A bulk-filled explosion-proof tire

An anti-explosion tire and filling technology, which is applied in the field of tires, can solve the problems of incomplete tire filling and uncertain pressure, and achieve the effects of improving service life and safety, good elasticity, and excellent road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

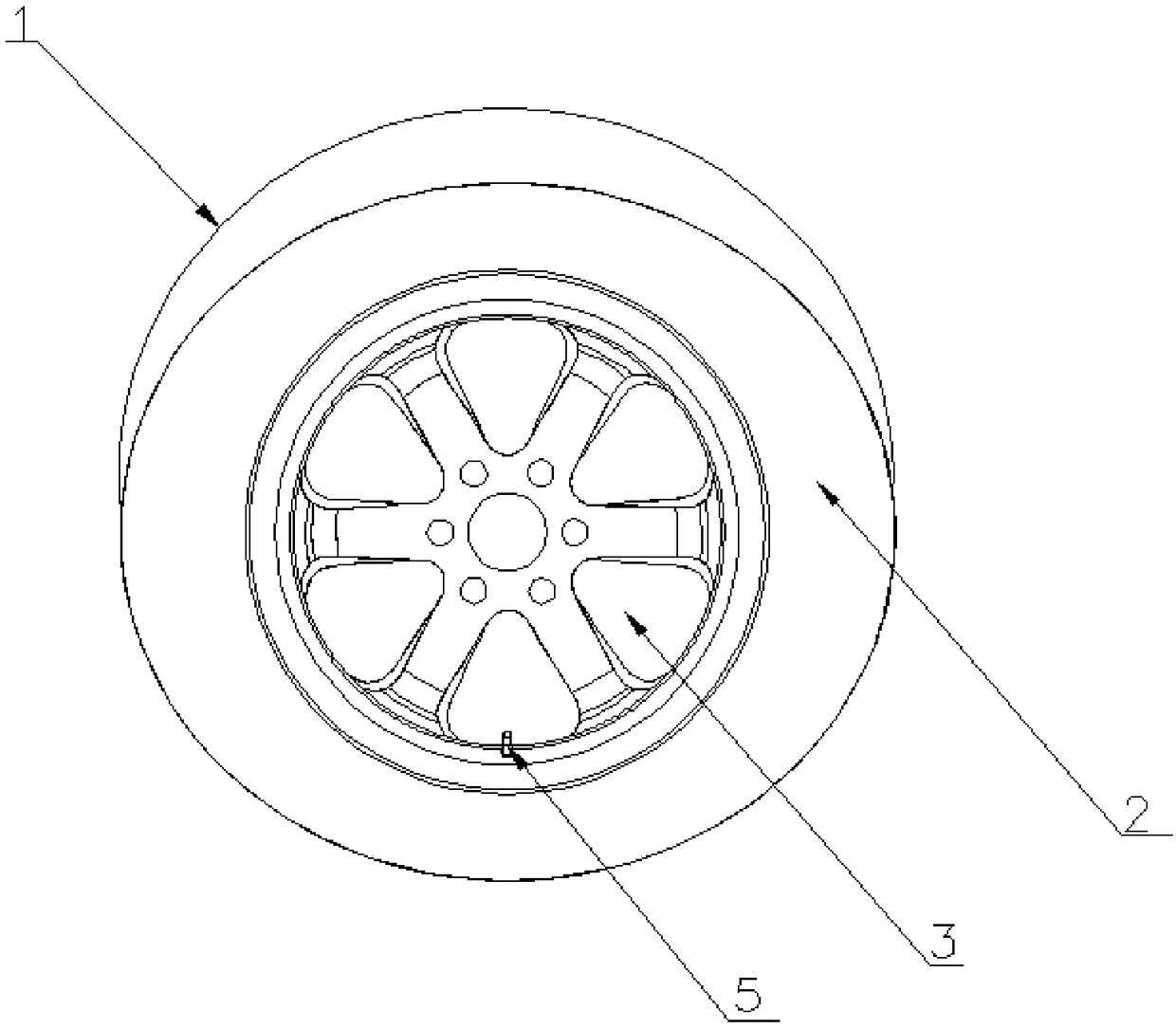

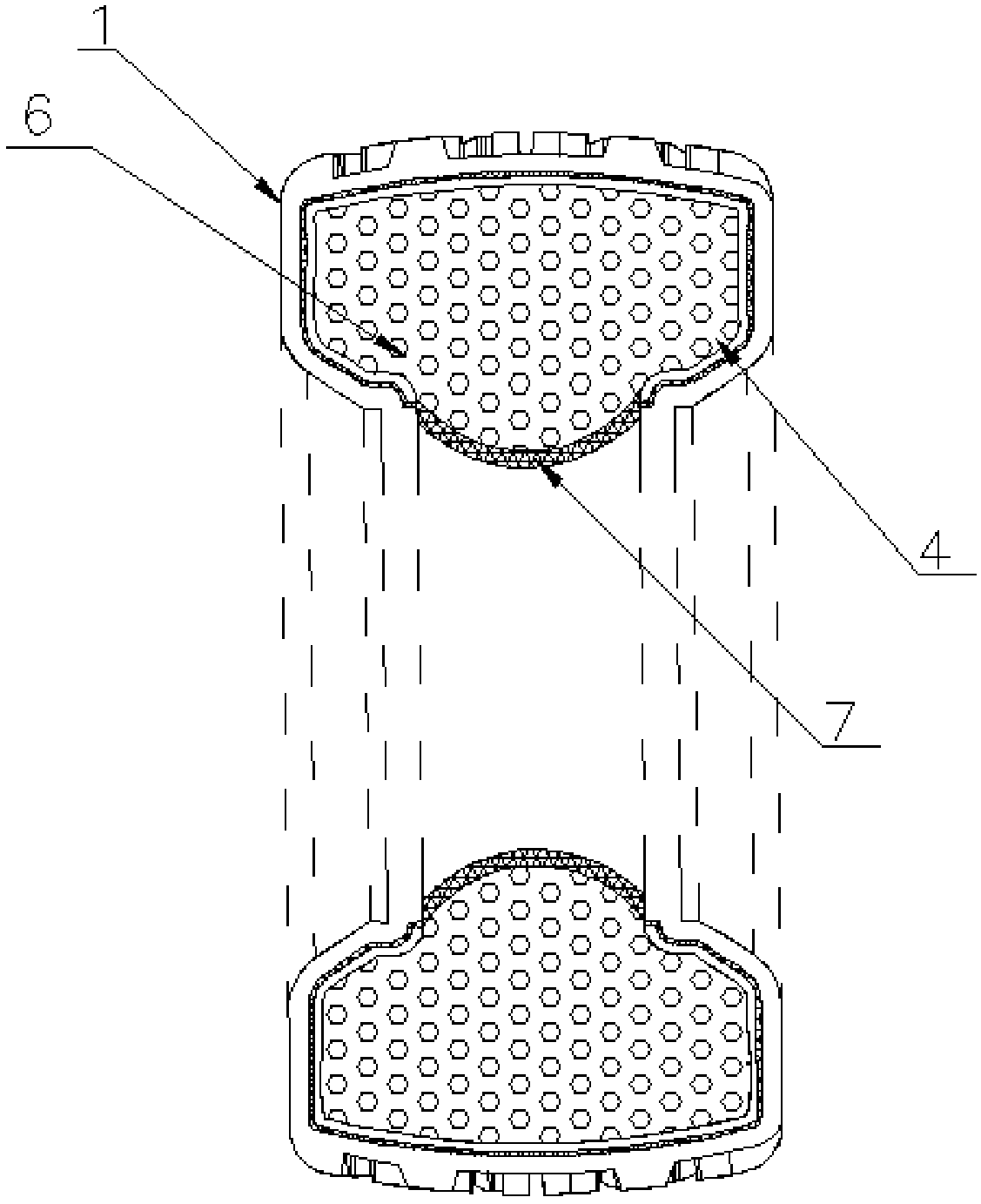

[0030] refer to Figure 1 to Figure 2 As shown, a loose ball filled type run-flat tire includes a tire body 1, the tire body 1 includes a tire 2 and a hub 3, an accommodating cavity 4 is formed between the tire 2 and the hub 3, and on the hub 3 An inflation port 5 is provided, and the housing cavity 4 is filled with several hollow soft rubber balls 6, each hollow soft rubber ball 6 is an independent individual, and the volume of the hollow soft rubber ball 6 filling the tire 2 is V 总 =1.05-1.2V 轮胎空间, The tire 2 is inflated through the inflation port 5, the volume in the accommodating cavity 4 decreases, the space becomes larger, the volume of the hollow soft rubber ball 6 shrinks, and the pressure increases, and the hollow soft rubber ball 6 becomes larger after the tire 2 is inflated. The internal pressure of the rubber ball 6 is balanced with the internal pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com