Tire bead adhesive for radial tire and preparation method thereof

A technology of seed radial wheel and nipple rubber, which is used in tire parts, tire rims, transportation and packaging, etc., can solve the problems of unfavorable processing and extrusion of rubber materials, limited amount of carbon black, and poor wear resistance of rubber materials. Small expansion, extended life, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Zinc glue of the present invention: with 50 parts of natural rubber NR and low-cis BR each as standard, 6 parts of zinc oxide; 3 parts of stearic acid; 2 parts of antiaging agent 4020; 1 part of antiaging agent RD; protective wax: 1.5 parts, reinforcing agent: 2.5 parts; accelerator: 1.2 parts; sulfur: 0.8 parts.

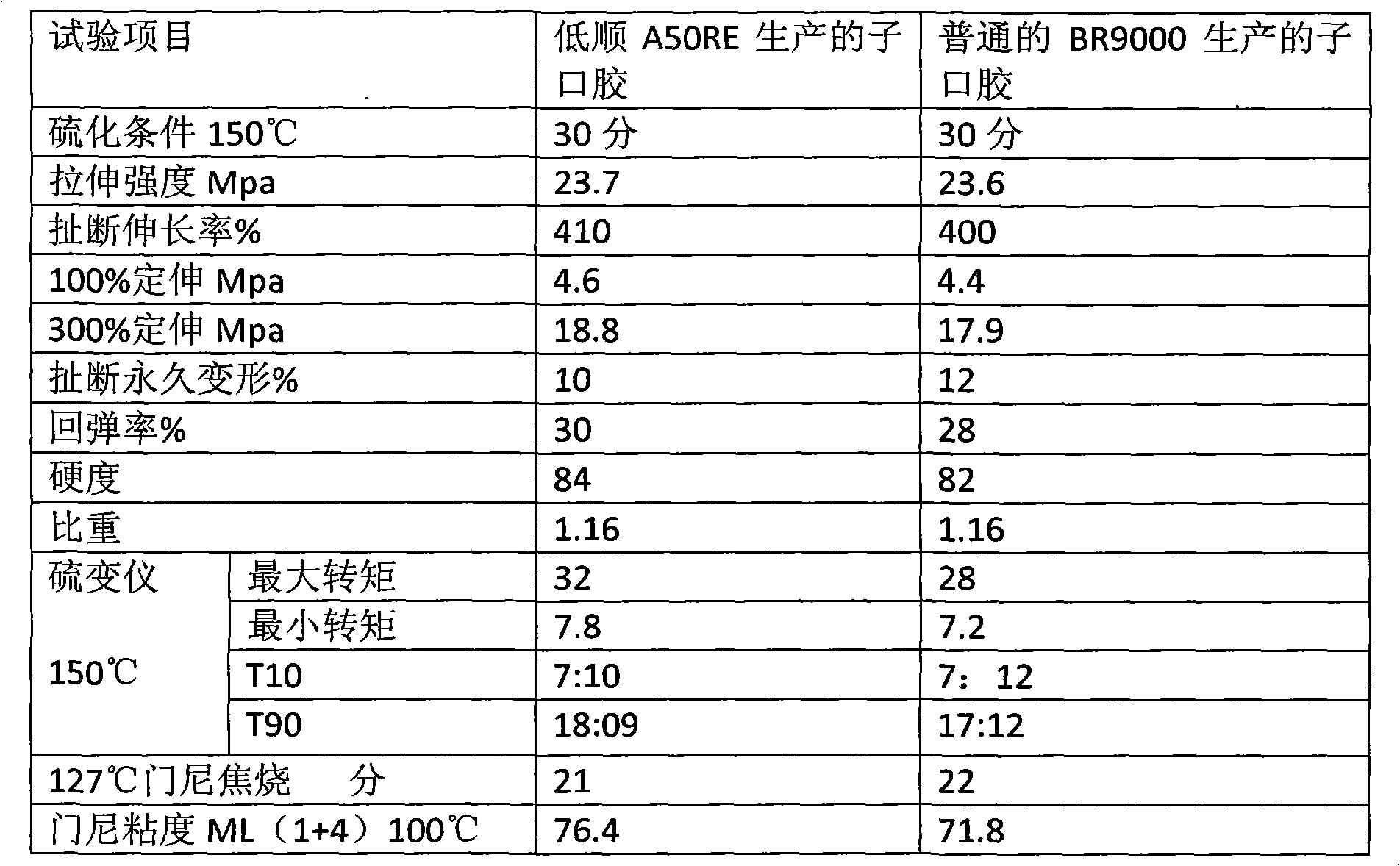

[0014] The above-mentioned juncture glue is compared with the common BR9000 juncture glue, and the comparative test is as follows: (because the common BR9000 juncture glue is a known technology, no detailed description is given).

[0015] The tire rim rubber that the above-mentioned preparation process of the present invention makes and common BR9000 rim rubber, after testing, the data comparison sees the following table for details:

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com