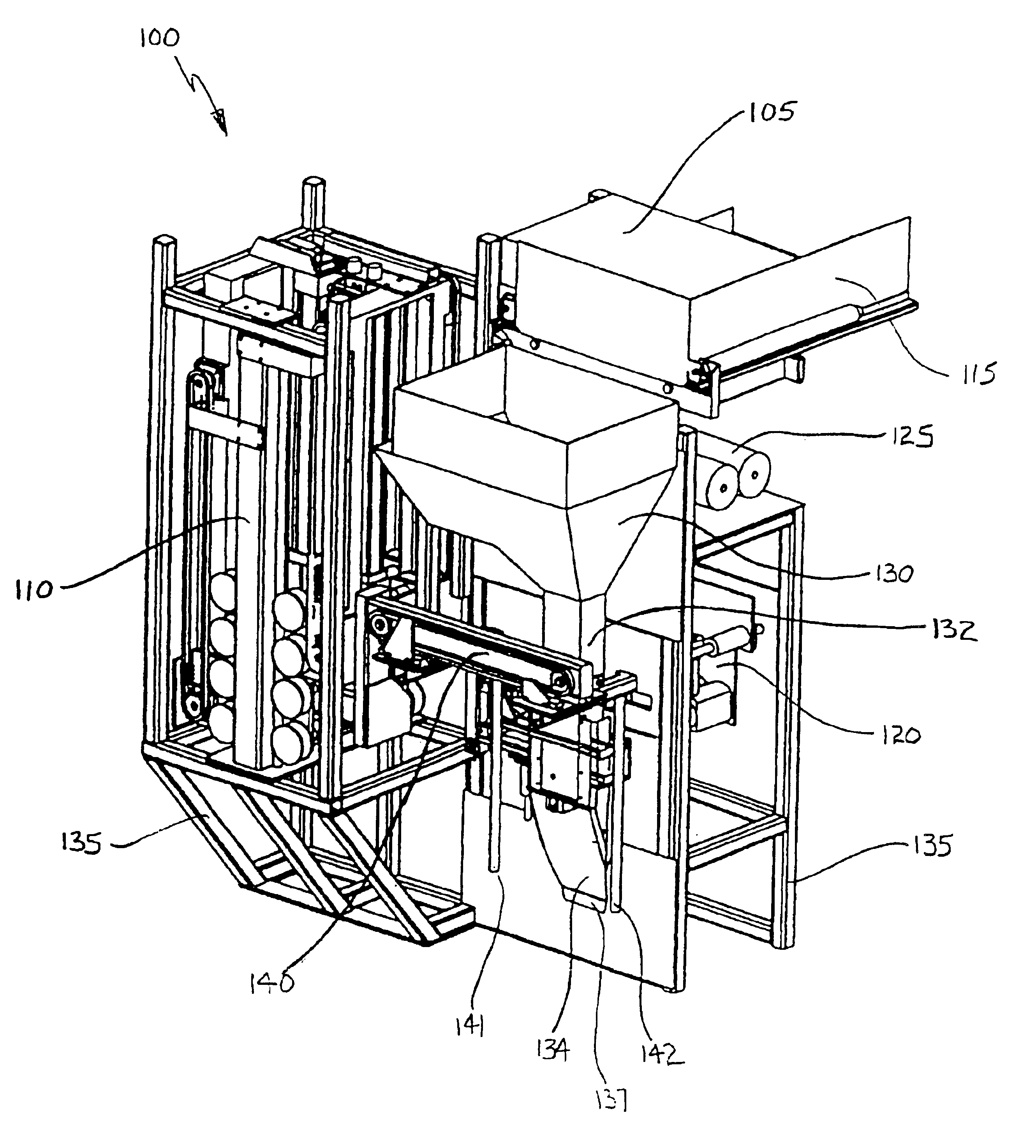

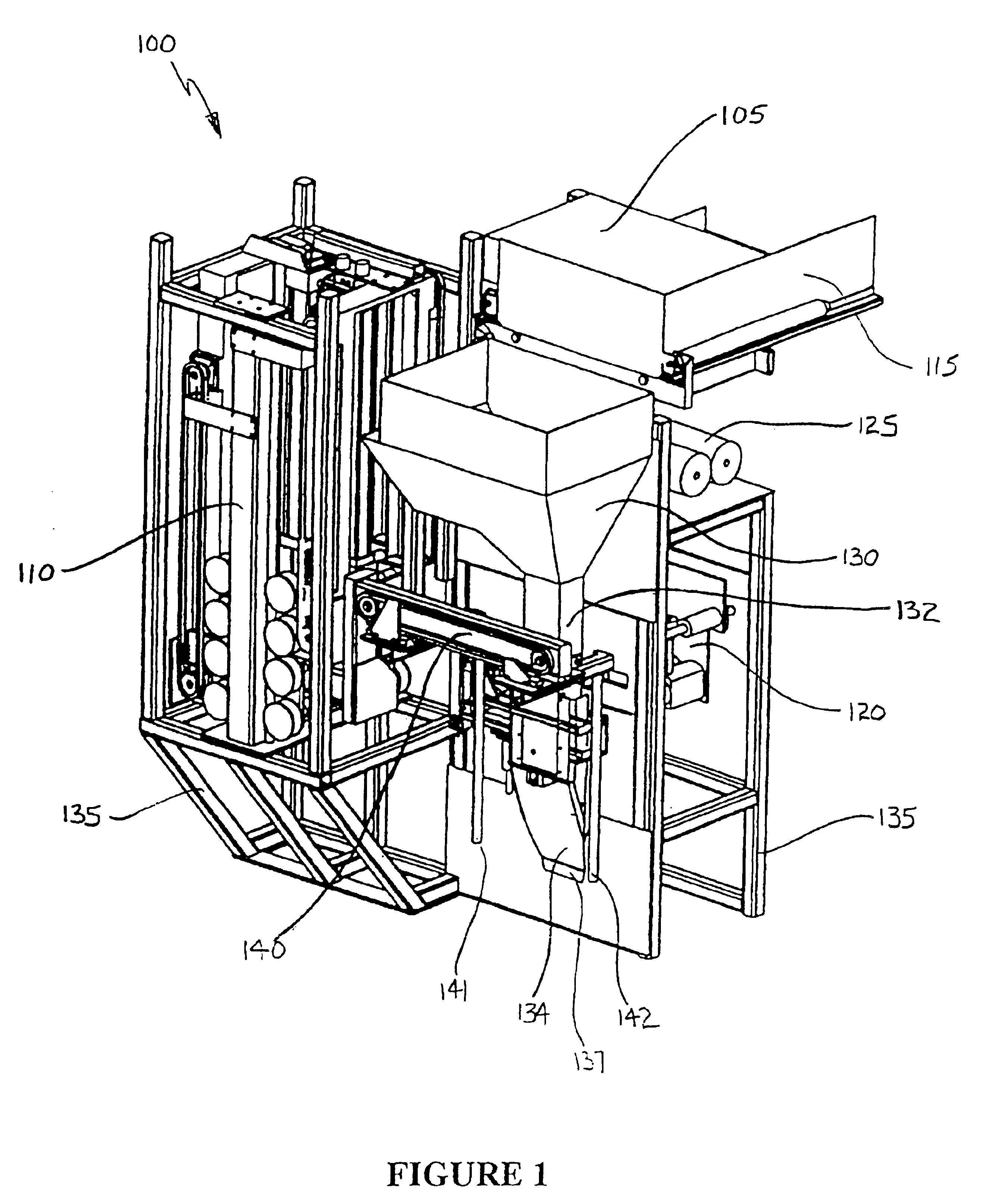

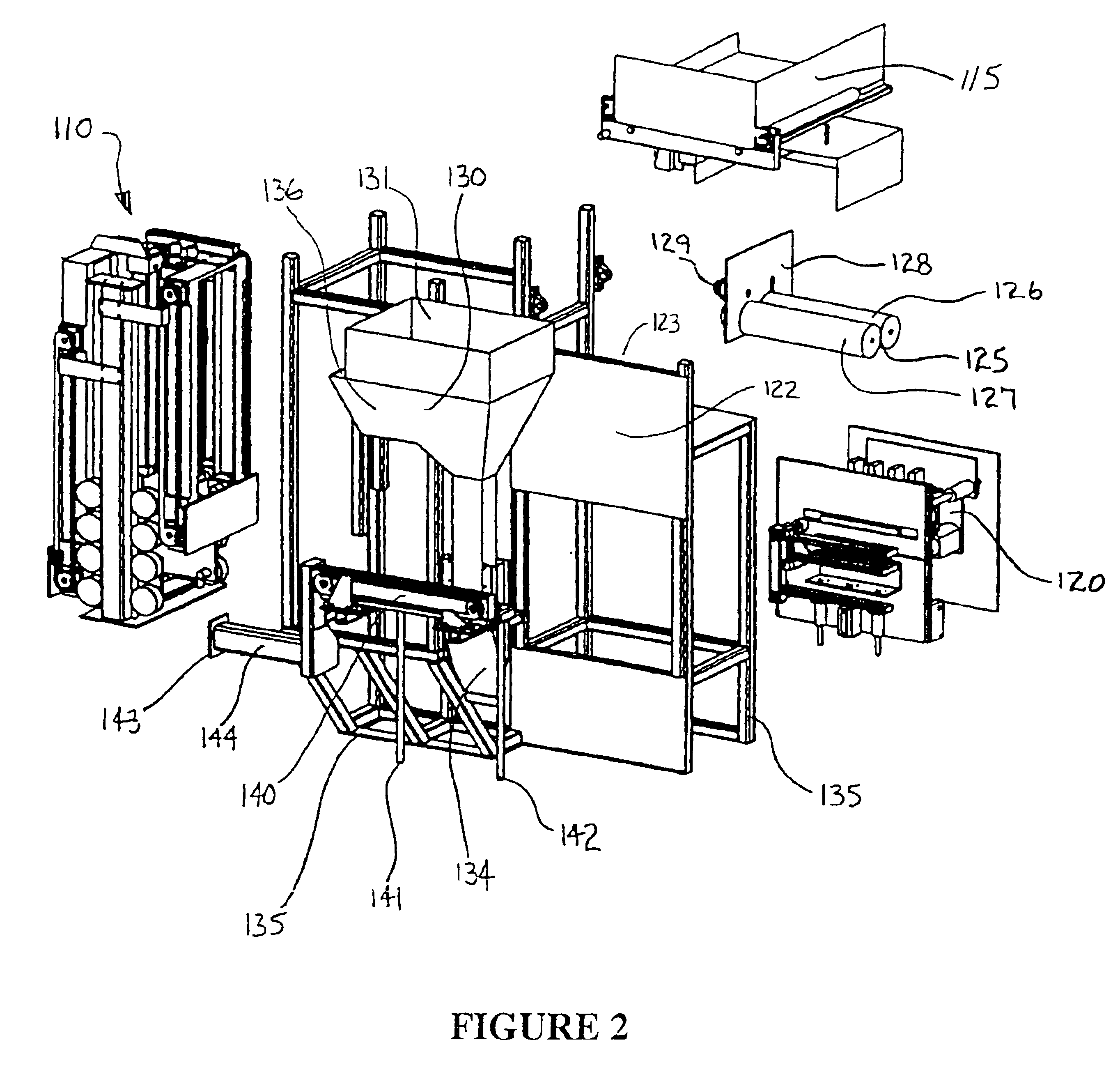

Bag filling apparatus for bagging particulate matter

InactiveUS6863094B2Facilitates easy routingFacilitates presentationBarrels/casks fillingSolid materialBulk fillEngineering

Methods and apparatuses for filling flexible receptacles or bags with bulk or particulate material is provided. In one aspect, an automatic sand bag filling apparatus is disclosed which includes a bulk fill channel which may be placed within the interior of each bag to be filled. The filling apparatus may have a metering device for providing the desired amount of bulk material to the fill channel. The fill channel may be moveable along a fixed path for engaging and advancing a series of interconnected bags. Articulating spreader bars may be provided to support the bag during filling. In one embodiment, the filling apparatus is mounted on a trailer assembly and includes a reservoir for storing the bulk sand. The sand may be transferred from the reservoir to the filling apparatus using augers, conveyors, etc. A preferred construction of a series of interconnected sand bags and a method of making a series of interconnected bags is also disclosed.

Owner:ENSOR EQUIP

Methods and structure to form high K metal gate stack with single work-function metal

ActiveUS9515164B2Simplify and improve performanceLower gate resistanceTransistorSemiconductor/solid-state device manufacturingLithographic artistFilling materials

A method for forming a replacement metal gate structure sharing a single work function metal for both the N-FET and the P-FET gates. The method oppositely dopes a high-k material of the N-FET and P-FET gate, respectively, using a single lithography step. The doping allows use of a single work function metal which in turn provides more space in the metal gate opening so that a bulk fill material may occupy more volume of the opening resulting in a lower resistance gate.

Owner:TESSERA LLC

Method and apparatus for auto-leveling of bulk fill hopper frame

A method and apparatus for automating some of the tasks that heretofore required operator action at headland turns or similar events are provided. The present invention automates operation of lift assist wheels and / or gull wings, such as those found on a stack-fold implement, based on the position of the tractor hitch to which the implement is coupled. An operator may control the position of the implement, such as at a headland turn, by raising and lowering the tractor hitch using a remote control. The invention enables the planter to compare the tractor hitch position relative to an implement position and control operation of the implement accordingly without additional user inputs.

Owner:CNH IND CANADA

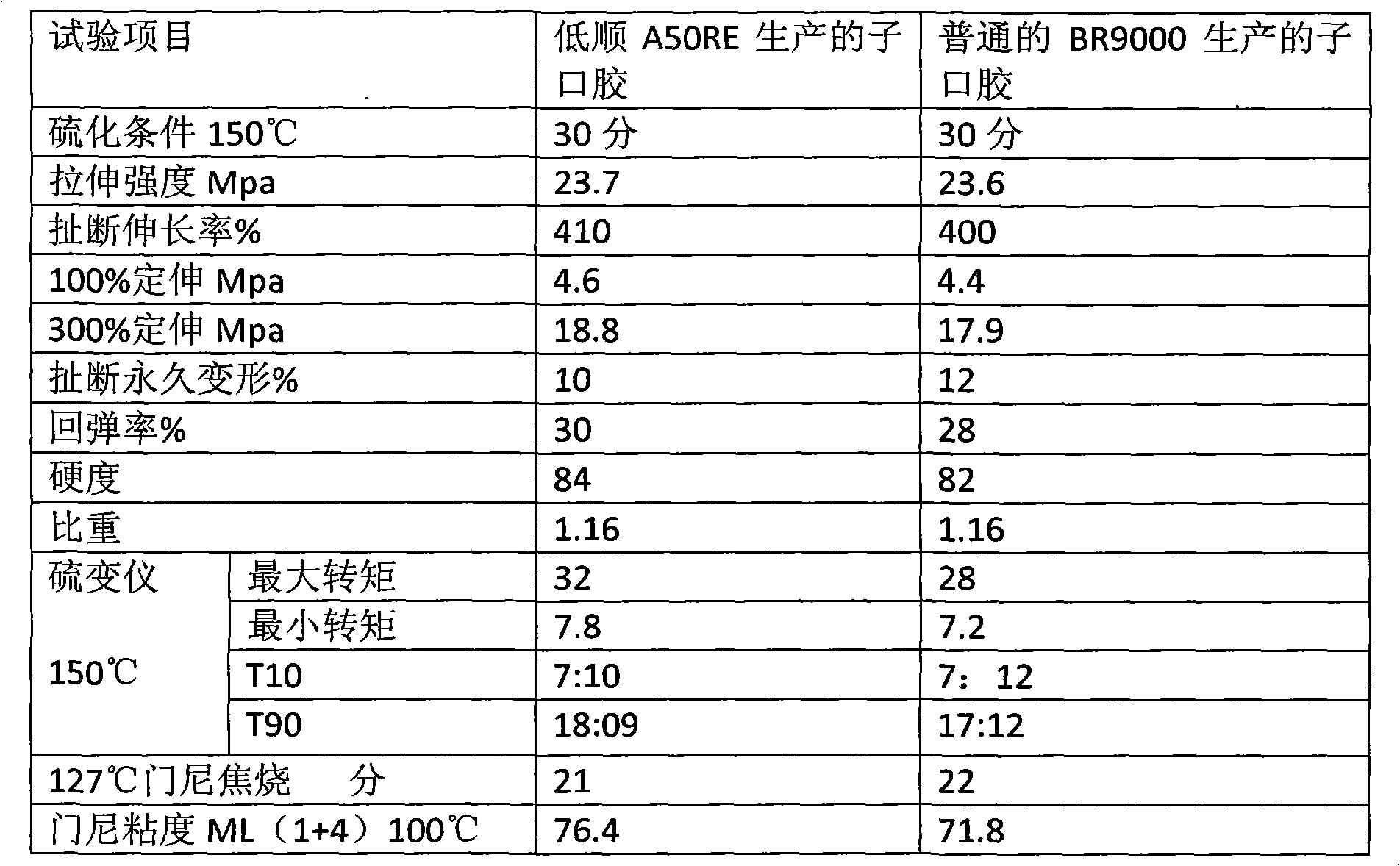

Tire bead adhesive for radial tire and preparation method thereof

The invention mainly discloses a tire bead adhesive for a radial tire. The adhesive is characterized by being prepared from the following components by mass: with 50 parts of natural rubber NR and 50 parts of low cis BR as standard, 6+-1 parts of zinc oxide, 3+-0.5 parts of stearic acid, 2+-0.5 parts of an anti-aging agent 4020, 1+-0.5 parts of an anti-aging agent RD, 1.5+-0.5 parts of protective wax, 2.5+-1 parts of a strengthening agent, 1.2+-0.5 parts of a promoter and 0.8+-0.3 part of sulphur. The invention has the following advantages: a, since low cis BR can be used to substantially substitute aromatic hydrocarbons during utilization, cost for the adhesive is reduced; b, usage amount of resin can be increased, which ensures technical viscosity of the adhesive; c, since low cis BR rapidly eats carbon black, considerable carbon black can be filled, and a reverse smelting process is employed, thereby saving time and improving production efficiency; d, overall performance of the adhesive is similar to the performance of imported low cis adhesives; e, Mooney viscosity can be controlled to be in a range of 45 to 51.

Owner:DOUBLE COIN GRP JIANGSU TIRE

Stack-Fold Implement Having Bulk Fill System

ActiveUS20120000404A1Overcomes drawbackLarge capacitySpadesAgricultural machinesBulk fillEngineering

A stack-fold implement having a central bulk fill hopper assembly is provided. The bulk fill hopper assembly is mounted to the center frame section of the stack-fold implement and does not affect the narrowness of the stack-fold implement when it's in a stacked, transport position. The hopper assembly includes a pair of bulk fill hoppers or tanks supported by cradle that is in turn supported by a pair of wheels. The cradle is removably coupled to the center frame section by a plurality of rigid frame members.

Owner:CNH IND CANADA

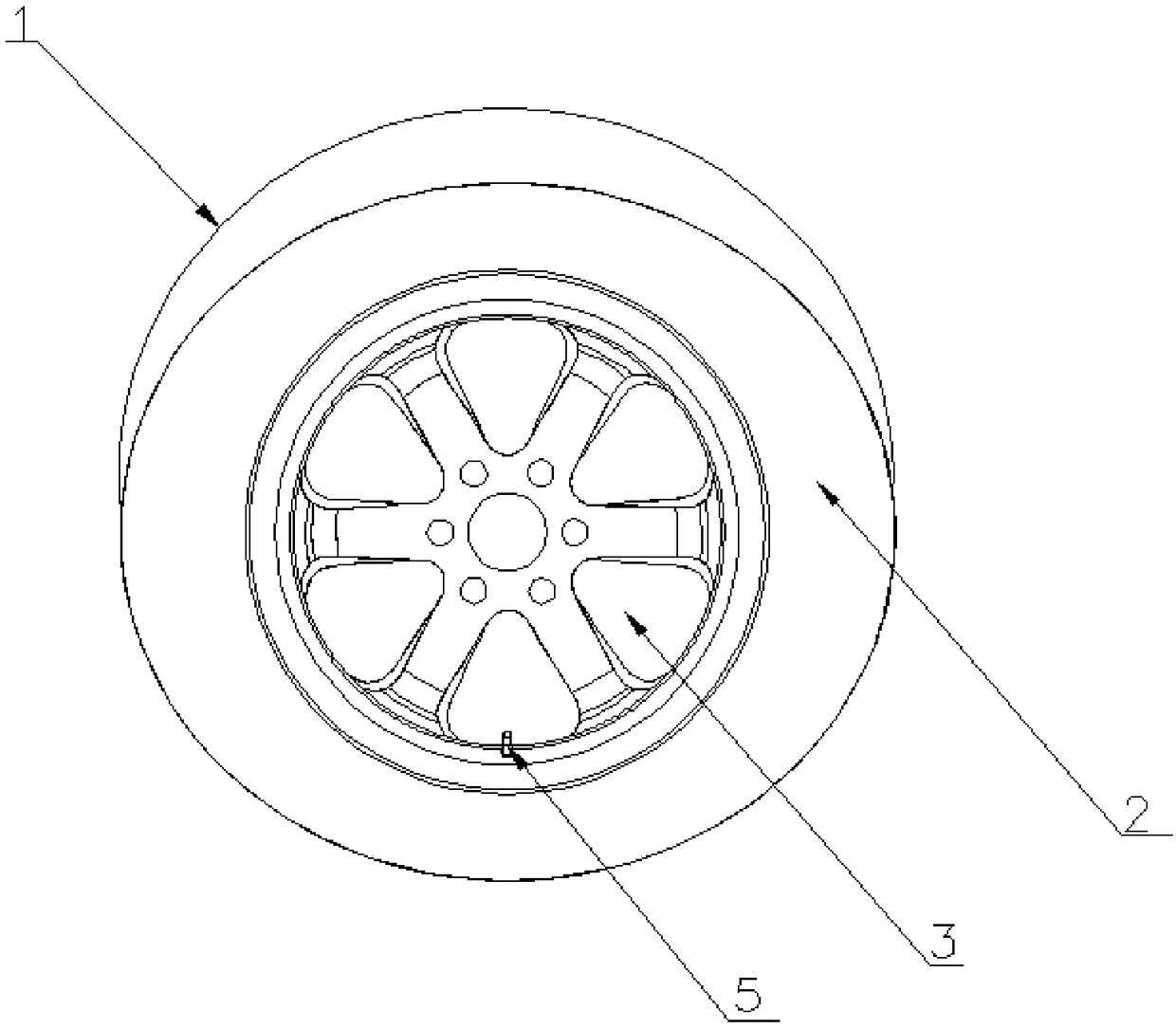

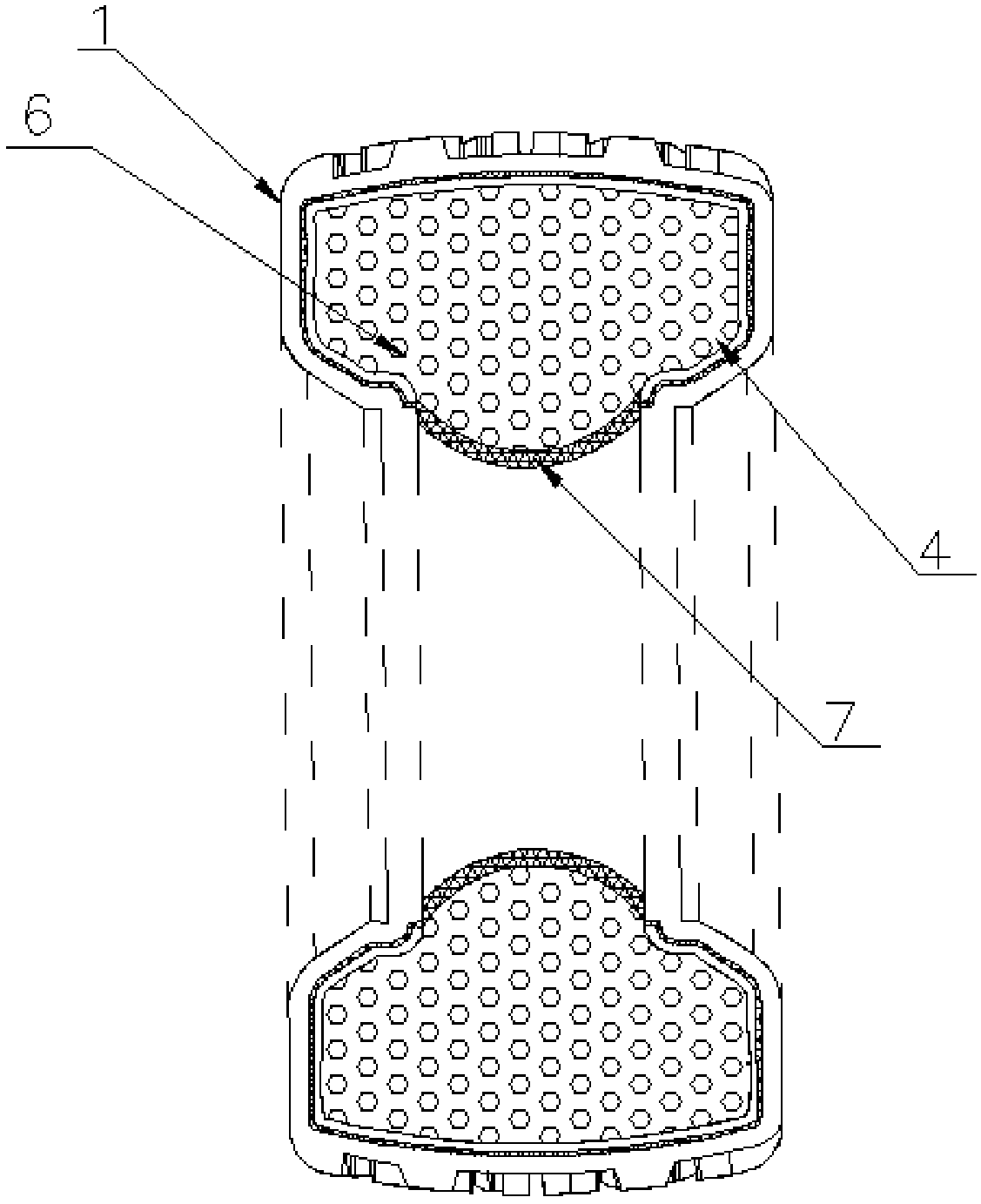

A bulk-filled explosion-proof tire

InactiveCN108973532AAvoid dangerous situationsImprove road performanceWith separate inflatable insertsWith multiple inflatable chambersInternal pressureBulk fill

A bulk-filled explosion-proof tire includes a tire body, the tire body comprises a tire and a hub, A receiving cavity is formed between the tire and the hub, A plurality of hollow soft glue balls arefilled in the accommodating cavity, The tire is inflated through an inflating port, the volume in the accommodating cavity is reduced, the space is enlarged, the volume of the hollow soft rubber ballis reduced, and the pressure is enlarged. The internal pressure of the hollow soft rubber ball after inflating the tire is balanced with the internal pressure of the tire after inflating the tire, sothat the tire body is explosion-proof. The invention is simple in structure, so that that tyre is effectively prevent from bursting, running performance is good, durability is high, cost is lower thansolid tire, when hard puncturing tyre damage and possibly together with a punctured close to a hollow soft rubber ball, the remaining hollow soft rubber ball in tire is still intact, and block the damaged area, thus maintaining most of the pressure in the original tire gas, the tire has only a small amount of air leakage.

Owner:JIANGSU TOPOWER WHEEL

A kind of preparation method of spherical hexagonal boron nitride aggregate

The invention provides a preparation method of a spherical hexagonal boron nitride aggregate, and relates to the preparation method of the spherical hexagonal boron nitride aggregate. The invention aims at solving the problems that orientation and difficulty in filling of a large amount are easy to generate during dispersion of layered hexagonal boron nitride in a system. The method comprises thefollowing steps: (1) preparation of an alkaline earth metal carbonate-oxide composite sintering aid; (2) hexagonal boron nitride, a dispersant, an adhesive and a sintering aid are used for preparing water base slurry; (3) spraying and granulation are carried out; (4) rubber discharging is carried out; (5) sintering is carried out in order to obtain the spherical hexagonal boron nitride aggregate.The spherical hexagonal boron nitride aggregate has high sphericility, a continuous bridge forming and overlapping mode appears between primary particles for aggregation with isotropy, and the methodhas a simple process and is friendly to environment.

Owner:上海百图高新材料科技有限公司

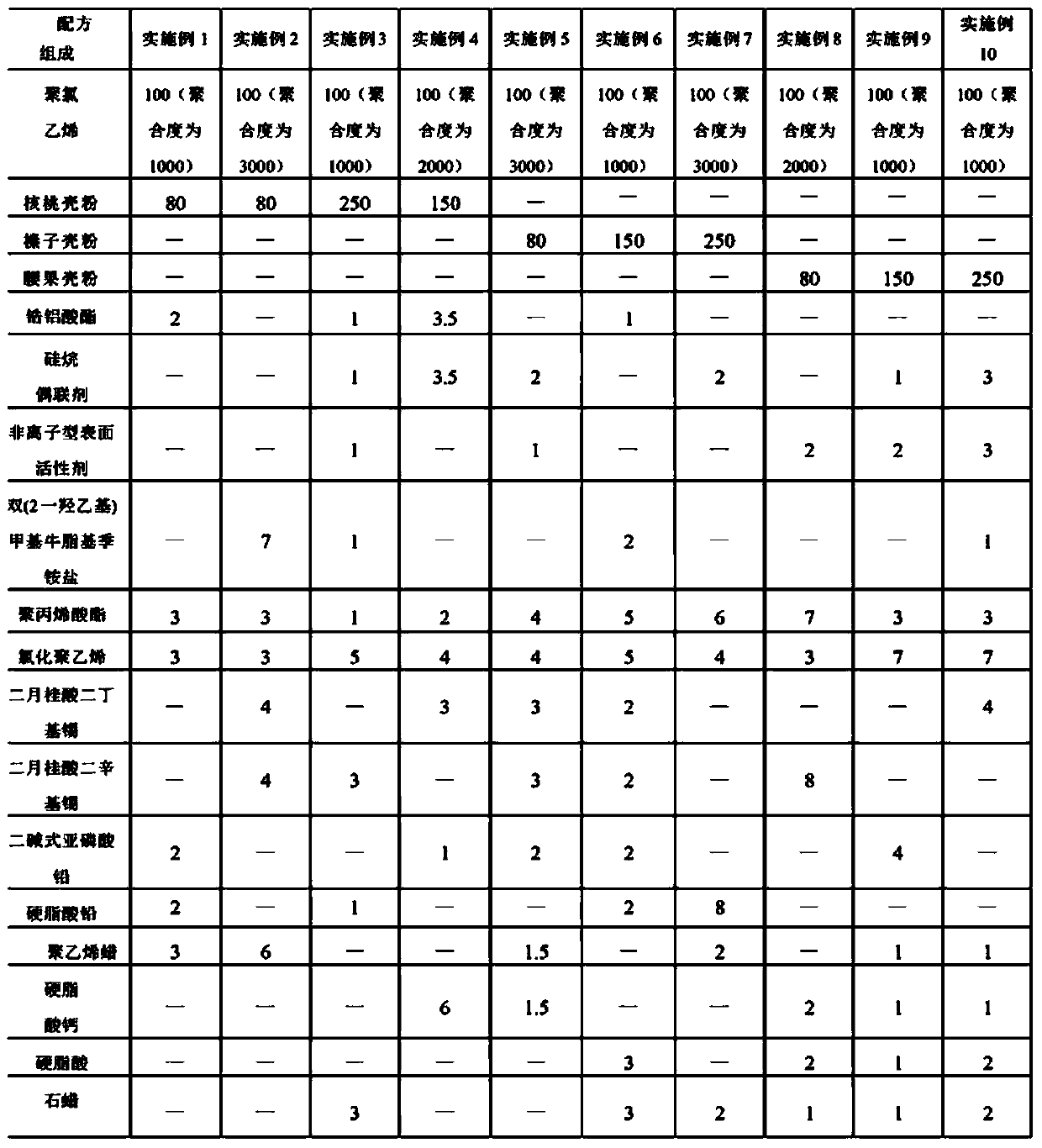

Polyvinyl chloride/modified nut shell powder composite material and preparation method thereof

The invention relates to a polyvinyl chloride / modified nut shell powder composite material and a preparation method thereof, belonging to the technical field of composite materials. According to the invention, the polyvinyl chloride / modified nut shell powder composite material is obtained by the following raw materials in parts by weight: 100 parts of polyvinyl chloride with polymerization degree of 2000-3000, 150-250 parts of nut shell powder, 2-7 parts of surface modifier, 6-10 parts of polymer modifier, 4-8 parts of heat stabilizer and 3-6 parts of lubricant; and the preparation method of the polyvinyl chloride / modified nut shell powder composite material comprises the following steps of: (1) raw material pretreatment; (2) nut shell powder modification; and (3) kneading and material preparation. The polyvinyl chloride / modified nut shell powder composite material provided by the invention can be used for filling a large quantity of modified nut shell powders and has the advantages of higher filling degree, good compatibility with plastics as well as better mechanical performances, such as reinforcement performance, toughening performance and so on.

Owner:云南鑫乾矿业有限公司

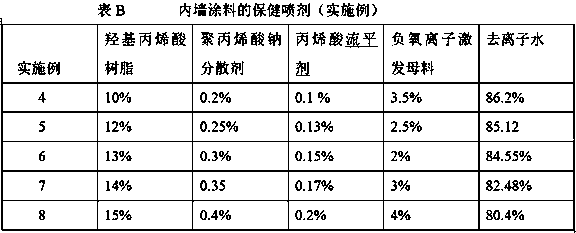

Negative oxygen ion excitation master batch and health-care spray of interior wall coating thereof

The negative oxygen ion excitation master batch comprises the following components: a negative ion excitation base material, and auxiliary materials for accurately regulating and controlling the proportion of the base material in the finish product and achieving a uniform dispersion effect. The master batch is characterized in that the excitation base material is ThO2 accounting for 2-10 wt%, andthe balance being dispersion auxiliary materials. According to the process production method, tailings of thorium-rich paragenic ore can be used as a raw material for further fine washing, enrichmentand selective removal to obtain a low-cost basic raw material, and fine control is achieved by virtue of a large amount of filler and a trace amount of high-purity commercial thorium, so that the process production method is low in cost, efficient and reliable. The interior wall coating health-care spray prepared from the negative oxygen ion excitation master batch has the advantages that the interior illumination index of the product is not detected, the concentration of air negative ions is 4000-13000, the exterior illumination index conforms to the GB6566-2010 provisions, and the spray canbe applied to decorated closed spaces and vehicles.

Owner:马娜

Deep trench liner removal process

ActiveUS8313661B2Reducing and minimizing damageElectric discharge tubesElectrolytic capacitorsFilling materialsBulk fill

A liner removal process is described, wherein an excess portion of a conformal liner formed in a trench is substantially removed while reducing or minimizing damage to a bulk fill material in the trench.

Owner:TOKYO ELECTRON LTD

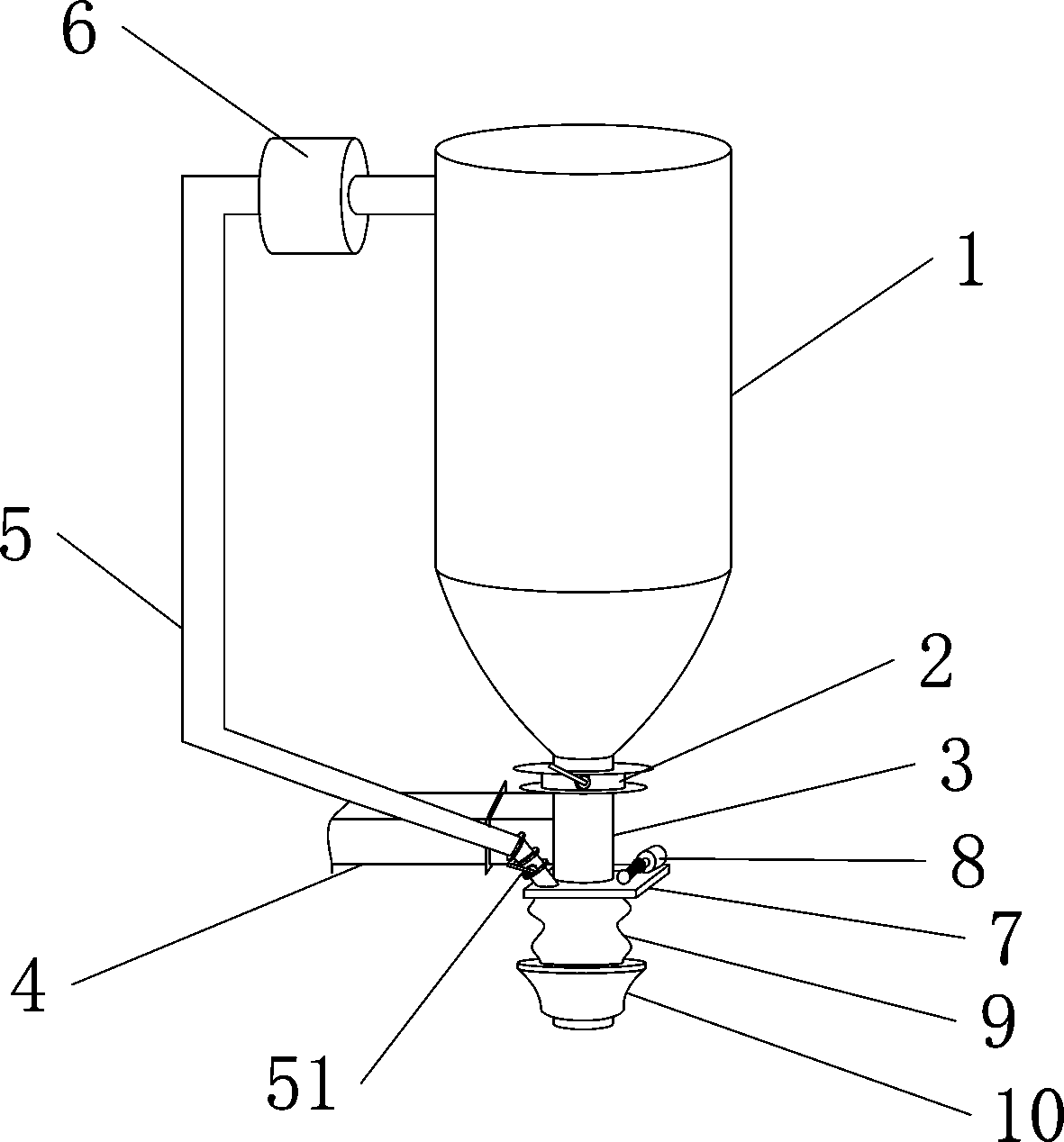

Negative pressure bulk tank car device

The invention belongs to the technical field of mechanical loading and unloading equipment, and particularly relates to a negative pressure bulk tank car device. The device comprises a finished product tank, a discharging pipe arranged at the discharging end of the finished product tank, a negative pressure pipe, an exhaust fan, a mounting platform, a lifting device, a telescopic part and a bulk head, wherein the lifting device is arranged on the upper surface of the mounting platform, the lifting device can drive the bulk head to move up and down, the bulk head drives the telescopic part to stretch and retract, the telescopic part and the bulk head are provided with a communicating hollow layer, the hollow layer communicates with one end of the negative pressure pipe, and the other end ofthe negative pressure pipe communicates with the top of the finished product tank. When the negative pressure bulk filling tank device carries out discharging on a carrying vehicle, the lifting device adjusts the position of the bulk head according to an actual height of the carrying vehicle, the dust raising phenomenon can be caused, the bulk head and the telescopic part can be subjected to negative pressure through the exhaust fan, the dust is sucked away and sent back to the interior of the finished product tank to be reused, the dust raising phenomenon is eliminated, the product waste isreduced, the operation efficiency is improved, and the health and environment of workers are protected.

Owner:偃师市神龙环保材料有限公司

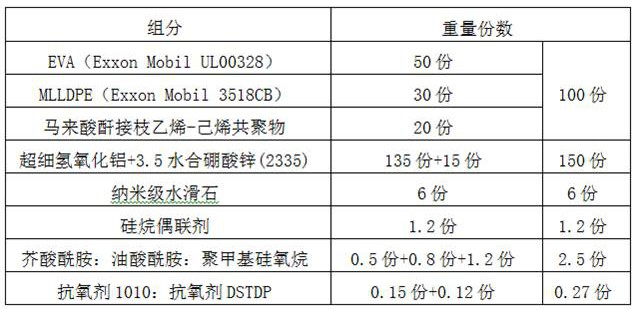

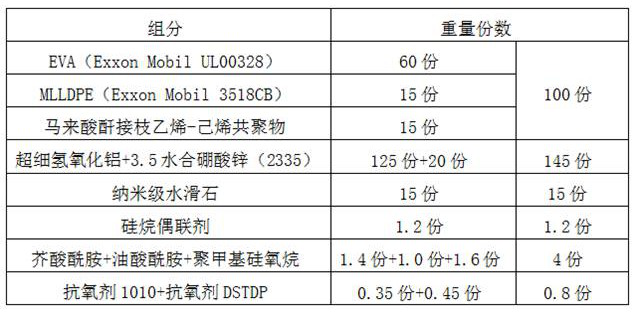

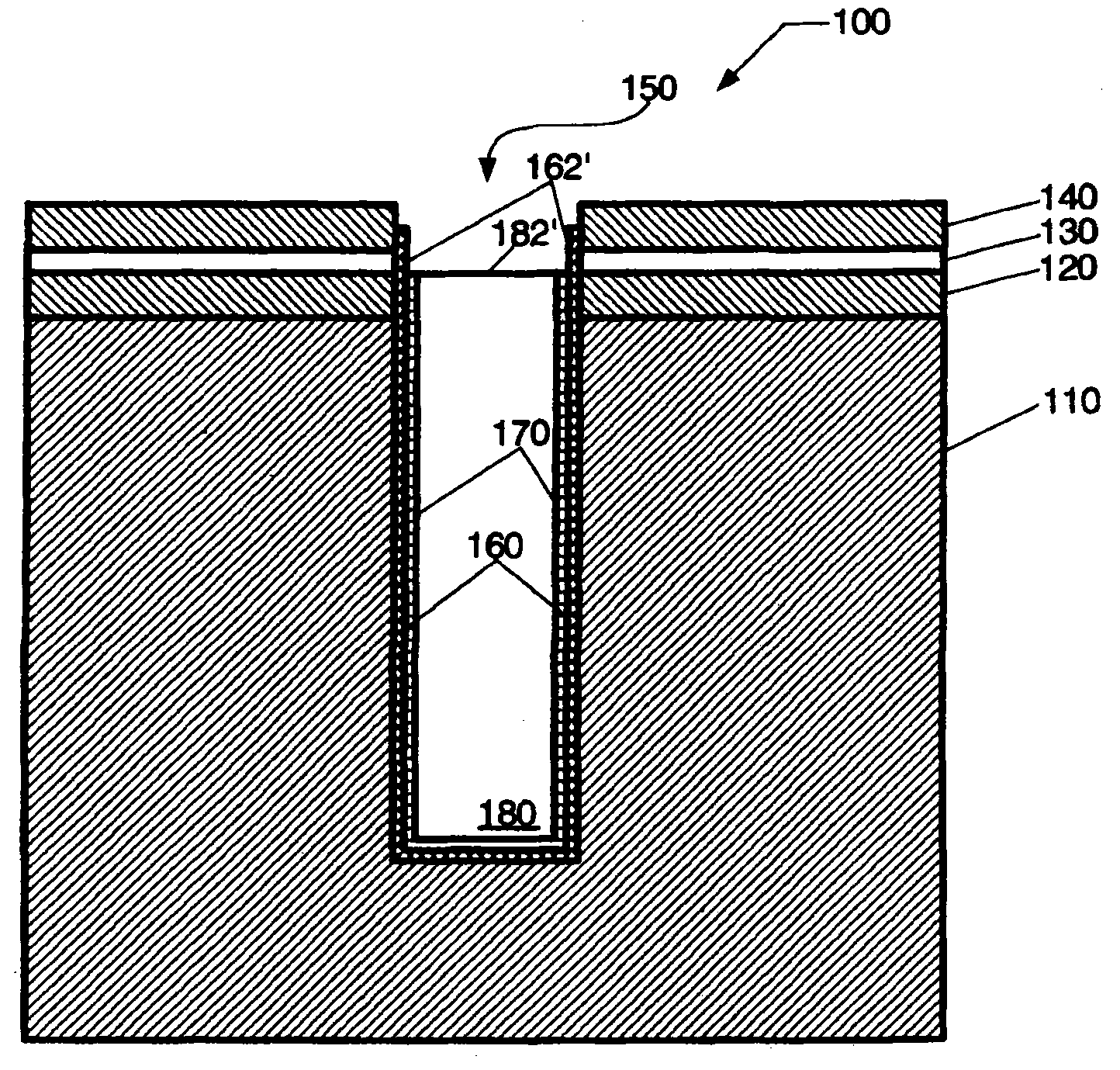

A low-friction, low-smoke, halogen-free, flame-retardant sheath material suitable for air-blown optical cable laying and preparation method thereof

The invention discloses a low-friction, low-smoke, halogen-free flame-retardant sheathing material suitable for air-blown optical cable laying and a preparation method thereof. The sheathing material is composed of the following parts by weight of raw materials: 100 parts of matrix resin, composite filler type flame-retardant 100-150 parts of compound lubricant, 5-15 parts of nano-scale hydrotalcite, 1-2 parts of silane coupling agent, 1-4 parts of compound lubricant, 0.2-0.8 part of compound antioxidant, after mixing, extrusion, In the steps of granulation, cooling, screening and packaging, in the present invention, the friction coefficient of the sheath material obtained through careful formulation selection and processing is as low as 0.1 or less, the extrusion speed is fast, and the rejection rate is low, which is especially suitable for pipelines. In the construction of laying multiple optical cables by air blowing, because of the combination of hydrotalcite and various lubricants, it breaks through the common low-smoke halogen-free flame retardant sheath material due to a large amount of aluminum hydroxide and magnesium hydroxide. 0.25 or more will affect the air-blown laying of the optical cable.

Owner:JIANGSU LINRY NEW MSTAR TECH

Deep trench liner removal process

InactiveCN102087974AEasy to understandElectric discharge tubesSemiconductor/solid-state device manufacturingFilling materialsBulk fill

The present invention describes a deep trench liner removal process, wherein an excess portion of a conformal liner formed in a trench is substantially removed while reducing or minimizing damage to a bulk fill material in the trench.

Owner:TOKYO ELECTRON LTD

Preparation method and application of high-performance motor packaging material

The invention relates to the field of motor packaging, in particular to a preparation method and application of a high-performance motor packaging material. The preparation method of the high-performance motor packaging material comprises the following steps: (1) preparing the resin A; (2) preparing a curing agent; and (3) performing an action process of the resin and the curing agent to obtain the high-performance motor packaging material, wherein the mass ratio of the resin A to the curing agent is 1: (0.7-1.3); the resin A in the step (1) is prepared from the following raw materials: 3, 4-epoxy hexyl methyl-3, 4-epoxy cyclohexyl formate, acrylic polyurethane resin, a toughening agent, a novel functional filling agent, an anti-settling agent and a coupling agent; raw materials for preparing the curing agent in the step (2) comprise methyl tetrahydrophthalic anhydride, polyether polyol, novel functional filling powder, an anti-settling agent and an accelerant. According to the motor packaging material, the modified powder is used as a filling material, so that the motor packaging material has the characteristic of large usage amount, and the cost can be reduced; and on the basis of using a large amount of filling powder, the motor packaging material with relatively good toughness, strength and temperature-resistant effect is prepared.

Owner:厦门市宜帆达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com