Negative pressure bulk tank car device

A technology of filling trucks and negative pressure, applied in the field of negative pressure bulk filling trucks, can solve the problems affecting the health and environmental protection of employees in the working environment, products with dust phenomenon, and inability to cooperate, so as to protect the health of employees and the environment, and eliminate the phenomenon of dust. , the effect of reducing product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

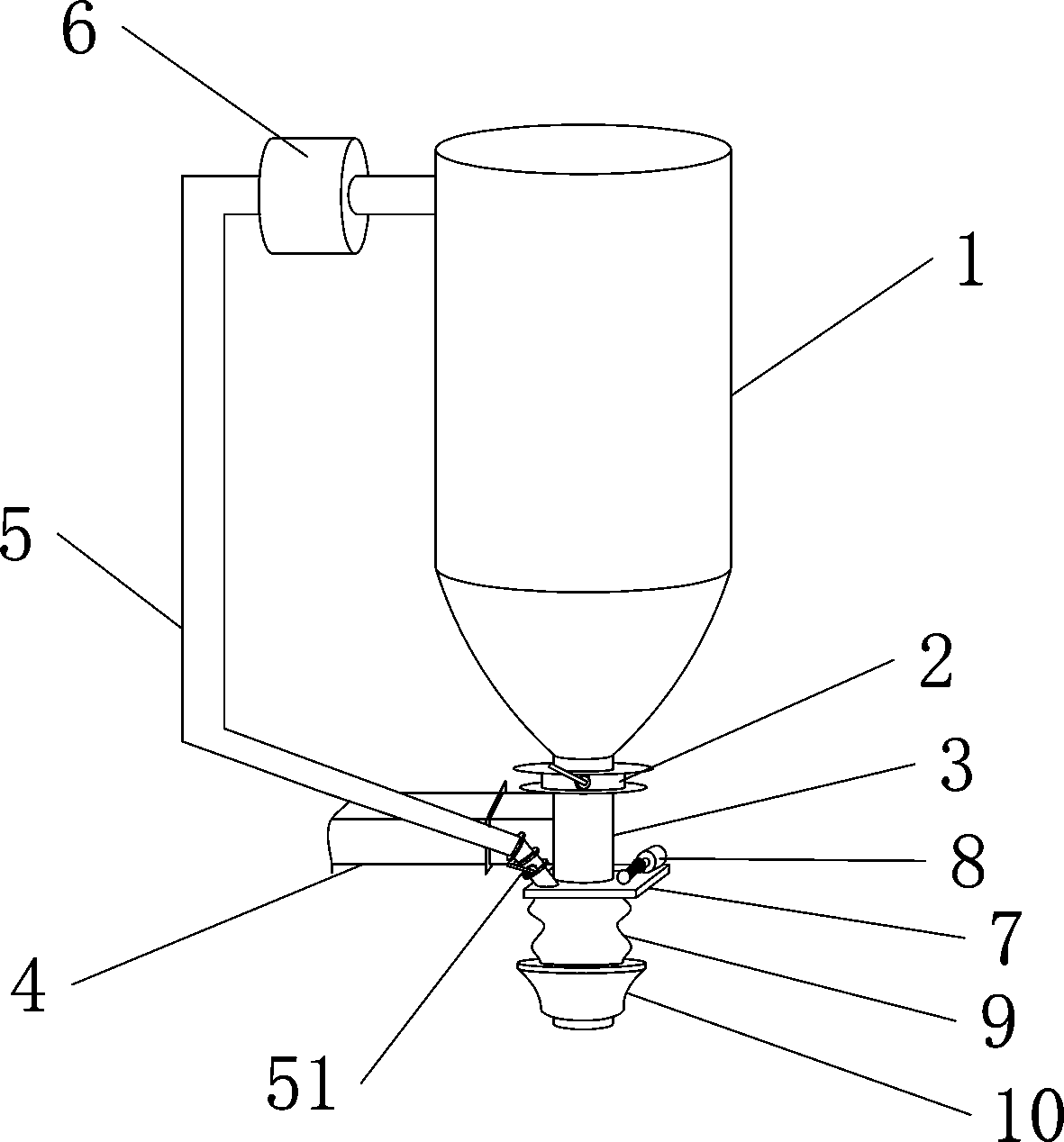

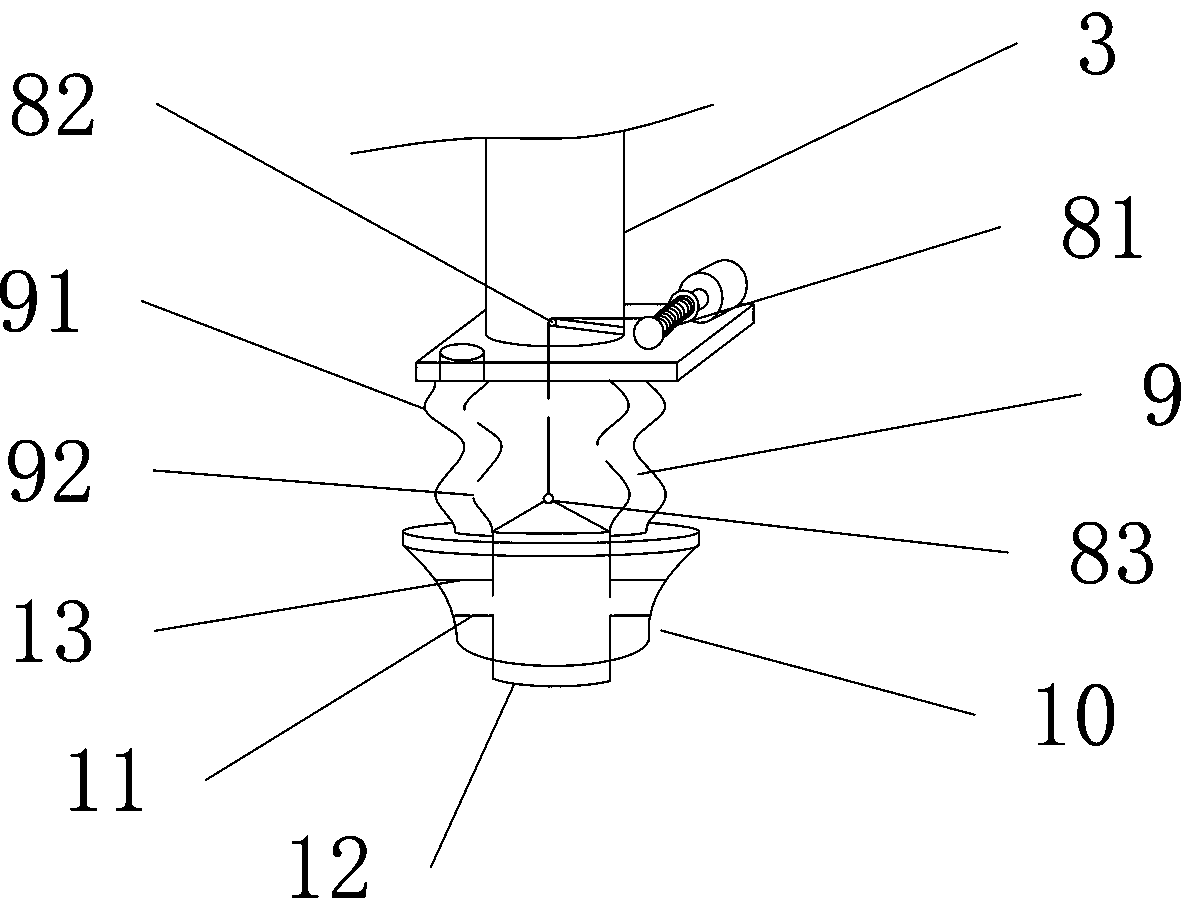

[0022] Please refer to figure 1 An embodiment is shown: a negative pressure bulk filling device, including a finished product tank 1, a discharge valve 2, a discharge pipe 3, an air delivery chute 4, a negative pressure pipe 5, an exhaust fan 6, an installation platform 7, Lifting device 8, telescopic part 9, bulk head 10, the discharge end of the finished product tank 1 is connected with the feed end of the discharge valve 2, and the discharge end of the discharge valve 2 is connected with the discharge pipe 3 is connected to the feed end, the side of the discharge pipe 3 is connected to the discharge end of the air delivery chute 4, the discharge end of the discharge pipe 3 is equipped with the installation platform 7, the installation The upper surface of the platform 7 is equipped with the negative pressure pipe 5, the lower surface of the installation platform 7 is equipped with the telescopic part 9, the feed end of the telescopic part 9 is connected to the discharge end...

Embodiment 2

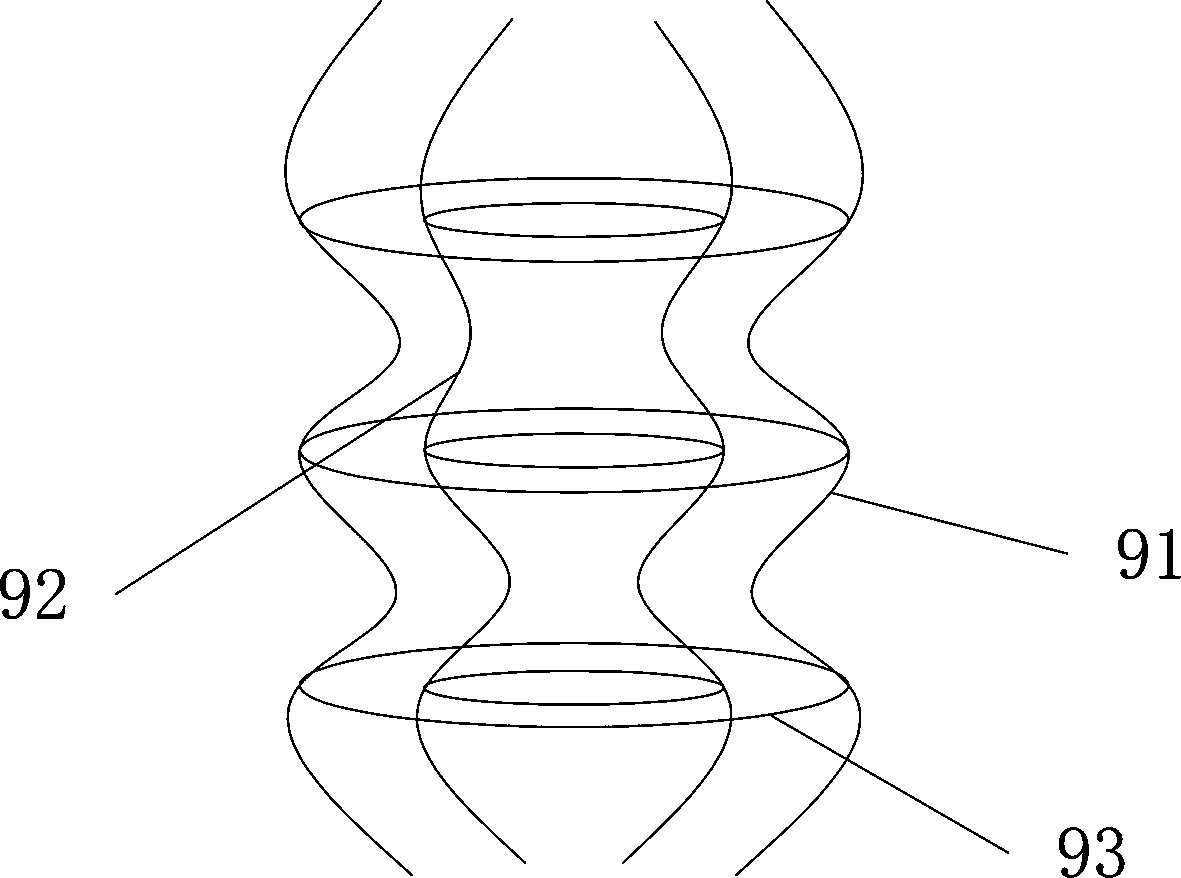

[0025] Based on the above examples, please refer to figure 2 In an embodiment shown, the telescopic part 9 is provided with a first filter bag 91 located on the outer layer and a second filter bag 92 located on the inner layer, and the second filter bag 92 is connected to the outlet of the discharge pipe 3 The feed end is connected.

[0026] Embodiment 2 On the basis of Embodiment 1, preferably, the telescopic part 9 is set as a double-layer circular filter bag, and the second filter bag 92 in the inner layer communicates with the discharge end of the discharge pipe 3 , to facilitate the material circulation of the finished product filling 1. And in the process of air extraction by the exhaust fan 6, external impurities can be filtered out to ensure the purity of the material.

Embodiment 3

[0028] On the basis of the above embodiments, embodiment 3 shows that both the first filter bag 91 and the second filter bag 92 are provided with several support rings 93 on the inner circumference.

[0029] According to the above-mentioned embodiment, preferably, several support rings 93 are arranged on the inner circumference of the first filter bag 91 and the second filter bag 92, when the lifting device 8 drives the bulk head 10 to rise, it will squeeze and stretch part 9, the first filter bag 91 and the second filter bag 92 will be closely attached to each other, resulting in the disappearance of the hollow layer. When the exhaust fan 6 sucks air, the negative pressure generated cannot reach the bulk head 10, and the support ring 93 can be set to maintain the hollow layer. It is always present to ensure that the negative pressure reaches the bulk head 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com