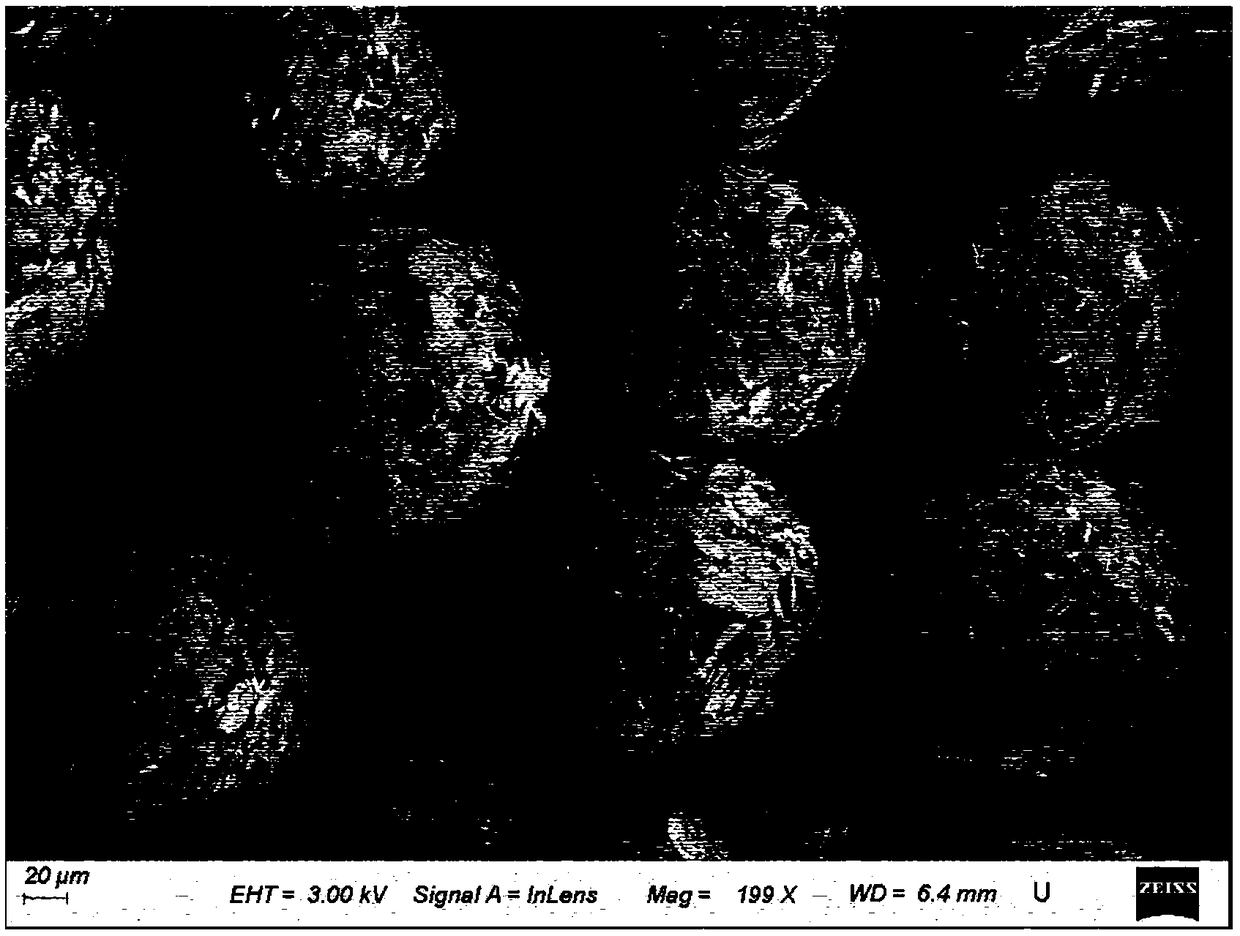

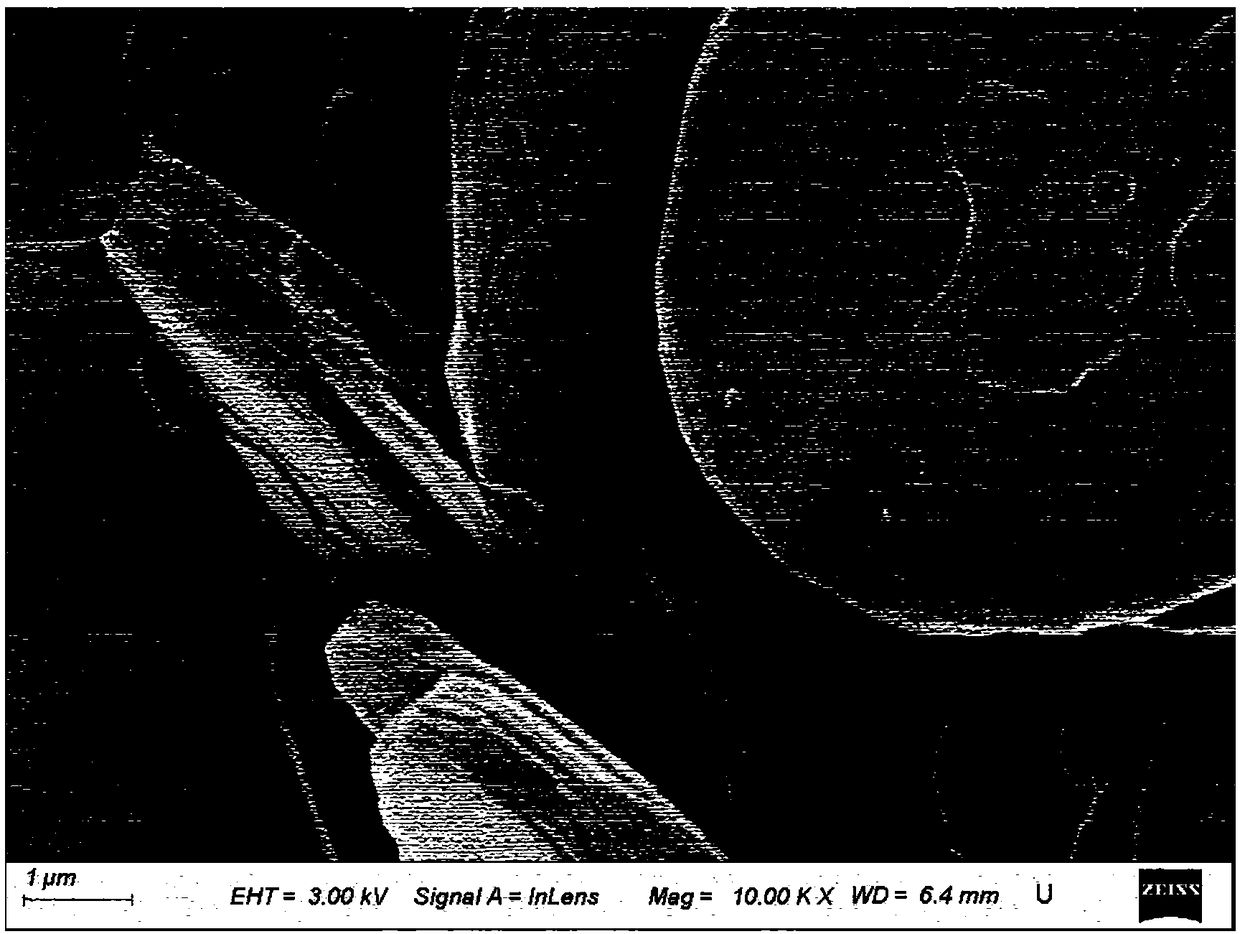

A kind of preparation method of spherical hexagonal boron nitride aggregate

A technology of hexagonal boron nitride and agglomerates, which is applied in the field of preparation of hexagonal boron nitride agglomerates, can solve the problem that the orientation of layered hexagonal boron nitride is difficult to fill in large quantities, and achieves high sphericity, smooth surface and specific surface area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the preparation method of the spherical hexagonal boron nitride aggregate of the present embodiment comprises the following steps:

[0016] 1. According to the weight ratio of oxide and alkaline earth metal carbonate (9-1.5): 1, add oxide and alkaline earth metal carbonate into the ball mill, and obtain alkaline earth metal carbonate-oxide composite sintering aid through ball milling. agent;

[0017] 2. Weigh 59% to 83% of hexagonal boron nitride, 1% to 6% of dispersant, 15% to 30% of binder and 1% to 5% of alkaline earth metal carbonate-oxidized Compound sintering aid, dispersant, binder and composite sintering aid are added to water and mixed uniformly, then hexagonal boron nitride is added and mixed uniformly to obtain water-based slurry; the mass content of solids in the water-based slurry 10% to 60%;

[0018] 3. Carry out spray granulation treatment to the water-based slurry obtained in step 2 by spray drying method, and continuously stir...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the alkaline earth metal carbonate described in step 1 is calcium carbonate; the others are the same as Embodiment 1.

specific Embodiment approach 3

[0022] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the oxide described in step 1 is one or two kinds of oxides of transition elements, the main group III, and the main group IV. The above combinations or composite oxides; others are the same as the specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com