Negative oxygen ion excitation master batch and health-care spray of interior wall coating thereof

A technology of negative oxygen ions and negative ions, which can be used in coatings and other directions to solve problems such as process design difficulties and technical obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

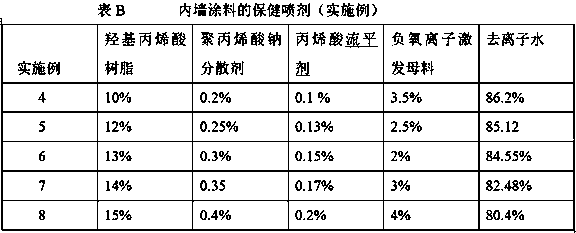

Examples

Embodiment Construction

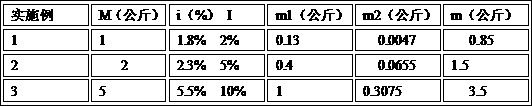

[0043] The present invention will be described in detail below through specific examples.

[0044] The excitation masterbatch is prepared by the following process steps:

[0045] 1. Select raw materials:

[0046] a) Rare earth ores with high thorium content in Sichuan or Inner Mongolia are crushed and used as basic raw materials for extracting active ingredients;

[0047] b) Select fibrous hydrous magnesium silicate as the dispersed filler.

[0048] 2. Base material processing:

[0049] a) Soak rare earth ore blocks evenly broken into centimeter squares with 5% molar concentration of hydrochloric acid solution for at least 1 hour, then rinse the treated thorium-containing ore blocks with clean water, dry them, and set them aside;

[0050] b) Break the dried ore into 0.5 cm square again, repeat step 2.a);

[0051] c) Then bake and dry at a temperature not lower than 100°C for more than 1 hour, crush and grind to 1500 mesh, and make a semi-finished base material with a weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com