Polyvinyl chloride/modified nut shell powder composite material and preparation method thereof

A technology of nut shell powder and polyvinyl chloride is applied in the field of composite materials to achieve the effects of reducing weight and production cost, improving impact resistance and stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

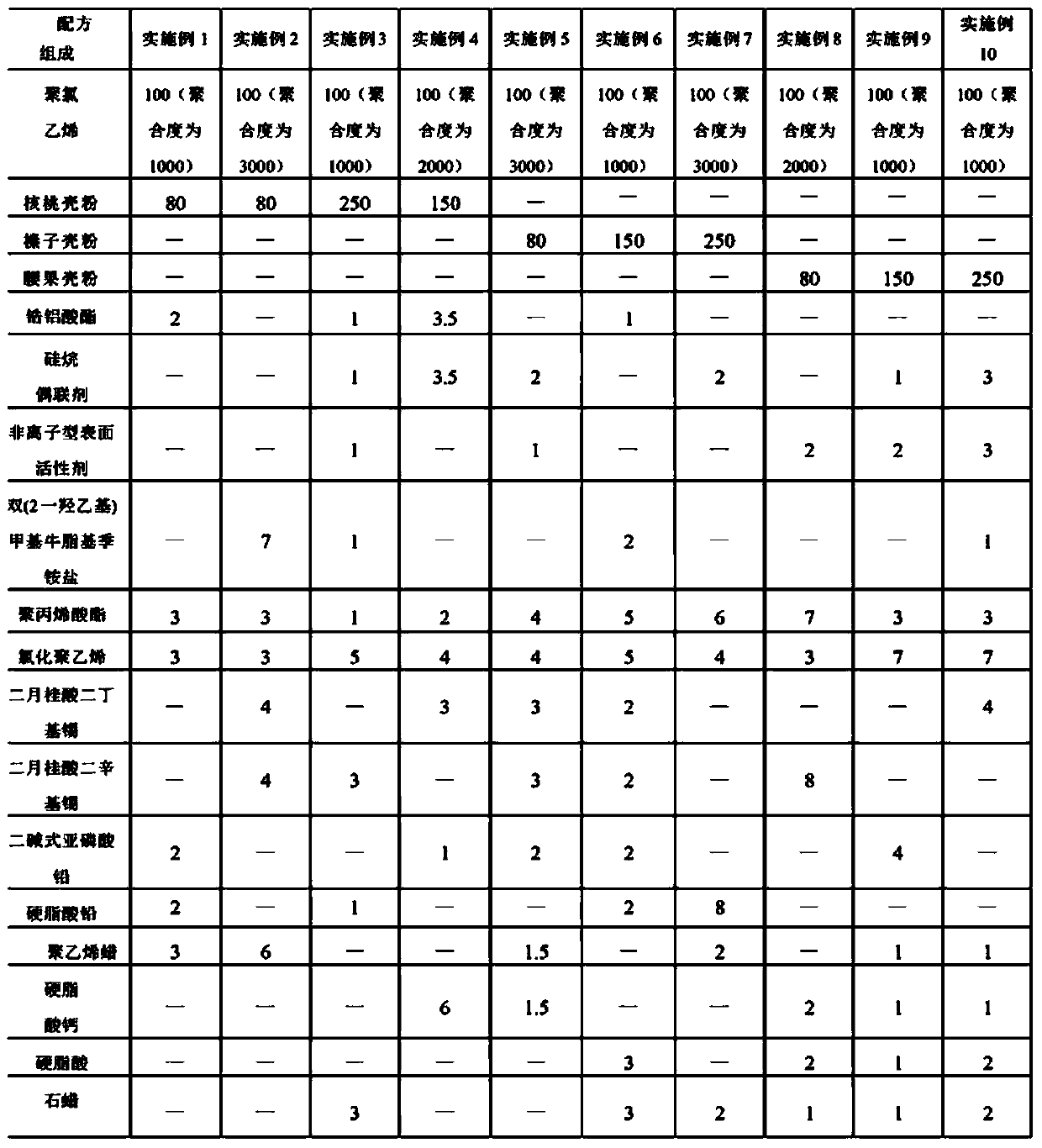

[0019] A polyvinyl chloride / modified nut shell powder composite material is made from the raw materials in the polyvinyl chloride / nut shell powder composite material formula (parts by weight) in Table 1, and its preparation method comprises the following steps:

[0020] (1) Raw material pretreatment: grind the walnut shells into fine powder with an agricultural grinder, and then grind them into 220-mesh fine powder with a high-speed rotor mill, and take walnut shell powder and surface modifier in specified parts by weight according to the formula in Table 1 , preheating and drying the walnut shell powder at 100°C for 2.5 hours until the water content is ≤0.3%, diluting the surface modifier with petroleum ether at 70°C to prepare a 10wt% solution;

[0021] (2) Modification of nut shell powder: In a high-speed mixer, add the dilution of the surface modifier to the walnut shell powder, and stir at high speed for 15 minutes to obtain the modified walnut shell powder;

[0022] (3) ...

Embodiment 2

[0024] A polyvinyl chloride / modified nut shell powder composite material is made from the raw materials in the polyvinyl chloride / nut shell powder composite material formula (parts by weight) in Table 1, and its preparation method comprises the following steps:

[0025] (1) Raw material pretreatment: After the walnut shell is ground into fine powder with an agricultural grinder, it is then ground into a 260-mesh fine powder with a high-speed rotor mill, and walnut shell powder and surface modification are taken according to the formula in Table 1. The walnut shell powder was preheated and dried at 110°C for 3.5 hours until the moisture content was ≤0.3%, and the surface modifier was diluted with 80°C petroleum ether to prepare a 14wt% solution;

[0026] (2) Modification of nut shell powder: In a high-speed mixer, the surface modifier dilution was added to the walnut shell powder, and stirred at high speed for 30 minutes to obtain modified walnut shell powder;

[0027] (3) Knea...

Embodiment 3

[0029] A polyvinyl chloride / modified nut shell powder composite material is made from the raw materials in the polyvinyl chloride / nut shell powder composite material formula (parts by weight) in Table 1, and its preparation method comprises the following steps:

[0030] (1) Raw material pretreatment: After walnut shells are ground into fine powder with an agricultural pulverizer, they are then ground into 320-mesh fine powder with a high-speed rotor mill, and walnut shell powder and surface modification are taken according to the formula in Table 1 agent, the walnut shell powder was preheated and dried at 100°C for 3 hours, and dried to a moisture content of ≤0.3%, and the surface modifier was diluted with 80°C petroleum ether to prepare a 12wt% solution;

[0031] (2) Modification of nut shell powder: In a high-speed mixer, the surface modifier dilution was added to the walnut shell powder, and stirred at high speed for 20 minutes to obtain modified walnut shell powder;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com