Preparation method and application of high-performance motor packaging material

A packaging material and high-performance technology, which is applied in the field of high-performance motor packaging material preparation, can solve the problems of mechanical properties, toughness and durability, etc., and achieve high glass transition temperature, balanced tensile strength, and improved Dispersion effect

Pending Publication Date: 2022-05-31

厦门市宜帆达新材料有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical solution of the present invention is proposed to solve the problem that the existing motor packaging materials cannot have good mechanical properties, toughness and durability when adding fillers to increase heat resistance and increase the glass transition temperature of the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

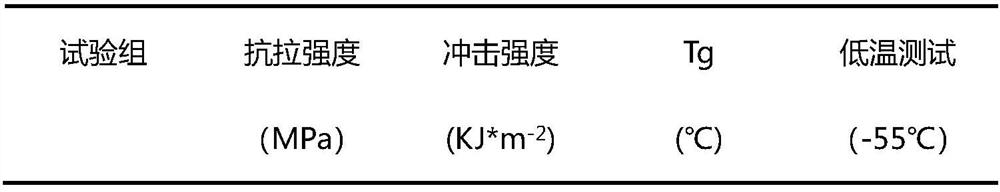

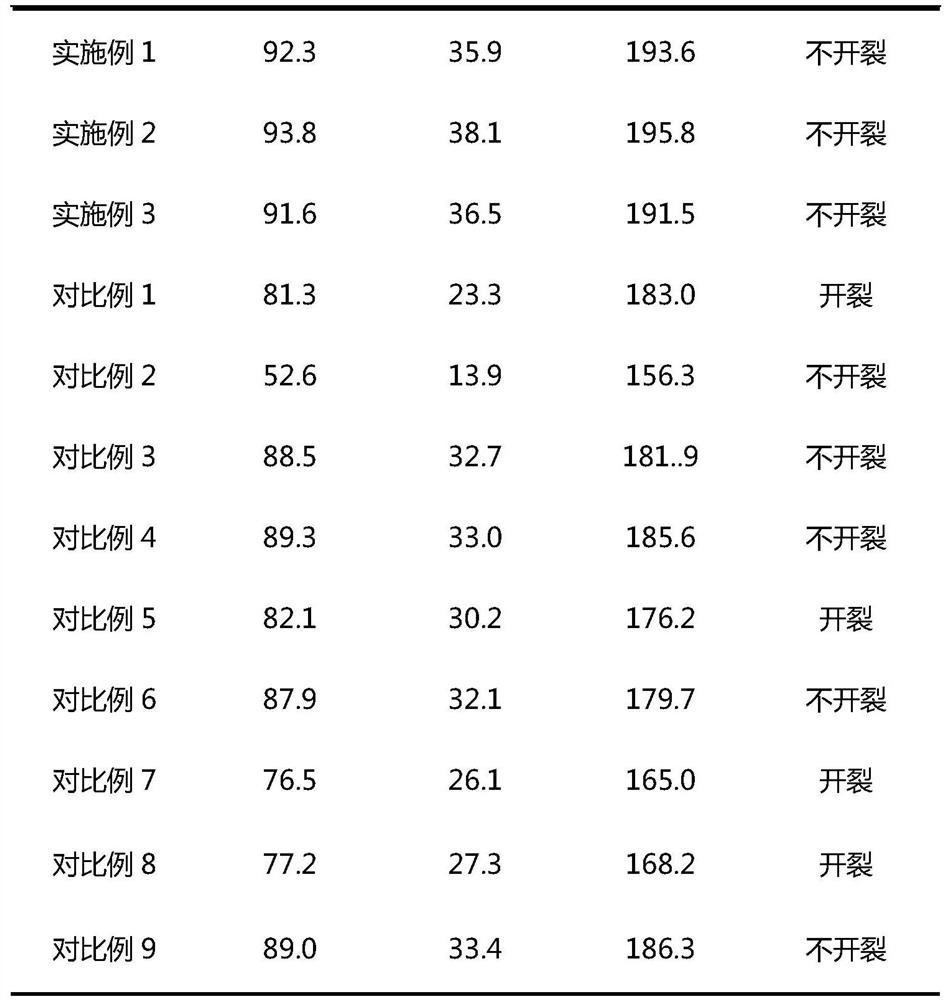

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the field of motor packaging, in particular to a preparation method and application of a high-performance motor packaging material. The preparation method of the high-performance motor packaging material comprises the following steps: (1) preparing the resin A; (2) preparing a curing agent; and (3) performing an action process of the resin and the curing agent to obtain the high-performance motor packaging material, wherein the mass ratio of the resin A to the curing agent is 1: (0.7-1.3); the resin A in the step (1) is prepared from the following raw materials: 3, 4-epoxy hexyl methyl-3, 4-epoxy cyclohexyl formate, acrylic polyurethane resin, a toughening agent, a novel functional filling agent, an anti-settling agent and a coupling agent; raw materials for preparing the curing agent in the step (2) comprise methyl tetrahydrophthalic anhydride, polyether polyol, novel functional filling powder, an anti-settling agent and an accelerant. According to the motor packaging material, the modified powder is used as a filling material, so that the motor packaging material has the characteristic of large usage amount, and the cost can be reduced; and on the basis of using a large amount of filling powder, the motor packaging material with relatively good toughness, strength and temperature-resistant effect is prepared.

Description

A kind of preparation method of high-performance motor packaging material and its application Technical field: The present invention relates to the field of motor packaging, in particular to a method for preparing a high-performance motor packaging material and its application use. Background technique: [0002] With the development of society, people have higher and higher requirements for motor packaging; the potting material factory of the motor requires The following characteristics: It should have good fluidity before curing, and can penetrate into the uneven gap on the winding surface. After potting, the workpiece is outside. The surface should be smooth and flat, so that the motor has basically the same moment of inertia when rotating. Reduce the sudden change in speed and steering of the motor. The vibration caused by the sudden thermal change of mechanical stress during cooling reduces the resistance of the cooling medium to the rotating part of the motor. to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L63/00C08L75/14C08K9/06C08K3/013C08G59/24C08G59/42C08G59/62

CPCC08L63/00C08G59/24C08G59/4215C08G59/62C08G59/4284C08L2203/206C08L2201/08C08L75/14C08K9/06C08K3/013

Inventor 张婷郑可生

Owner 厦门市宜帆达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com