A low-friction, low-smoke, halogen-free, flame-retardant sheath material suitable for air-blown optical cable laying and preparation method thereof

A flame-retardant sheath and low-friction technology, applied in the field of low-friction, low-smoke, halogen-free flame-retardant sheath material and its preparation, can solve problems such as large frictional resistance, less lubricant addition, and laying a sufficient number of optical cables, etc., to achieve Flame retardant properties are not affected by the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

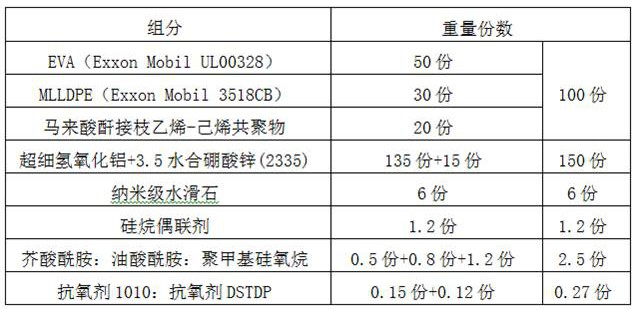

[0016] A low-friction, low-smoke, halogen-free, flame-retardant sheath material suitable for air-blown optical cables, comprising the following components in parts by weight:

[0017]

[0018] The MLLDPE used (Exxon Mobil 3518CB) was purchased from Exxon Mobil Corporation.

[0019] The performance of the above-mentioned flame retardant sheathing material is tested. The coefficient of friction of the sheathing material is as low as 0.09, the flame retardant performance is good, and the mechanical properties also meet the requirements of relevant standards. Therefore, it is particularly convenient for the construction of air-blown laying of multiple optical cables in the pipeline. .

Embodiment 2

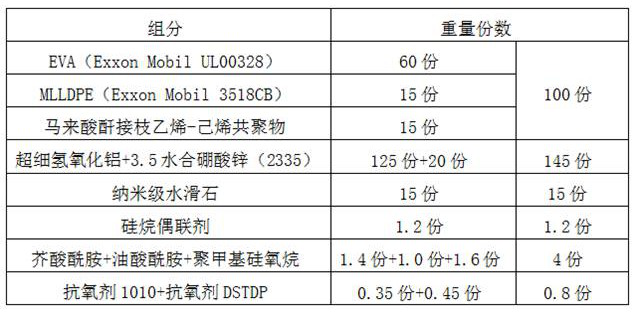

[0021] A low-friction, low-smoke, halogen-free, flame-retardant sheath material suitable for air-blown optical cables, comprising the following components in parts by weight:

[0022]

[0023] The friction coefficient of the sheath material is as low as 0.15, the flame retardant performance is good, and the mechanical properties meet the relevant standards, so it is also suitable for the construction of air-blown laying of multiple optical cables in the pipeline.

Embodiment 3

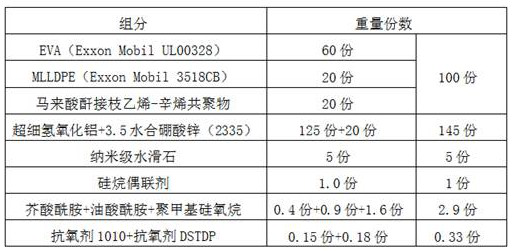

[0025] A low-friction, low-smoke, halogen-free, flame-retardant sheath material suitable for air-blown optical cables, comprising the following components in parts by weight:

[0026]

[0027] The performance of the above-mentioned flame retardant sheathing material is tested, the friction coefficient of the sheathing material is as low as 0.12, the flame retardant performance is high, and the mechanical properties meet the standard requirements, so it is convenient for the construction of air-blown laying of multiple optical cables in the pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com