Bulk material bagging device

A bagging device and material bagging technology, applied in the field of bags, can solve the problems of affecting hygiene and affecting the weight accuracy of packaging, and achieve the effect of simple structure and simplified transportation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

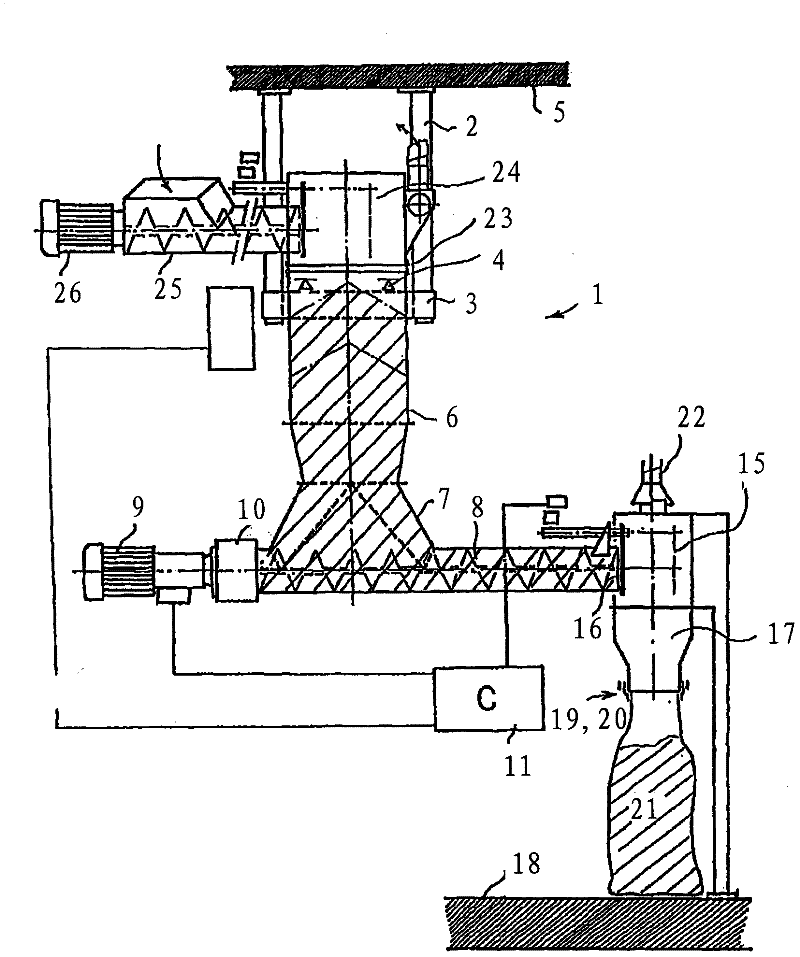

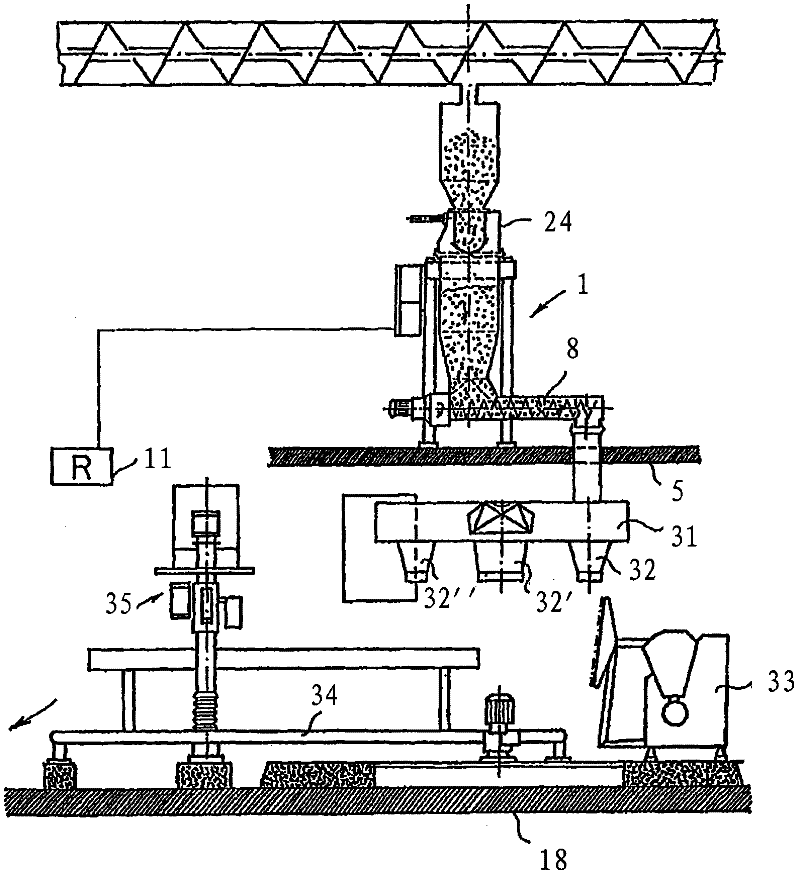

[0115] refer to figure 1 . A differential scale 1 is supported by a column 2 , a platform 3 and a weight detection device 4 , or suspended on a top cover 5 .

[0116] The differential bagging scale 1 mainly consists of a weighing container 6, a transfer unit 7 and a forced screw unloader 8, which is driven by a drive motor 9 through a reducer 10 and controlled by a computer 11. The coarse-flow and fine-flow batching can be carried out with a screw feeder having two rotational speeds, or the fine-flow batching can be carried out by a separately driven fine-flow screw, not shown.

[0117] In order not to cause uncontrollable idling of the feed device 8 , the discharge opening 16 is opened and closed in a controlled manner by the computer 11 via a valve 15 . The bagging head 17, which is supported independently of the differential bagging scale 1 on the floor 18, has a charging connection 19 and a bag holder 20, the latter in figure 1 A pocket 21 is held tightly in the center....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com