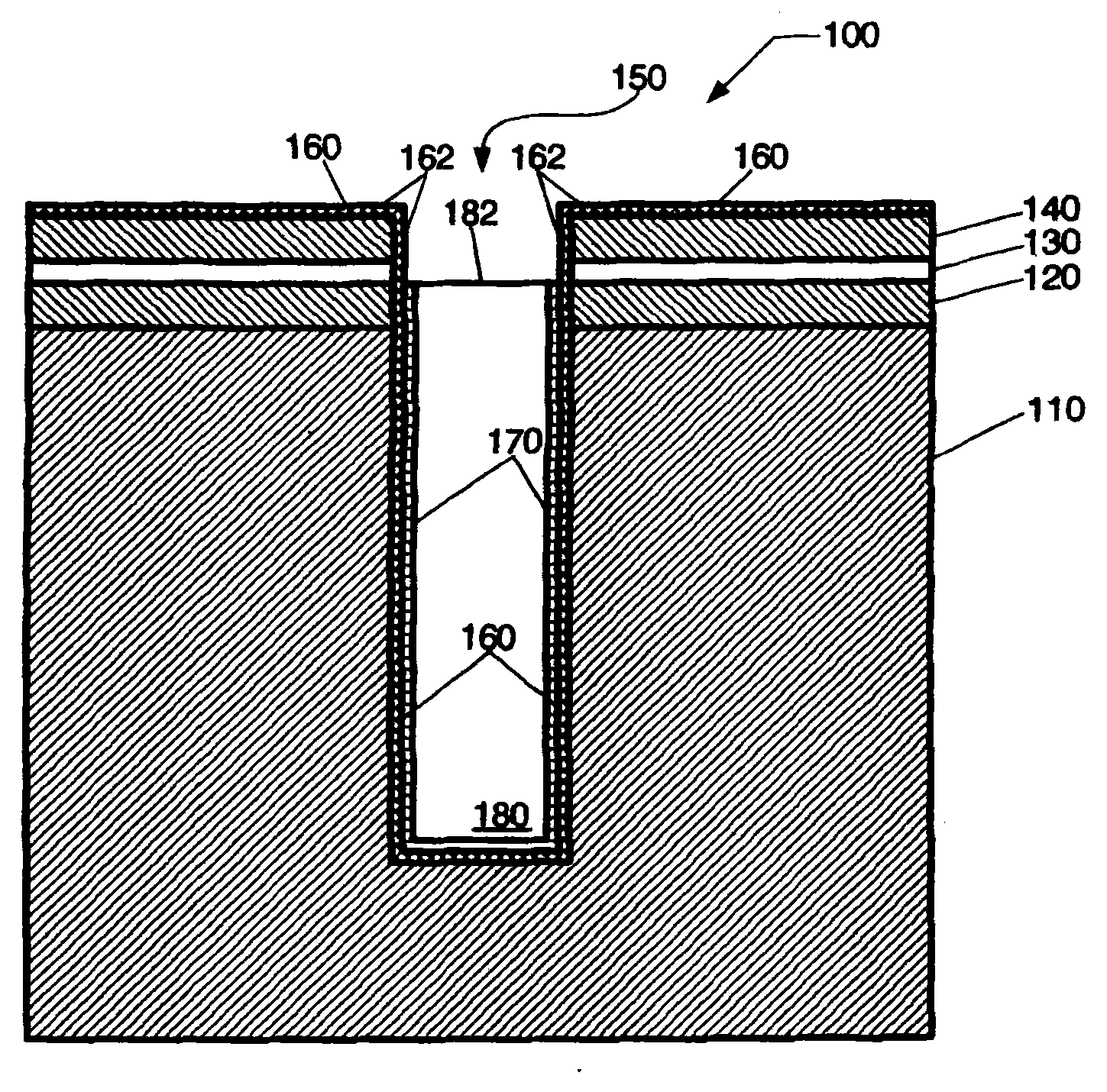

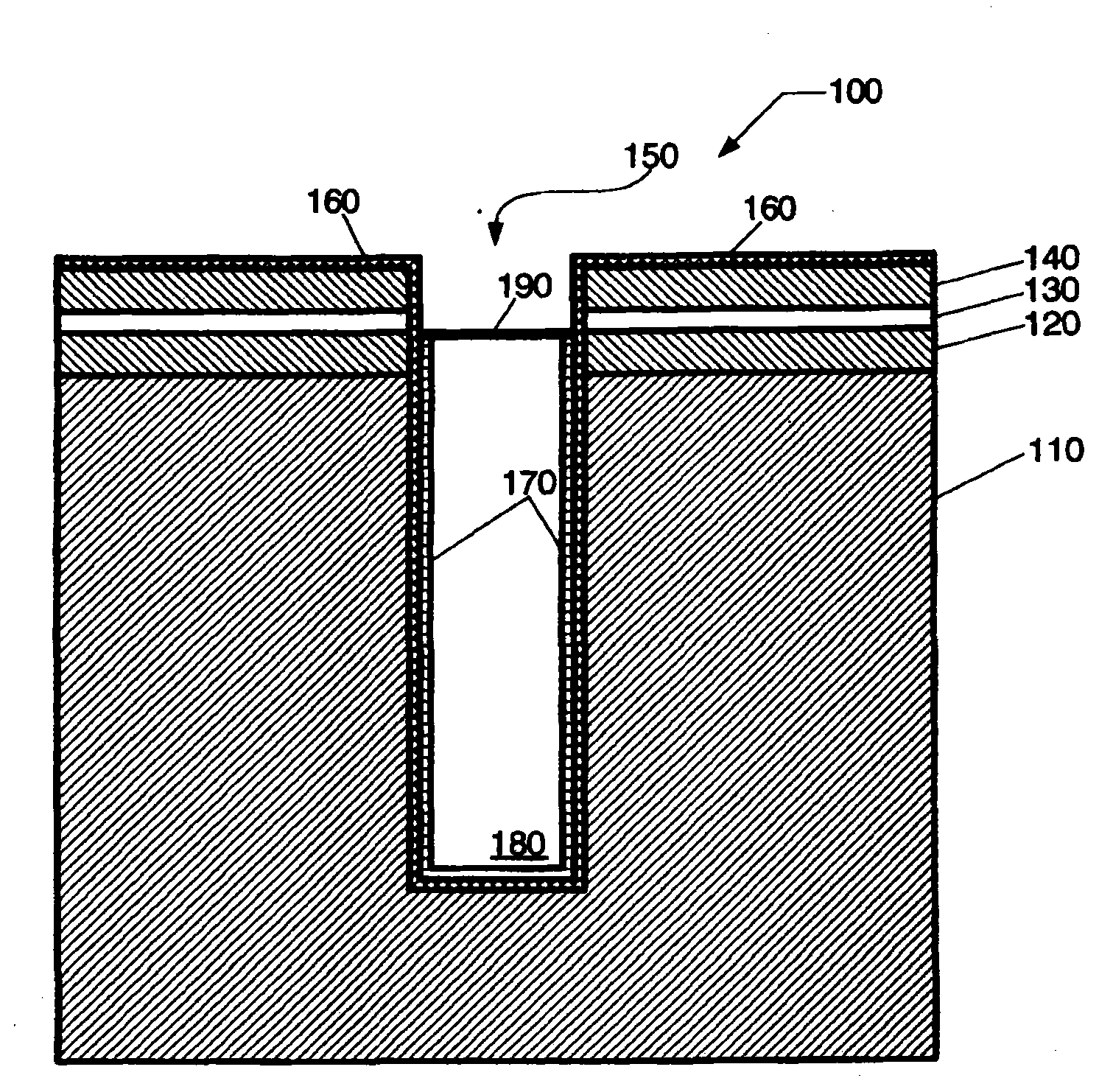

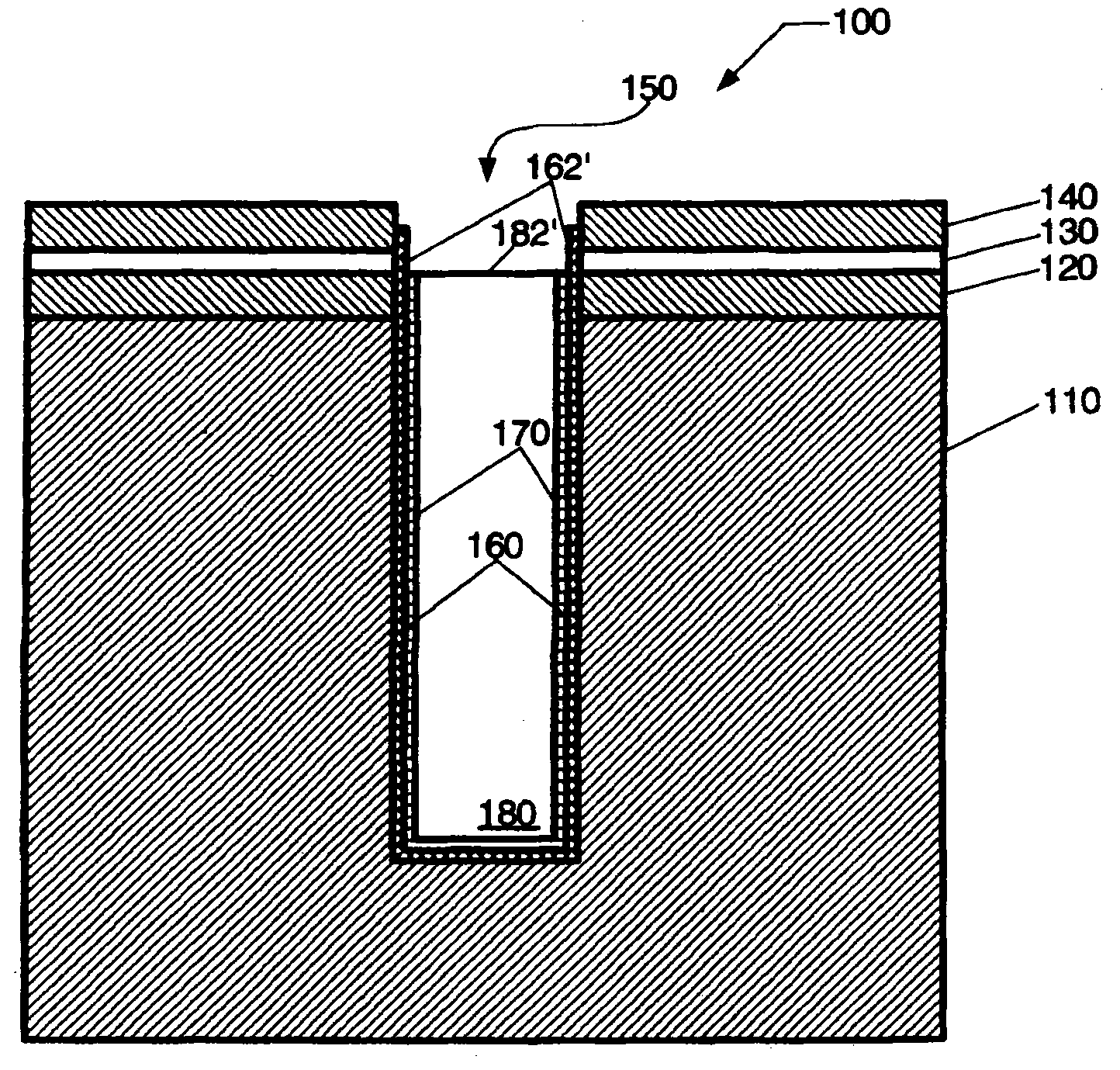

Deep trench liner removal process

一种衬里、沟槽的技术,应用在放电管、电气元件、半导体/固态器件制造等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following description, specific details are set forth for purposes of illustration and not limitation, such as specific geometries of processing systems, descriptions of the various components and processes used therein. However, it should be understood that the invention may be practiced in other embodiments that do not conform to the specific details described above.

[0018] Similarly, for purposes of illustration, specific quantities, materials and structures are set forth to enable a thorough understanding of the invention. However, the invention may be practiced without the specific details described above. Furthermore, it should be understood that the various embodiments shown in the drawings are illustrative representations and are not necessarily drawn to scale.

[0019] Reference throughout this specification to "one embodiment" or "an embodiment" or variations thereof means that a particular feature, structure, material, or characteristic described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com